Protective cutting construction method for tunnel segment

A technology of tunnel segment and construction method, applied in the field of construction engineering, can solve the problems of surrounding influence, protection of cutting area, damage of surrounding structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific example and accompanying drawing, the present invention will be further described:

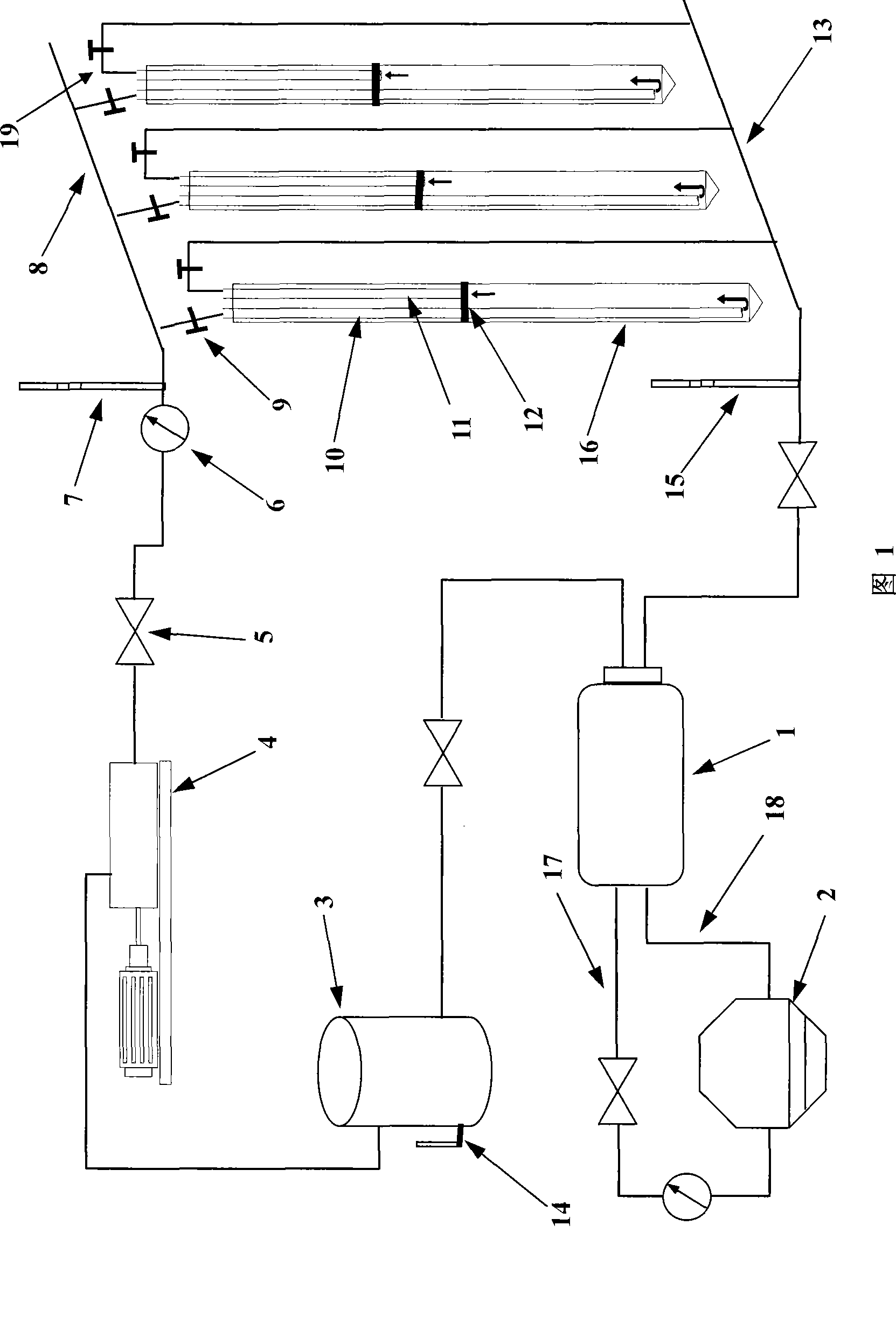

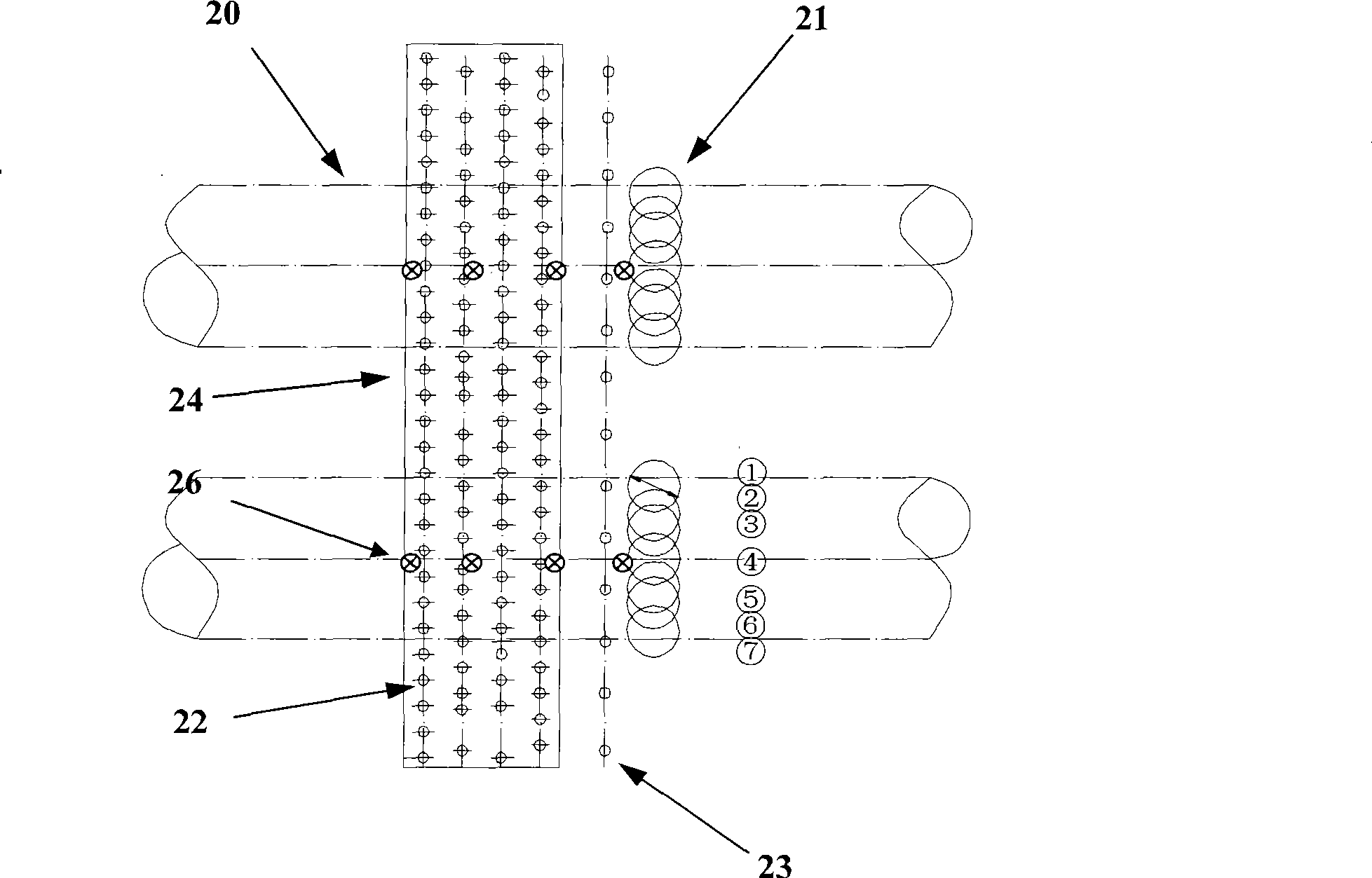

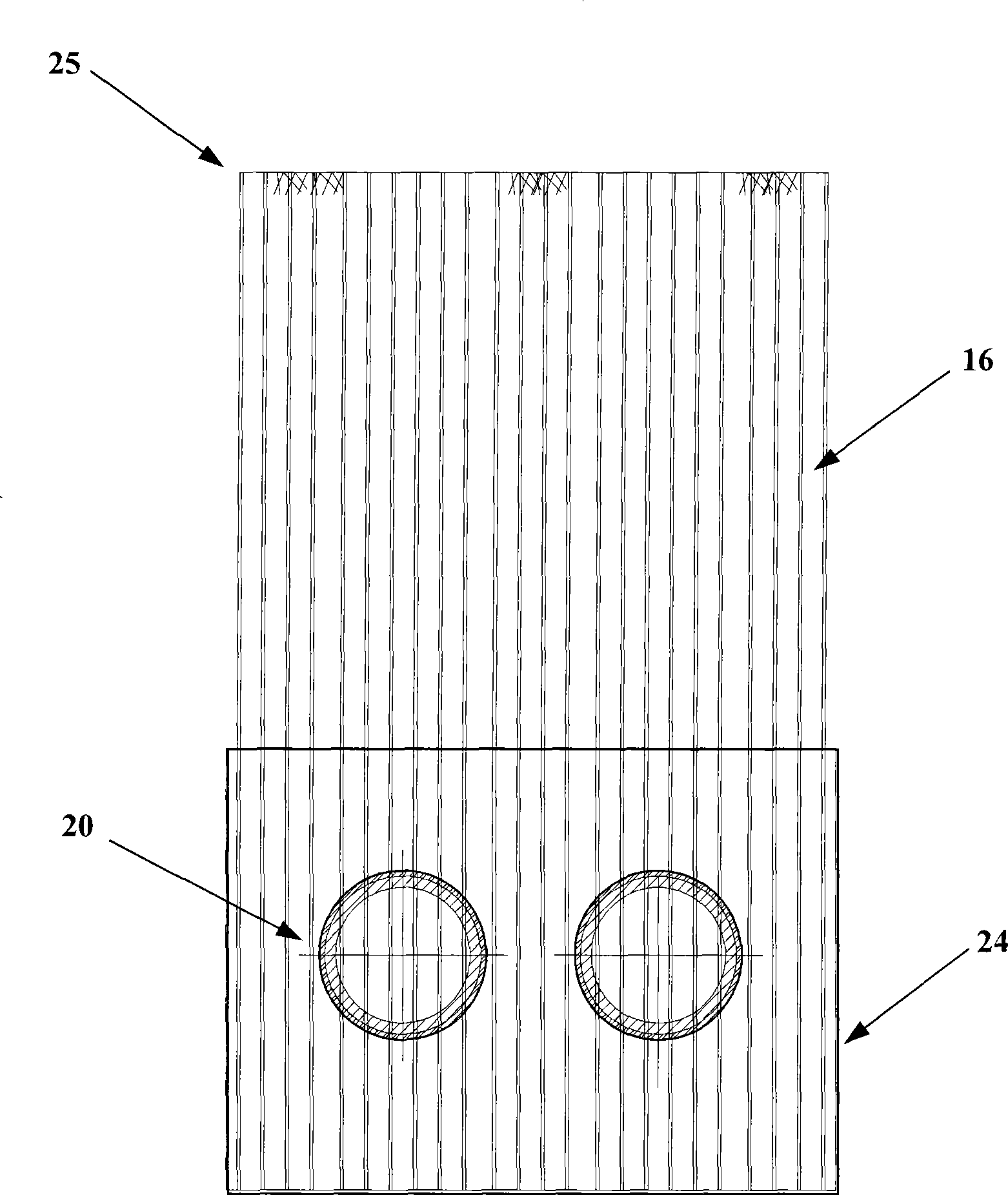

[0024] After the construction of the main tunnel structure of a project in Shanghai was completed, a dangerous situation occurred during the construction of the bypass passage, which caused the collapse of the nearby tunnel and the loss of soil near the tunnel. After repeated program demonstrations afterwards, the program of open cut and repair of tunnels in the entire subsidence area was adopted. After the collapse of the tunnel, the tunnel in the damaged section has been filled with soil and artificial grouting materials, and the intact tunnel has also been filled with muddy water. Before the construction of the underground diaphragm wall in the foundation pit, it is necessary to cut and clean the tunnel segments first. In order to prevent the intact tunnel from further subsidence and damage, the vertical freezing method is used to freeze the tunnel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com