Three-dimensional braided carbon fiber reinforced polyetheretherketone composite material and preparation method thereof

A technology of polyether ether ketone and composite materials, which is applied in the direction of carbon fiber, fiber treatment, fiber type, etc., can solve the problems of easy delamination, poor stiffness and strength performance, and can not be used, so as to achieve full fiber impregnation, improved bending strength, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

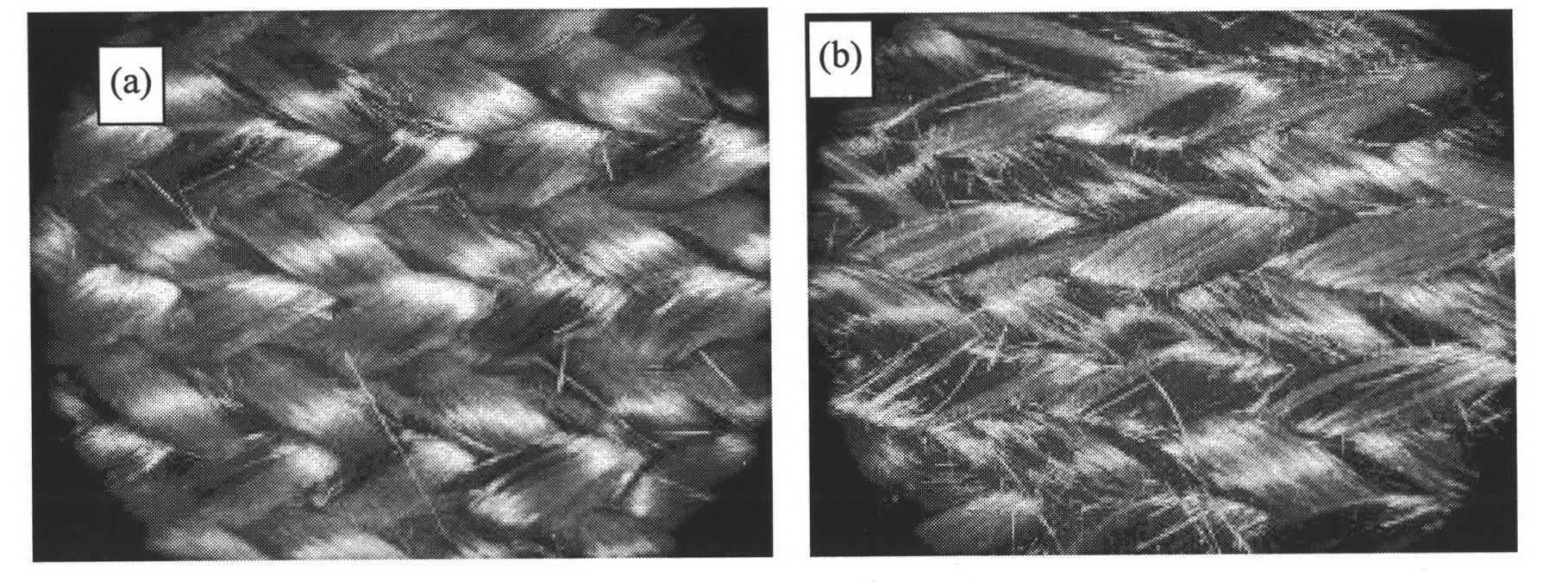

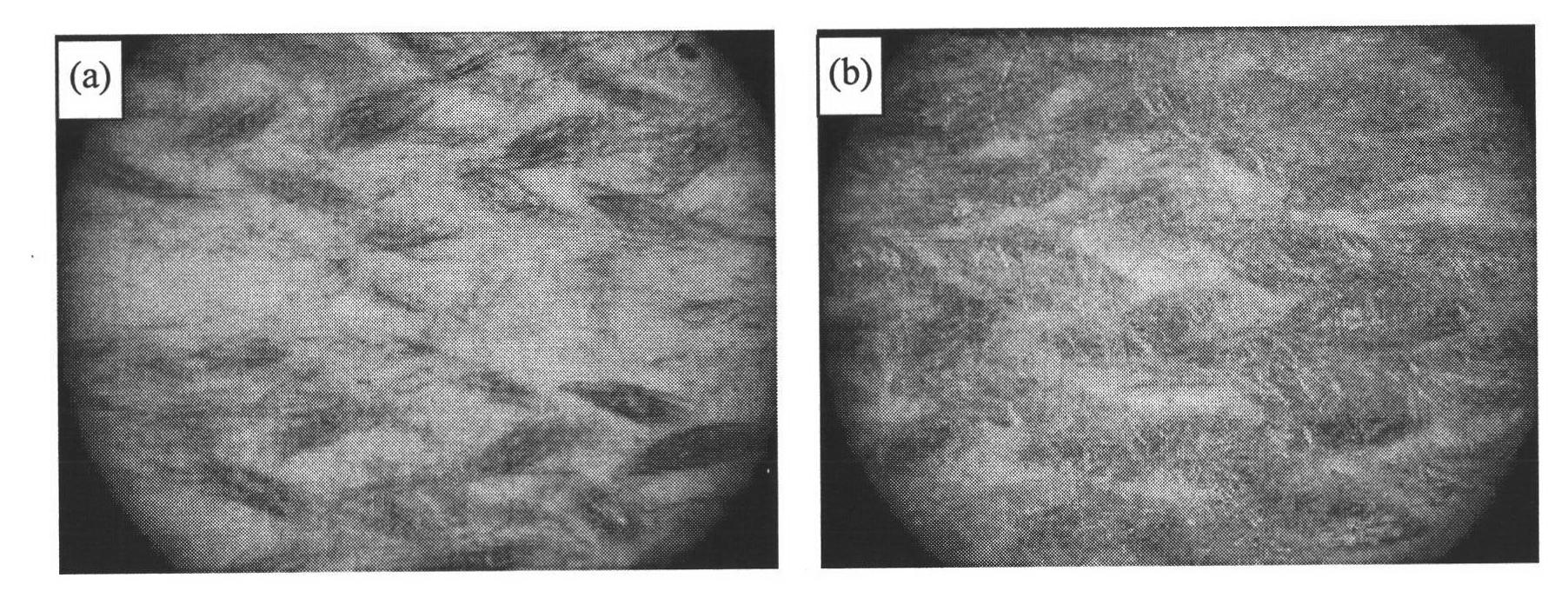

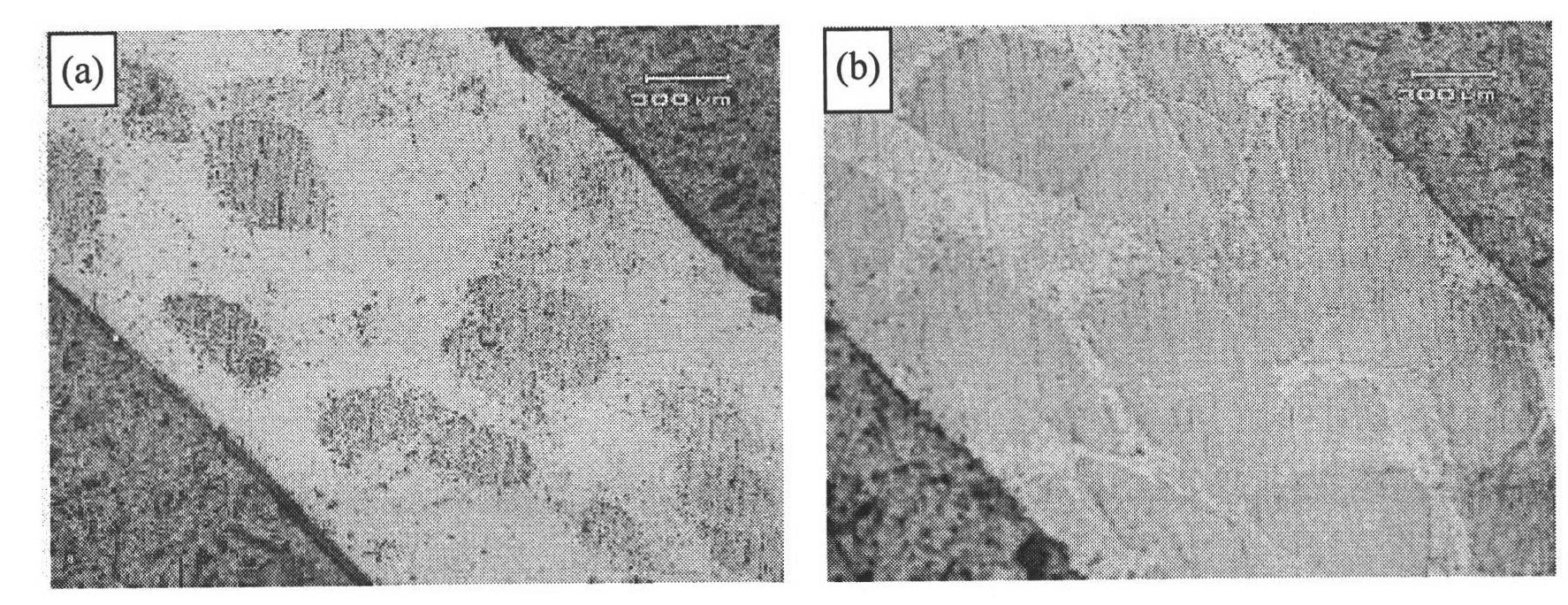

[0017] Polyetheretherketone fiber (produced by ZYEX, UK, fiber diameter 30 microns) and 6K polyacrylonitrile-based carbon fiber (supplied by Shanxi Coal Chemical Co., Ltd., fiber diameter 7 microns) were mixed in three dimensions and five directions according to the carbon fiber volume content of 18% ( figure 1 a), mixed fabric in 5wt% (NH 4 ) 2 HPO 4 After boiling in the solution for 40 minutes, rinse and dry repeatedly with distilled water, put the mixed fabric into a mold, place it in a vacuum hot press, heat it to 150°C, start vacuuming continuously, and keep it at this temperature for 2 hours, and then heat it at 15°C Raise the temperature to 370°C at a speed of 1 / min, keep it warm for 40min, pressurize at 0.3MPa, remove the vacuum, keep the temperature for 30min, cool down slowly, and release the mold when the product temperature is lower than 100°C. The bending strength of the obtained composite material along the fiber weaving direction is 252MPa, the photo of its su...

example 2

[0019] Polyether ether ketone fiber (produced by ZYEX, UK, fiber diameter 30 microns) and carbon fiber 12K polyacrylonitrile base (provided by Shanxi Coal Chemical Industry Co., Ltd., fiber diameter 7 microns) were mixed in three dimensions and five directions according to the carbon fiber volume content of 54%. Mixed fabric at 5wt% (NH 4 ) 2 HPO 4 After boiling in the solution for 40 minutes, rinse and dry repeatedly with distilled water, put the mixed fabric into a mold, place it in a vacuum hot press, heat it to 150°C, start vacuuming continuously, and keep it at this temperature for 2 hours, and then heat it at 15°C / min speed up to 370°C, keep warm for 40min, pressurize 0.6MPa, remove the vacuum, continue to maintain the temperature for 60min, slowly cool down, demould when the product temperature is lower than 100°C, and the bending strength of the obtained composite material along the fiber weaving direction reaches 501 MPa.

example 3

[0021] Polyetheretherketone fiber (produced by ZYEX, UK, fiber diameter 30 microns) and carbon fiber 6K polyacrylonitrile base (provided by Shanxi Coal Chemical Industry Co., Ltd., fiber diameter 7 microns) were mixed in three dimensions and five directions according to the carbon fiber volume content of 54% ( figure 1 b), mix the fabric at 5wt% (NH 4 ) 2 HPO 4 After boiling in the solution for 40 minutes, rinse and dry repeatedly with distilled water, put the fabric into a mold, place it in a vacuum hot press, heat it to 150°C, start to vacuum continuously, and keep it warm at this temperature for 2 hours, and then heat it at 15°C / min speed up to 370°C, keep warm for 40min, pressurize 0.6MPa, remove the vacuum, continue to maintain the temperature for 60min, slowly cool down, demould when the product temperature is lower than 100°C, and the bending strength of the obtained composite material along the fiber weaving direction reaches 556MPa, the photo of its surface structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com