Impact strength and fatigue analysis method of transmission differential

A technology of impact strength and fatigue analysis, applied in instruments, special data processing applications, electrical digital data processing, etc., can solve the problem that the life of the differential housing cannot meet the actual working conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Now in conjunction with accompanying drawing, the present invention will be further described:

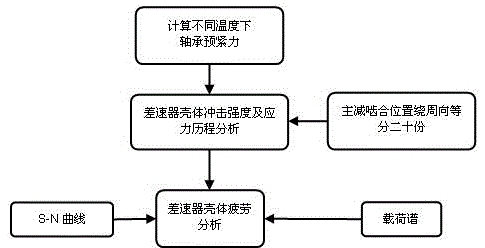

[0010] A transmission differential impact strength and fatigue analysis method, the specific implementation method is divided into three parts, respectively, the preload method of the tapered bearing with temperature, differential circumferential 20 equal parts and impact strength analysis method and fatigue life analysis method.

[0011] The first part, the preload method of tapered bearing with temperature. Due to the inconsistency of the materials of the differential case, the tapered bearing and the transmission case, their thermal expansion coefficients are different, resulting in the change of the preload of the tapered bearing with the change of temperature. The invention establishes the finite element model of the relevant parts such as the cone bearing, the differential case and the transmission case, and sets "contact" for the assembly relationship to ensure the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com