Patents

Literature

36 results about "Transient stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transient stress analysis is used to analyze events with known time-varying loads, small displacement, and linear material models. With transient stress, you can produce the dynamic response of a structure subjected to time-varying loads. Add ground acceleration components in any or all three global directions to determine the dynamic response.

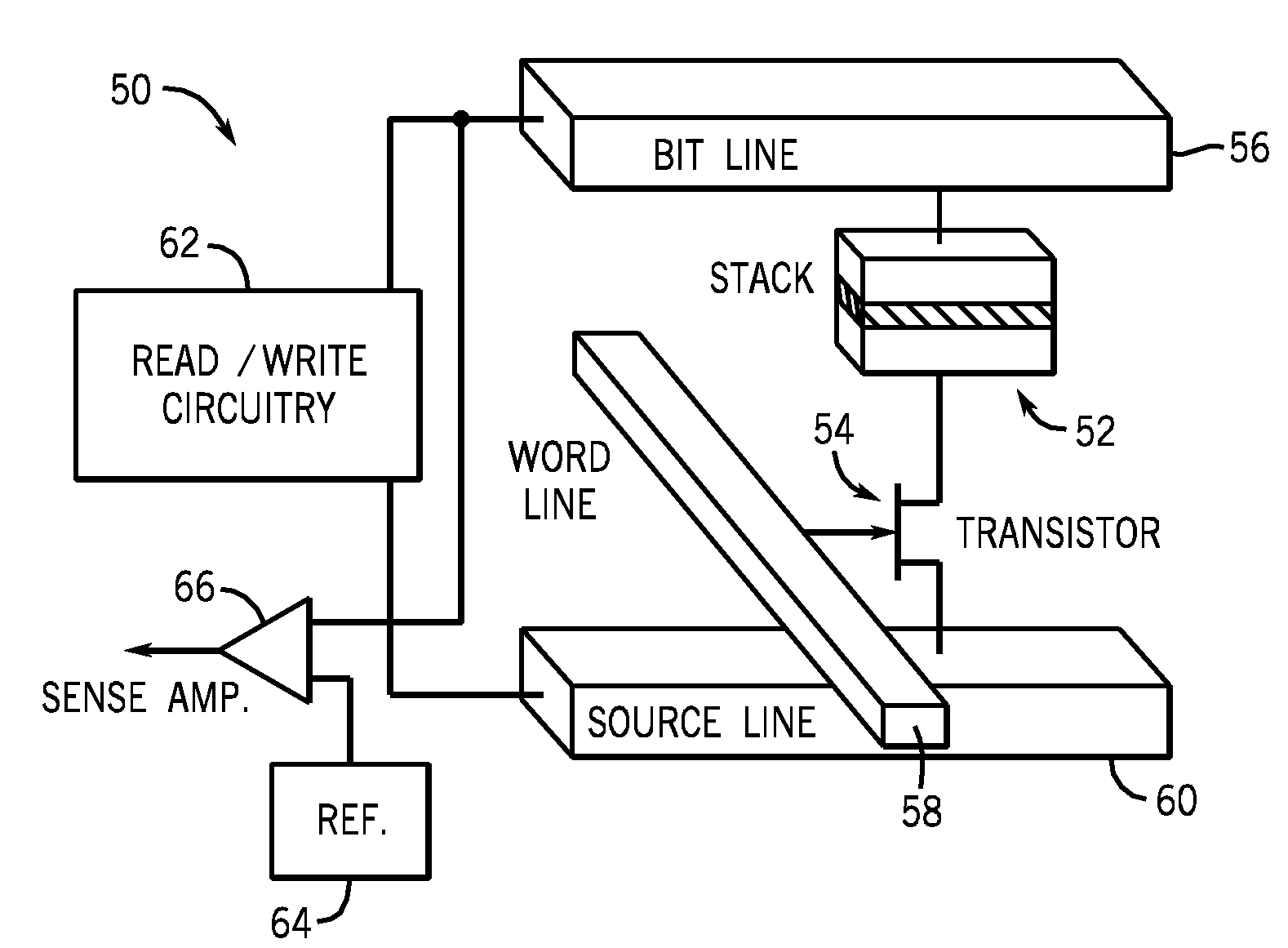

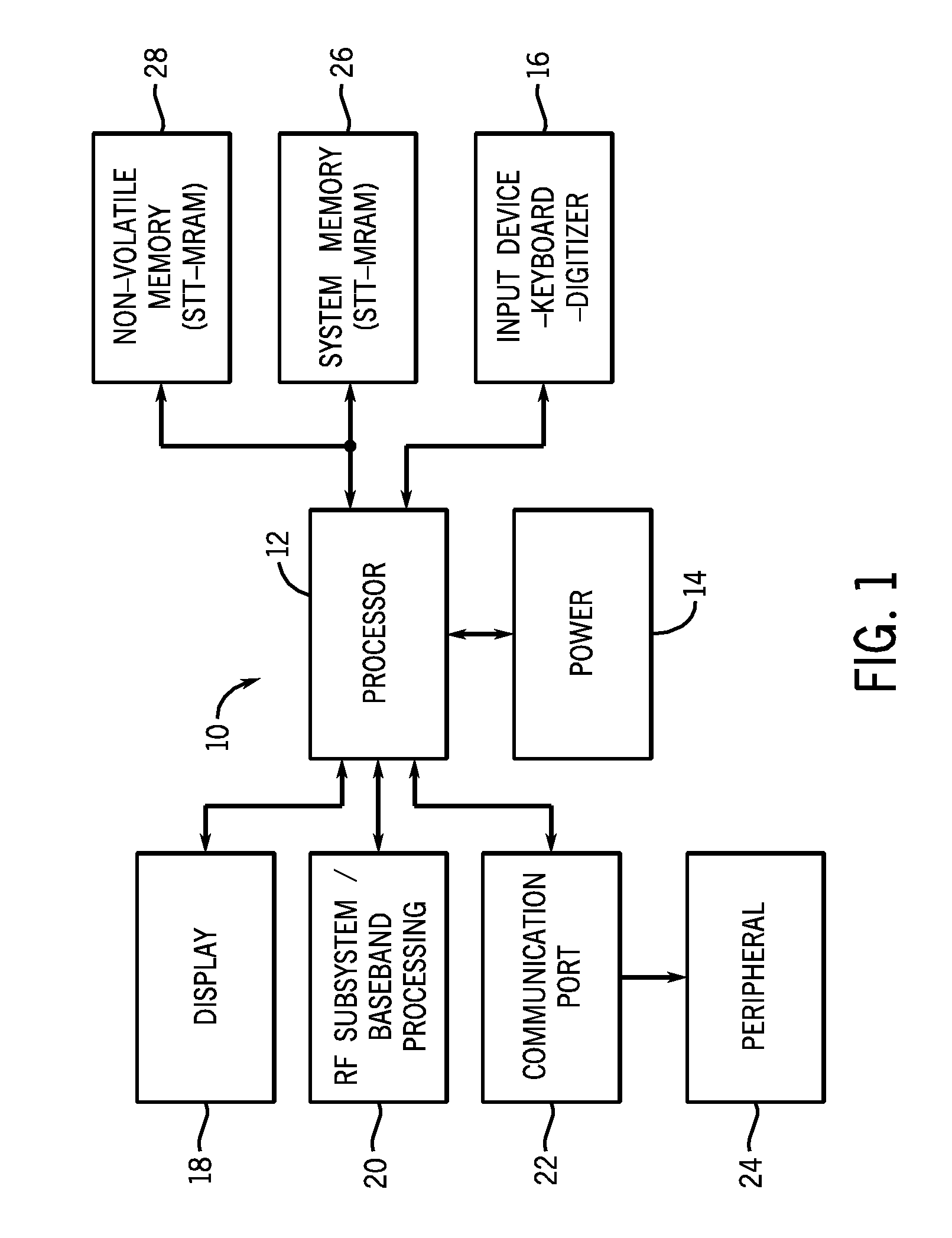

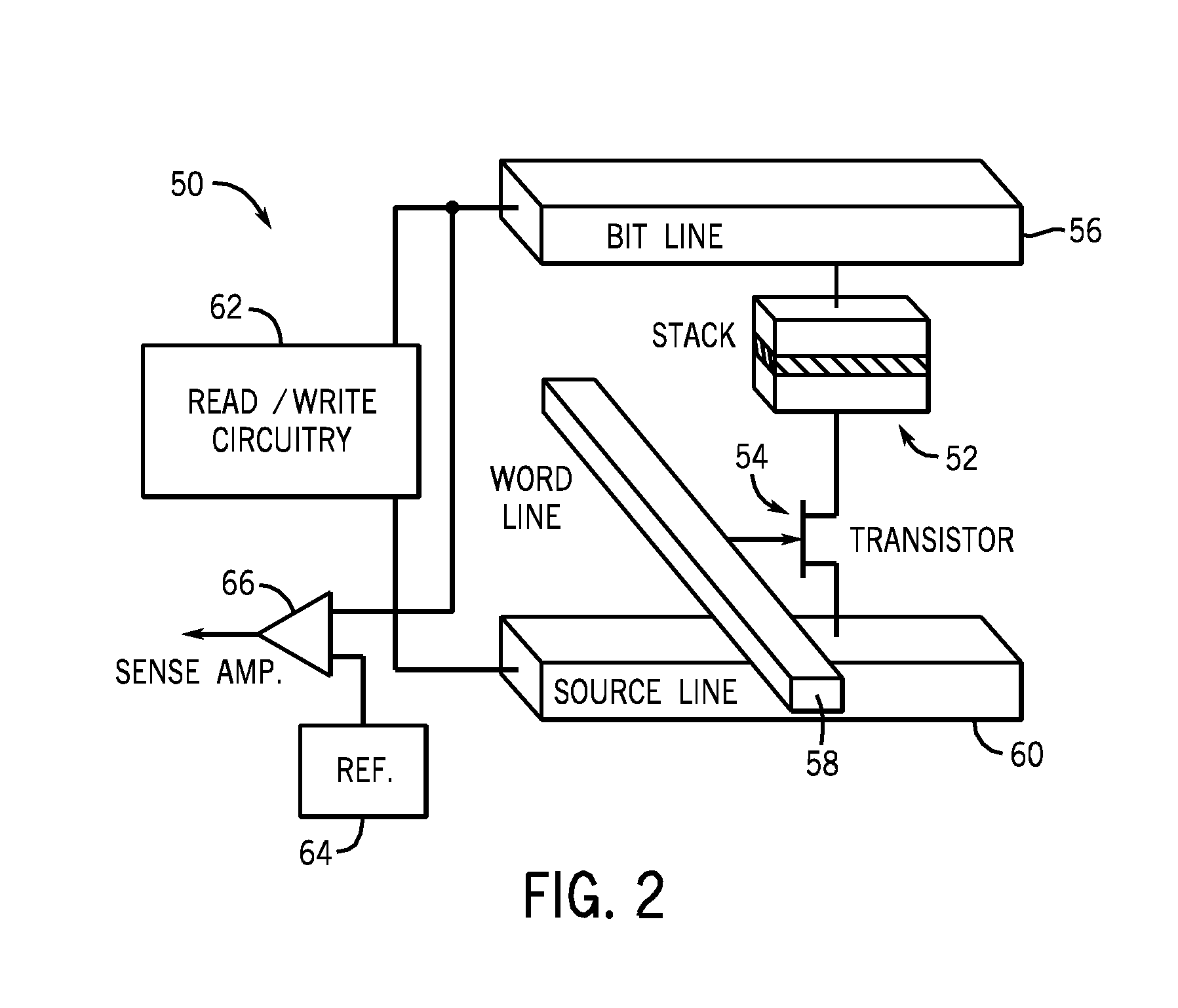

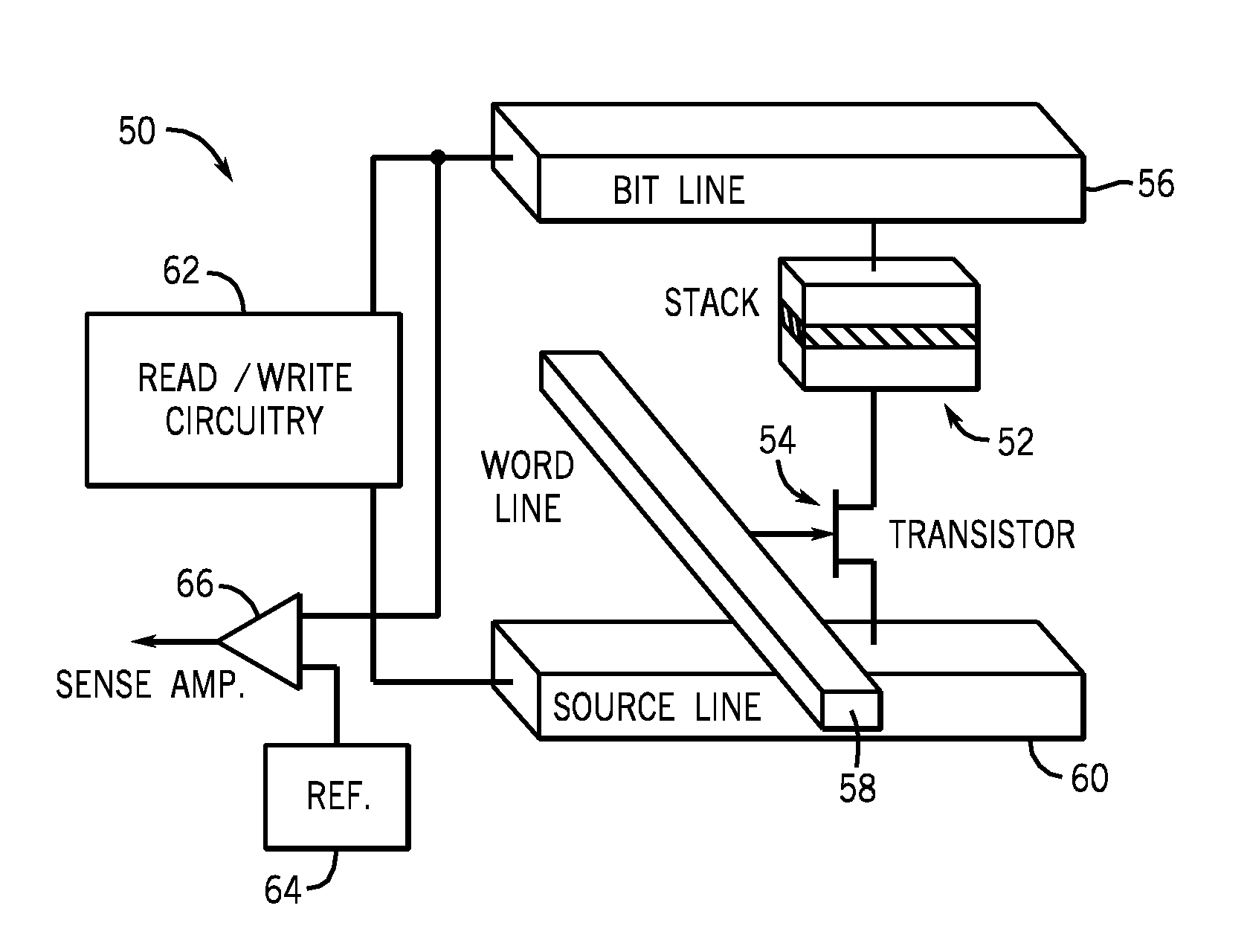

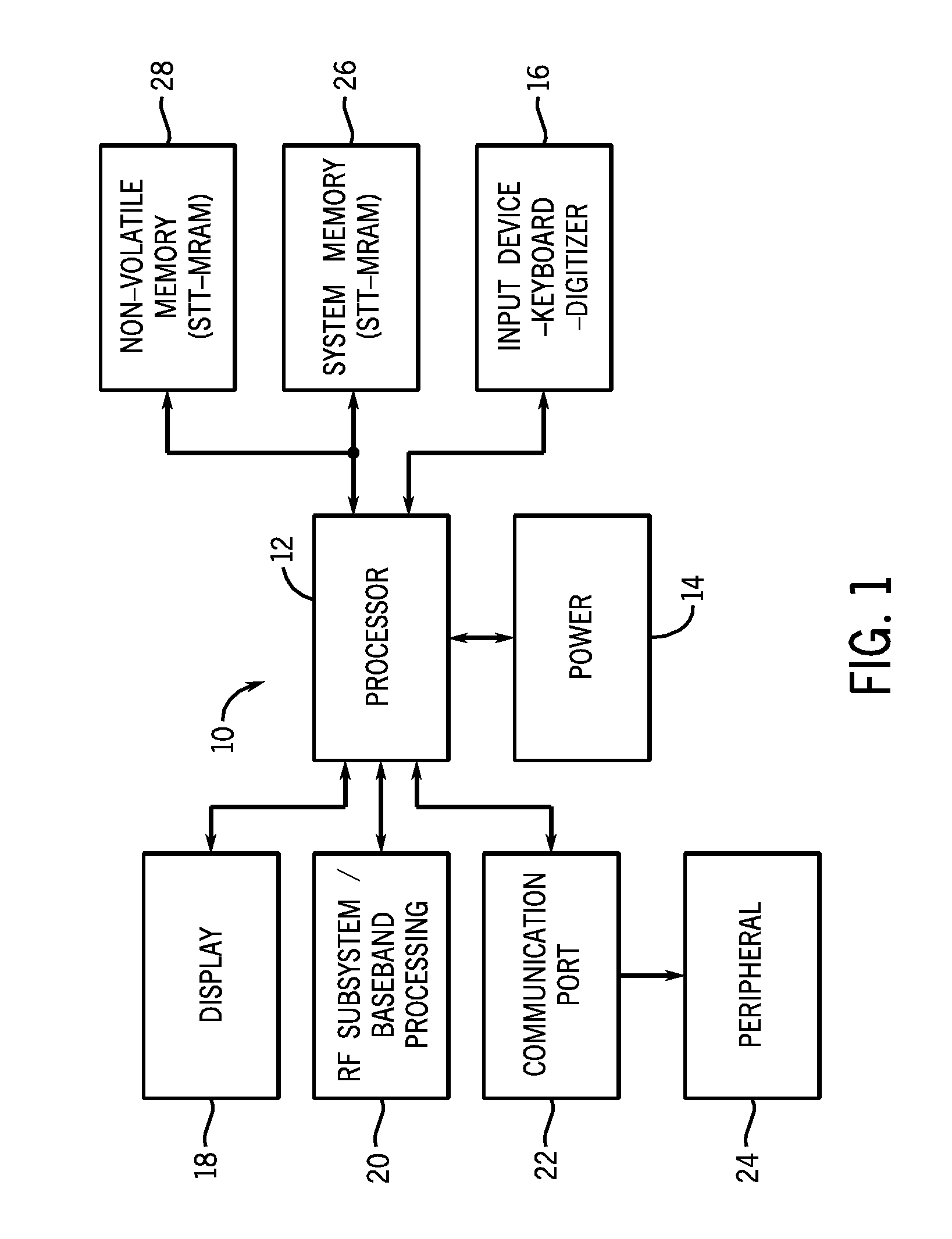

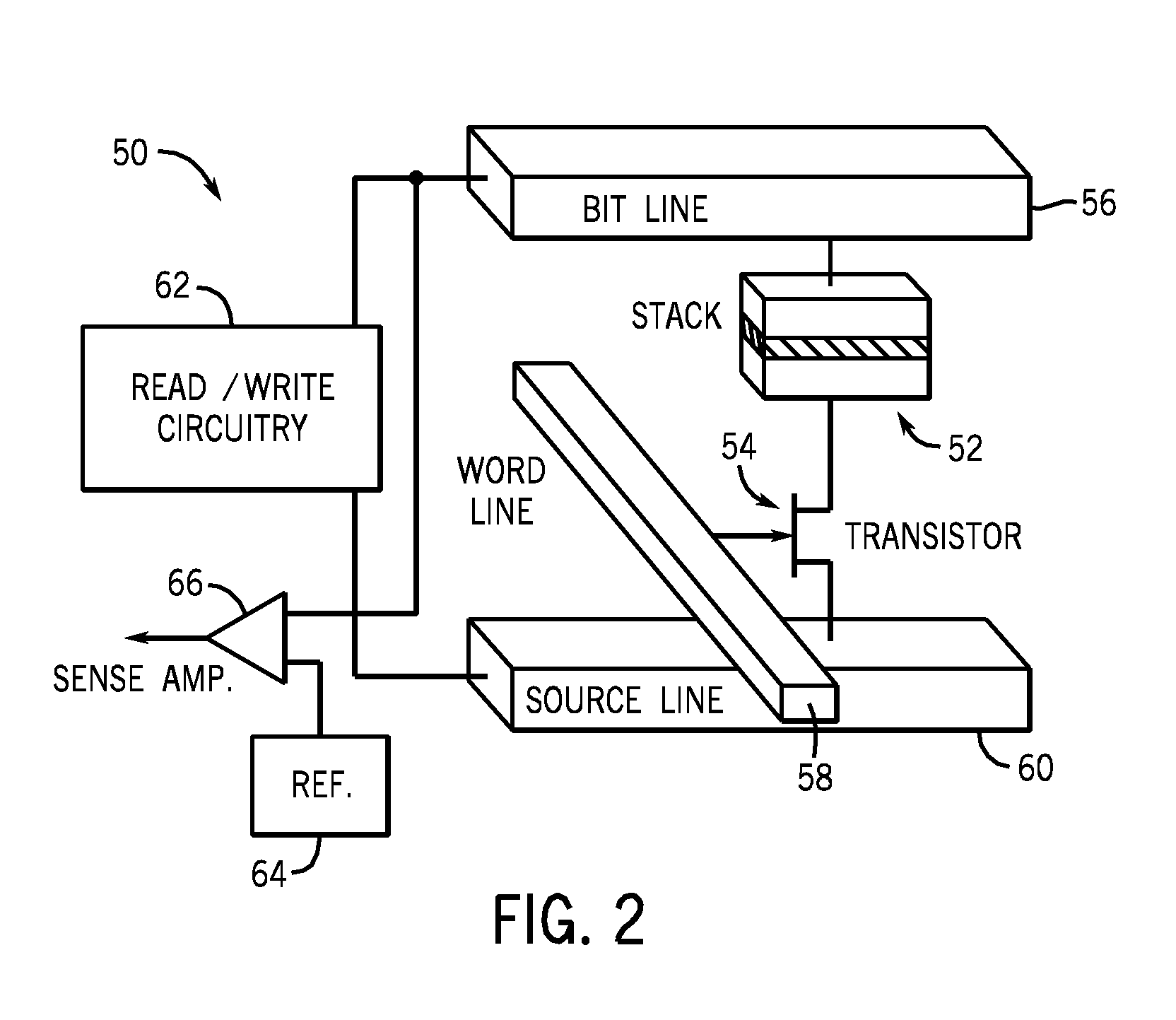

Stt-mram cell structure incorporating piezoelectric stress material

A magnetic memory cell including a piezoelectric material, and methods of operating the memory cell are provided. The memory cell includes a stack, and the piezoelectric material may be formed as a layer in the stack or adjacent the layers of the cell stack. The piezoelectric material may be used to induce a transient stress during programming of the memory cell to reduce the critical switching current of the memory cell.

Owner:MICRON TECH INC

Stt-mram cell structure incorporating piezoelectric stress material

ActiveUS20130064011A1Magnetic-field-controlled resistorsSolid-state devicesMagnetic memoryUnit structure

A magnetic memory cell including a piezoelectric material, and methods of operating the memory cell are provided. The memory cell includes a stack, and the piezoelectric material may be formed as a layer in the stack or adjacent the layers of the cell stack. The piezoelectric material may be used to induce a transient stress during programming of the memory cell to reduce the critical switching current of the memory cell.

Owner:MICRON TECH INC

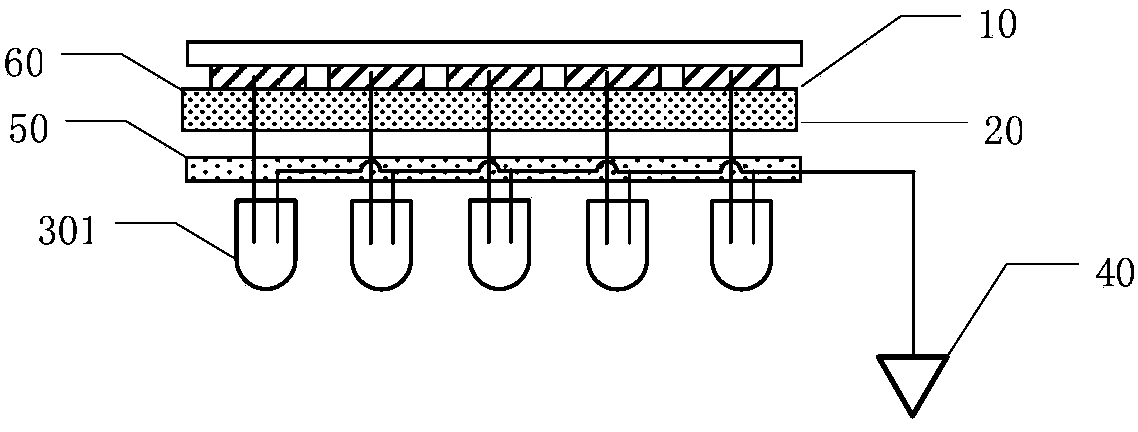

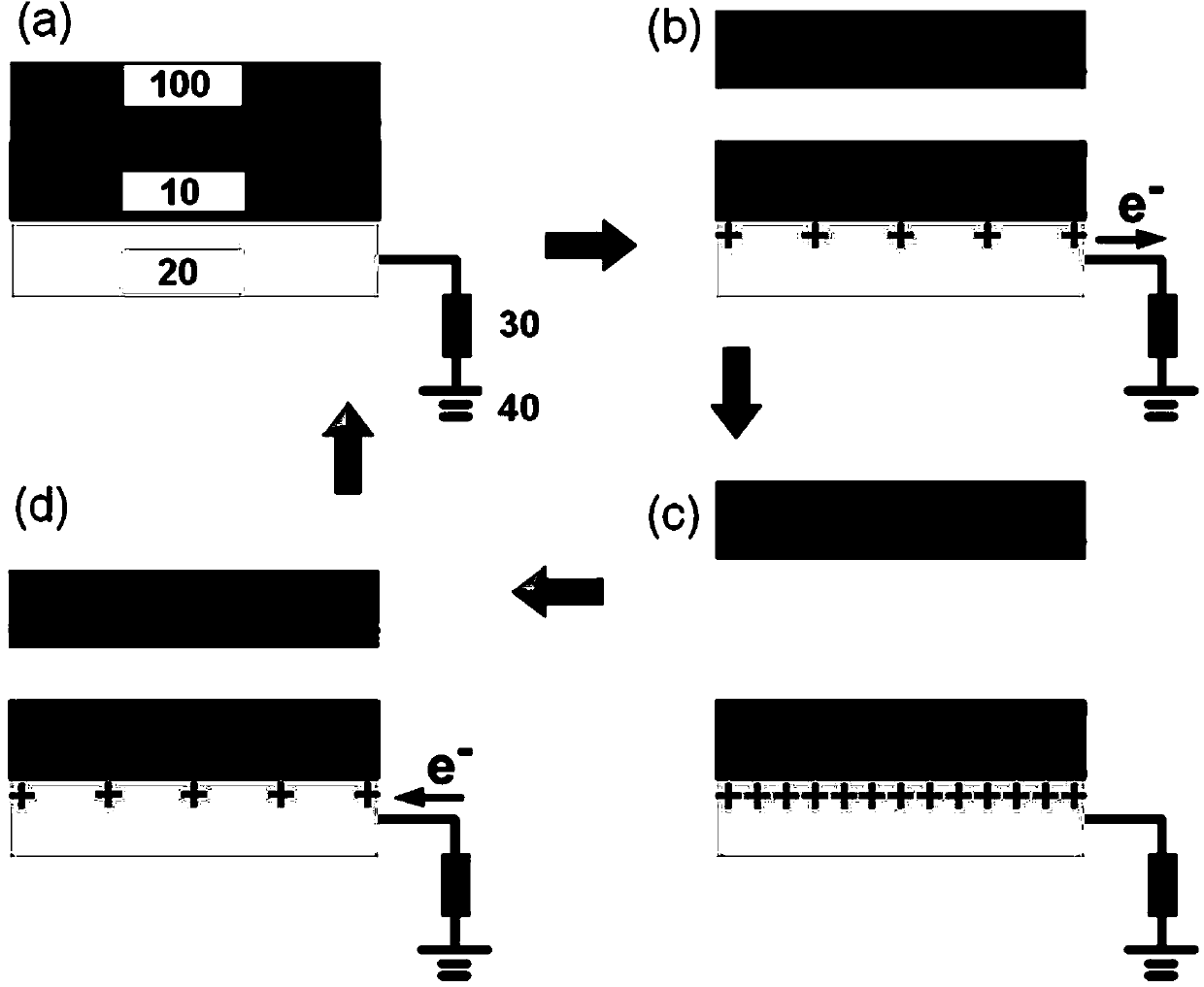

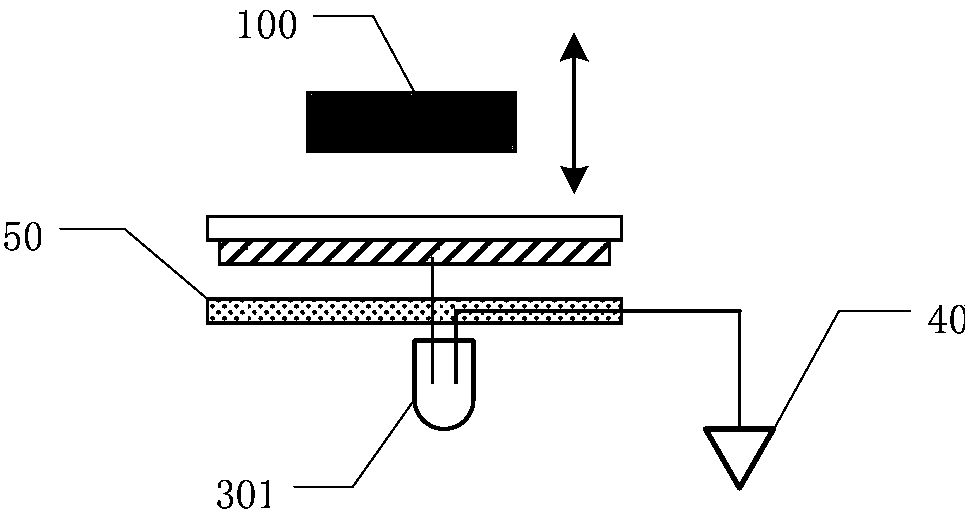

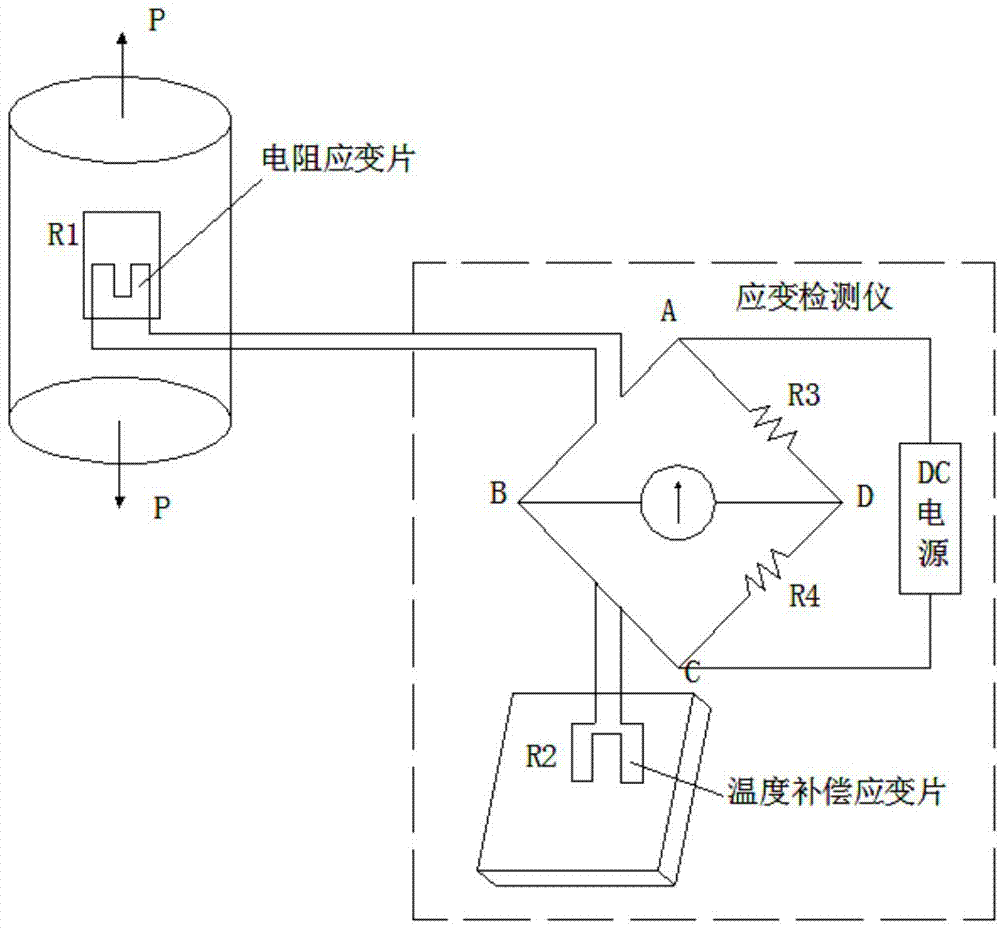

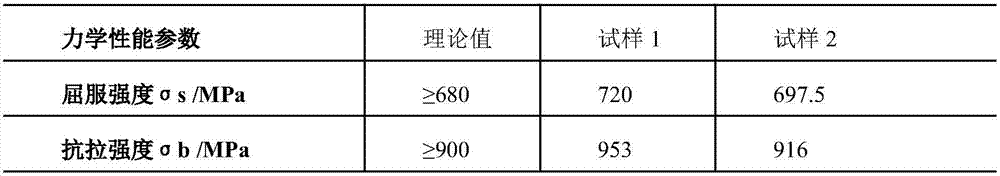

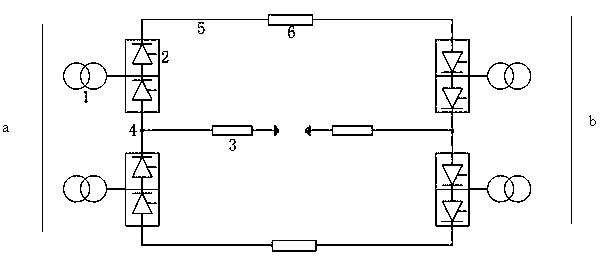

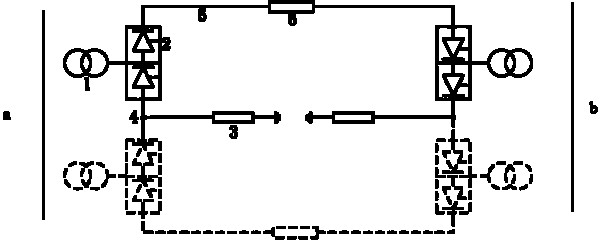

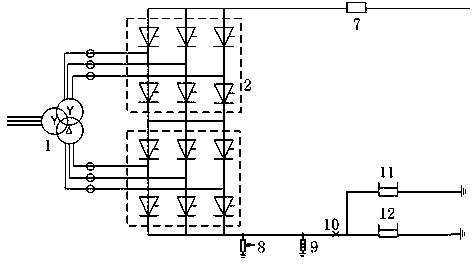

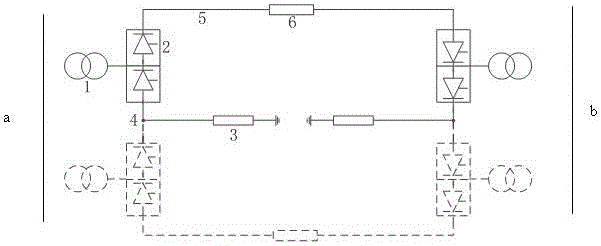

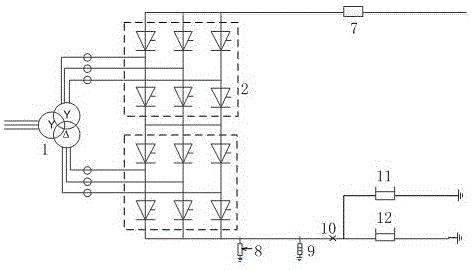

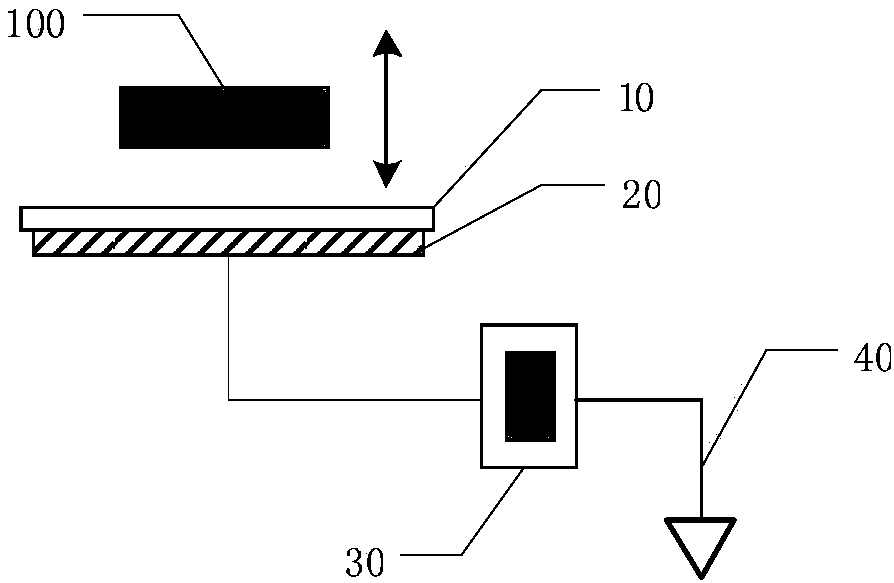

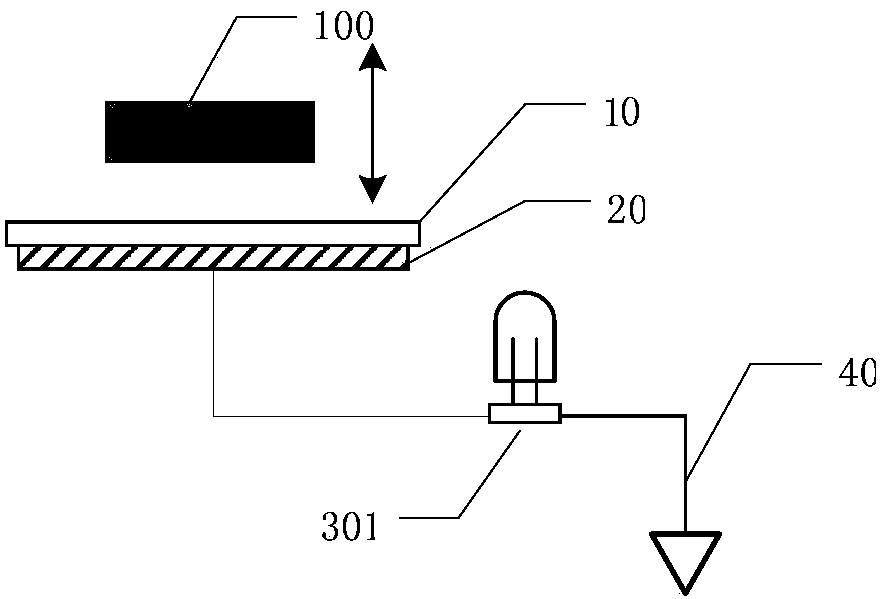

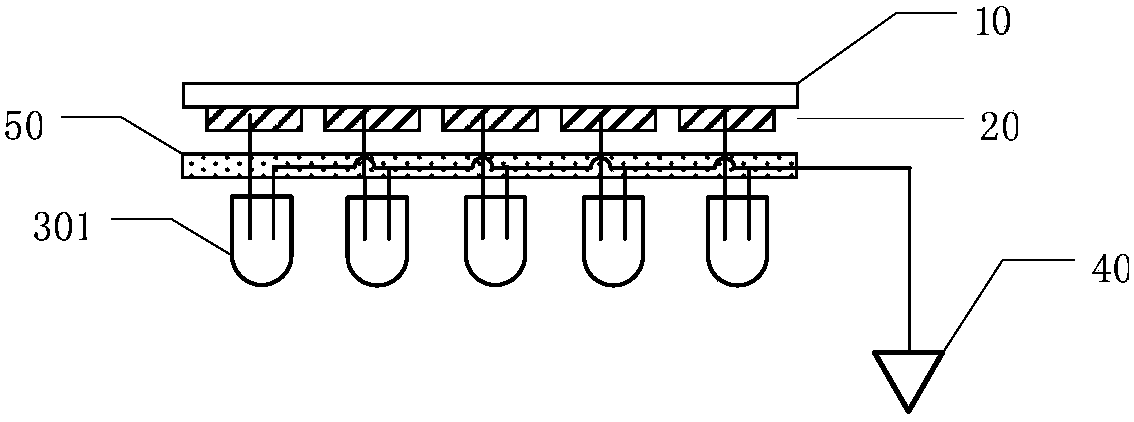

Self-driven transient stress sensing device

ActiveCN104868778ASelf-drivingImprove signal response strengthForce measurementFriction generatorsLuminous intensityEngineering

According to the present invention, by utilizing the characteristics of an electret material, an efficient contact-separation type friction nanometer generator is formed between a stress applying object and a sensing device contact layer, and is combined with the light emitting diodes skillfully, so that a self driven visual stress sensing device is constructed. Each light emitting diode corresponds to a friction nanometer generator unit, and when the external stress is applied to a contact layer of a sensor, a generated corresponding output signal drives the corresponding diode to emit light. The luminous intensity of the diodes is increased along with the increase of the applied stress, and the stress can be determined by analyzing the luminous intensity of the diodes, thereby realizing the visualization of the stress sensing. A stress visual device of the present invention has the characteristic of self-driven output, can analyze the external stress without needing an external power supply, and can be used to detect the spatial distribution of pressure.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

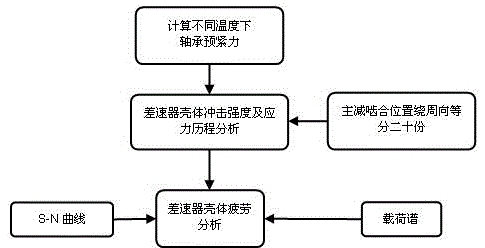

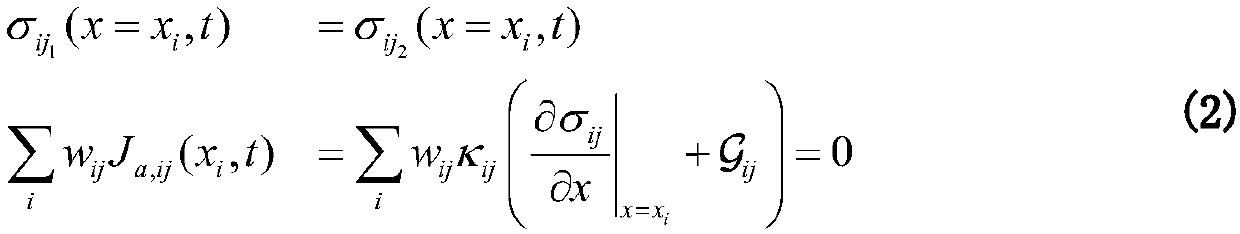

Impact strength and fatigue analysis method of transmission differential

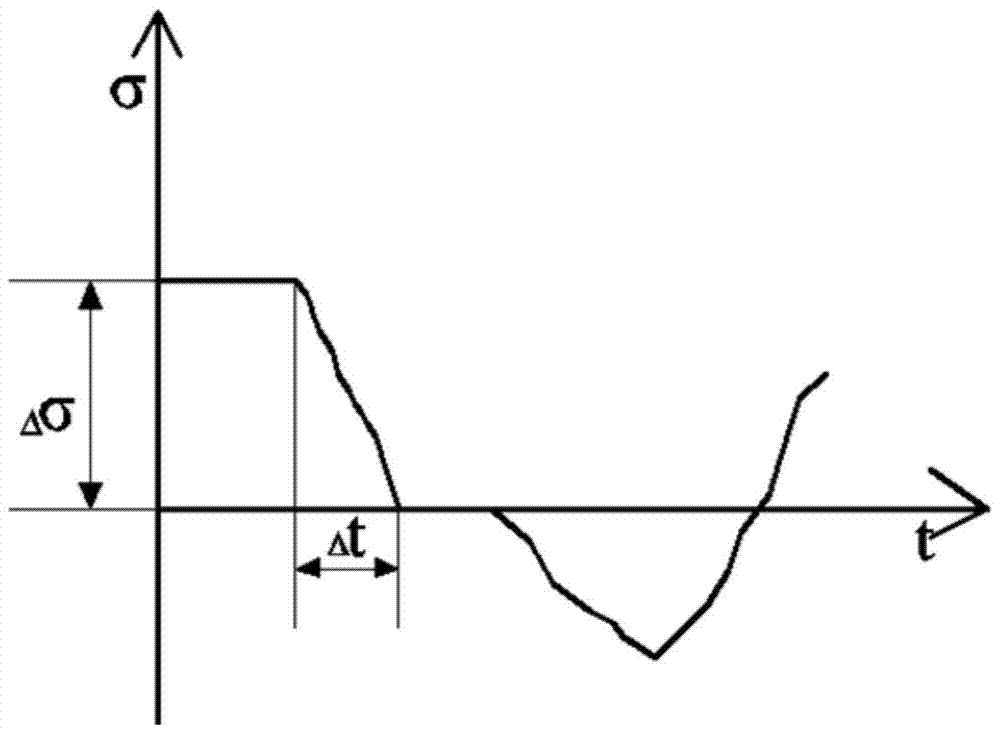

ActiveCN105488298ADesign optimisation/simulationSpecial data processing applicationsForce methodSimulation

The invention discloses an impact strength and fatigue analysis method of a transmission differential. The impact strength and fatigue analysis method comprises three parts including a pretightening force method of a cone bearing along with temperature, a circumferential 20-bisection and impact strength analysis method of the differential and a fatigue life analysis method. Since transient stress generated by actually rotating a differential shell for one circle is difficult through an analogy method, the impact strength and fatigue analysis method uses a method that the engaging position of a main-reduction gearwheel is bisected into 20 parts circumferentially to combine quasi-static analysis results to obtain a transient stress course that the differential shell rotates for one circle, so that the transient stress generated by actually rotating the differential shell for one circle is simulated, each torque level of a finished automobile load spectrum and a corresponding rotation circle number are combined, linear scaling is carried out on a stress analysis result according to a load ratio of load to stress analysis, finally, the fatigue loss of each torque level is finally overlapped, and fatigue endurance life in a differential shell working process, i.e., under the load spectrum, is calculated. The defect that differential shell is subjected to over design or the service life can not meet a practical working condition can be solved.

Owner:GETRAG JIANGXI TRANSMISSION

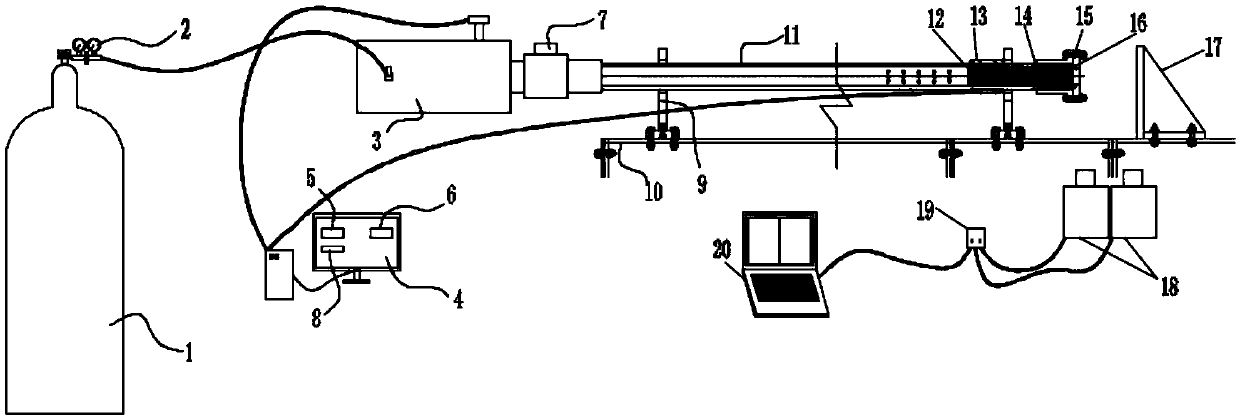

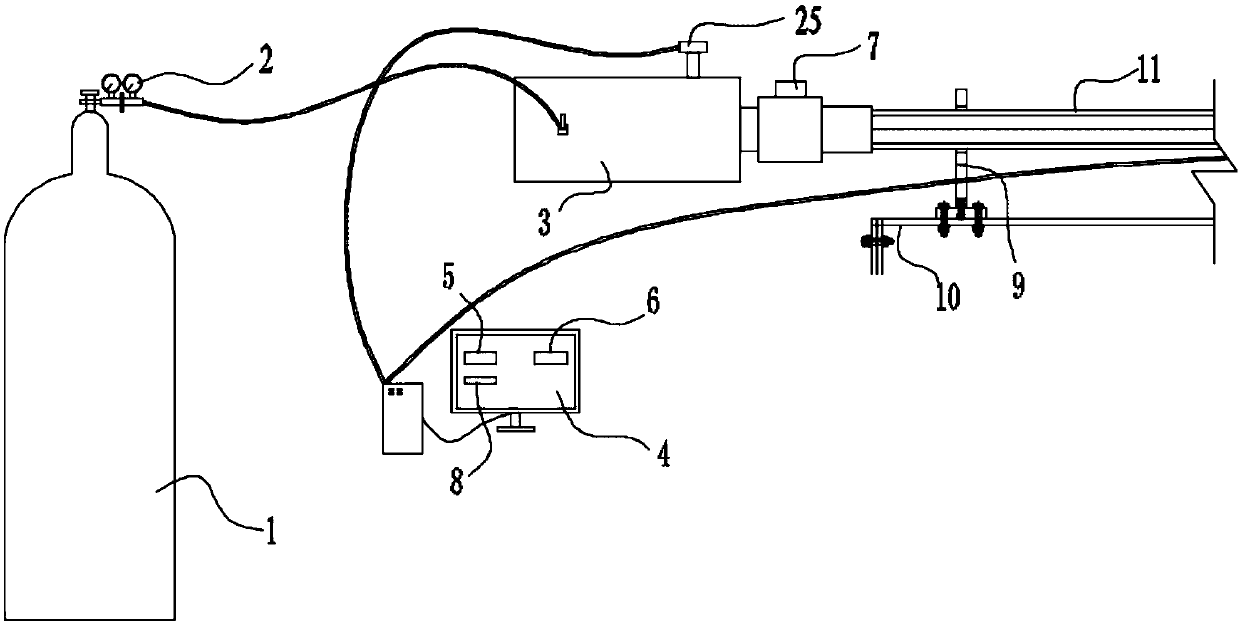

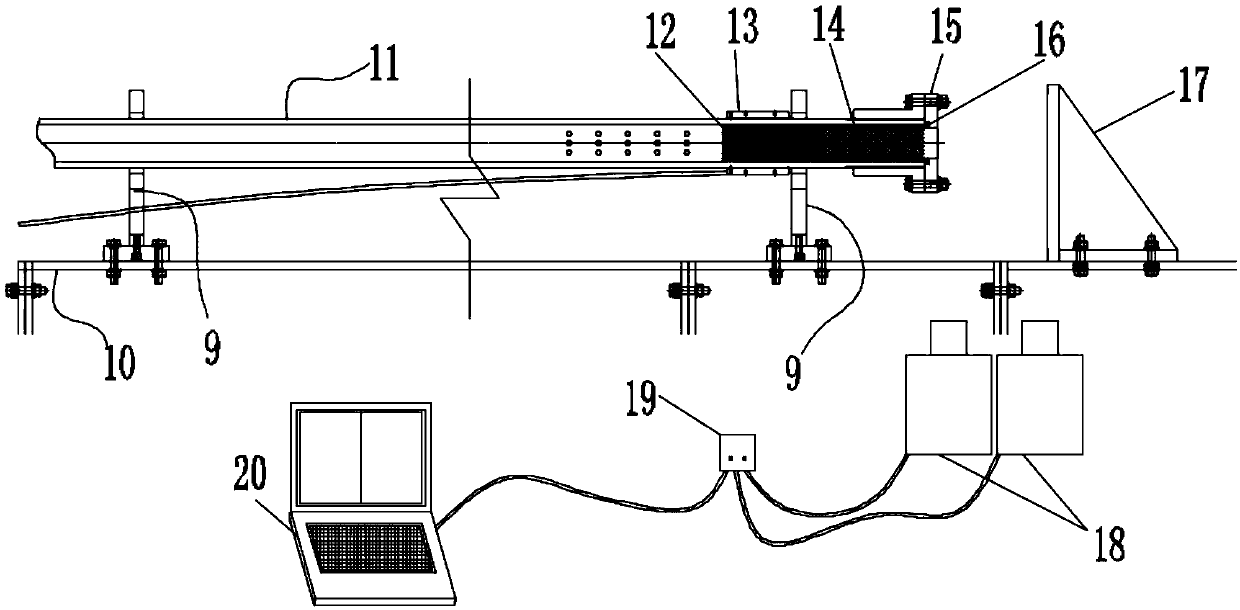

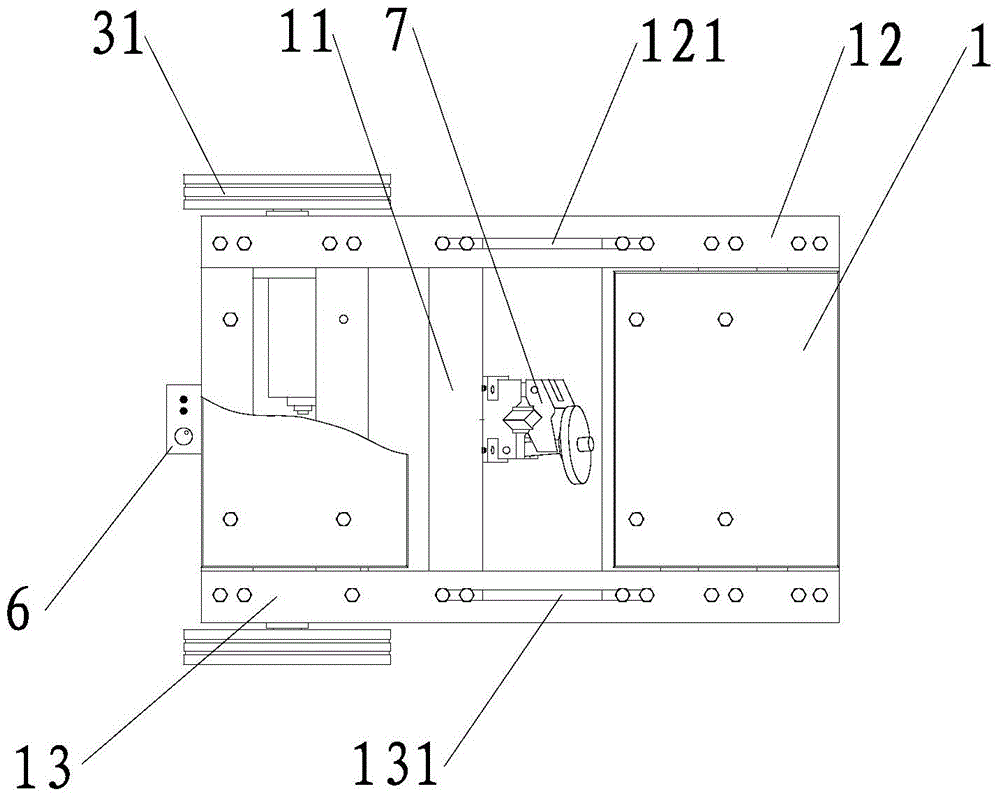

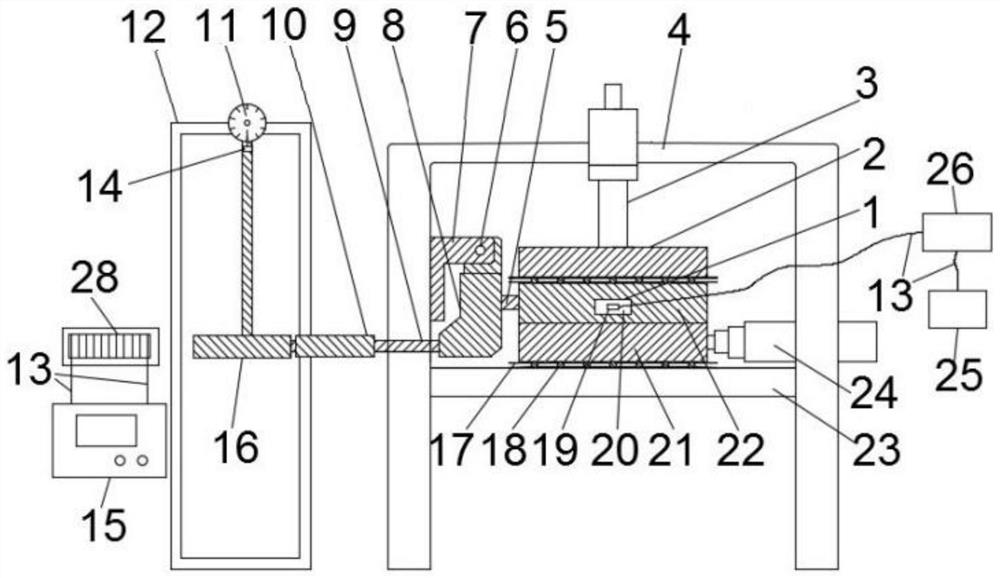

Impact test device and method used for rock or concrete test sample

The invention discloses an impact test device and method used for a rock or concrete test sample. The impact test device comprises a launching system, a fixing support, an electronic laser velocimeter, a high-speed camera shooting system and a test sample baffle, the test sample baffle and the launching system are arranged oppositely, and the electronic laser velocimeter is used for detecting thespeed of the launched test sample; the launching system comprises a nitrogen steel cylinder, a gas storage room, a launching barrel, a sabot and a sabot and test sample separating device, and the gasstorage room is connected with the launching barrel through an electromagnetic switch. During usage, the gas storage room is filled with gas through the nitrogen steel cylinder, then the electromagnetic switch is rapid switched on, gas flows push the sabot with the test sample to conduct launching rapidly from the launching barrel, then, the test sample and the sabot are separated, the test sampleimpacts on the test sample baffle, impact data of the test sample is recorded through the electronic laser velocimter and the high-speed camera shooting system, and the transient stress strain fieldof the test sample impact is analyzed through 3DDIC software. The test device is easy and convenient to assemble, efficient in test process and high in repeatability.

Owner:WUHAN UNIV

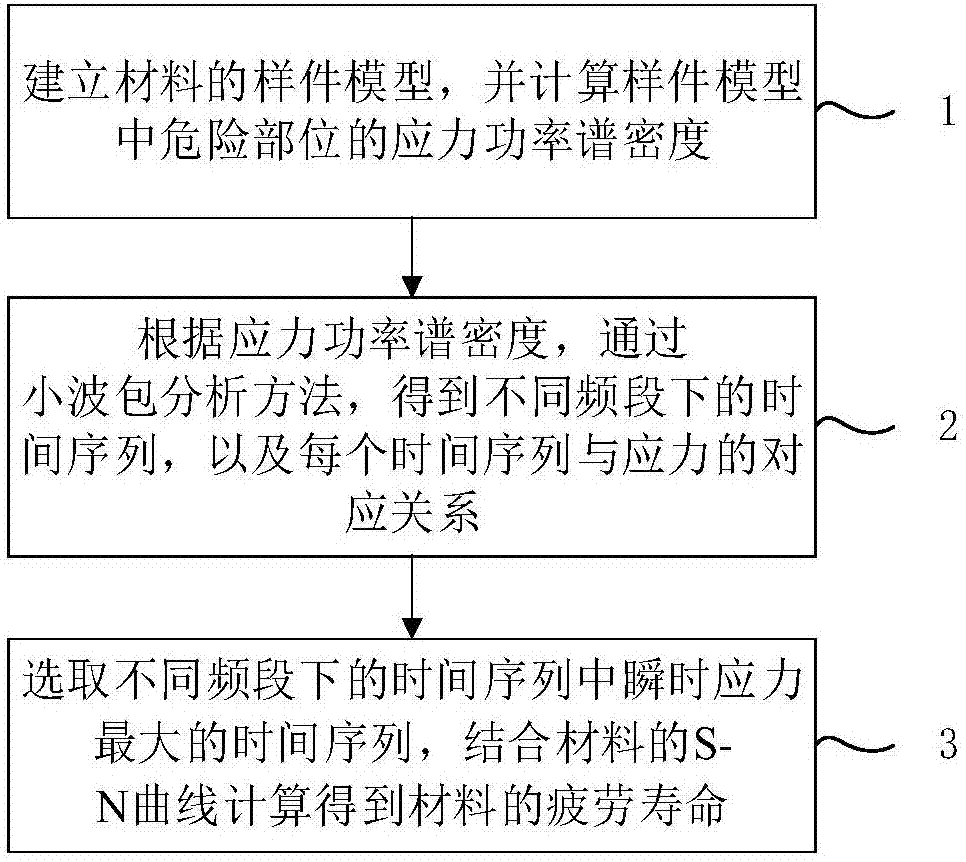

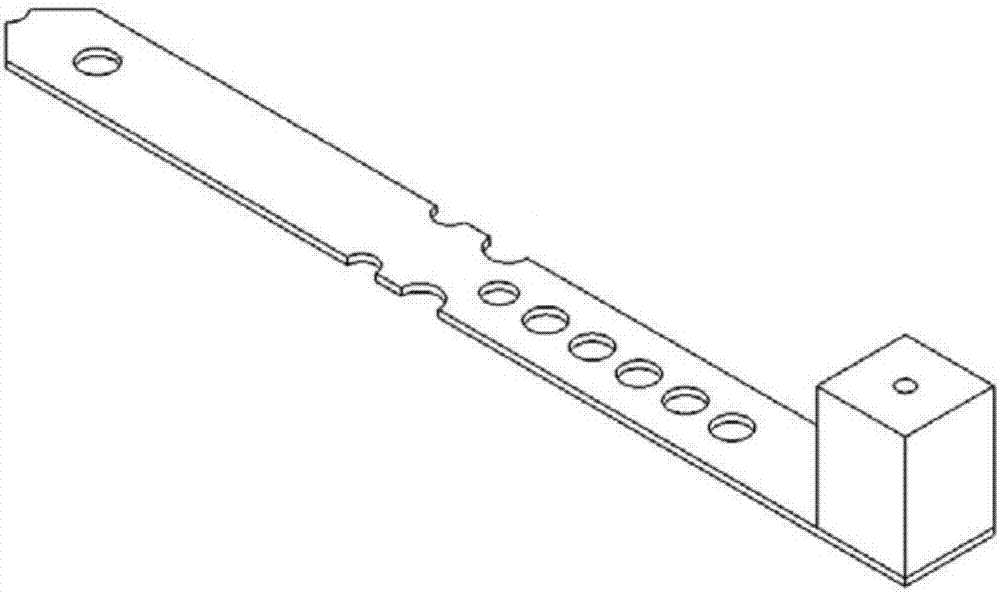

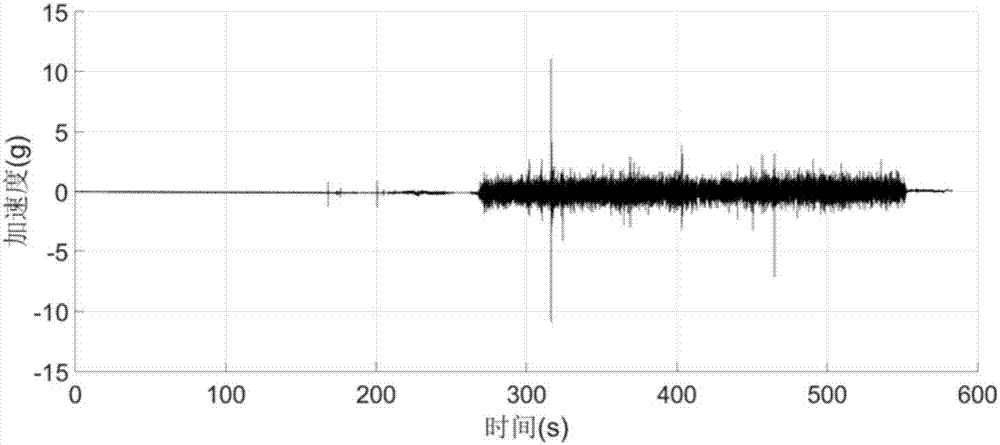

Method for predicting fatigue life of material based on wavelet packet analysis

ActiveCN107389478APrevent lossThe estimate is accurateMaterial strength using repeated/pulsating forcesAlgorithmSpectral density

The invention relates to a method for predicting the fatigue life of a material based on wavelet packet analysis. The method comprises the following steps: establishing a sample piece model of the material and calculating stress powder spectrum density of a dangerous part in the sample piece model; according to the stress power spectrum density, obtaining time sequence under different frequency bands and the corresponding relation between each time sequence and the stress according to a wavelet packet analysis method; selecting the time sequence, with the maximal transient stress, in the time sequences under different frequency bands, and calculating by combining an S-N curve of the material to obtain the fatigue life of the material. Compared with the prior art, the method has the advantages of accurate prediction result, high practical performance, convenience in implementation and the like.

Owner:SHANGHAI UNIV OF ENG SCI

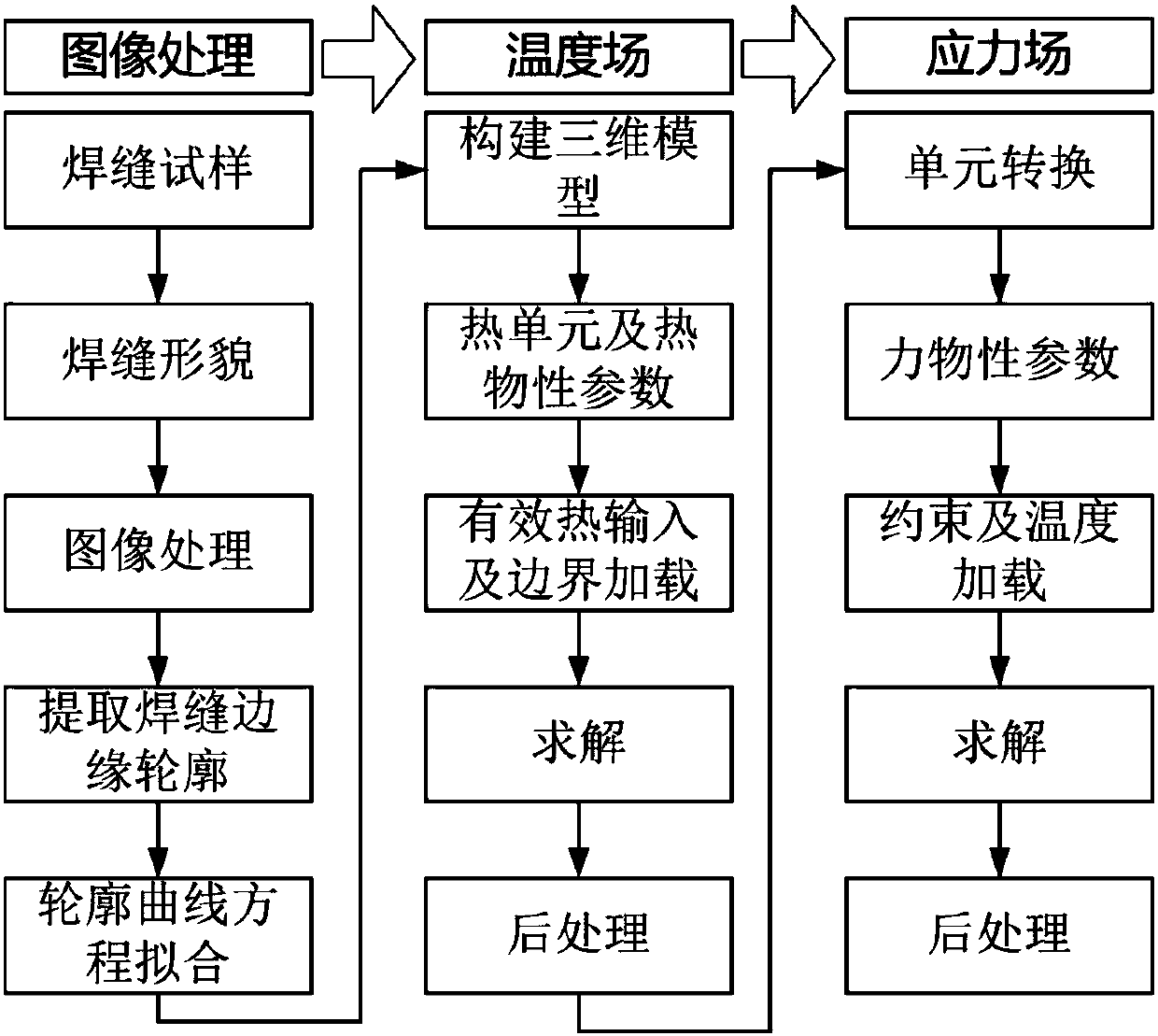

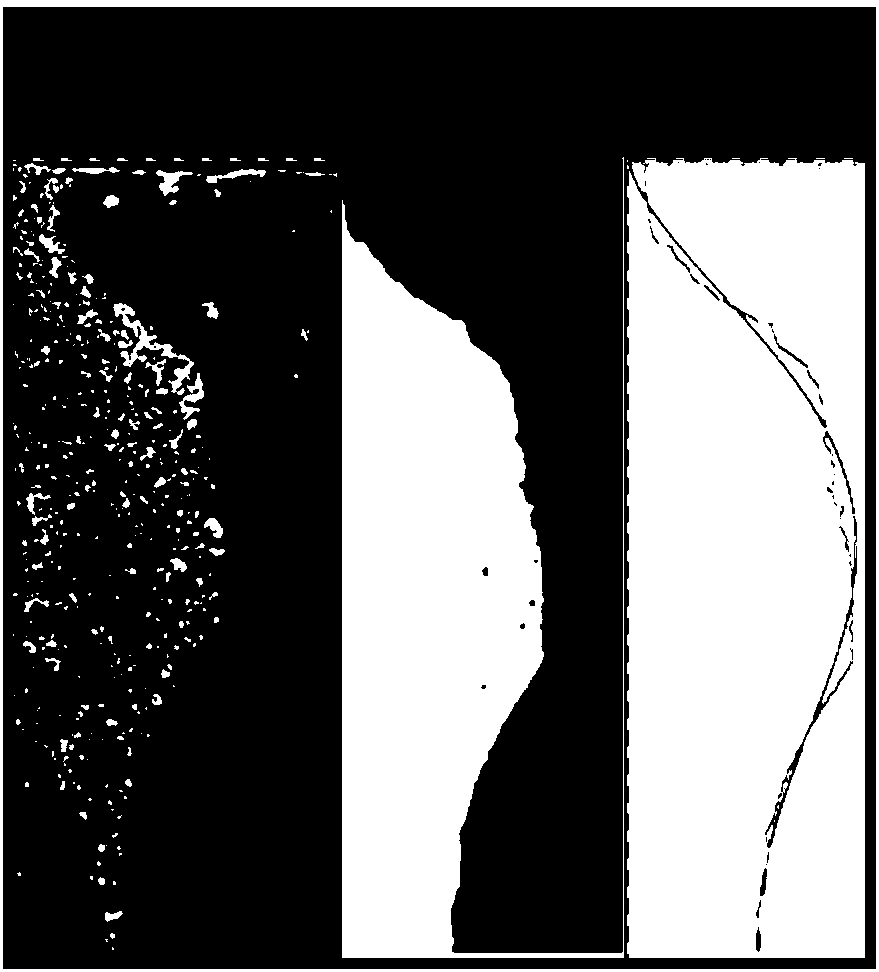

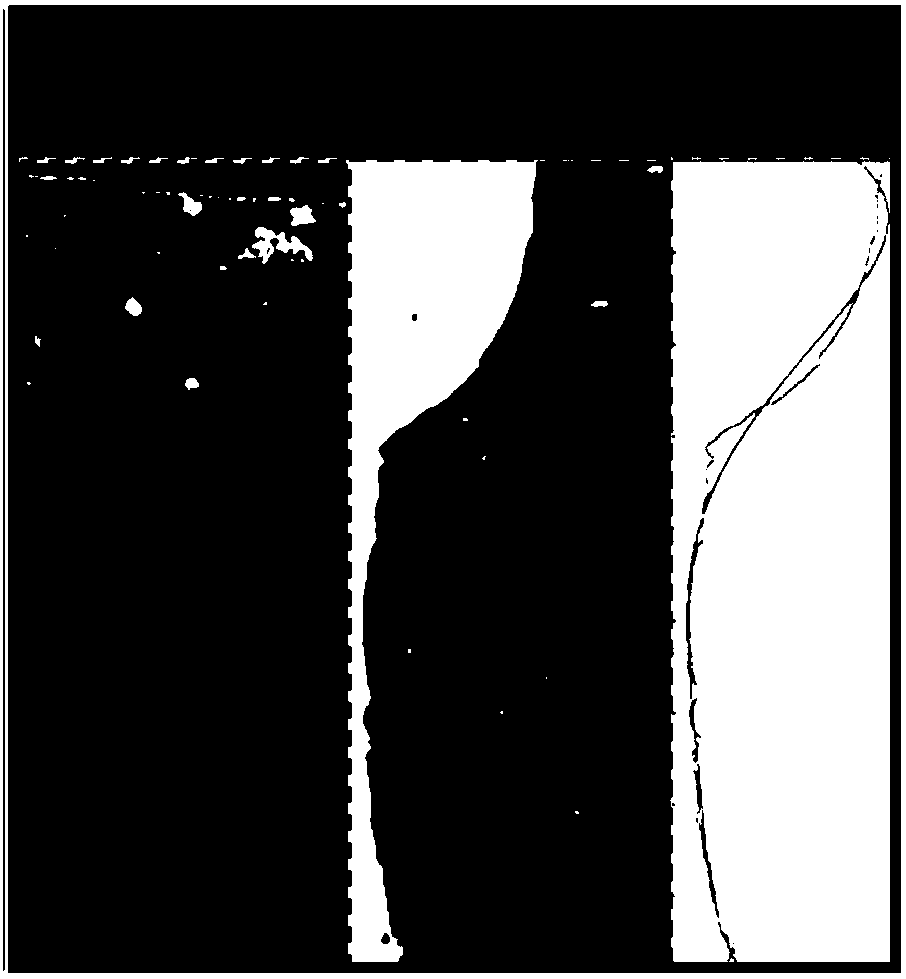

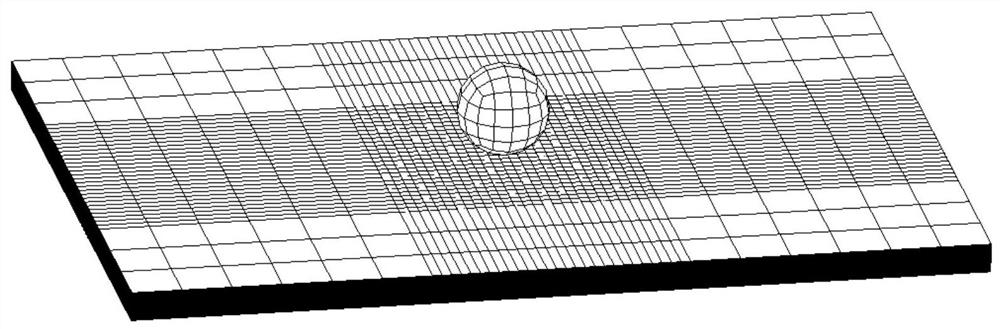

Welding seam image extraction fitting-based welding stress deformation prediction method and system

ActiveCN108022236APredict Weld StressPredictive statusImage enhancementImage analysisEngineeringWeld seam

The invention discloses a welding seam image extraction fitting-based welding stress deformation prediction method and system, and belongs to the field of welding machining. The method comprises the steps of 1, obtaining a contour line based on a welding seam image, and performing fitting to form a function curve; 2, building a three-dimensional geometric model of welding seam appearance based onthe function curve, dividing a temperature field unit in the three-dimensional geometric model, and setting a thermophysical parameter, a thermal input and a boundary loading quantity of a welding material, thereby obtaining a transient temperature field; and 3, selecting a stress field unit from the three-dimensional geometric model, setting a mechanical physical parameter of the welding material, and loading a parameter of the transient temperature field to a node corresponding to the stress field unit, thereby obtaining transient stress and deformation distribution. The system comprises a module for executing the method. The temperature field is accurately simulated through image extraction and fitting; the problem of poor precision of non-uniform temperature field simulation is effectively solved; and accurate simulation calculation of stress deformation of a welding process is ensured.

Owner:HUAZHONG UNIV OF SCI & TECH

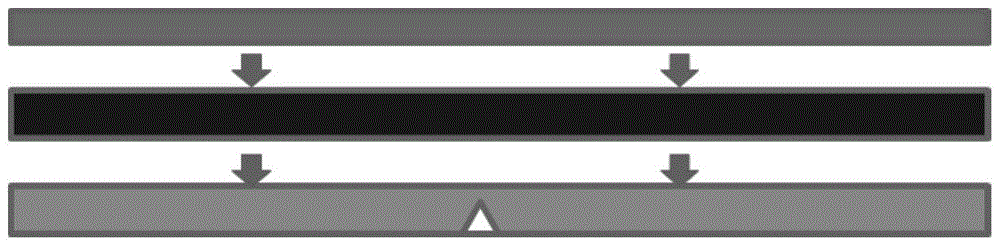

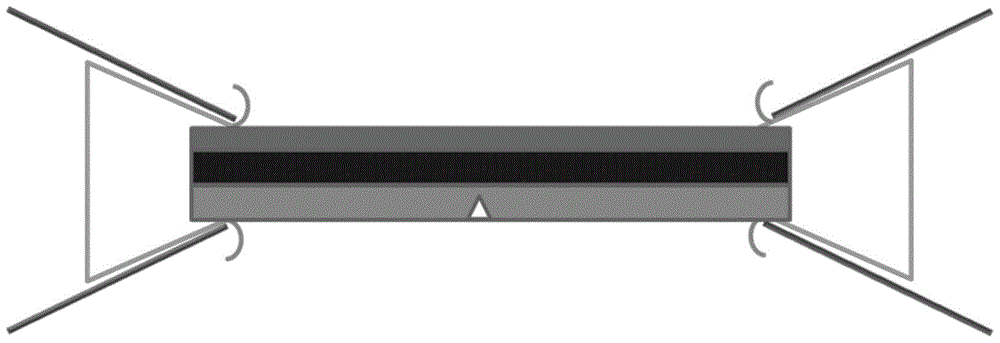

Flexible film brittle failure method

InactiveCN105699167AProne to brittle failureEnhanced likelihood of brittle fracturePreparing sample for investigationScanning electron microscopeElectron microscope

The invention relates to the field of scanning electron microscope sample preparation and particularly relates to a flexible film brittle failure method. The flexible film brittle failure method comprises the following steps of: processing a silicon wafer into a long and thin strip, thereby obtaining a pre-carved silicon wafer; bonding the pre-carved silicon wafer and a flexible film; fixing two ends of the silicon wafer with clips, and then feeding the silicon wafer into a cooling liquid so as to fully cool the silicon wafer; rapidly taking out the frozen silicon wafer, bending the frozen silicon wafer towards a side with a slot until the frozen silicon wafer is subjected to brittle failure, thereby obtaining a flexible film subjected to brittle failure. In a process of reducing the flexibility of the film at a low temperature, the method is capable of limiting film movement by virtue of binding of the pre-carved silicon wafer, concentrating transient stress and generating high strain rate, thereby easily obtaining a complete brittle fracture surface and overcoming various problems of obvious plastic deformation, unevenness and the like of the prepared fracture surface.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

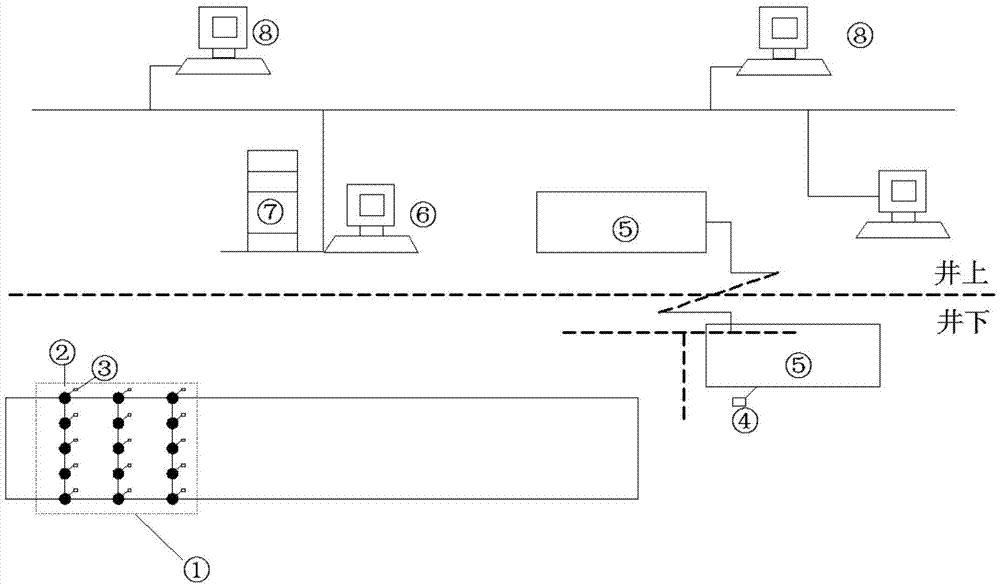

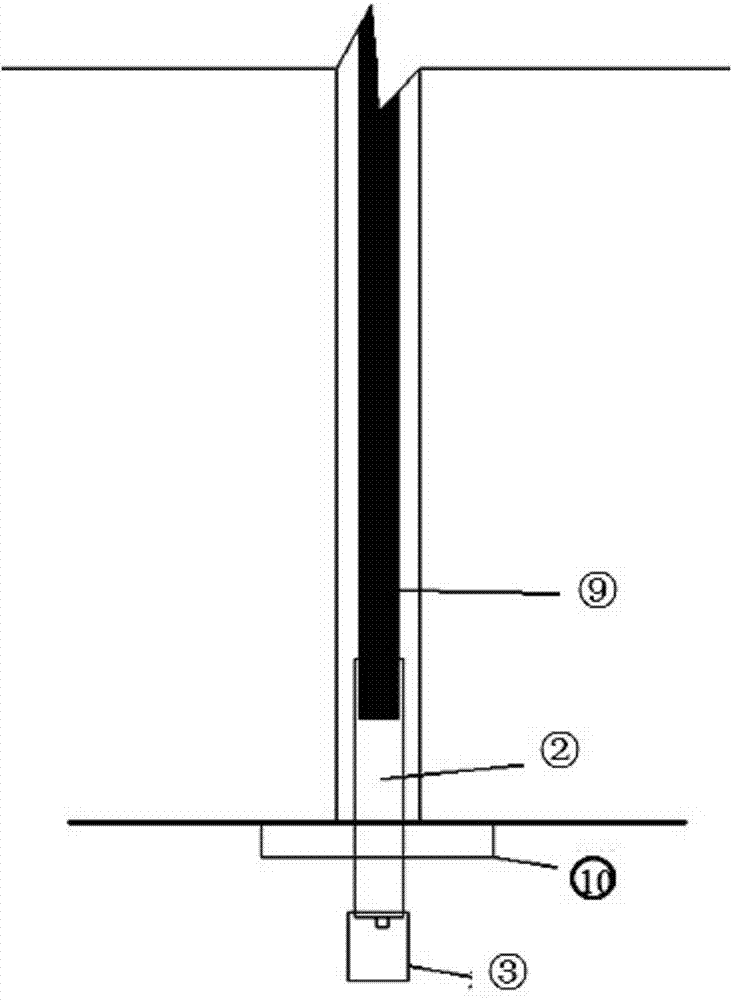

Surrounding rock anchor bolt stress wave positioning monitoring system

InactiveCN104763453ARealize real-time monitoringRealize early warningMining devicesAnchoring boltsEngineeringTime dynamics

The invention discloses a surrounding rock anchor bolt stress wave positioning monitoring system. The surrounding rock anchor bolt stress wave positioning monitoring system comprises an anchor bolt monitoring matrix which is fixed in an underground tunnel or a mined-out area and formed by a plurality of anchor bolts; the tail end of every anchor bolt is provided with a ground pressure sensor, a wireless transmitter and a battery module; the surrounding rock anchor bolt stress wave positioning monitoring system also comprises an underground wireless receiver and a repeater; the surrounding rock anchor bolt stress wave positioning monitoring system also comprises an aboveground repeater, an early warning software computer, a server and a client computer. According to the surrounding rock anchor bolt stress wave positioning monitoring system, the real-time dynamic monitoring can be performed on the surrounding rock stress and transient stress waves, the high-frequency collection on the ground pressure information is implemented, the comprehensive analysis is performed on the surrounding rock stress and the instantaneous stress waves, the ground pressure monitoring and early warning of the three-dimensional space are performed, the cost is low, the installation is convenient, the applicability is wide, and the operation is simple.

Owner:CHINA ACAD OF SAFETY SCI & TECH

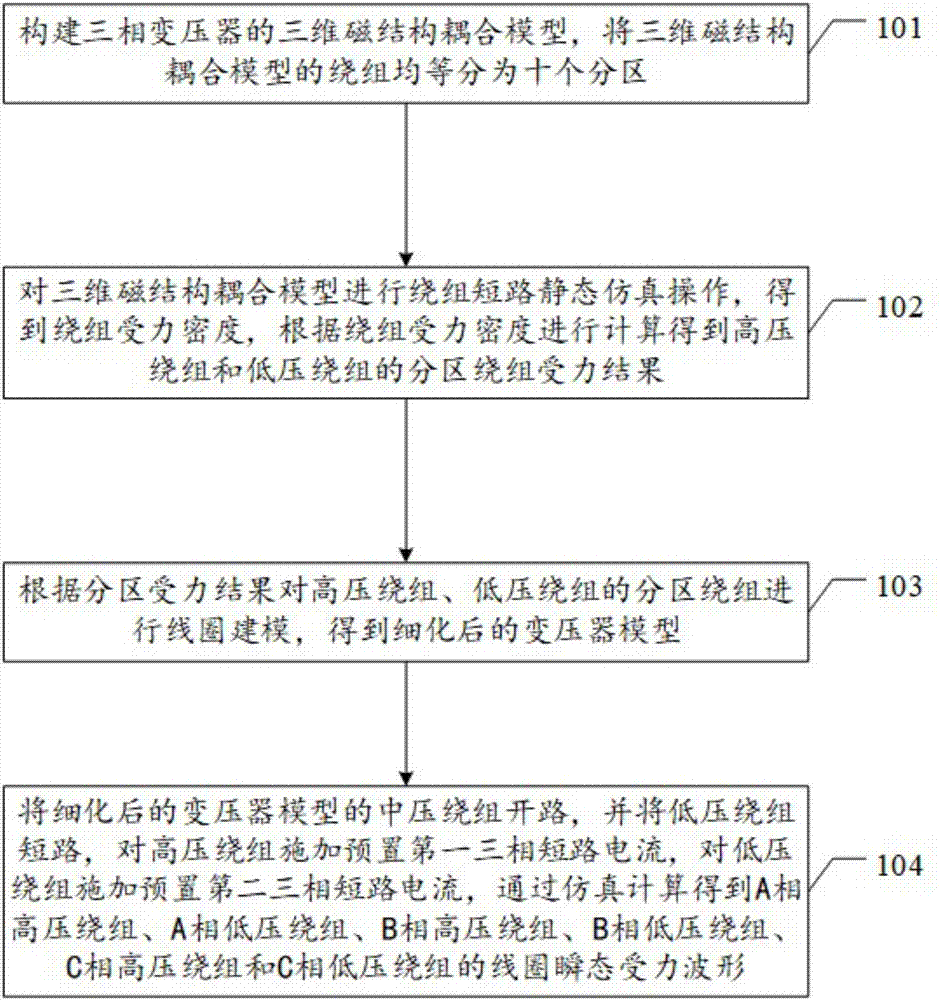

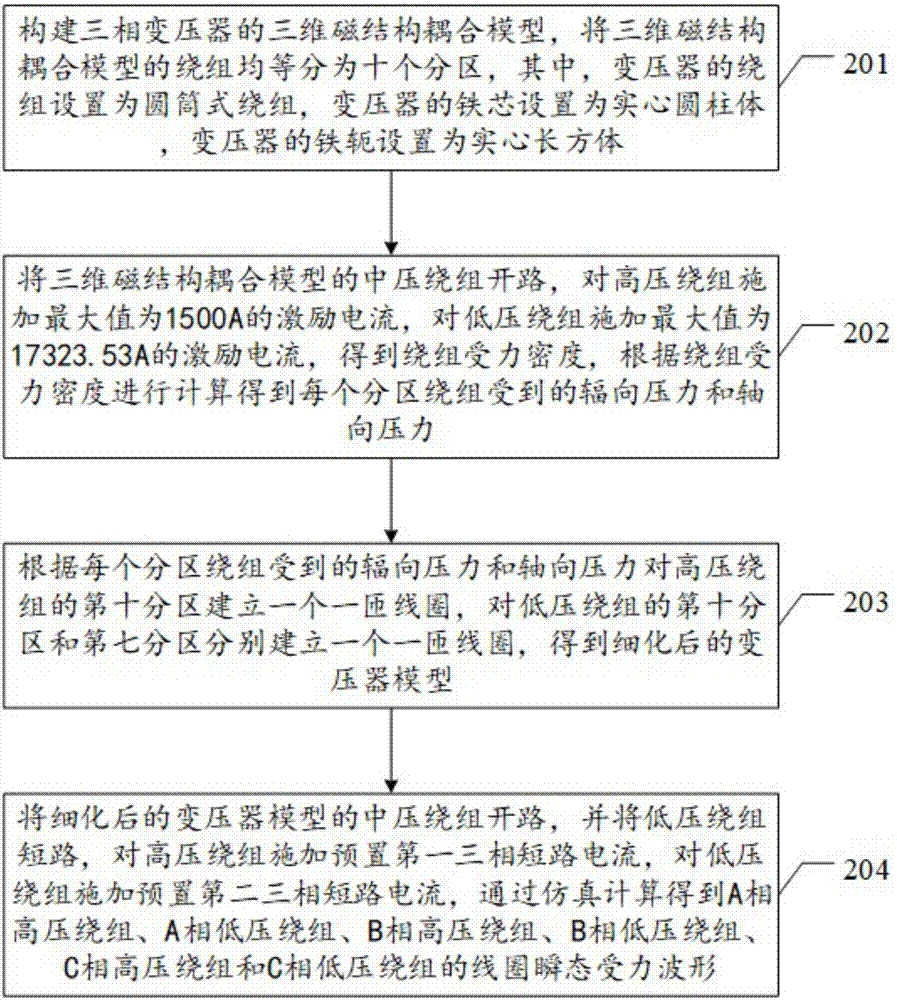

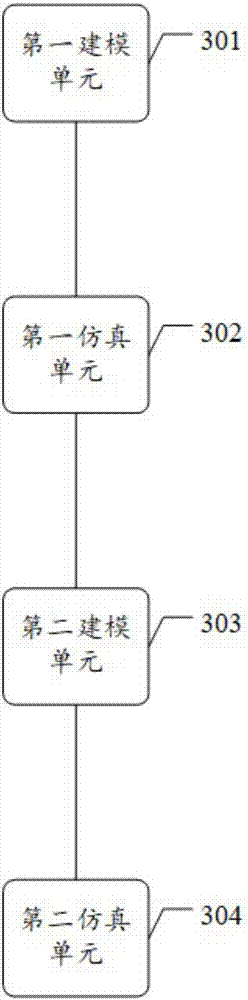

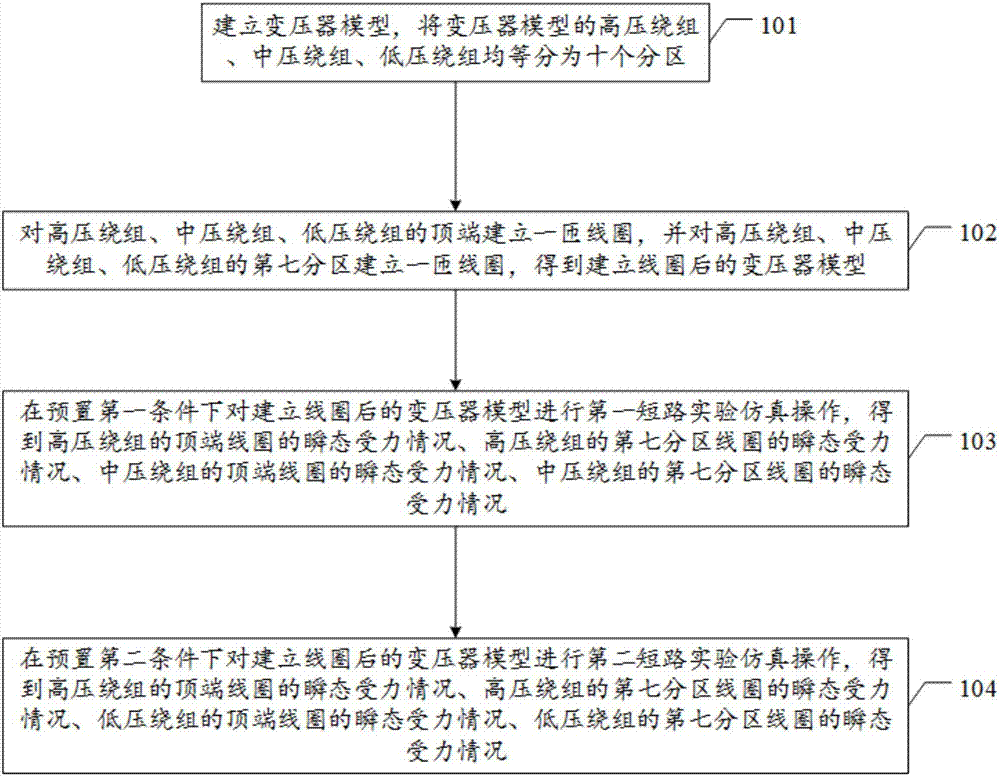

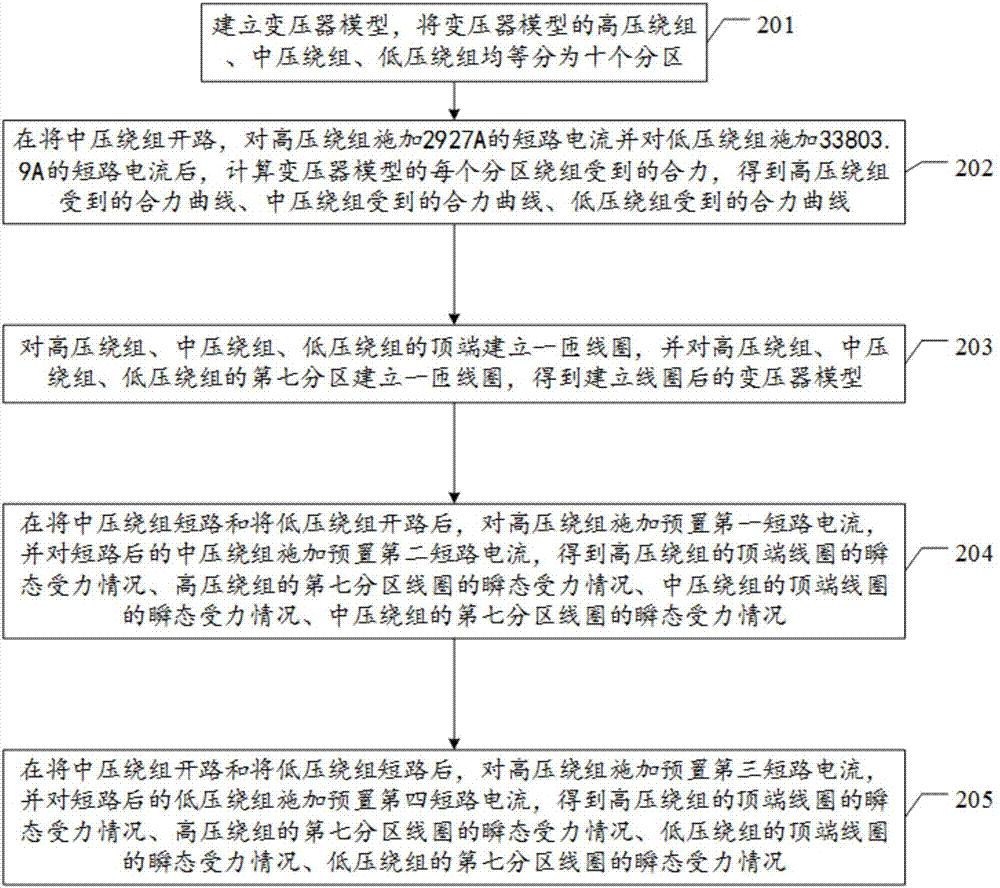

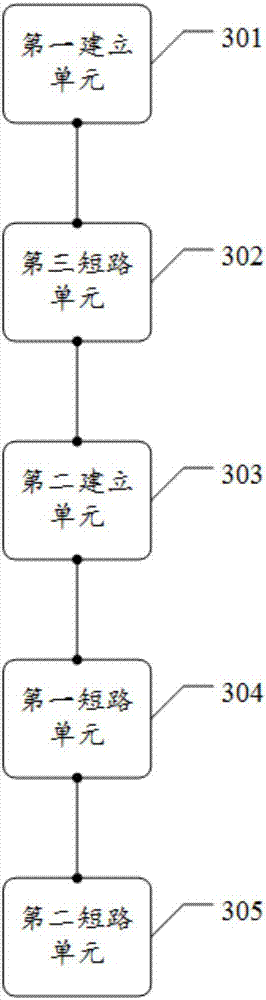

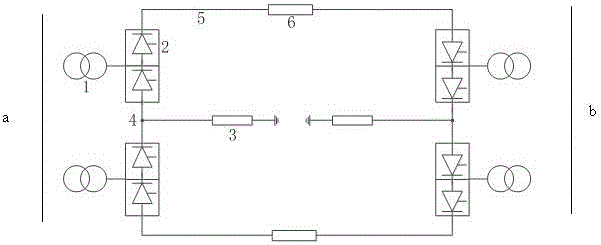

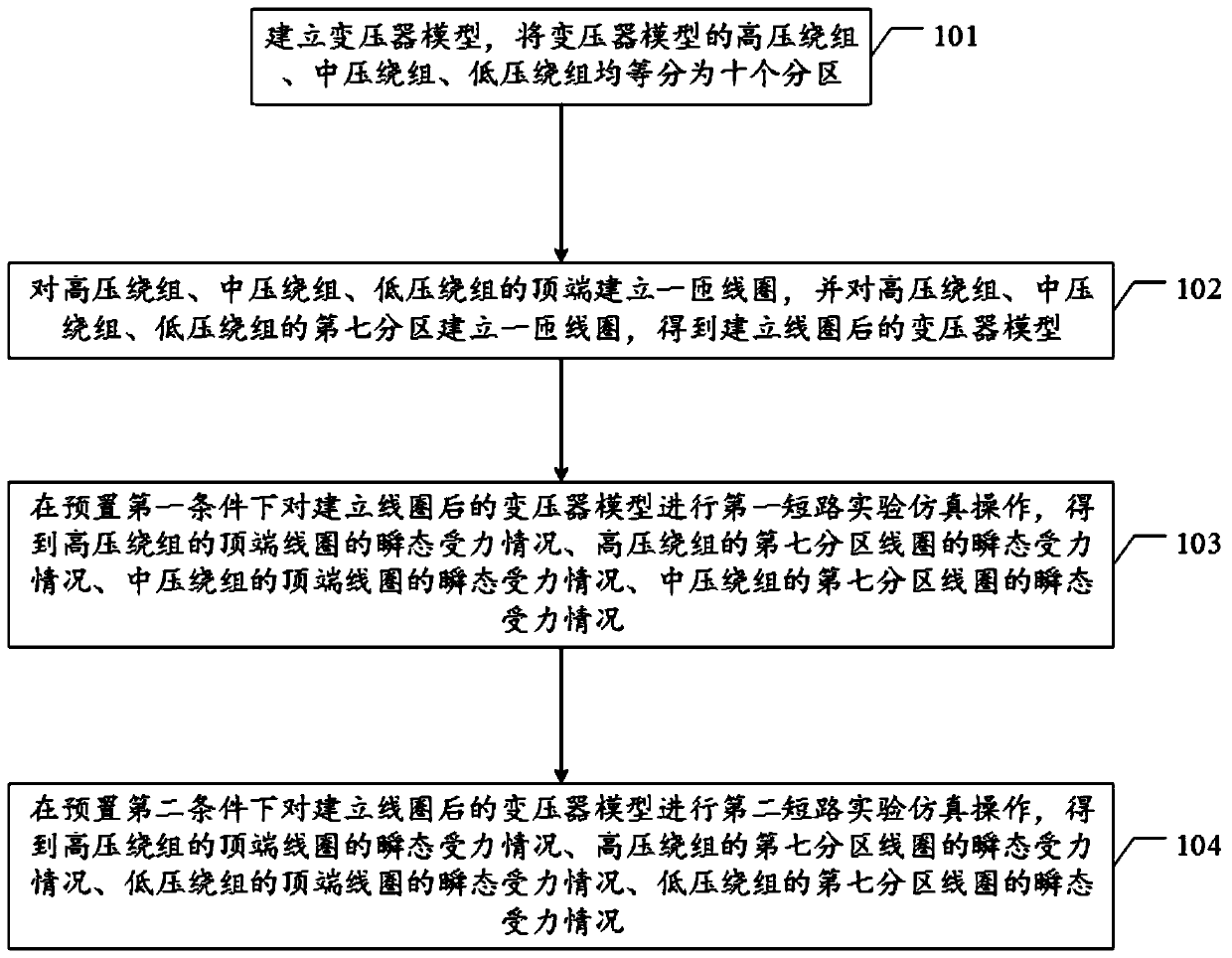

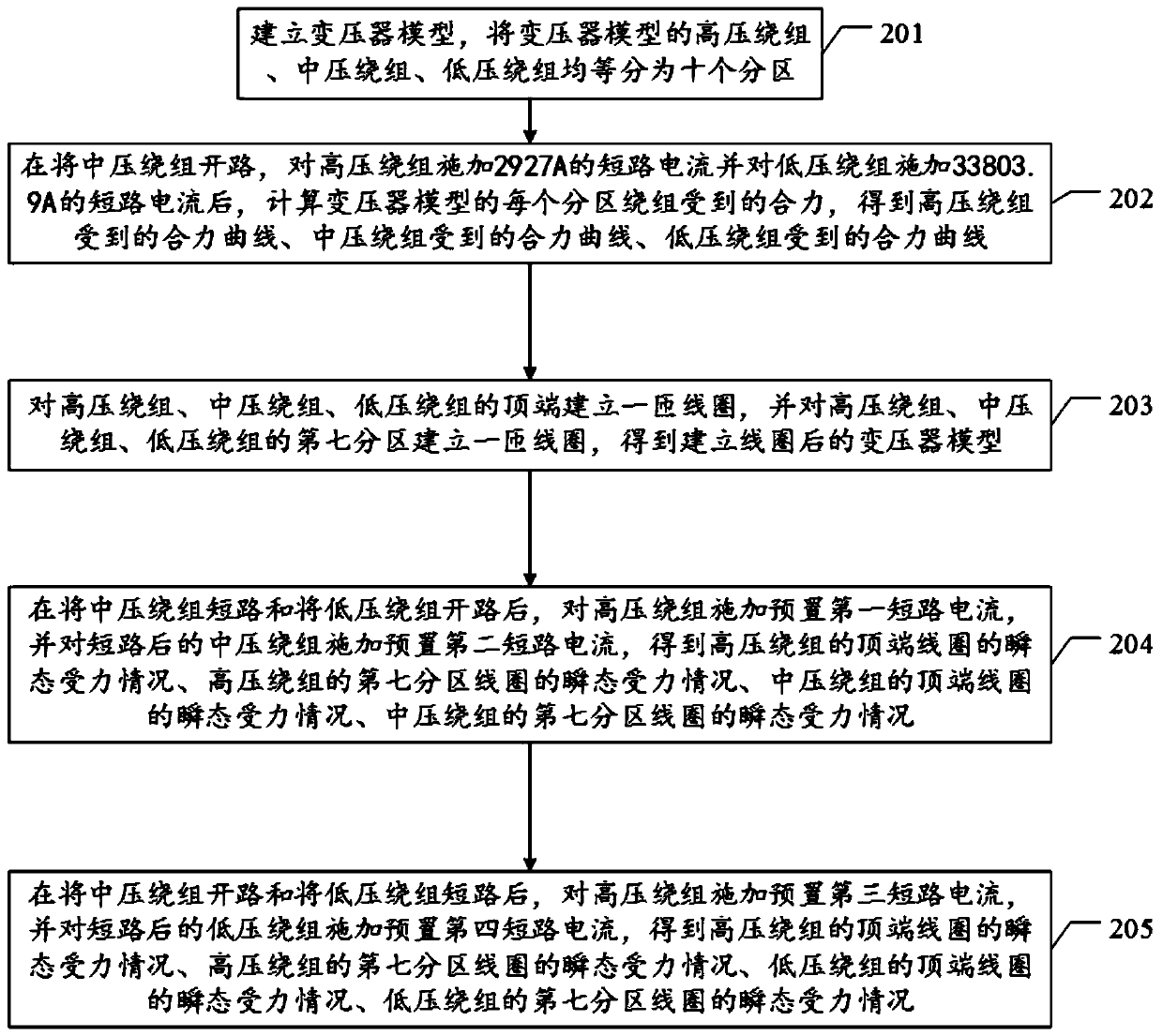

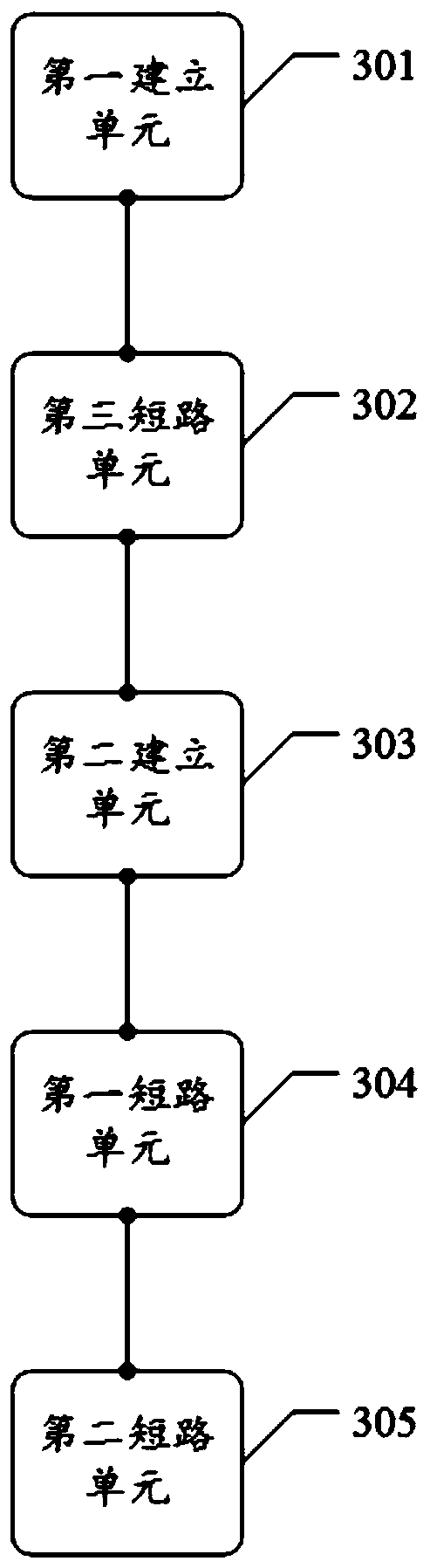

Power transformer winding short-circuiting transient stress analysis method and device

ActiveCN107423528AImprove short circuit strengthTransformers/inductances coils/windings/connectionsDesign optimisation/simulationEngineeringElectromagnetic field

The embodiment of the invention discloses a power transformer winding short-circuiting transient stress analysis method and device. A three-dimensional magnetic structure coupling model of a three-phase transformer is built, static simulation of winding short-circuiting is pre-conducted on the coupling model, the stress result of a winding is obtained, according to the stress result of the winding, coil modeling is further conducted on the coupling model according to the stress result of the winding, a refined transformer model is obtained, under the three-phase short-circuiting condition, transient electromagnetic field simulation analysis is conducted on the refined transformer model, the transient stress of a single coil of the winding is analyzed, a transient stress curve showing the change of winding coils along with time is obtained, and a forceful basis is provided for the accumulative effect of a deformer under the short-circuit impact, the anti-short-circuit strength improvement of the deformer and other kinds of related research.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

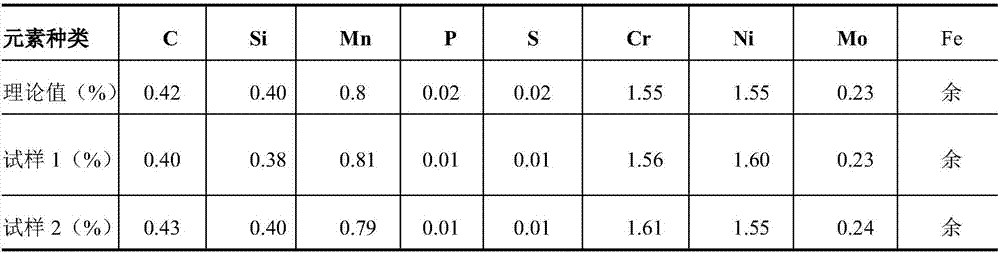

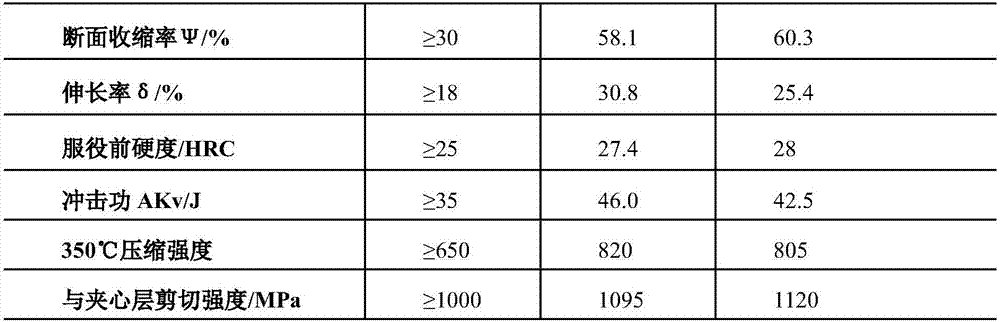

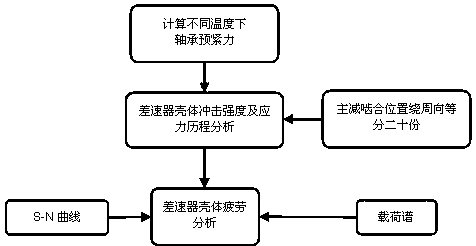

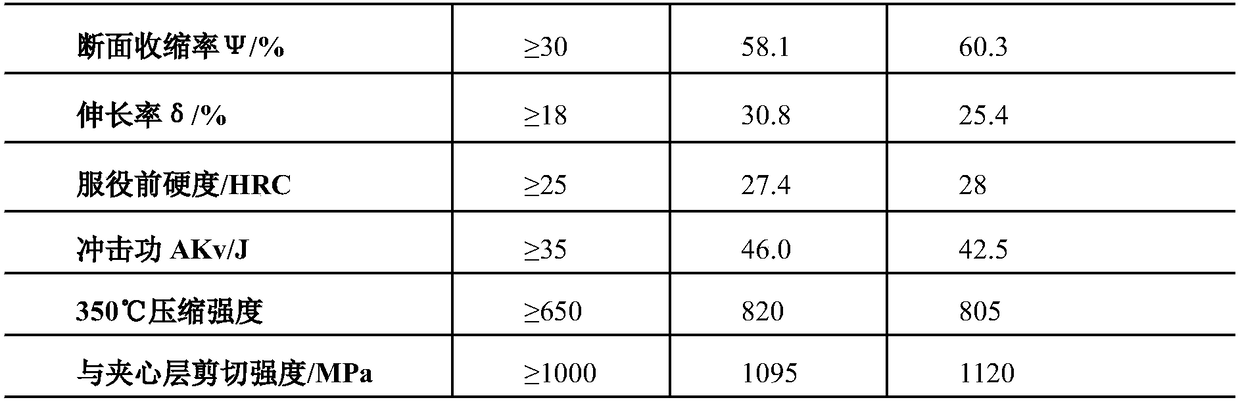

Special cast steel used for preparing large hot-work die under high temperature and heavy load conditions and preparation method of special cast steel

The invention discloses special cast steel used for preparing a large hot-work die under the high temperature and heavy load conditions. The special cast steel is composed of, by mass, 0.35-0.5% of carbon elements, 0.2-0.6% of silicon elements, 0.6-1.0% of manganese element, less than or equal to 0.02% of phosphorus elements, less than or equal to 0.02% of sulfur elements, 1.4-1.7% of chromium elements, 1.4-1.7% of nickel elements, 0.15-0.3% of molybdenum elements and the balance iron and impurities. The novel cast steel used for preparing the large hot-work die is provided, when the large hot-work die is matched with an eighty-thousand-ton die-forging hydraulic press for forming materials difficult to form under the extreme conditions with the temperature being higher than 350 DEG C and the local transient stress being greater than 650 MPa, the properties of the aspects of hardness, strength, plasticity and toughness of the large hot-work die can meet the requirements, the problem that a die substrate is severely and plastically deformed and cracked when the strength and hardness of the hot-work die are reduced rapidly under the extreme conditions is avoided, and the problem that the die fails seriously and cannot not used is avoided; and thus the service life of the hot-work die is remarkably prolonged.

Owner:CHONGQING UNIV +3

Method for calculating transient stress of E type lightning arrester

ActiveCN103473387AAdd slope linkImprove control protection logicSpecial data processing applicationsHigh-voltage direct currentPower equipment

The invention discloses a method for calculating the transient stress of an E type lightning arrester. The method comprises the following steps of (1) determining a protection logic; (2) establishing a high-voltage direct current electromagnetic transient simulation model, and modeling the protection logic; (3) executing EMTDC (electromagnetic transients including DC) electromagnetic transient simulation, observing a measurement signal curve, and verifying whether a grounding electrode open circuit protection action logic meets a requirement or not; (4) recording the maximum energy of the E type lightning arrester under a grounding electrode open circuit failure. According to the method, the shortcoming of excessive idealization of a control protection logic of a conventional calculation model is overcome, and a measurement signal triggering-based control protection logic is adopted, namely sampling filtering and judging links for measuring voltage and current are added as protection triggering bases; in an exit phase shifting protection process, a slope link is added, and a triggering angle is phase-shifted at speed of 4 degrees per millisecond; the control protection logic for the simulation model is improved to be more consistent with an actual running condition; when the method is used for selecting an energy parameter of the E type lightning arrester, higher safety is ensured, and power equipment on a neutral generatrix can be effectively protected.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

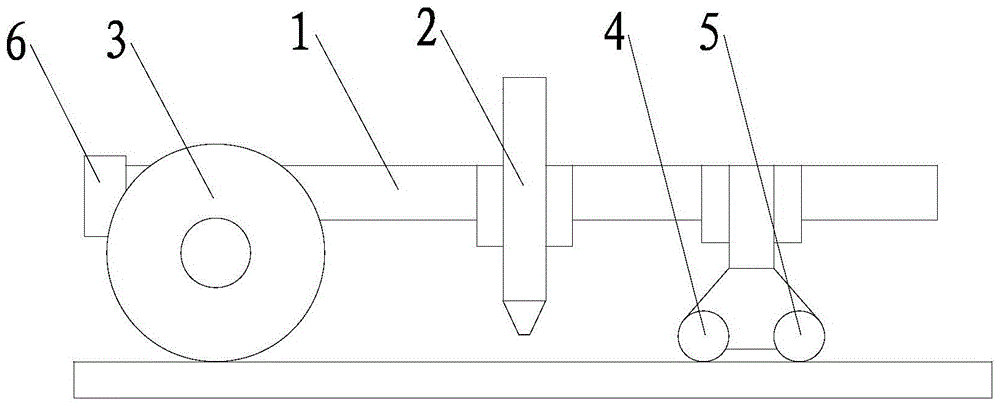

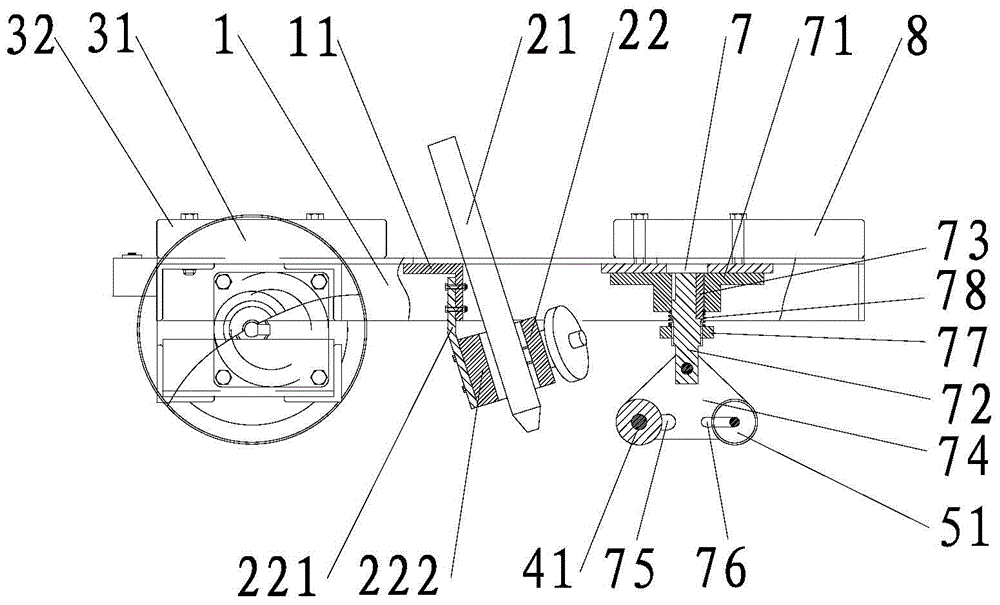

An aluminum alloy thin plate welding equipment

InactiveCN104002025BSimple structureEasy to useWelding/cutting auxillary devicesAuxillary welding devicesControl systemUltimate tensile strength

The invention provides an aluminum alloy thin plate welding method and an aluminum alloy thin plate welding device. The aluminum alloy thin plate welding method and the aluminum alloy thin plate welding device are easy to use and are slightly influenced by welding space. The method includes the steps that high-temperature metal with strength unrecovered after welding is rolled to compensate compression plastic strain generated in the heating process, so that the shrinkage amount of weld joints is reduced, transient stress in the welding process is lowered, and then transient welding deformation is reduced; the metal which is rolled and is still in a cooling shrinkage and stretched state is extruded, under the action of extrusion force, a part of tensile stress is offset, and workpieces are protected against hot cracks. The aluminum alloy thin plate welding device comprises a trolley frame, a TIG welding device, a plate pressing device, a rolling device, an extrusion device and a control system, wherein the TIG welding device, the plate pressing device, the rolling device, the extrusion device and the control system are arranged on the trolley frame; the plate pressing device, the TIG welding device, the rolling device and the extrusion device are sequentially arranged in alignment at predetermined intervals. The aluminum alloy thin plate welding method can be achieved by using the aluminum alloy thin plate welding device.

Owner:HUAQIAO UNIVERSITY

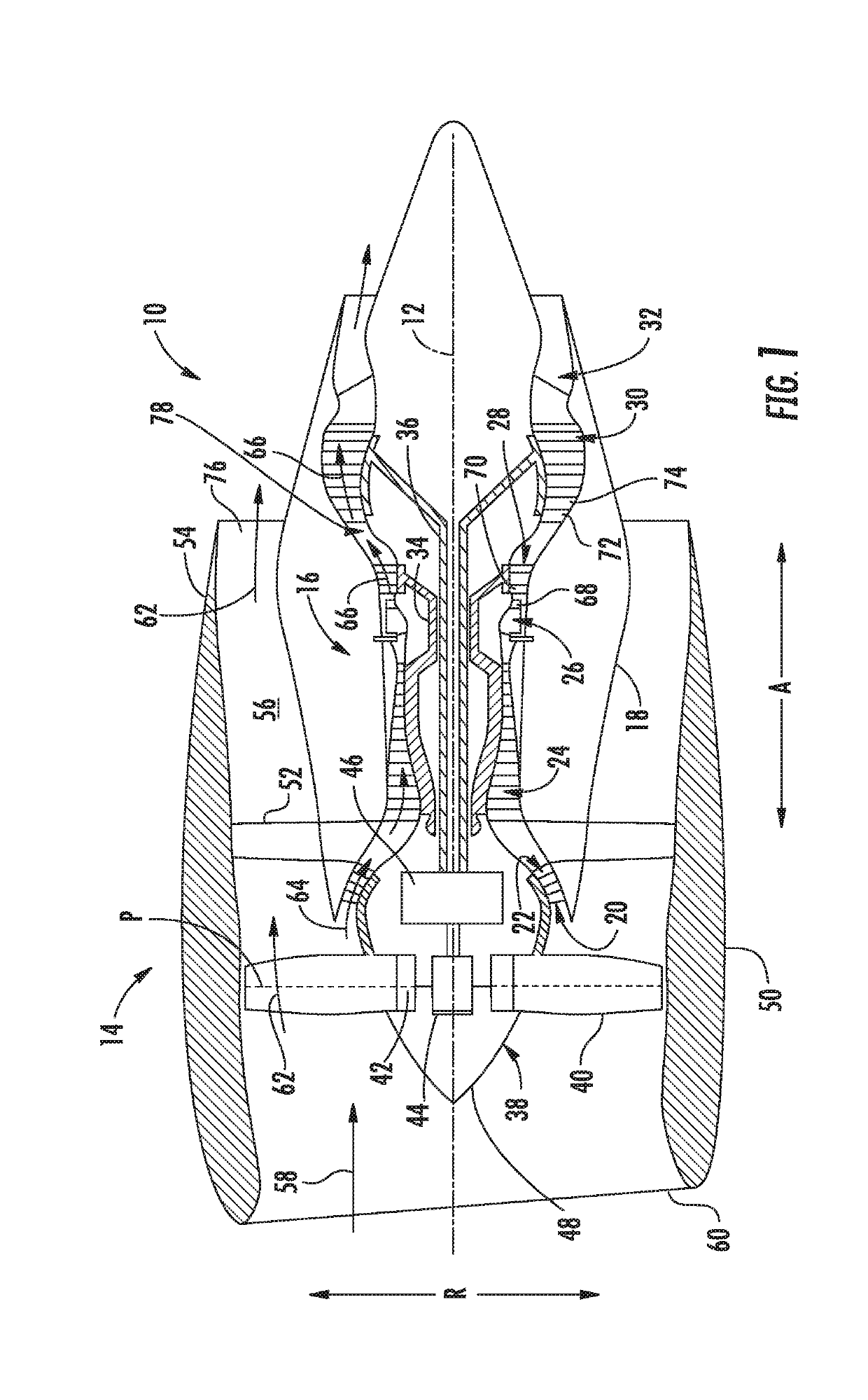

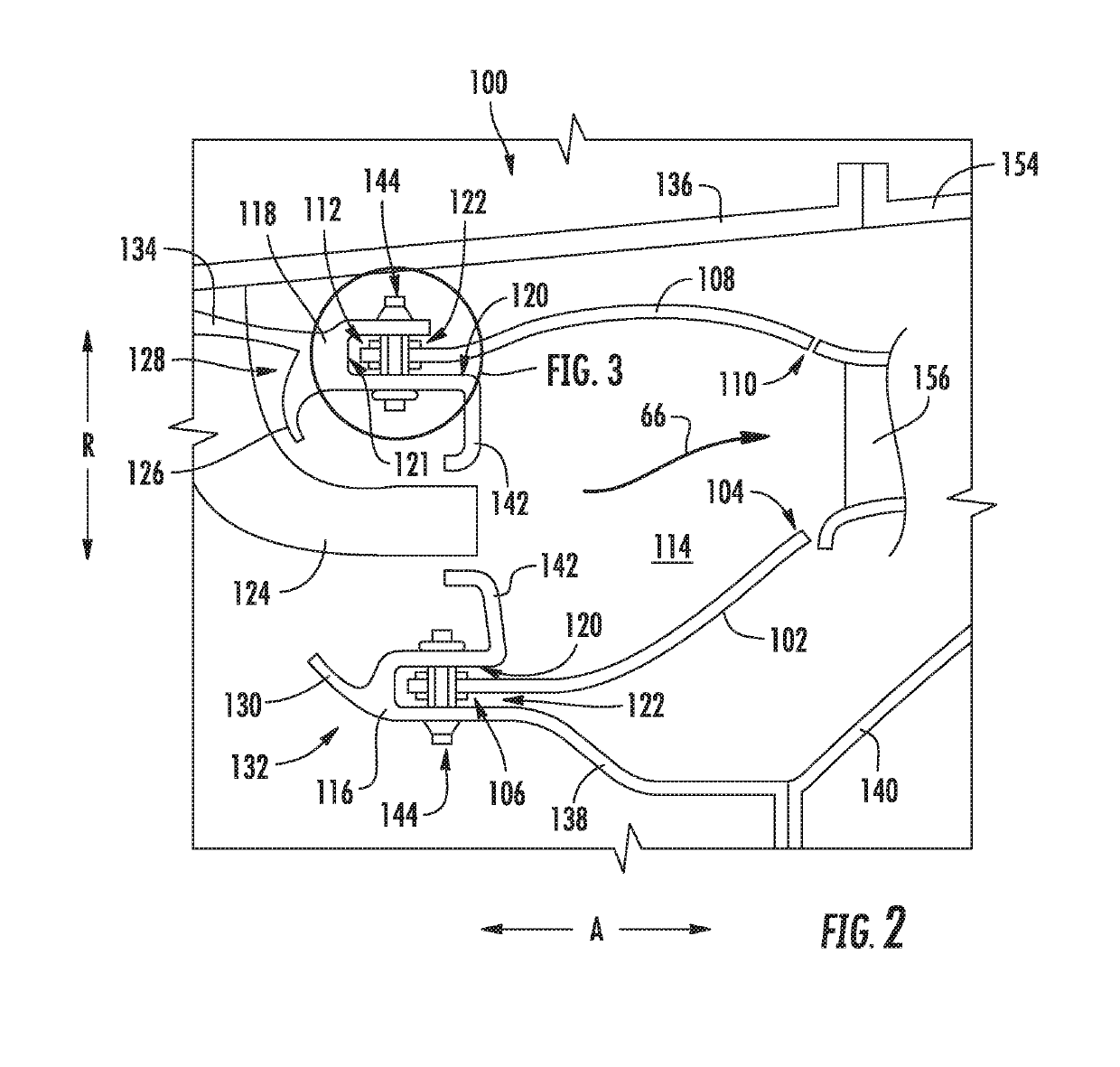

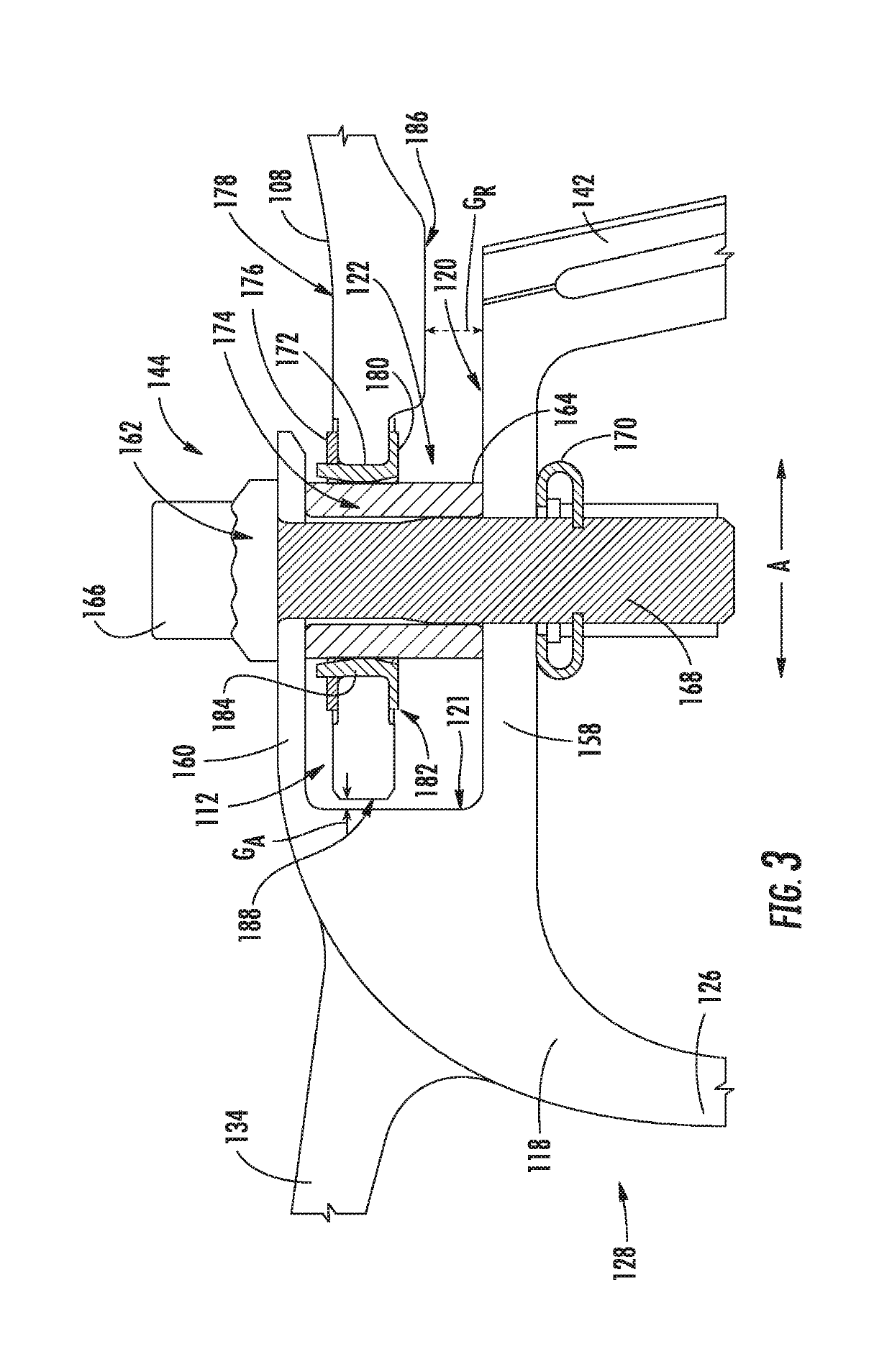

Combustor Assembly for a Turbine Engine

A combustor assembly for a gas turbine engine includes a dome defining a slot. The combustor assembly also includes a liner at least partially defining a combustion chamber and extending between an aft end and a forward end. At least a portion of the forward end is received within the slot of the dome. The forward end of the liner defines a plurality of warming holes that allow for a warming airflow to flow therethrough to warm the forward end at a faster rate during transient operating conditions of the engine thereby reducing transient stresses and increasing liner durability.

Owner:GENERAL ELECTRIC CO

High-temperature fatigue-creep interaction damage assessment method and system and storage medium

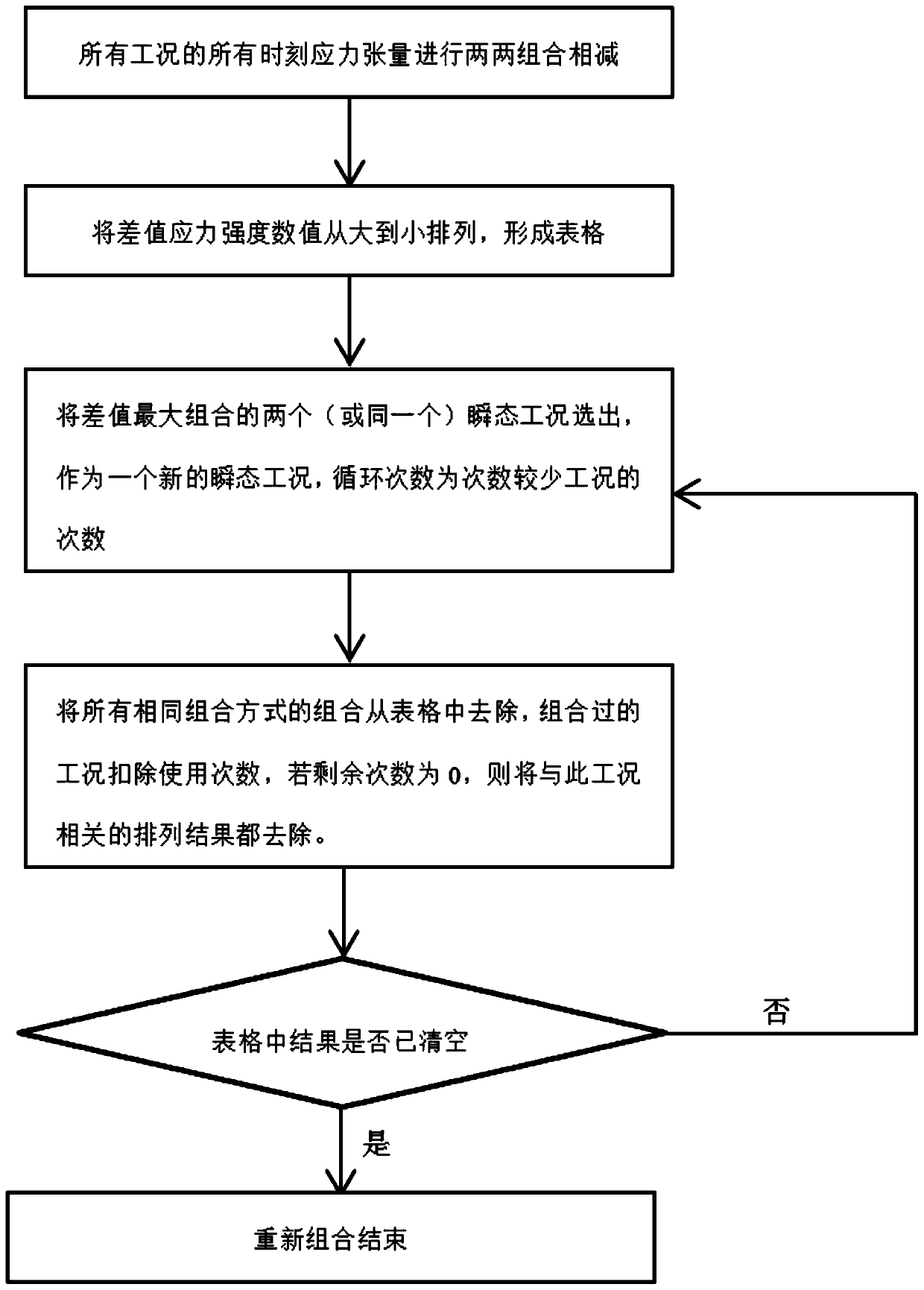

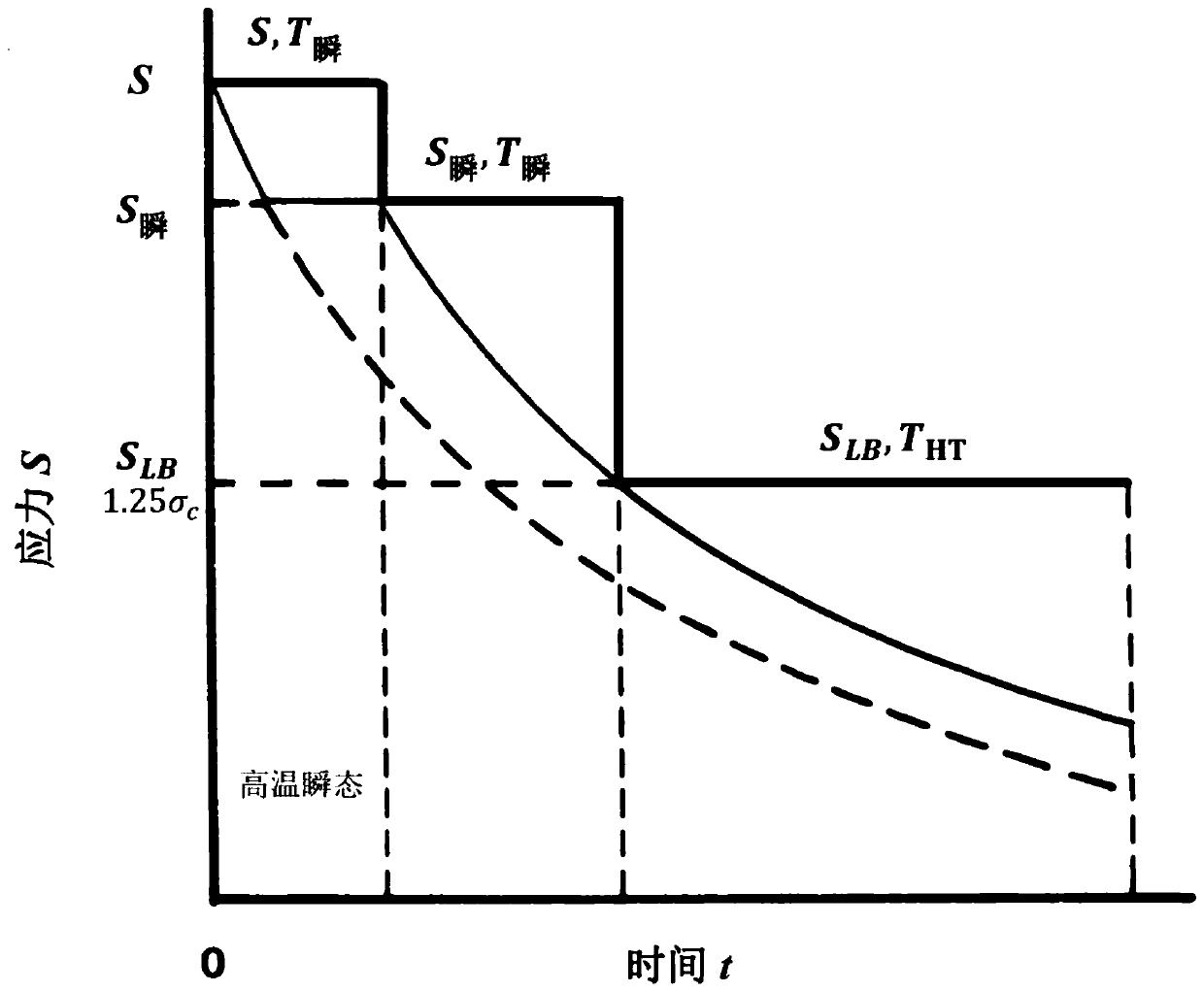

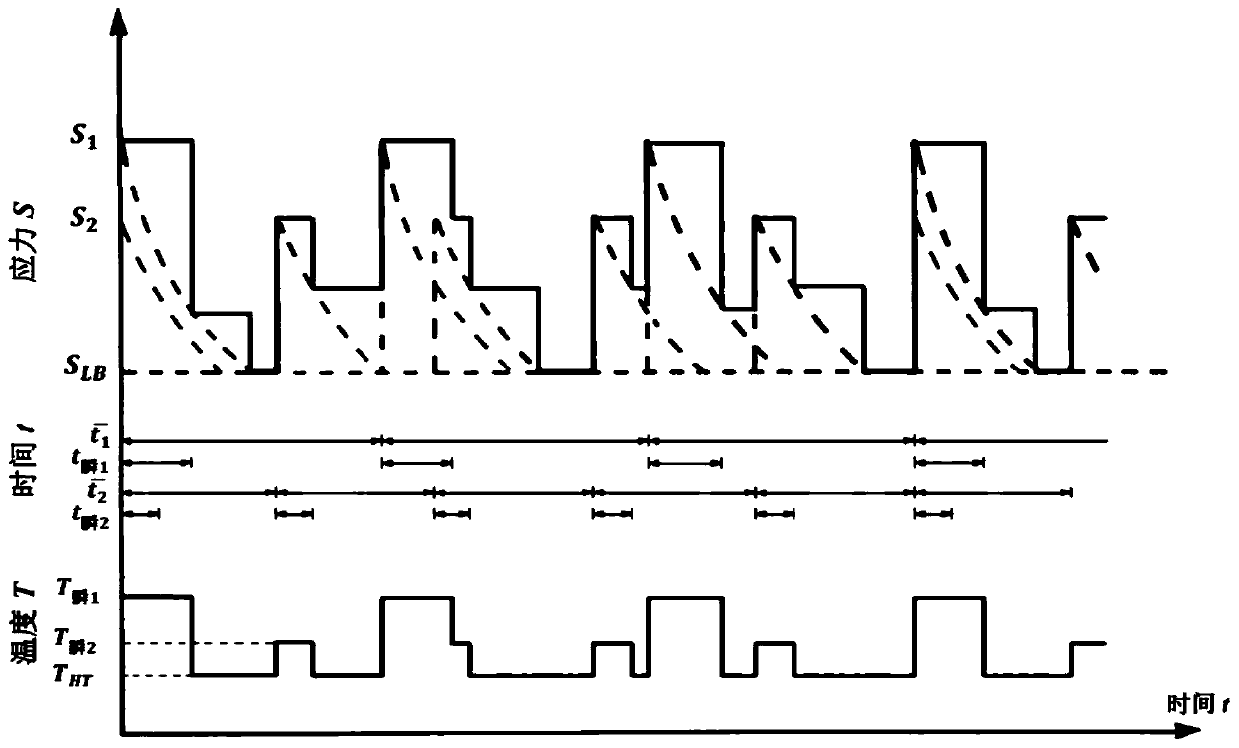

ActiveCN111475972AReduce computational workloadReduce computational difficultyGeometric CADSustainable transportationFatigue damageTransient state

The invention discloses a high-temperature fatigue-creep interaction damage assessment method and system and a storage medium, and the method comprises the steps: obtaining a steady-state stress analysis result and a transient-state stress analysis result of a to-be-assessed structure under multiple working conditions through a finite element analysis method based on linear elasticity; according to the steady state stress analysis result and the transient state stress analysis result, obtaining a deformation and strain analysis result of an evaluation point of the to-be-evaluated structure; according to the deformation and strain analysis result, carrying out fatigue damage calculation on the evaluation point under different working conditions, and obtaining a fatigue accumulated damage factor; obtaining creep damage evaluation results of the evaluation points under transient and steady-state working conditions at high temperature; and obtaining a fatigue-creep interaction damage evaluation result of the evaluation point according to the fatigue accumulation damage factor and the creep damage evaluation result. The method can reduce the calculation workload, the calculation difficulty and the calculation time, is easier to implement, has higher generalizability, and can be widely applied to the technical field of data processing.

Owner:DONGFANG (GUANGZHOU) HEAVY MASCH CO LTD

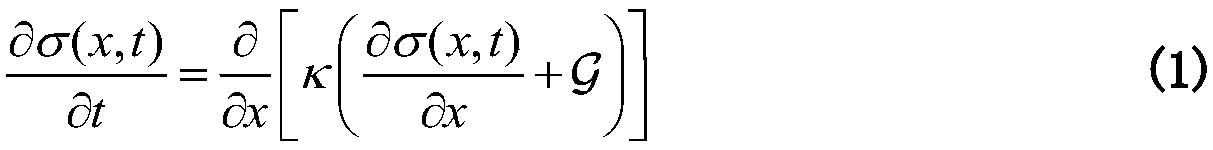

Feature function-based on-chip metal interconnected network electro-migration reliability analysis method

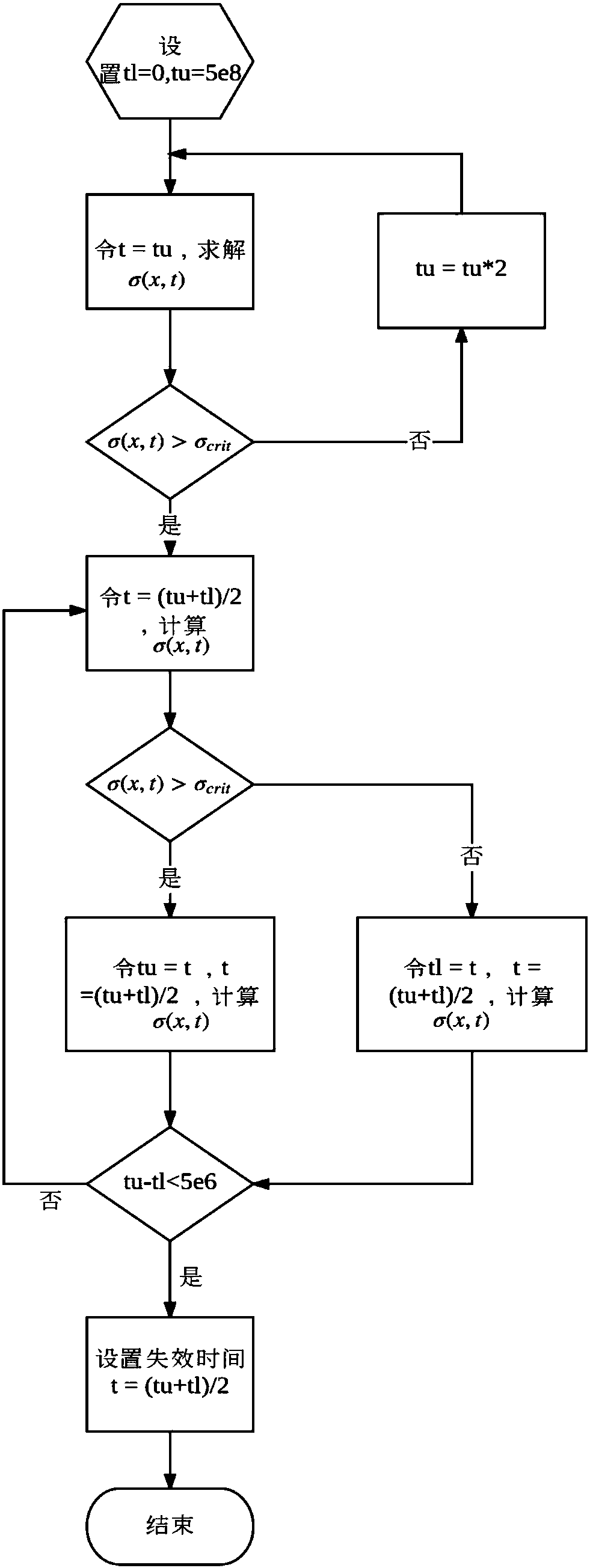

InactiveCN108170923AAccurate solutionEfficient solutionComplex mathematical operationsMetal interconnectAnalysis method

The invention discloses a feature function-based on-chip metal interconnected network electro-migration reliability analysis method. The method comprises the following steps of: dividing interconnected networks in a chip into same-layer metals to form an interconnected tree; extracting parameters on the interconnected tree; taking the interconnected tree as a basic unit of electro-migration; and modeling the electro-migration on the interconnected tree by using a Korhonen equation. According to the method, a feature function-based method is adopted to correctly and efficiently solve the Korhonen equation on the interconnected tree. On the basis of solving a transient stress, a bisection method is adopted to solve an electro-migration failure time.

Owner:BEIJING UNIV OF TECH

A transmission differential impact strength and fatigue analysis method

ActiveCN105488298BDesign optimisation/simulationSpecial data processing applicationsForce methodLoad ratio

The invention discloses an impact strength and fatigue analysis method of a transmission differential. The impact strength and fatigue analysis method comprises three parts including a pretightening force method of a cone bearing along with temperature, a circumferential 20-bisection and impact strength analysis method of the differential and a fatigue life analysis method. Since transient stress generated by actually rotating a differential shell for one circle is difficult through an analogy method, the impact strength and fatigue analysis method uses a method that the engaging position of a main-reduction gearwheel is bisected into 20 parts circumferentially to combine quasi-static analysis results to obtain a transient stress course that the differential shell rotates for one circle, so that the transient stress generated by actually rotating the differential shell for one circle is simulated, each torque level of a finished automobile load spectrum and a corresponding rotation circle number are combined, linear scaling is carried out on a stress analysis result according to a load ratio of load to stress analysis, finally, the fatigue loss of each torque level is finally overlapped, and fatigue endurance life in a differential shell working process, i.e., under the load spectrum, is calculated. The defect that differential shell is subjected to over design or the service life can not meet a practical working condition can be solved.

Owner:GETRAG JIANGXI TRANSMISSION

A special cast steel for preparing large hot forging dies under high temperature and heavy load conditions and its preparation method

Owner:CHONGQING UNIV +3

220 kV transformer winding short-circuit current-applied stress calculation method

The embodiment of the invention discloses a 220 kV transformer winding short-circuit current-applied stress calculation method. The method comprises, before transient stress analysis on a transformer winding is implemented, analyzing the overall stress state of the winding when short-circuit current reaches the peak to concluding the parts of the winding which are under high stress; then under the situation that transient current is applied, partitioning models of the weak parts in a refined mode to obtain time-dependent stress curves of the weak parts. The embodiment of the invention also discloses a 220 kV transformer winding short-circuit current-applied stress calculation device.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

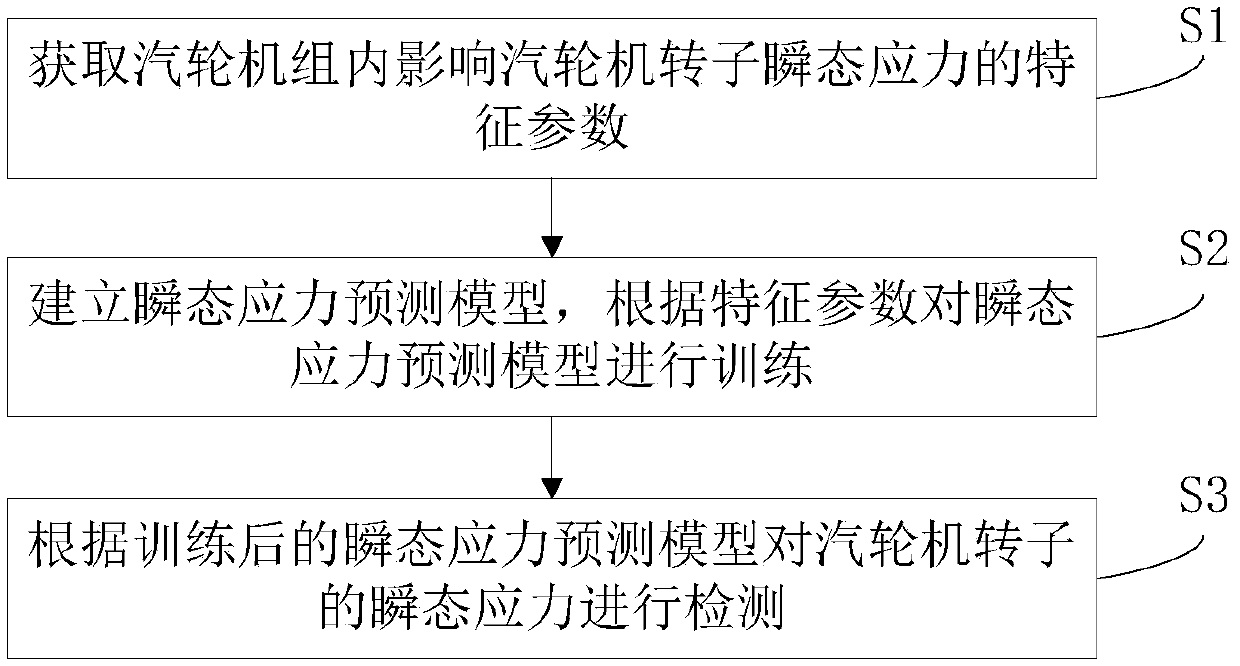

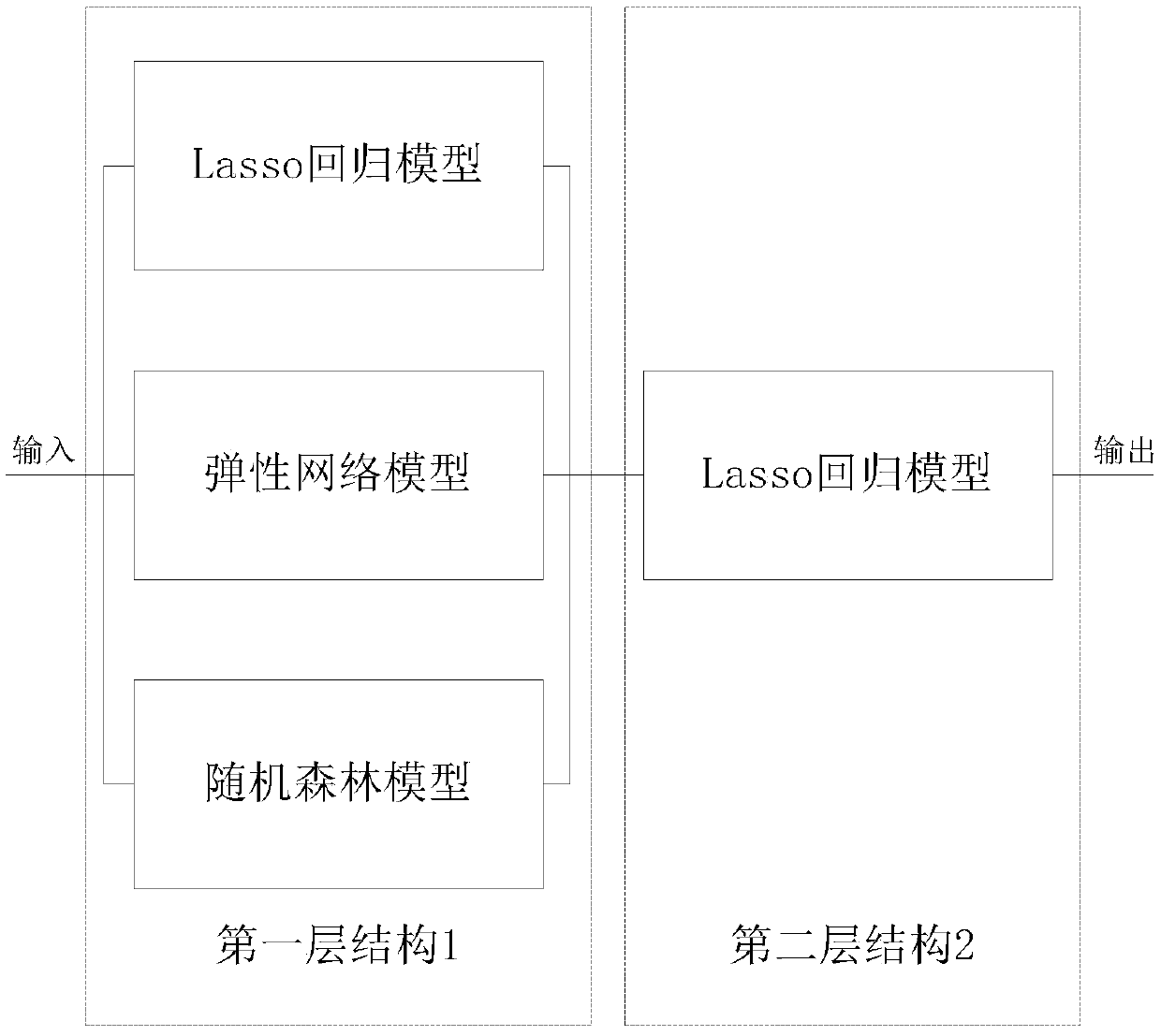

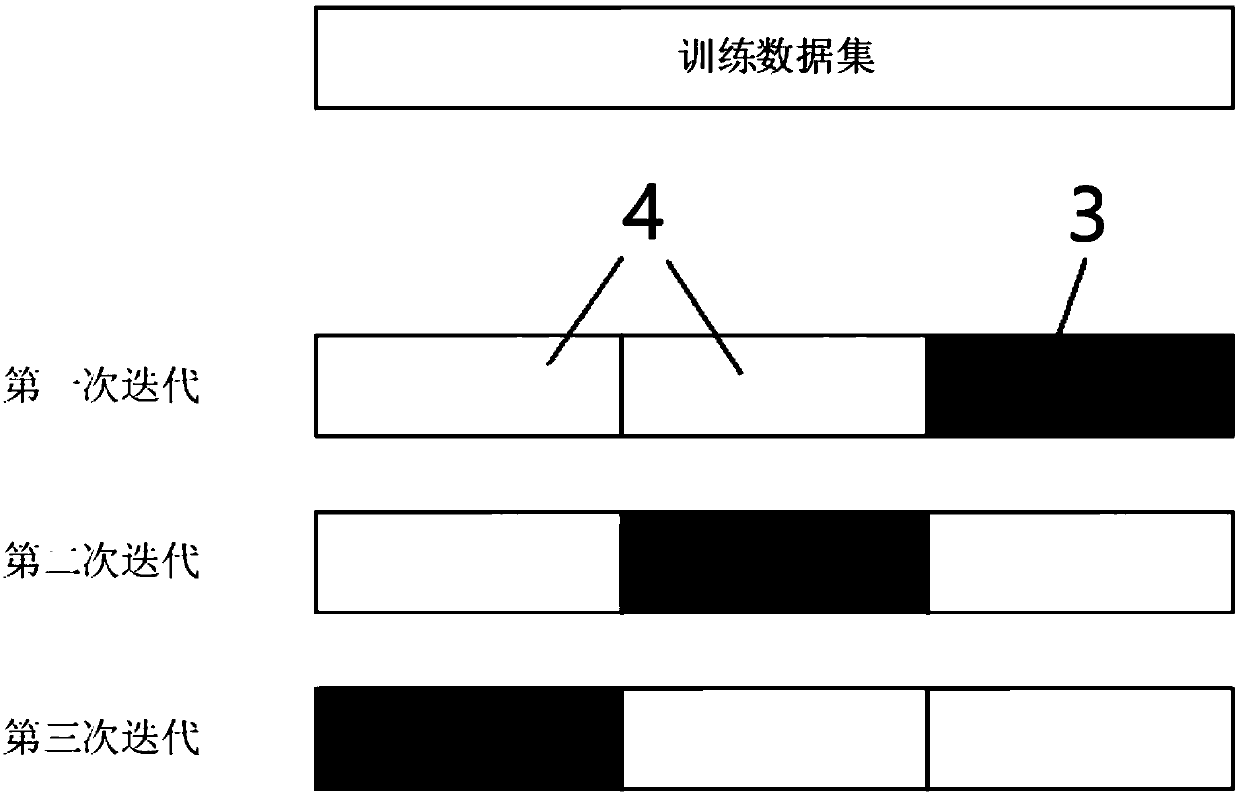

Turbine rotor transient stress detection method

InactiveCN109657285AHigh precisionImprove predictive performanceGeometric CADDesign optimisation/simulationEngineeringMulti parameter

The invention discloses a steam turbine rotor transient stress detection method, and relates to the field of steam turbines. The method comprises the steps of obtaining characteristic parameters influencing turbine rotor transient stress in a turbine set; Establishing a transient stress prediction model; the transient stress prediction model is trained according to the characteristic parameters, the transient stress prediction model comprises a two-layer structure, the first layer structure is composed of n different machine learning models, the outputs of the n machine learning models in thefirst layer structure are connected with the input of the machine learning model in the second layer structure, and n is larger than or equal to 2; And detecting the transient stress of the steam turbine rotor according to the trained transient stress prediction model. According to the detection method provided by the invention, the prediction capability of the transient stress prediction model oncomplex conditions is improved, information between data is fully learned, the precision of rotor transient stress prediction under the multi-parameter complex conditions is improved, and complex modeling is not needed.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

A kind of brittle fracture method of flexible film

InactiveCN105699167BProne to brittle failureEnhanced likelihood of brittle fracturePreparing sample for investigationScanning electron microscopeElectron microscope

The invention relates to the field of scanning electron microscope sample preparation and particularly relates to a flexible film brittle failure method. The flexible film brittle failure method comprises the following steps of: processing a silicon wafer into a long and thin strip, thereby obtaining a pre-carved silicon wafer; bonding the pre-carved silicon wafer and a flexible film; fixing two ends of the silicon wafer with clips, and then feeding the silicon wafer into a cooling liquid so as to fully cool the silicon wafer; rapidly taking out the frozen silicon wafer, bending the frozen silicon wafer towards a side with a slot until the frozen silicon wafer is subjected to brittle failure, thereby obtaining a flexible film subjected to brittle failure. In a process of reducing the flexibility of the film at a low temperature, the method is capable of limiting film movement by virtue of binding of the pre-carved silicon wafer, concentrating transient stress and generating high strain rate, thereby easily obtaining a complete brittle fracture surface and overcoming various problems of obvious plastic deformation, unevenness and the like of the prepared fracture surface.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

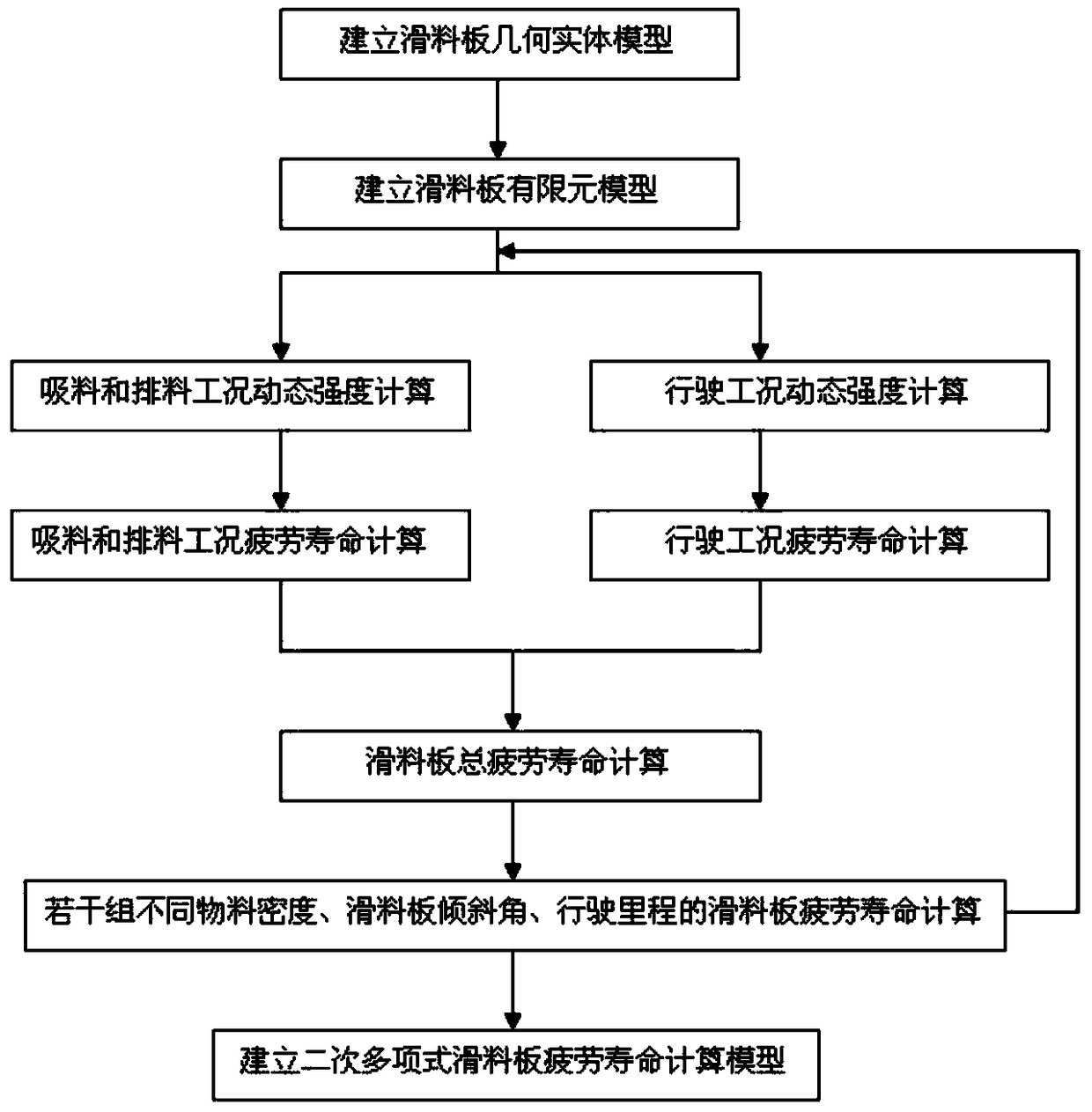

Calculation method for fatigue life of material sliding plate of material suction and discharge vehicle

ActiveCN108549749AImprove computing efficiencyImprove calculation accuracyGeometric CADSustainable transportationPower analysisElement model

The invention discloses a calculation method for fatigue life of a material sliding plate of a material suction and discharge vehicle. The method comprises the steps of performing power analysis on afinite element model to obtain a transient stress of a maximum stress node under the condition of different material densities, tilt angles of the material sliding plate and mileages; then calculatingthe fatigue lives of the material sliding plate under a material suction condition, a material discharge condition and a driving condition, and based on this, performing calculation to obtain the total fatigue life of the material sliding plate; and finally building a quadratic polynomial calculation model of the fatigue life of the material sliding plate under the condition of the different material densities, the different tilt angles of the material sliding plate and the different mileages. Through the calculation method for the fatigue life of the material sliding plate of the material suction and discharge vehicle, the material sliding plate of the material suction and discharge vehicle can be subjected to fatigue life calculation, so that the analysis time is shortened, the calculation efficiency and precision are high, and an engineering basis is provided for material selection of the material sliding plate.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

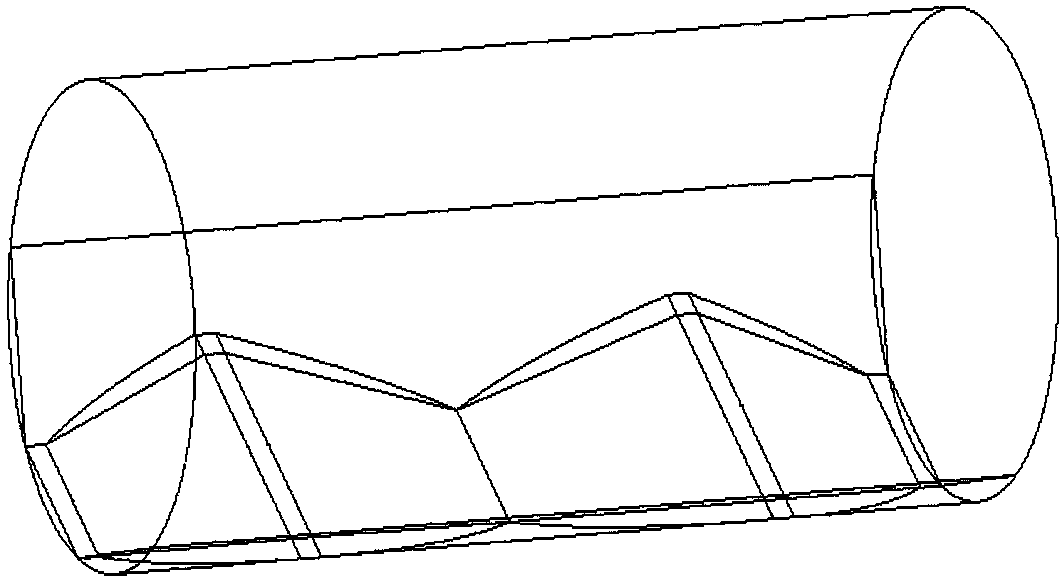

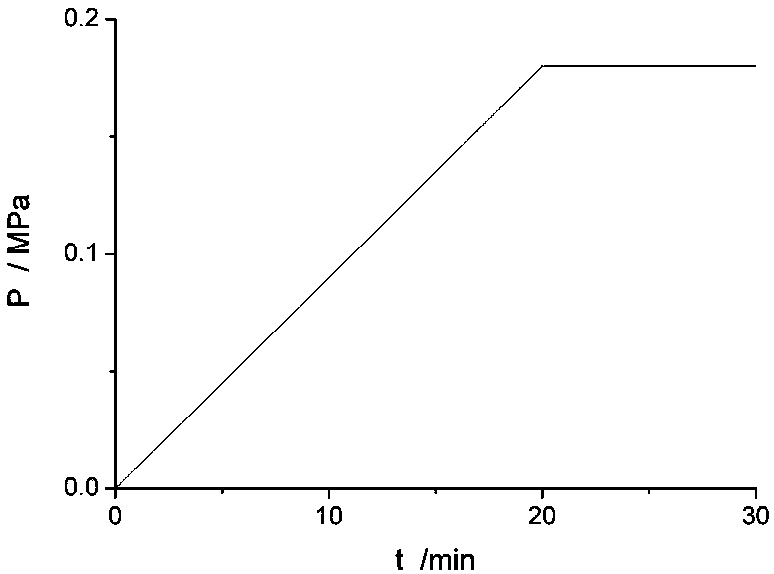

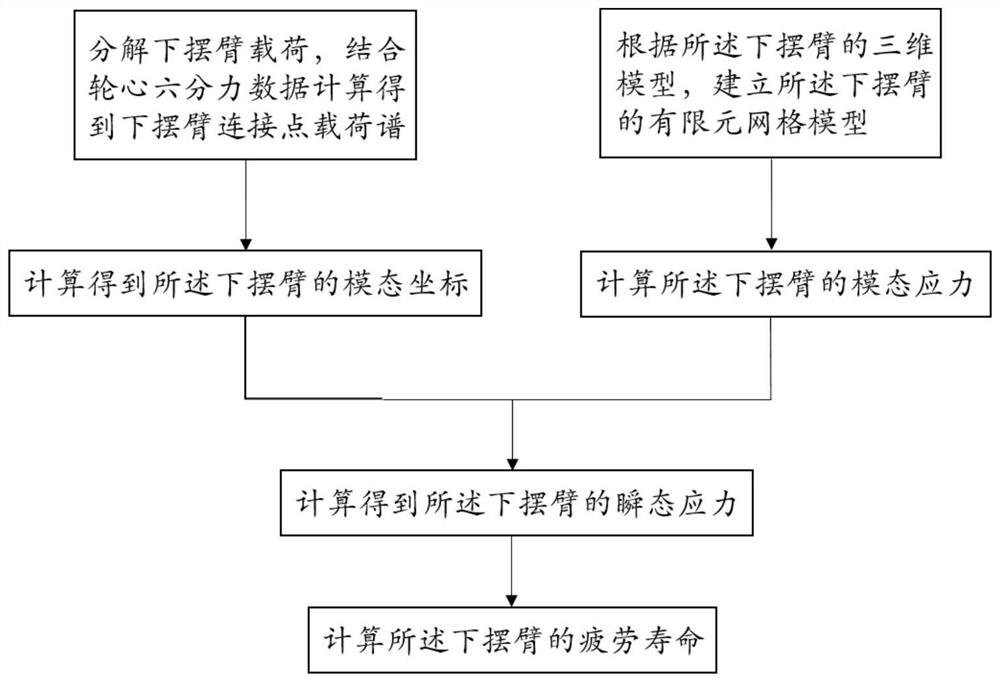

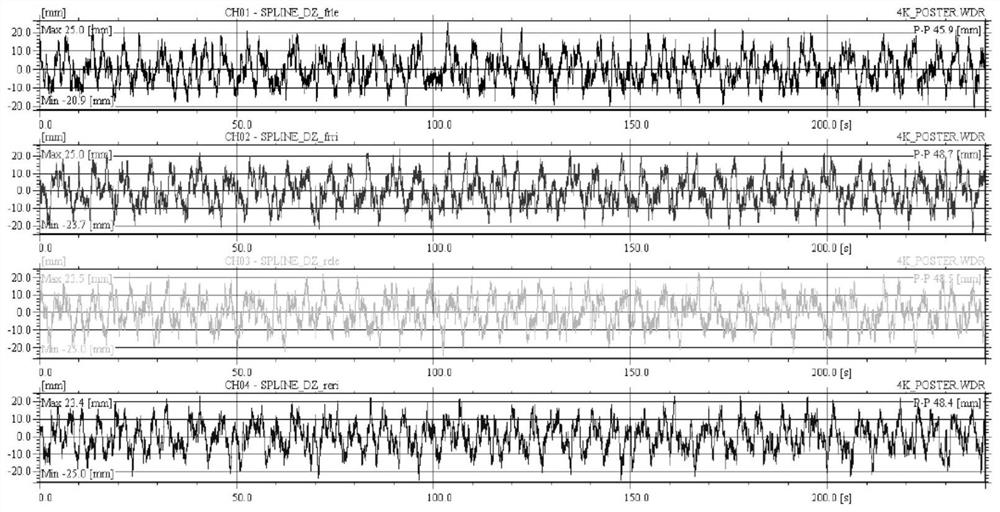

Passenger car lower swing arm transient fatigue analysis method and device

PendingCN113221427AAvoid calculation flawsReduce gapGeometric CADDesign optimisation/simulationCar passengerControl theory

The invention relates to a passenger car lower swing arm transient fatigue analysis method and device, and relates to the technical field of fatigue calculation. The passenger car lower swing arm transient fatigue analysis method comprises the steps of firstly decomposing a lower swing arm load, calculating and obtaining a lower swing arm connection point load spectrum in combination with wheel center six-component data, then calculating and obtaining modal coordinates of the lower swing arm by using the lower swing arm connection point load spectrum, establishing a finite element mesh model of the lower swing arm according to a three-dimensional model of the lower swing arm, calculating the modal stress of the lower swing arm; utilizing the modal stress and the modal coordinates to calculate the transient stress of the lower swing arm, and finally calculating the fatigue life of the lower swing arm based on the transient stress. According to the passenger car lower swing arm transient fatigue analysis method and device, the modal coordinates of the lower swing arm are obtained through transient response analysis, then the transient stress is obtained by combining the modal stress, then the fatigue life of the lower swing arm is obtained through calculation, the calculation defect of a traditional unit load method is avoided, and the calculation result is more accurate.

Owner:DONGFENG MOTOR GRP

A Method of Calculating the Transient Stress of E-type Surge Arrester

ActiveCN103473387BImprove control protection logicIn line with actual operating conditionsSpecial data processing applicationsHigh-voltage direct currentPower equipment

The invention discloses a method for calculating the transient stress of an E type lightning arrester. The method comprises the following steps of (1) determining a protection logic; (2) establishing a high-voltage direct current electromagnetic transient simulation model, and modeling the protection logic; (3) executing EMTDC (electromagnetic transients including DC) electromagnetic transient simulation, observing a measurement signal curve, and verifying whether a grounding electrode open circuit protection action logic meets a requirement or not; (4) recording the maximum energy of the E type lightning arrester under a grounding electrode open circuit failure. According to the method, the shortcoming of excessive idealization of a control protection logic of a conventional calculation model is overcome, and a measurement signal triggering-based control protection logic is adopted, namely sampling filtering and judging links for measuring voltage and current are added as protection triggering bases; in an exit phase shifting protection process, a slope link is added, and a triggering angle is phase-shifted at speed of 4 degrees per millisecond; the control protection logic for the simulation model is improved to be more consistent with an actual running condition; when the method is used for selecting an energy parameter of the E type lightning arrester, higher safety is ensured, and power equipment on a neutral generatrix can be effectively protected.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

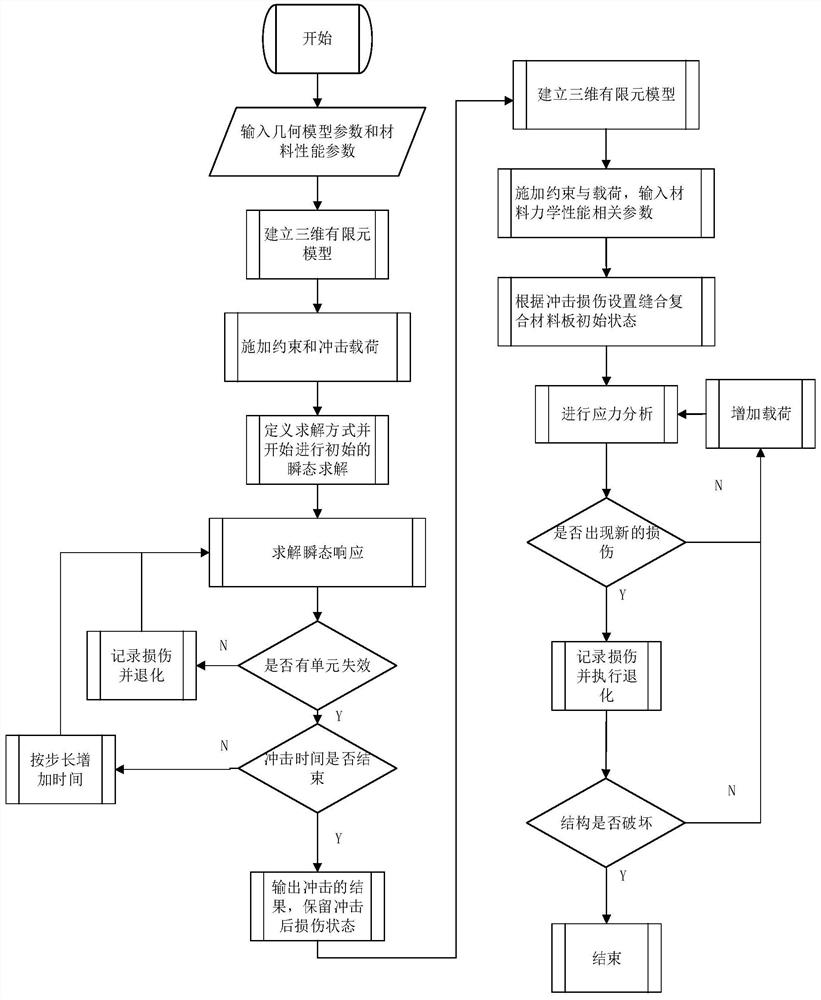

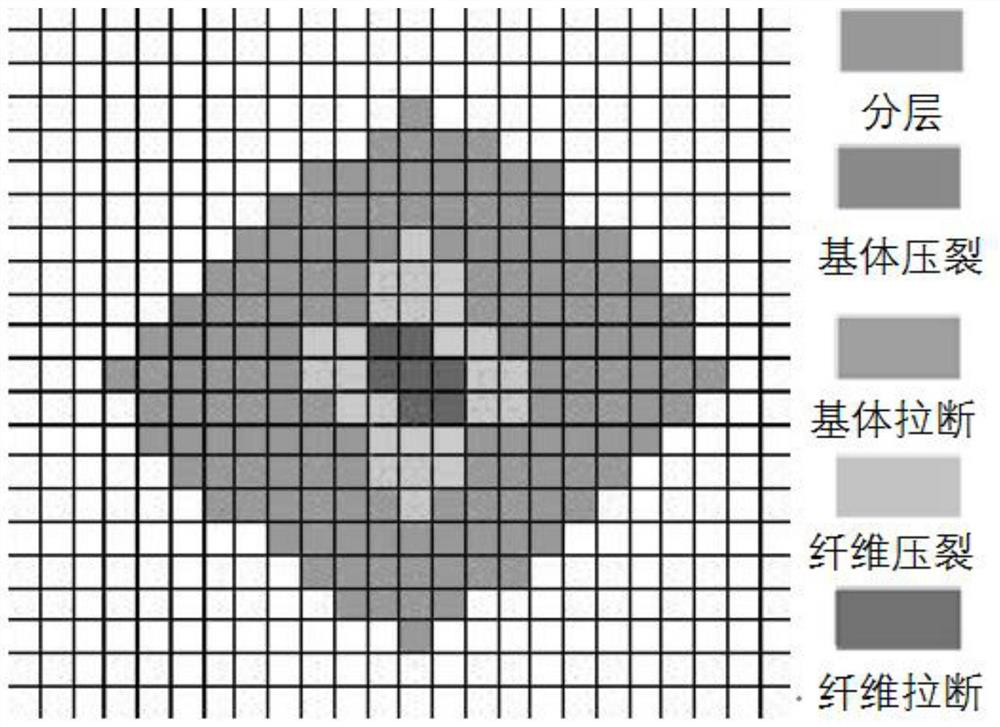

Whole-process analysis method of impact damage and residual strength of seamed composites

ActiveCN108427826BImprove fluencyStrong expandabilityDesign optimisation/simulationSpecial data processing applicationsResidual strengthUltimate tensile strength

The invention discloses a whole-process analysis method for impact damage and residual strength of a stitched composite material, comprising the following steps: (1) transient stress analysis of the stitched composite material under impact load; (2) determination of the impact damage criterion of the stitched composite material (3) Determination of mechanical properties degradation method of sutured composite material impact damage; (4) Static analysis of sutured composite material; (5) Determination of residual strength damage criterion of sutured composite material; (6) Determining the material of sutured composite material Performance degradation method; (7) Determination of structural failure criteria for stitched composites. The invention provides a comprehensive analysis method for impact damage and residual strength after impact, which not only considers the actual damage type and damage degree of the composite material structure after impact, but also does not need to observe impact damage to improve the residual strength. Therefore, the method of the present invention has high coherence, good expansibility, high prediction accuracy, and has considerable engineering application prospects.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Calculation method of force on 220kv transformer winding under short-circuit power

ActiveCN107273614BComputer aided designSpecial data processing applicationsControl theoryMechanical engineering

The embodiment of the invention discloses a 220 kV transformer winding short-circuit current-applied stress calculation method. The method comprises, before transient stress analysis on a transformer winding is implemented, analyzing the overall stress state of the winding when short-circuit current reaches the peak to concluding the parts of the winding which are under high stress; then under the situation that transient current is applied, partitioning models of the weak parts in a refined mode to obtain time-dependent stress curves of the weak parts. The embodiment of the invention also discloses a 220 kV transformer winding short-circuit current-applied stress calculation device.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

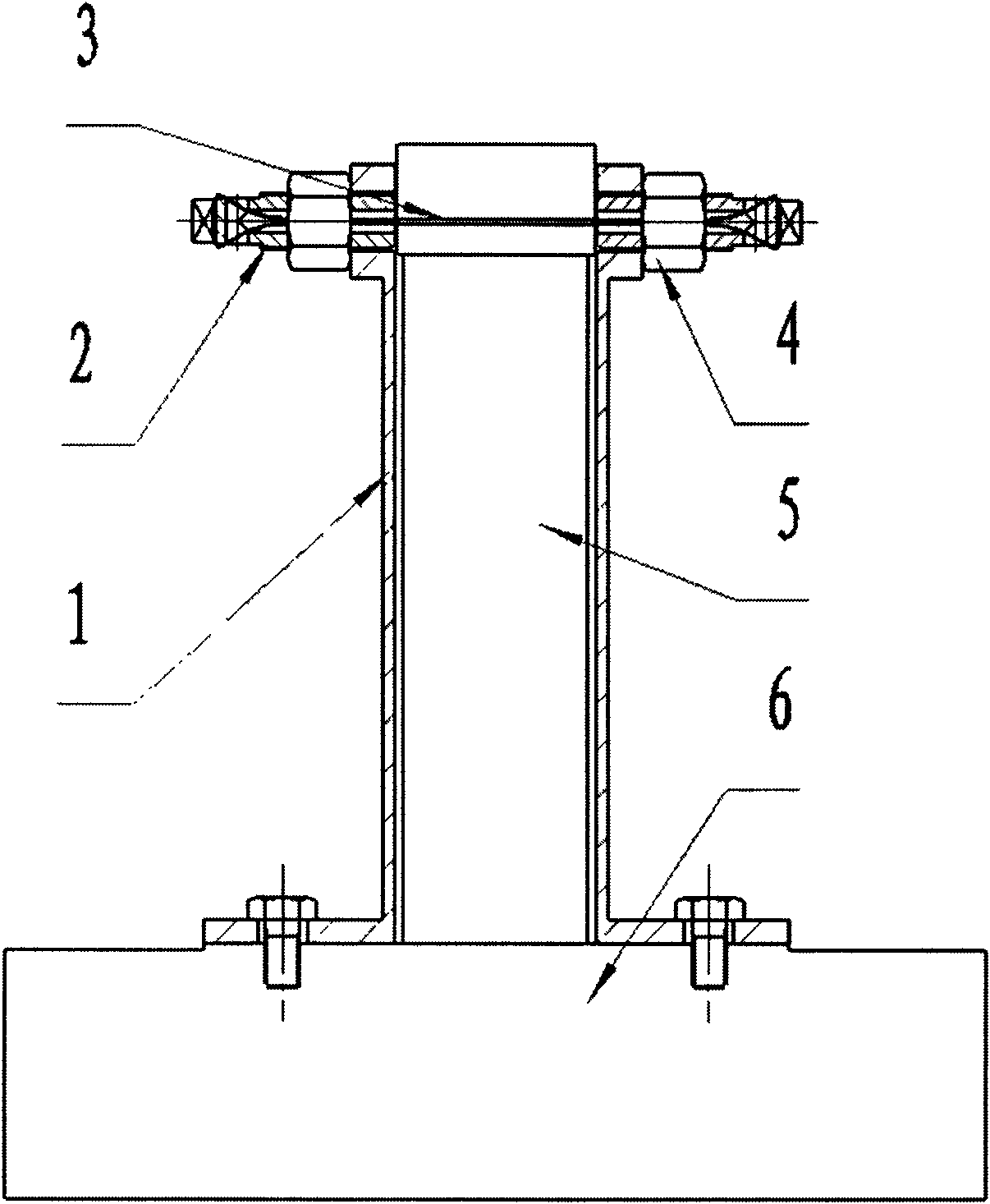

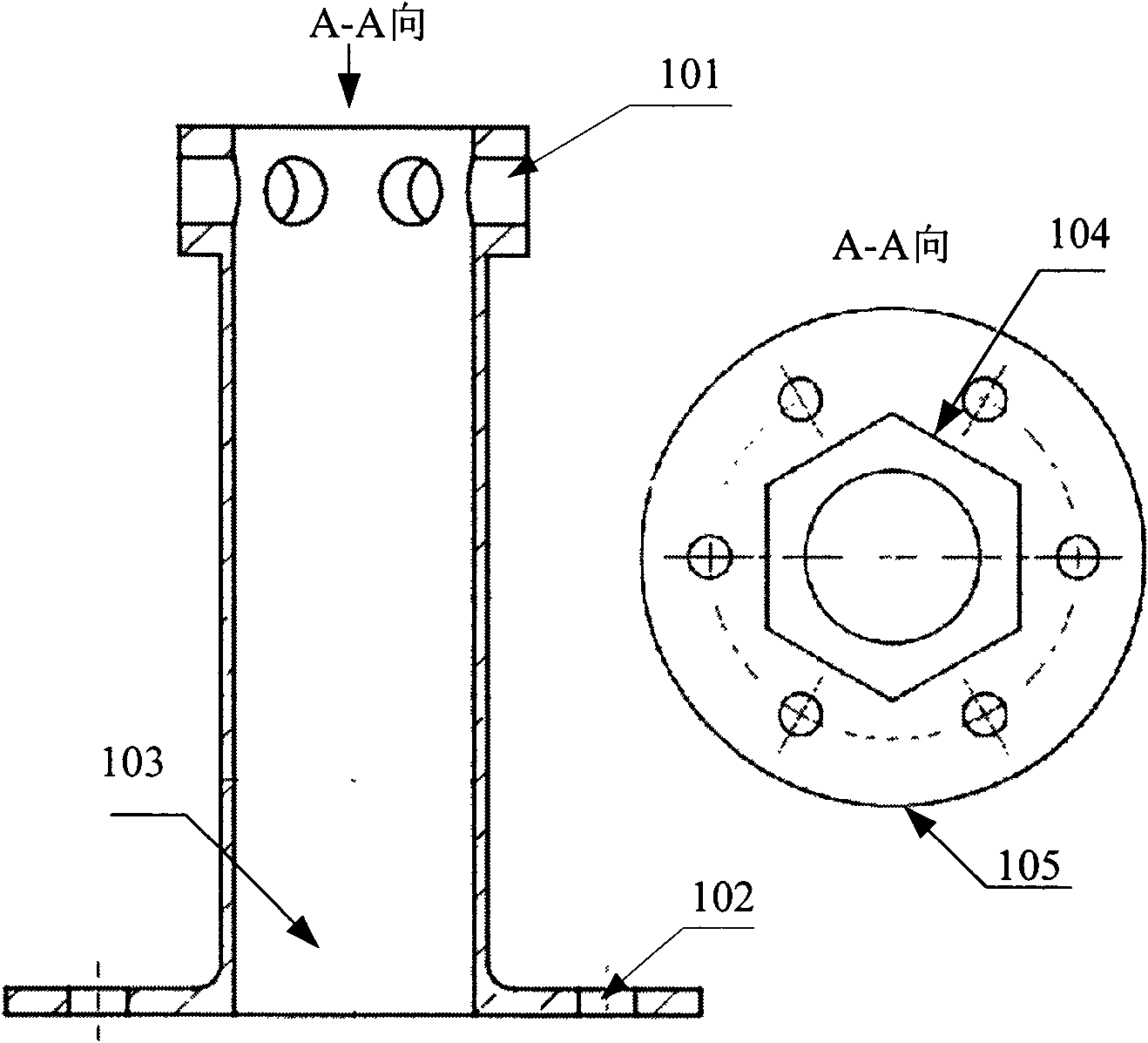

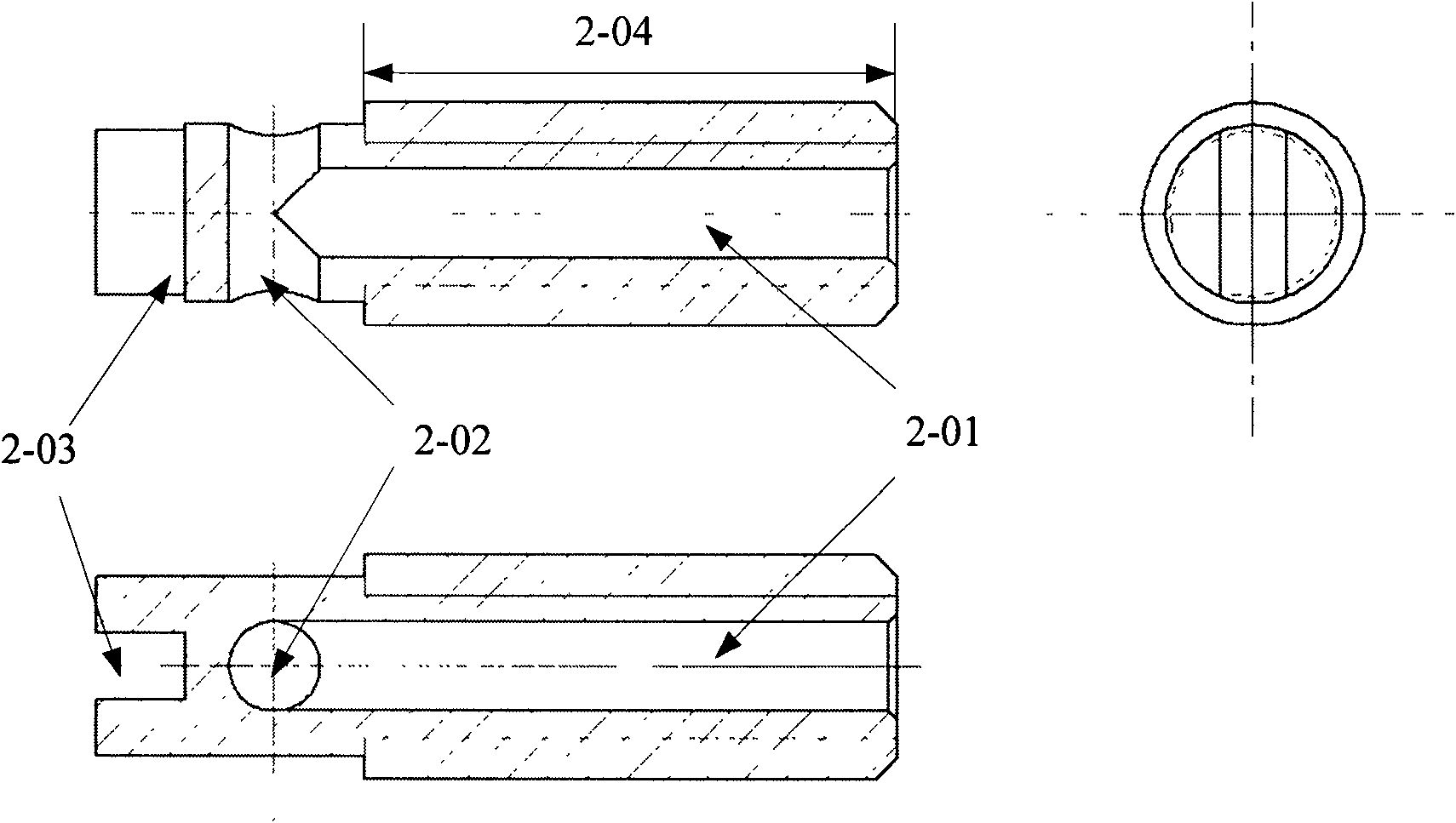

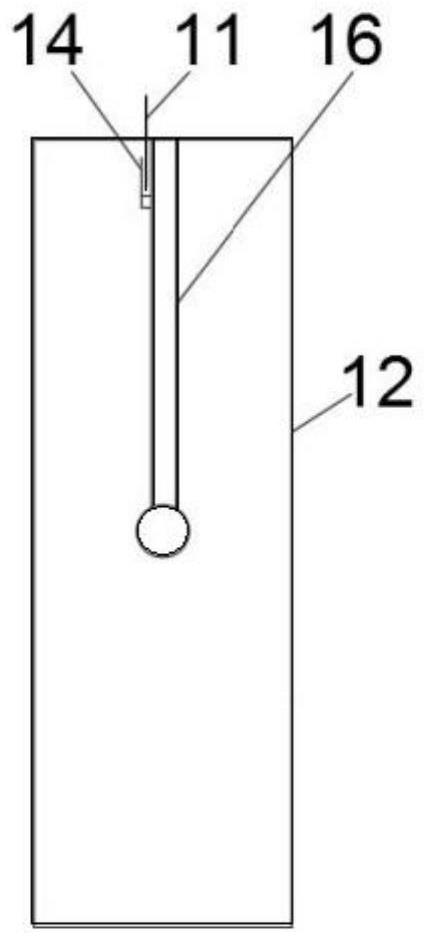

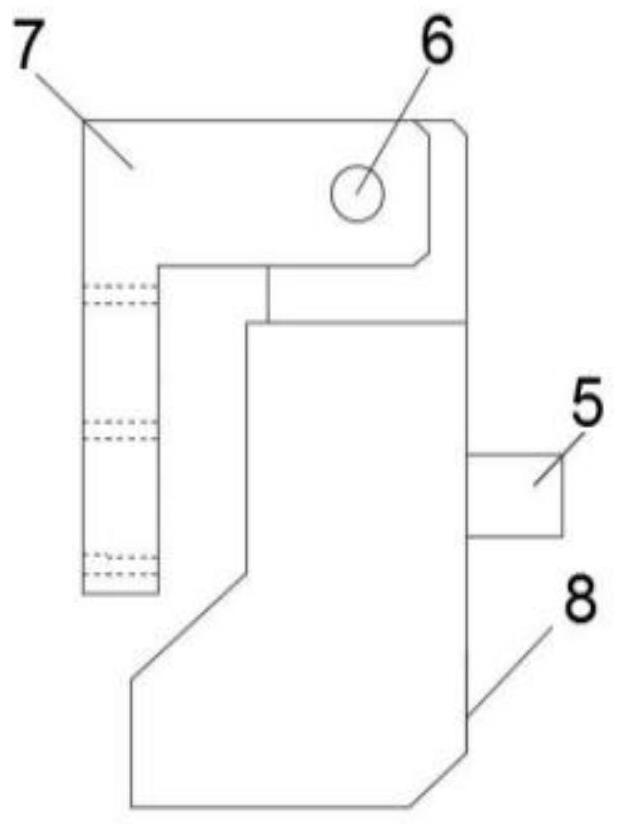

Flexible non-collision cold-finger limiting protecting device

ActiveCN101975649ANo transient stress impulsesImprove energy consumptionVibration testingFiberEngineering

The invention discloses a flexible non-collision cold-finger limiting protecting device which comprises an I-shaped outer support, six fiber joints, six pretightening nuts and three Kevlar fibers and is mainly characterized in that a flange at the top end of the outer support is orthohexagonal, and a through hole is respectively drilled at the centers of side walls of the outer support. A round flange is arranged at the bottom of the outer support, and six fixed holes are arranged on the circumference of the outer support. Each fiber is oppositely folded into double strands, and both ends are connected through the fiber joints to form a closed curve. Thus, when the three groups of fiber joints are respectively and symmetrically installed in the through holes on the lateral walls of the symmetrical surfaces of the flange at the top end of the outer support, six fiber nets which are staggered and radially arranged are formed at the center of the outer support, and the head of a cold finger is hooped in an enveloping area surrounded by the centers of the fibers. The pretightening nuts are in external threaded fit with the fiber joints, support against the lateral walls of the flange from the outer side and are used for providing the initial pretightening force of the fibers to bind the cold finger. The whole device is fastened on a testing soleplate or a base through the flange at the bottom of the outer support. The invention has the largest advantages that the transient stress impulse generated by collision to the cold finger can not appear in vibration testing, and the damage caused by position limitation to the cold finger is markedly decreased; and the contact area of the fibers and the cold finger is large, and the local stress of a limiting point is reduced.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

A Self-Driven Transient Stress Sensing Device

ActiveCN104868778BSelf-drivingImprove signal response strengthForce measurementFriction generatorsContact layerSelf driven

The present invention utilizes the characteristics of the electret material to form an efficient contact-separation triboelectric nanogenerator between the stress application object and the contact layer of the sensing device, and cleverly combines it with a light-emitting diode to construct a self-driven Visualized stress sensing device. Each light-emitting diode corresponds to a triboelectric nanogenerator unit. When external stress is applied to the contact layer of the sensor, the corresponding output signal generated drives the corresponding diode to emit light. The luminous intensity of the diode increases as the applied stress increases. The magnitude of the stress can be determined by analyzing the luminous intensity of the diode, thereby realizing the visualization of stress sensing. The stress visualization device of the present invention has the characteristics of self-driven output, can realize the analysis of external stress without external power supply, and can be used to detect the spatial distribution of pressure.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

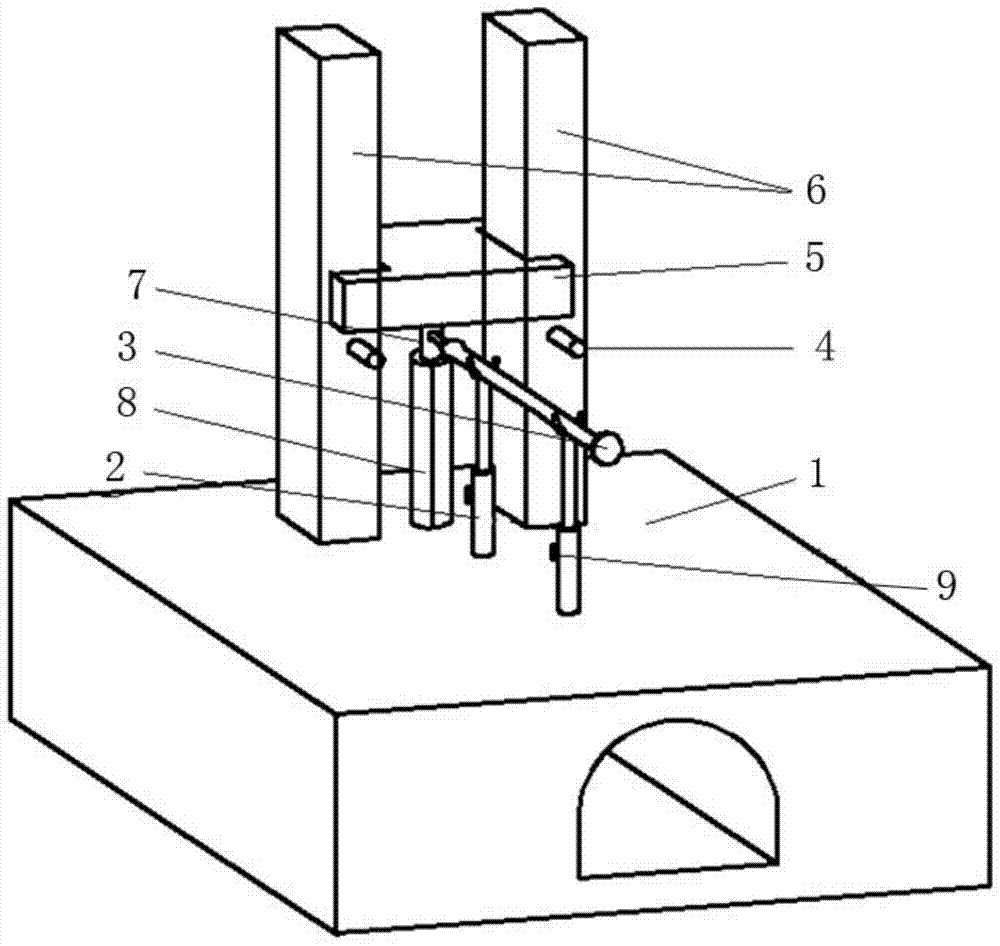

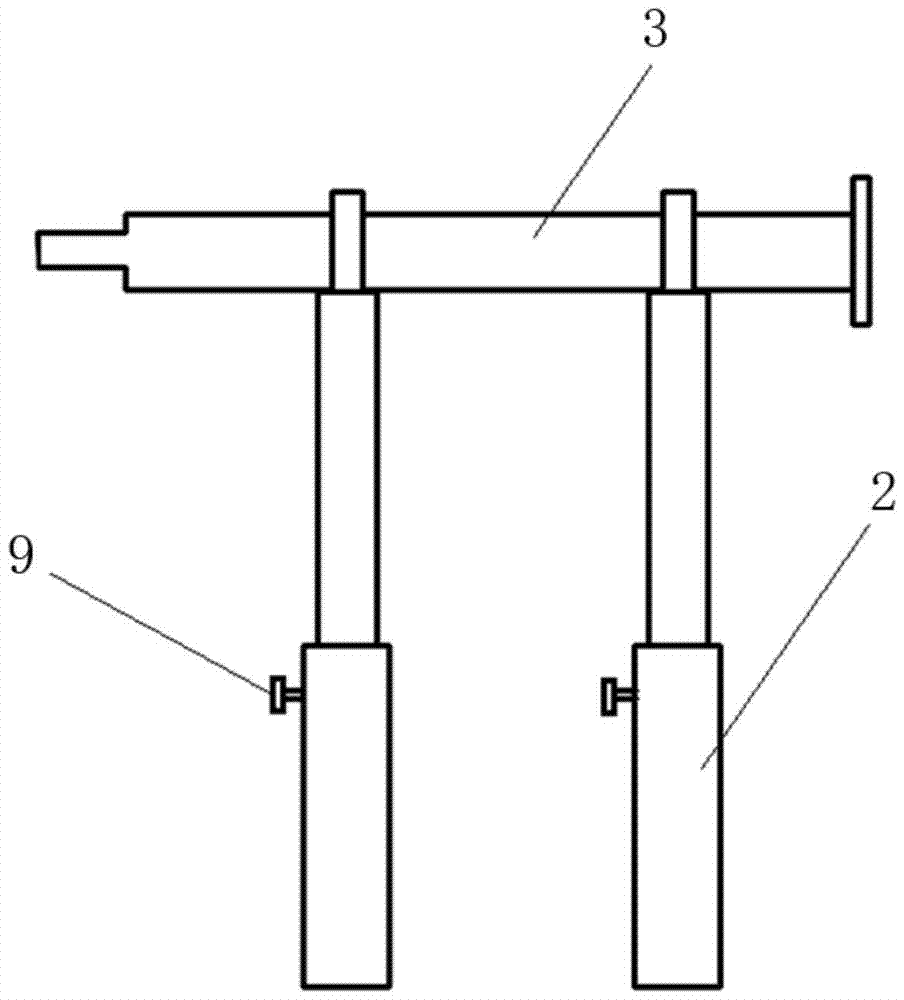

A device for imposing transient decompression stress waves in a large-scale similar experimental system

ActiveCN105259056BSolve the problem of low unloading rateSimple structureStrength propertiesDrop weightEngineering

The invention discloses a device for imposing transient pressure relief stress waves in a large-scale similar experiment system, which includes a test bench and a drop weight. Two guide columns parallel to each other are arranged on the top of the test bench, and the drop weight can move along the two guide columns. Sliding up and down, the first pressure-bearing column and the second pressure-bearing column are set between the two guide columns, the second pressure-bearing column is placed on the top of the first pressure-bearing column, and the initial position of the drop hammer is located at the first and second bearing columns. After the pressure columns are stacked, on the top of the second pressure-bearing column, the two guide columns are provided with a plurality of limit blocks for preventing the falling weight from sliding down. The height of each limit block is the same, and each limit block The distance from the top surface of the block to the bottom end surface of the drop hammer is smaller than the distance from the top surface of the first pressure-bearing column to the bottom end surface of the drop hammer. The invention can simulate the transient decompression stress wave produced in the excavation process of large-scale subsea tunnels, deep mine roadways and other projects, and solves the problem that the existing tests still remain at a low decompression load rate.

Owner:SHANDONG UNIV OF SCI & TECH

Blasting vibration simulation impact device for shear rheological test

PendingCN114324015AIncrease risk resistanceImprove test accuracyFlow propertiesMaterial strength using single impulsive forceData acquisitionBlasting vibration

The invention relates to a blasting vibration simulation impact device for a shear rheological test. The blasting vibration simulation impact device comprises an impact load generation mechanism, a transmission mechanism, a strain recording mechanism and a receiving mechanism. The impact load generating mechanism is provided with an angle dial, a pointer, a steel frame, a coil, a current controller and a pendulum bob; the transmission mechanism is provided with an incident rod, a sleeve and a combined plate; the strain recording mechanism is provided with a resistance strain gauge, a super-dynamic strain gauge and a data acquisition instrument which are connected through wires; the receiving mechanism is provided with an upper shear box, a lower shear box, a normal static load electric cylinder and a horizontal static load electric cylinder. The device is simple in structure and convenient to operate, the pendulum bob can be controlled by the current controller to generate impact load, or the pendulum bob is manually lifted to generate the impact load, so that the impact load is simply and safely generated, the impact load is applied to the upper shear box, and transient stress and high-frequency strain of a sample under the action of the impact load are recorded; and actual working conditions can be simulated more truly, so that the impact of blasting vibration simulation is more real and reasonable.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com