Three-dimensionally braided pressure gas bottle and preparation method thereof

A technology of three-dimensional weaving and manufacturing method, which is applied in the field of pressure vessels, can solve the problems of life limitation, poor mechanical properties between layers, such as pressure stability, impact and corrosion resistance of pressure vessel gas cylinders, and achieves strong design and preparation flexibility, Good high and low temperature stability, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

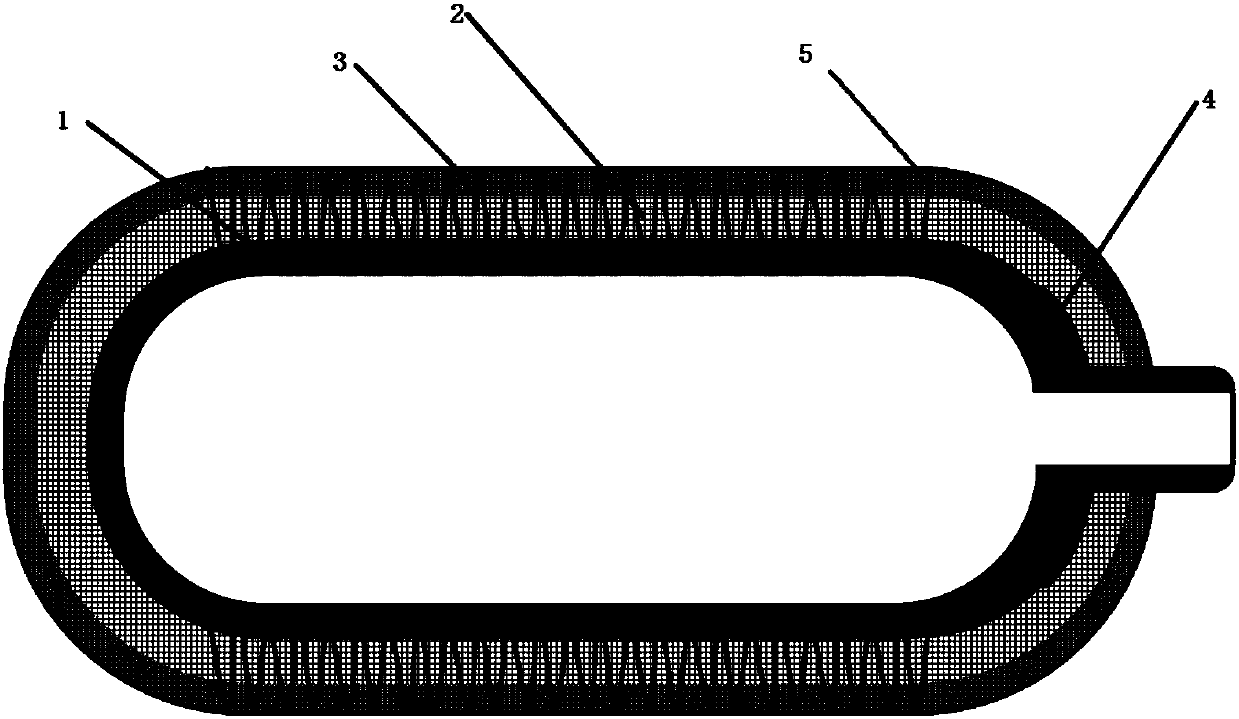

[0036] (1) A variety of high-performance fiber mixed yarns are used for three-dimensional braiding on the aluminum alloy metal liner layer 1. Among them, the inner layer 2 of the three-dimensional braided composite material uses carbon fiber and glass fiber hybrid yarns for three-dimensional fabric preparation, and carbon fiber The weight ratio to glass fiber is 2:1, the fabric adopts three-dimensional four-way structure, and the thickness of the single layer is 40mm. The surface layer 3 of the three-dimensional braided composite material is made of mixed yarns of carbon fiber and aramid fiber to prepare a three-dimensional fabric. The weight ratio of carbon fiber and aramid fiber is 3:1. The fabric is woven with a three-dimensional five-way structure, and the thickness of a single layer is 30mm.

[0037] (2) According to the conditions of pressure resistance and stress, after the inner layer 2 of the three-dimensional braided composite material and the surface layer 3 of the t...

Embodiment 2

[0044](1) A variety of high-performance fiber mixed yarns are used for three-dimensional braiding on the titanium alloy metal liner layer 1. Among them, the inner layer 2 of the three-dimensional braided composite material uses carbon fiber and glass fiber hybrid yarns for three-dimensional fabric preparation, and carbon fiber The weight ratio to glass fiber is 4:1, the fabric adopts three-dimensional five-way structure, and the thickness of the single layer is 30mm. The surface layer 3 of the three-dimensional braided composite material is made of mixed yarns of carbon fiber and aramid fiber to prepare a three-dimensional fabric. The weight ratio of carbon fiber and aramid fiber is 2:1. The fabric is woven with a three-dimensional six-way structure, and the thickness of a single layer is 20mm.

[0045] (2) According to the conditions of pressure resistance and stress, after the inner layer 2 of the three-dimensional braided composite material and the surface layer 3 of the thr...

Embodiment 3

[0052] (1) A variety of high-performance fiber mixed yarns are used for three-dimensional braiding on the hard alloy steel metal liner layer 1, wherein the inner layer 2 of the three-dimensional braided composite material uses carbon fiber and glass fiber hybrid yarns for three-dimensional fabric preparation , The weight ratio of carbon fiber to glass fiber is 4:1, the fabric adopts three-dimensional six-way structure, and the thickness of the single layer is 20mm. The surface layer 3 of the three-dimensional braided composite material is made of mixed yarns of carbon fiber and glass fiber to prepare a three-dimensional fabric. The weight ratio of carbon fiber to aramid fiber is 3:1. The fabric is woven with a three-dimensional four-way structure, and the thickness of a single layer is 10mm.

[0053] (2) According to the conditions of pressure resistance and stress, after the inner layer 2 of the three-dimensional braided composite material and the surface layer 3 of the three-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com