Nondestructive testing system and testing analysis method for three-dimensional braided composite material

A composite material and non-destructive testing technology, applied in the direction of material analysis using acoustic wave emission technology, can solve the problems of less materials to be tested and complex manufacturing process of three-dimensional braided composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

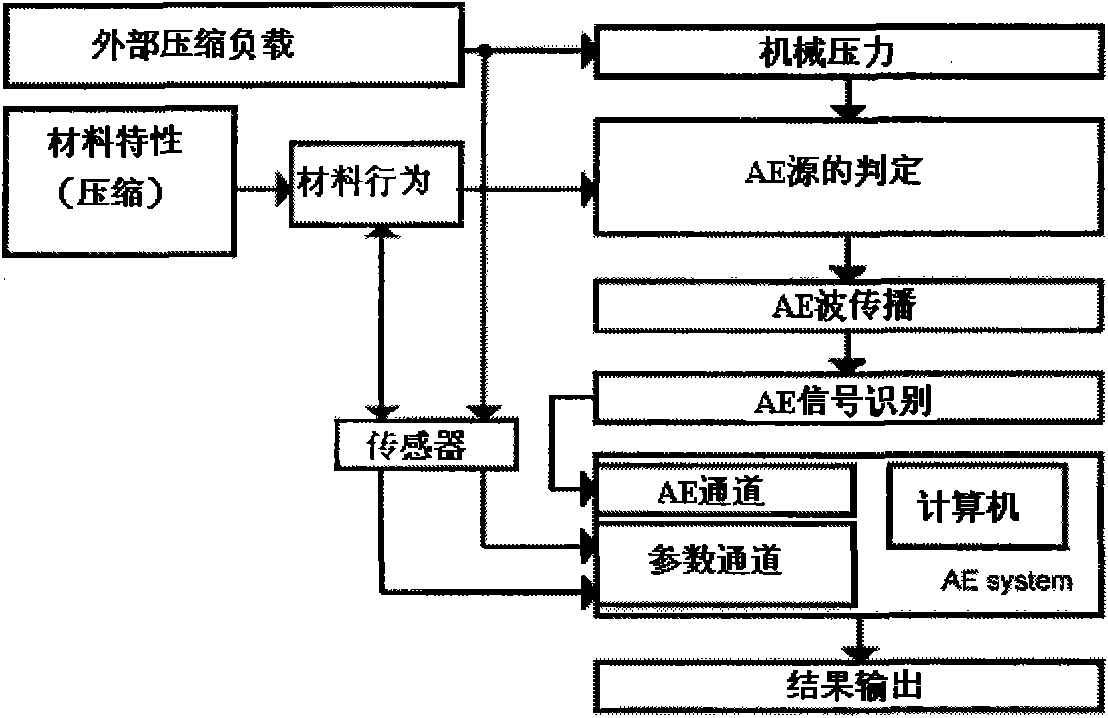

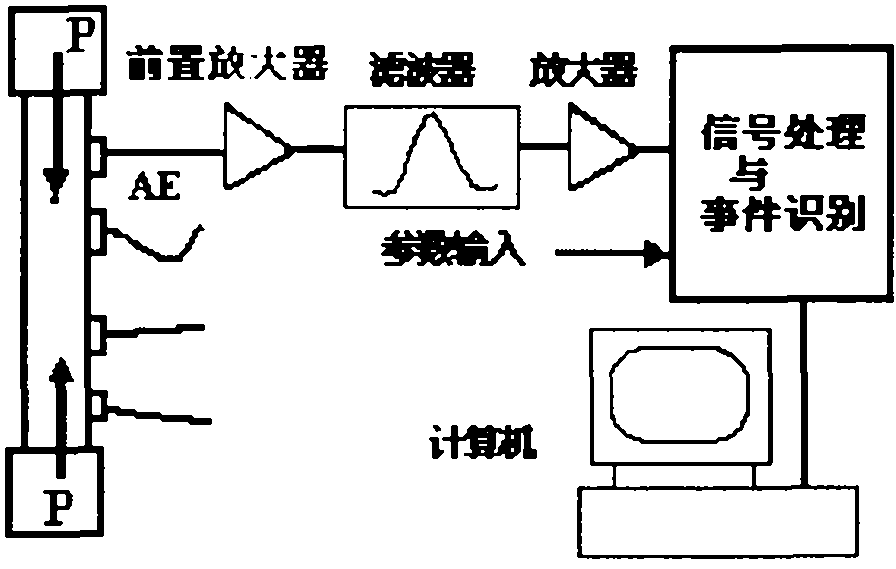

[0050] The principle of the non-destructive testing method for three-dimensional weaving composite materials based on acoustic emission technology is as follows: figure 1 As shown, when the three-dimensional braided composite material is subjected to an external load, the behavior of the material changes, and the phenomenon of acoustic emission occurs. The acoustic emission signal passes through the acoustic emission sensor (ie, the AE transducer) and the preamplifier, filter, and main amplifier. After high-speed A / D conversion, it enters the computer for analysis.

[0051] The acoustic emission signal propagates under the action of transient stress on the composite material part, and the damage of the material can be analyzed by digitizing the acoustic emission signal.

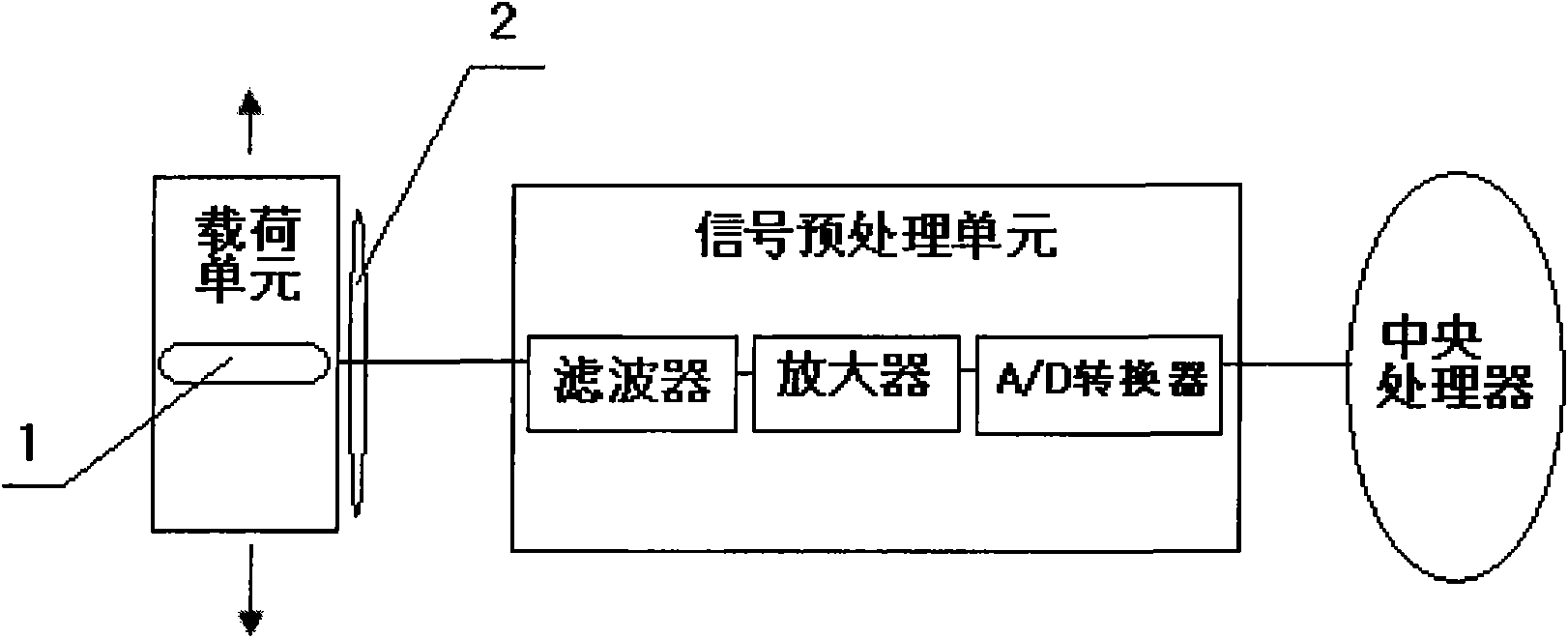

[0052] The processing process of the acoustic emission signal (that is, the AE signal) is as follows: image 3 As shown, among them, the acoustic emission sensor (that is, the AE transducer) is a functional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com