Impact test device and method used for rock or concrete test sample

A technology for concrete specimens and impact tests, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as the inability to study the impact characteristics of secondary ejection characteristics, the inability to accurately control the impact velocity, etc., to achieve simple and convenient assembly, Reduced hazards, highly reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

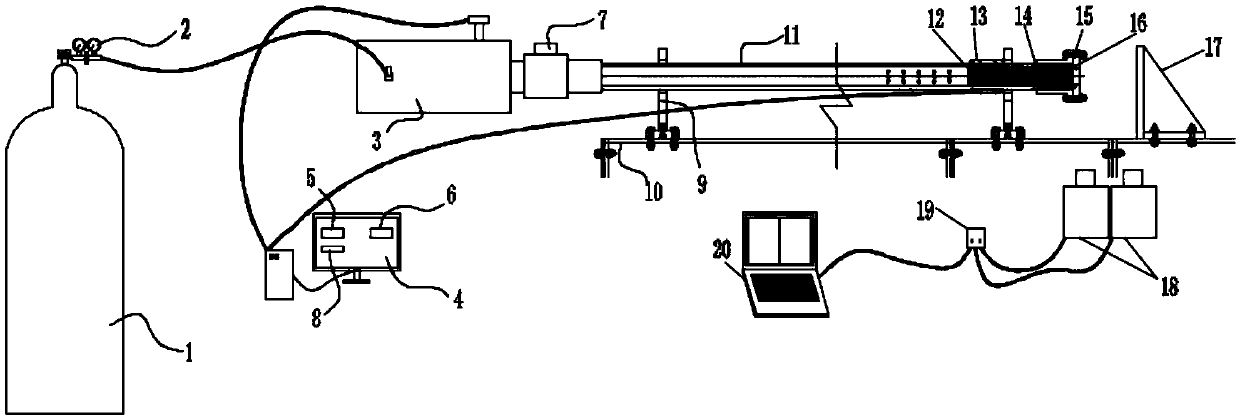

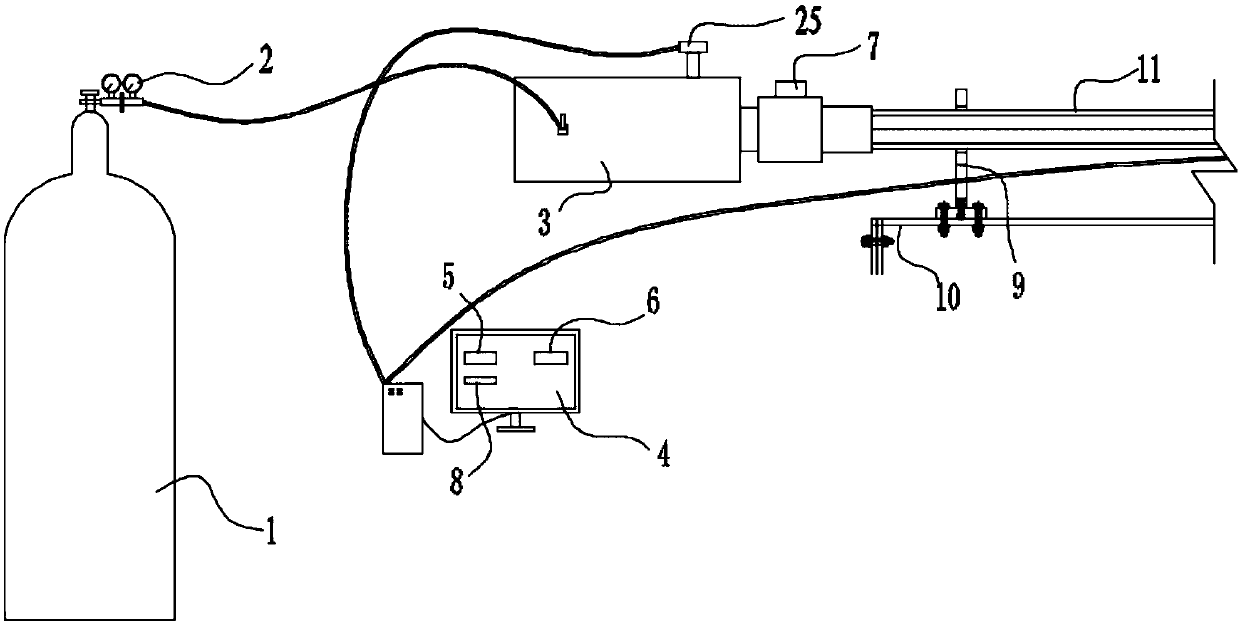

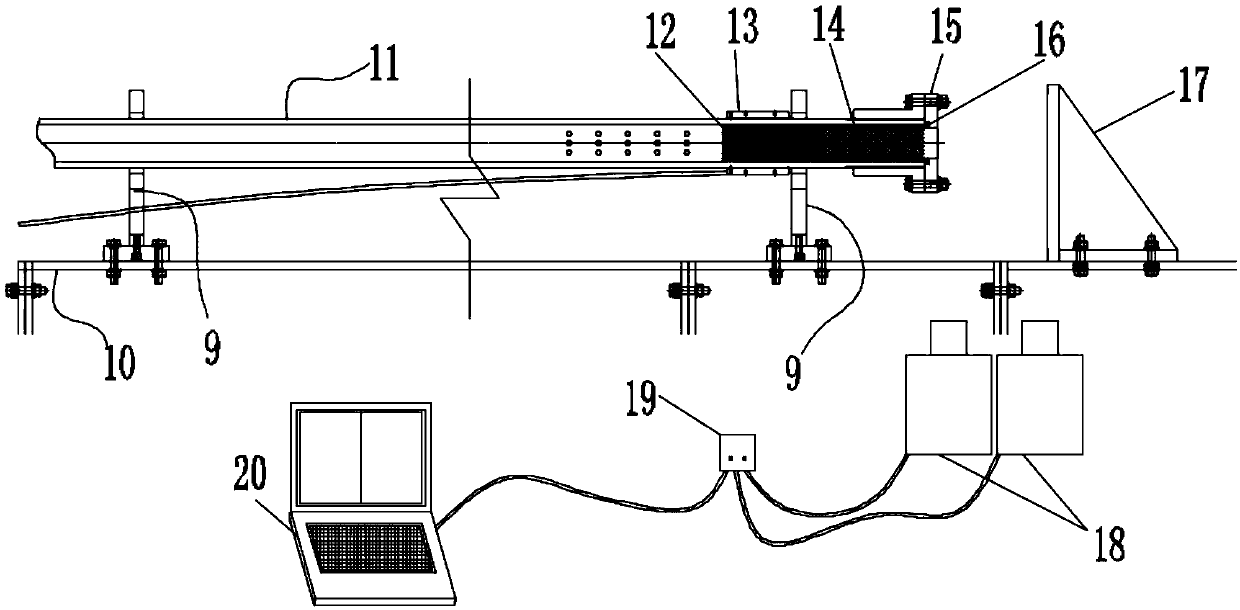

[0039] The device of the present invention is mainly used to explore the dynamic impact characteristics (fracture characteristics and secondary ejection situation) of concrete and rock test pieces and the impact test device of the stress and strain situation at the moment of impact, mainly comprising PC control computer 4, launch system, fixed Support, electronic laser velocimeter 13, high-speed camera 18 shooting system and test piece baffle 17, described fixed support is used for fixing launch system, and test piece baffle is set relative to launch system, and promptly described test piece baffle 17 is located at At the exit of the launch system, the electronic laser velocimeter 13 is located at the exit end of the launch system to detect the speed of launching rocks or concrete samples, and the high-speed camera 18 shooting system is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com