Patents

Literature

57results about How to "Neat cutting surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

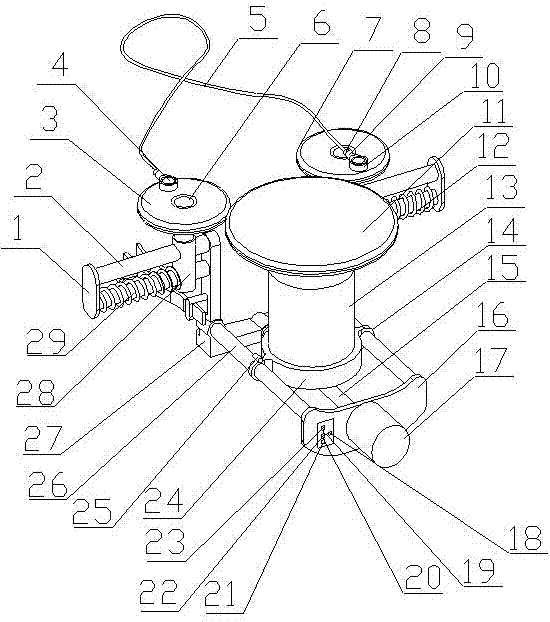

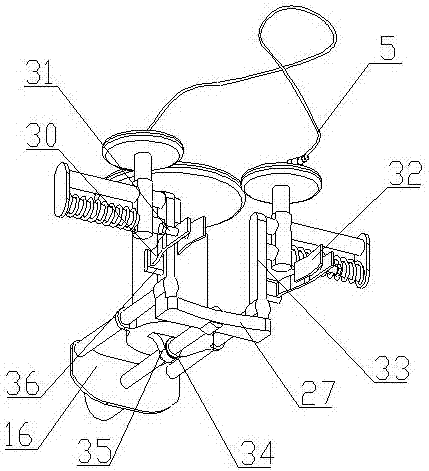

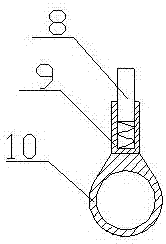

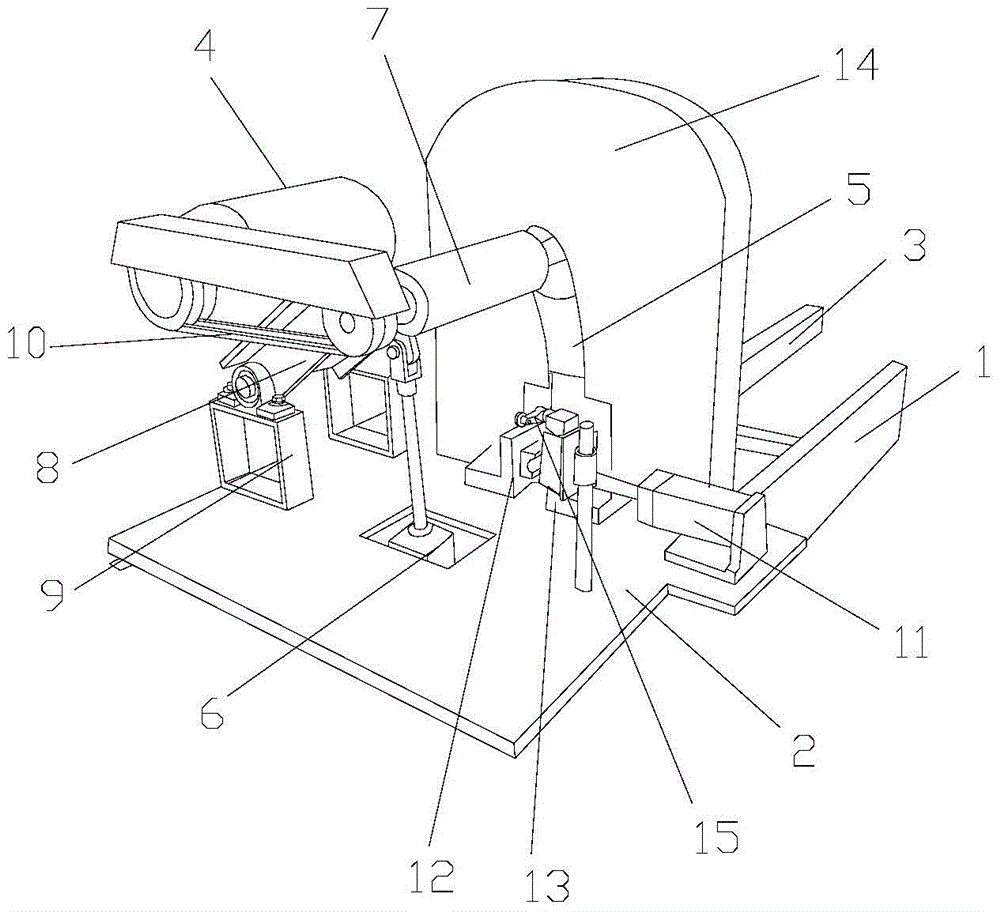

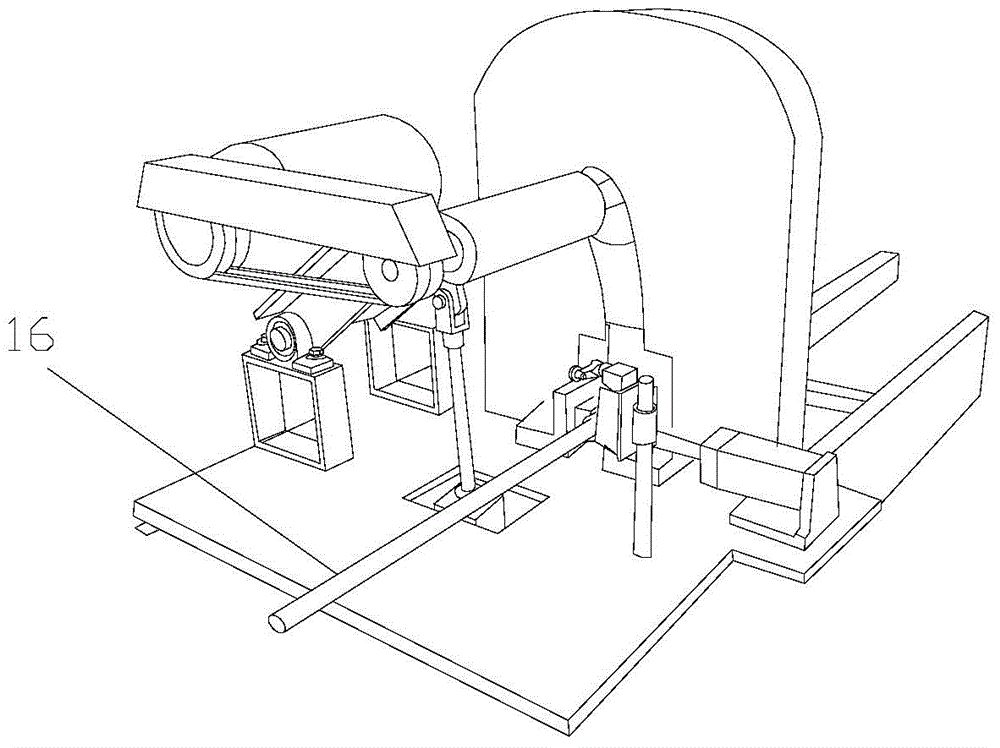

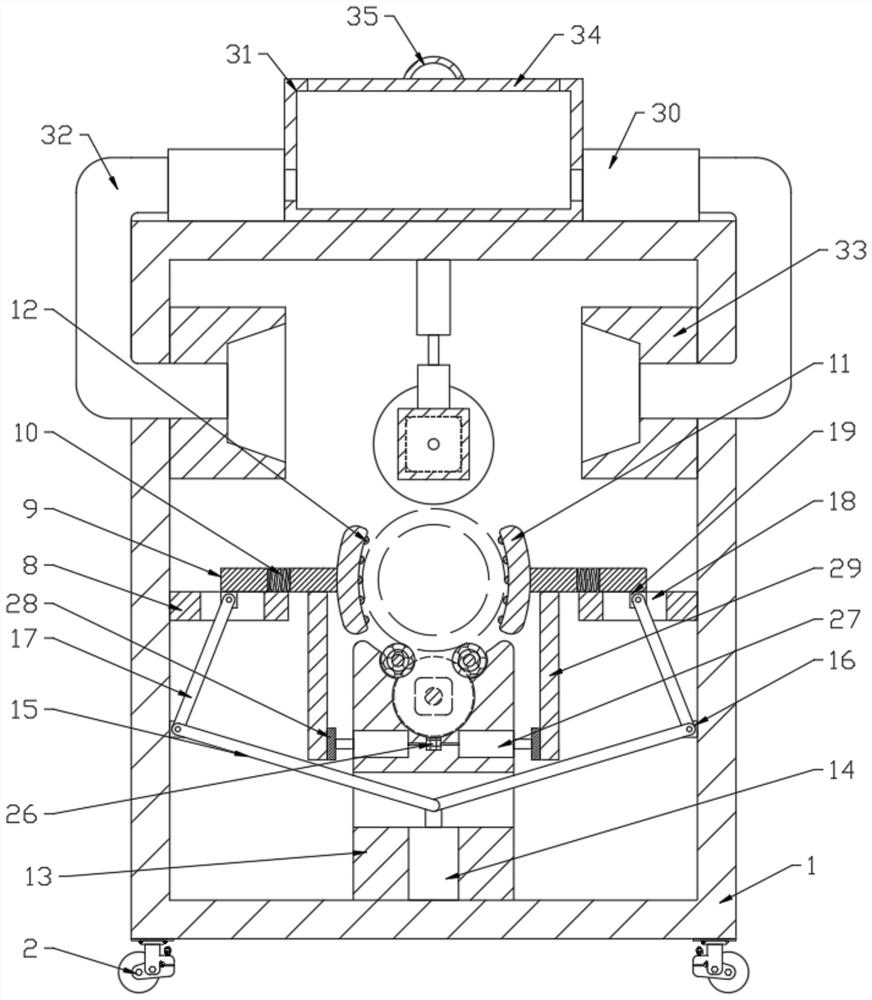

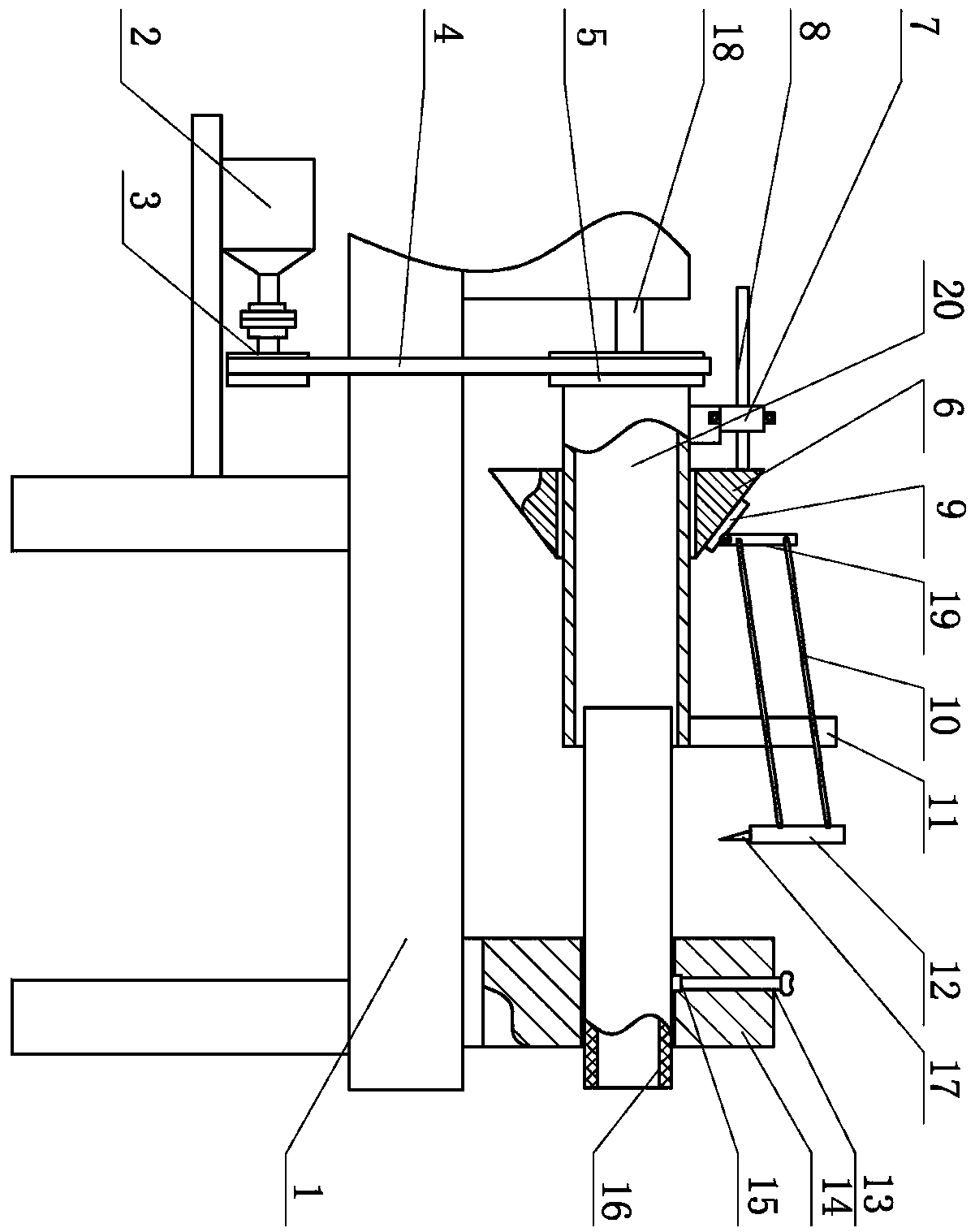

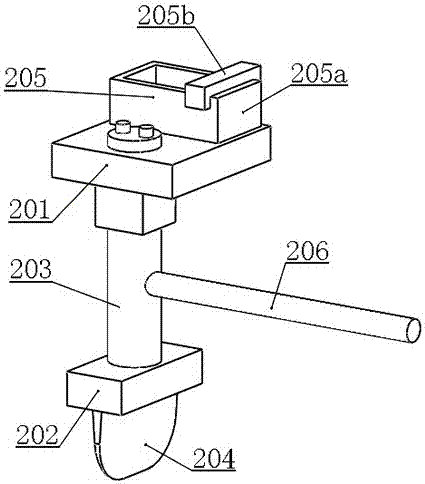

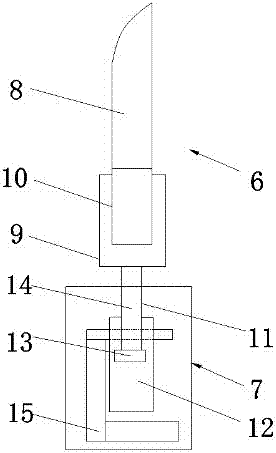

Livestock breeding ox horn cutting device

InactiveCN107877581ANeat cutting surfaceImprove cutting effectMetal working apparatusTaming and training devicesEngineeringScrew thread

The invention provides a livestock breeding ox horn cutting device and discloses a device for cutting an ox horn through gradual tensioning and reciprocating movement of a rope saw. The livestock breeding ox horn cutting device is characterized in that the middle of a supporting plate and the middle of a fixing plate are connected through a threaded shaft; two sliding bars are symmetrically arranged on the two sides of the threaded shaft; the two ends of the sliding bars are connected with the supporting plate and the fixing plate correspondingly; a moving chassis is arranged between the two sliding bars; a transmission block is arranged in the middle of the bottom end of the moving chassis; a threaded sleeve is arranged on the threaded shaft in a sleeving mode and connected with the transmission block; the two sides of the moving chassis are connected with the two sliding bars through sliding rings correspondingly; a fixed motor is arranged on one side of the fixing plate, and a motorshaft is connected with one end of the threaded shaft; and by adopting the device, the ox horn cutting effect can be effectively improved, and injuries to an ox can be reduced in the ox horn cuttingprocess.

Owner:南京白下高新技术产业园区投资发展有限责任公司

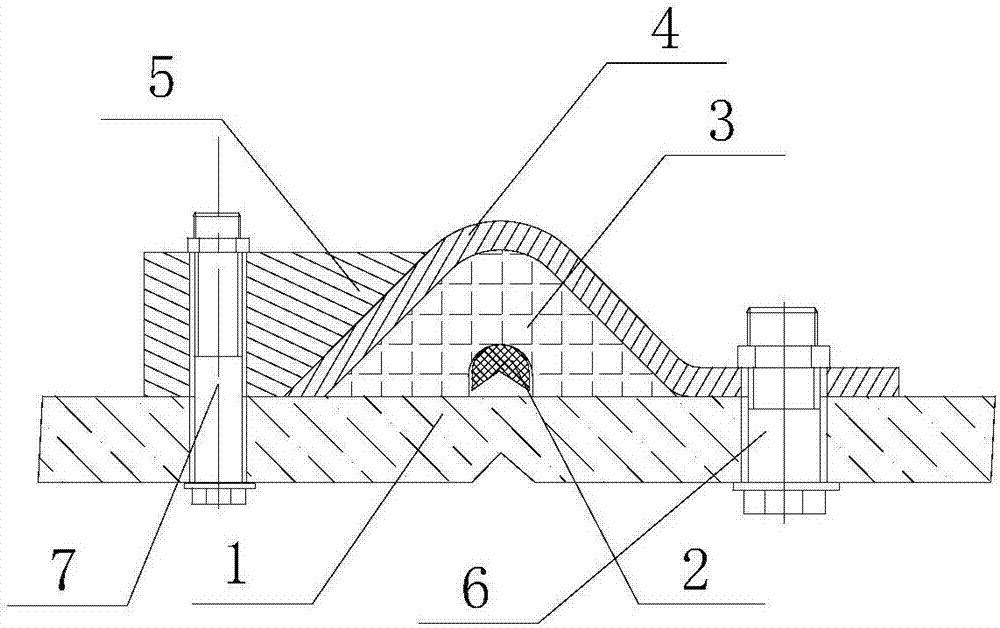

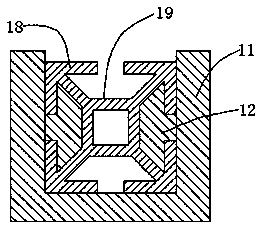

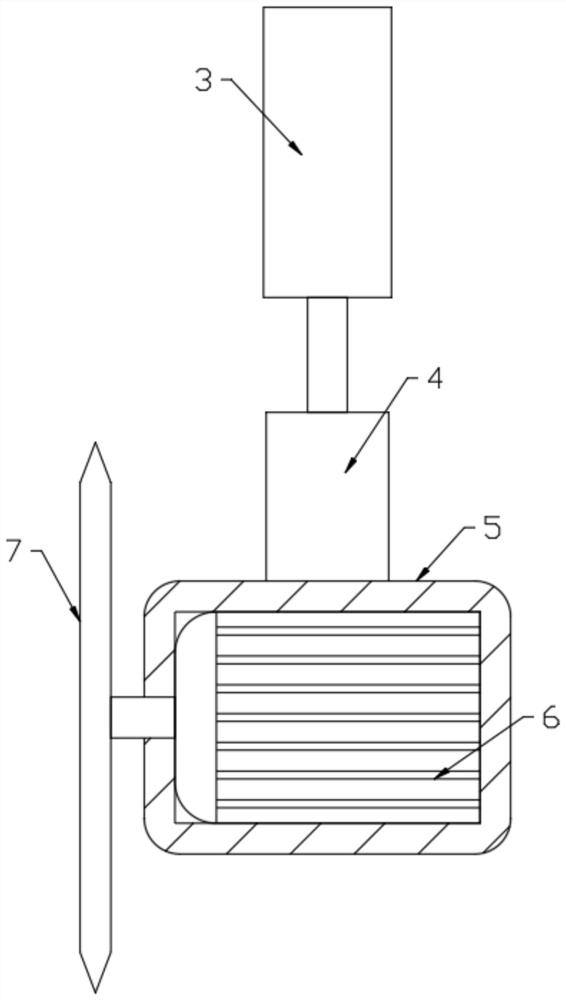

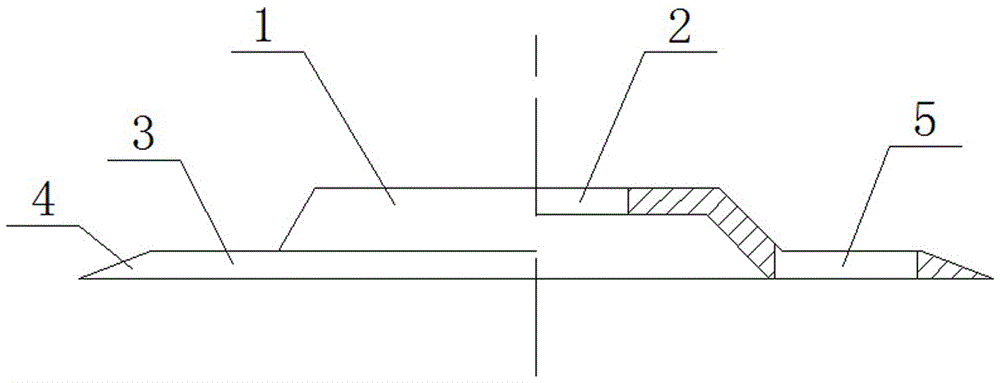

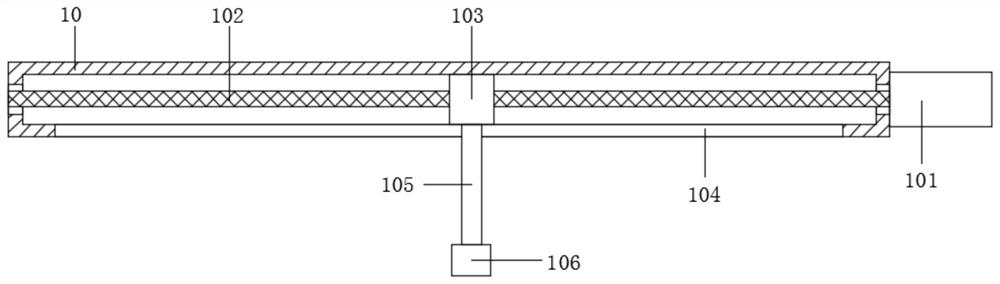

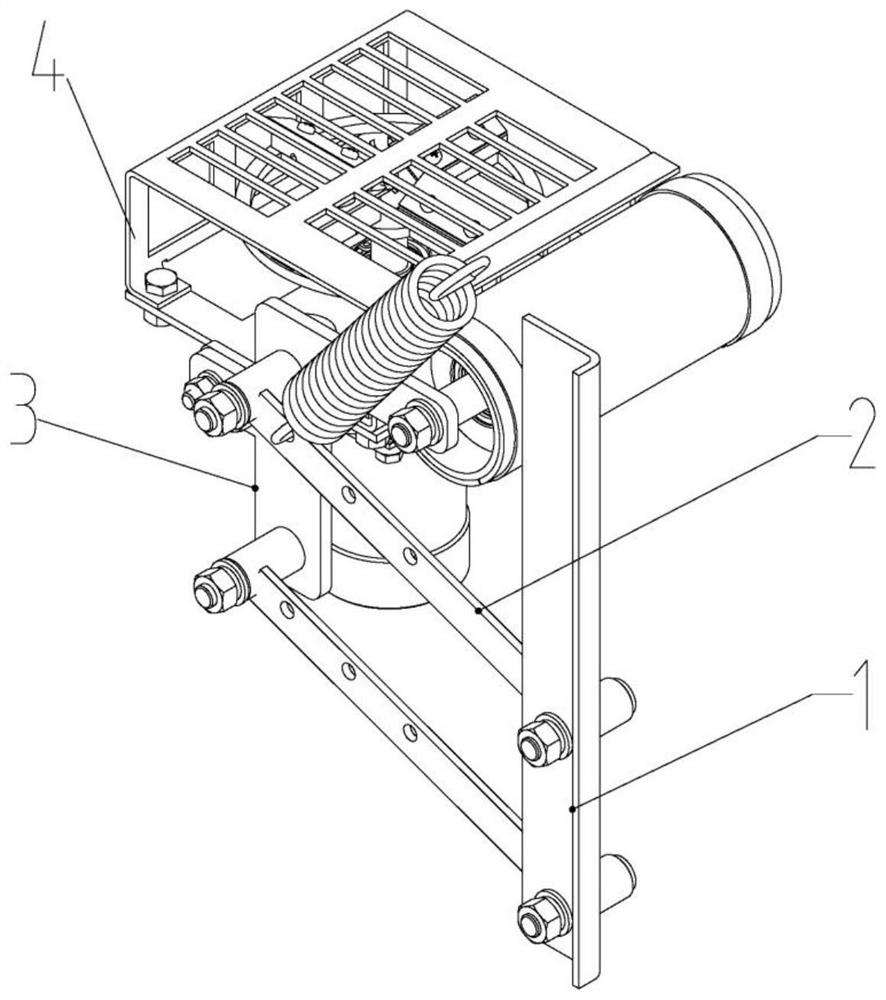

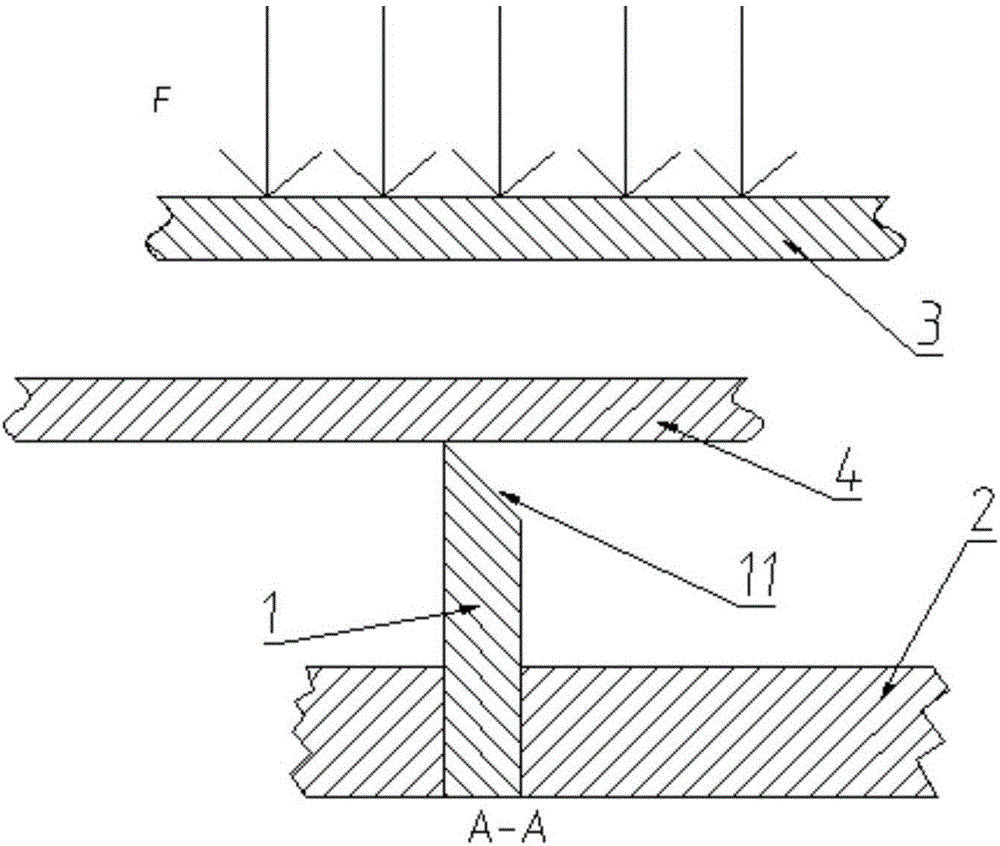

Cutting and separating device of fiber-reinforced composite material structure

ActiveCN107031871ANeat cutting surfaceNo wasteCosmonautic vehiclesCosmonautic component separationEngineeringMaterial structure

A cutting and separating device of a fiber-reinforced composite material structure comprises a composite material plate (1), an energy-gathered cutting cable (2), a buffer sheath (3) and a protective cover (4). The energy-gathered cutting cable (2) is mounted on one side of a separating face of the composite material plate (1), a groove is formed in the bottom edge of the buffer sheath (3), and the size of the groove is matched with the back size of the energy-gathered cutting cable (2). The outer surface of the buffer sheath (3) is sleeved with a main body part of the protective cover (4), and the main body part of the protective cover (4) and a cutting and separating part of the composite material plate (1) are fixed through an extending mounting face on one side. Energy-gathered jet flows generated by the energy-gathered cutting cable (2) cut off the composite material plate (1), and separating is completed.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

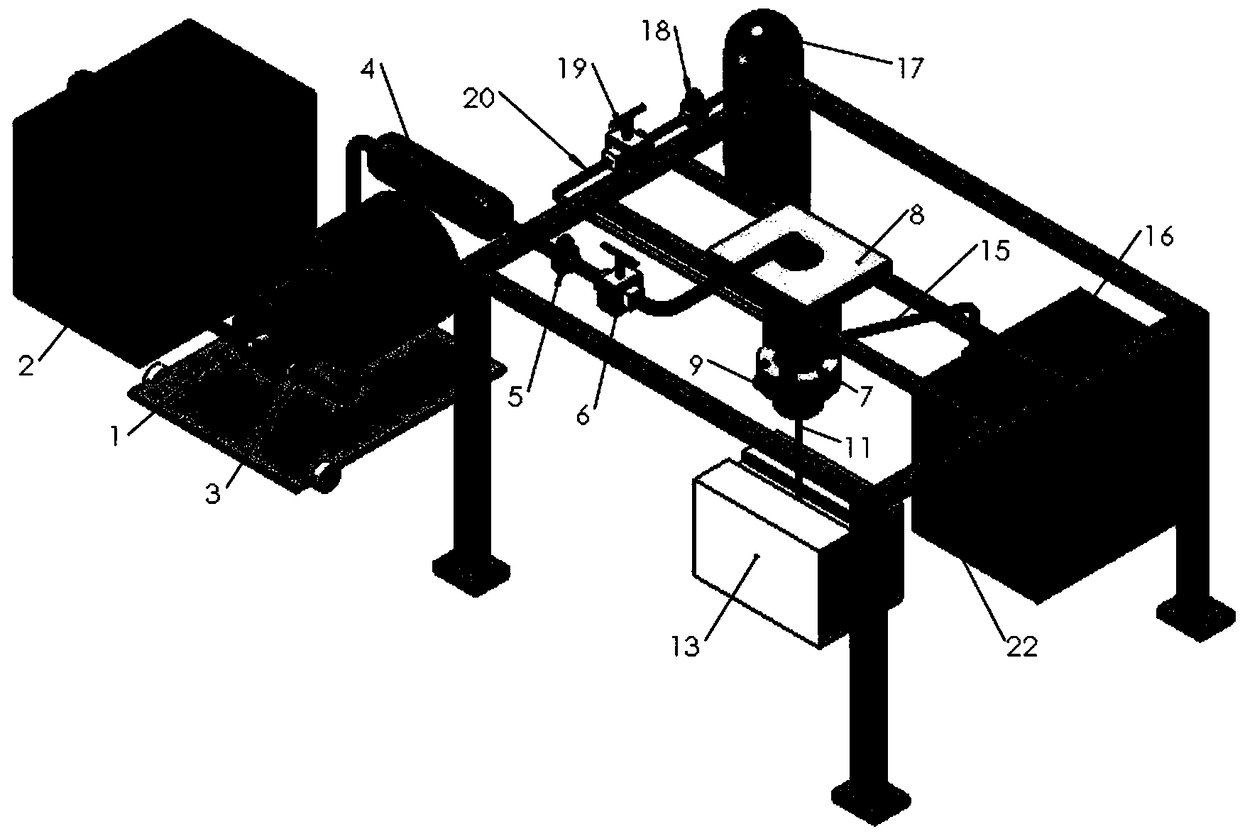

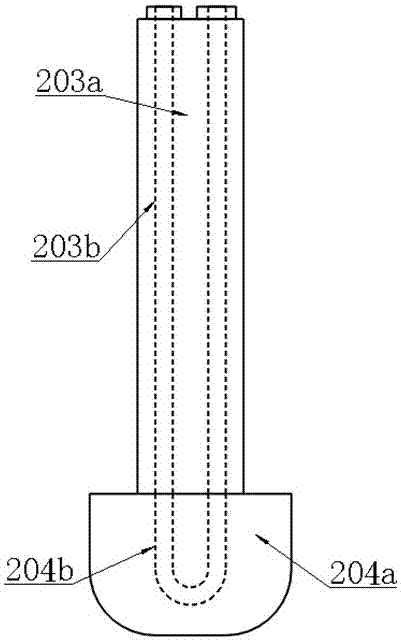

Underwater ventilation cavity assisted high-pressure water jet cutting device

InactiveCN109290958AEnsure safetyImprove cutting accuracyBlast gunsAbrasive feedersNumerical controlChemical reaction

The invention belongs to the field of underwater cold cutting, and particularly relates to an underwater ventilation cavity assisted high-pressure water jet cutting device. A high-pressure water tank,a high-pressure water pump, an energy accumulator, a pressure regulating valve, a flowmeter, a water pipe connector, a water cutter generator and a ruby nozzle are sequentially connected through a high-pressure water pipe; water in the high-pressure water tank forms a high-speed water jet flow at the ruby nozzle through the high-pressure water pipe; grinding sand is located on a water cutter numerical control guide rail installation frame and is connected with the water pipe connector through a grinding sand conveying pipe and a grinding and mixing pipe sequentially; a high-pressure gas cylinder, a gas pressure regulating valve, a gas flowmeter, a gas pipe, a gas cavity and an air bubble are sequentially connected through a pipeline; gas and the high-speed water jet flow are ejected ontoa workpiece to be cut so as to cut the workpiece; and the air bubble packs the jet flow at the position close to an outlet. According to the underwater ventilation cavity assisted high-pressure waterjet cutting device provided by the invention, the workpiece cannot be locally heated so as to be prevented from being deformed, no molten slags and chemical reaction is generated to cause toxic substances, the cutting accuracy is high, the cutting surfaces are in order, and the equipment performance and the service life are improved.

Owner:HARBIN ENG UNIV

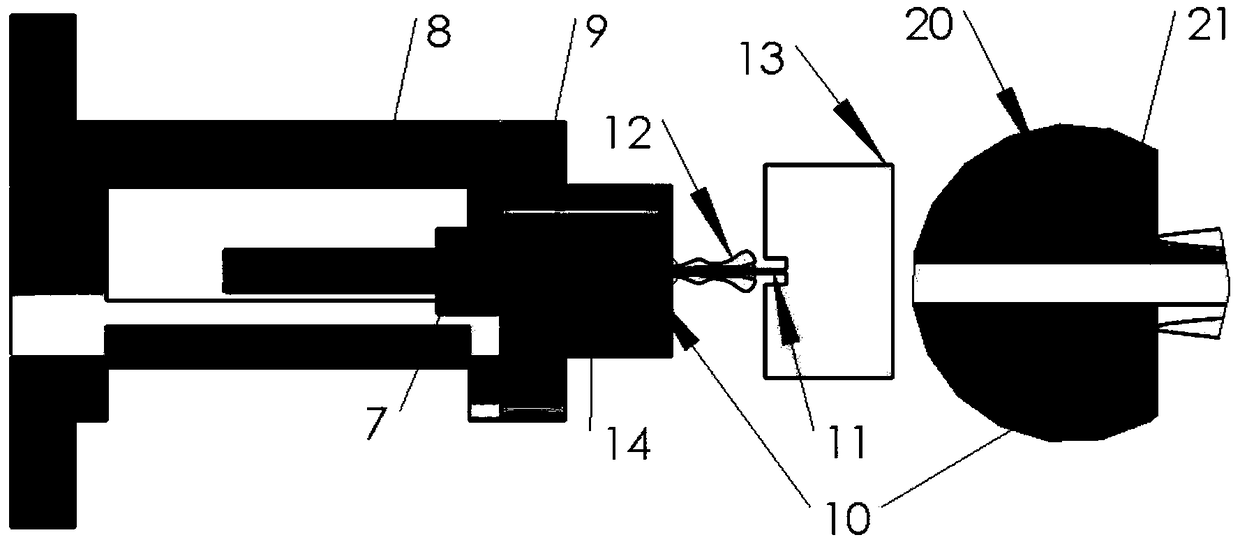

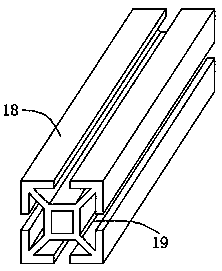

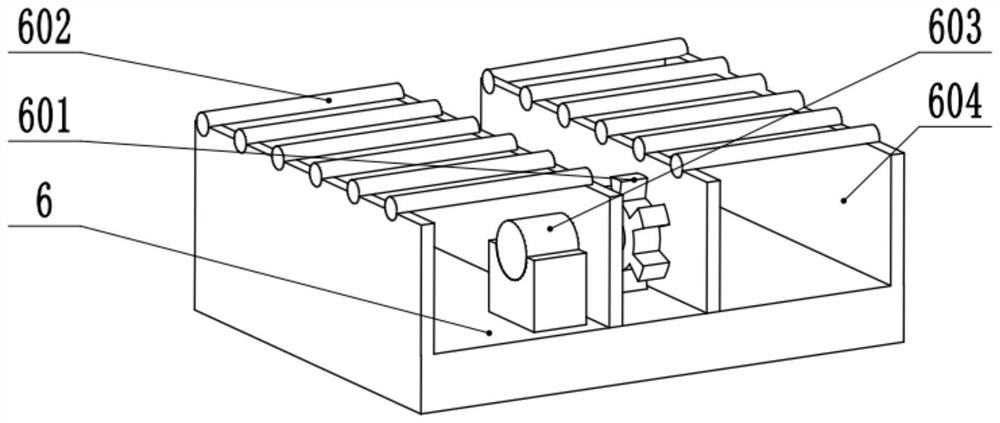

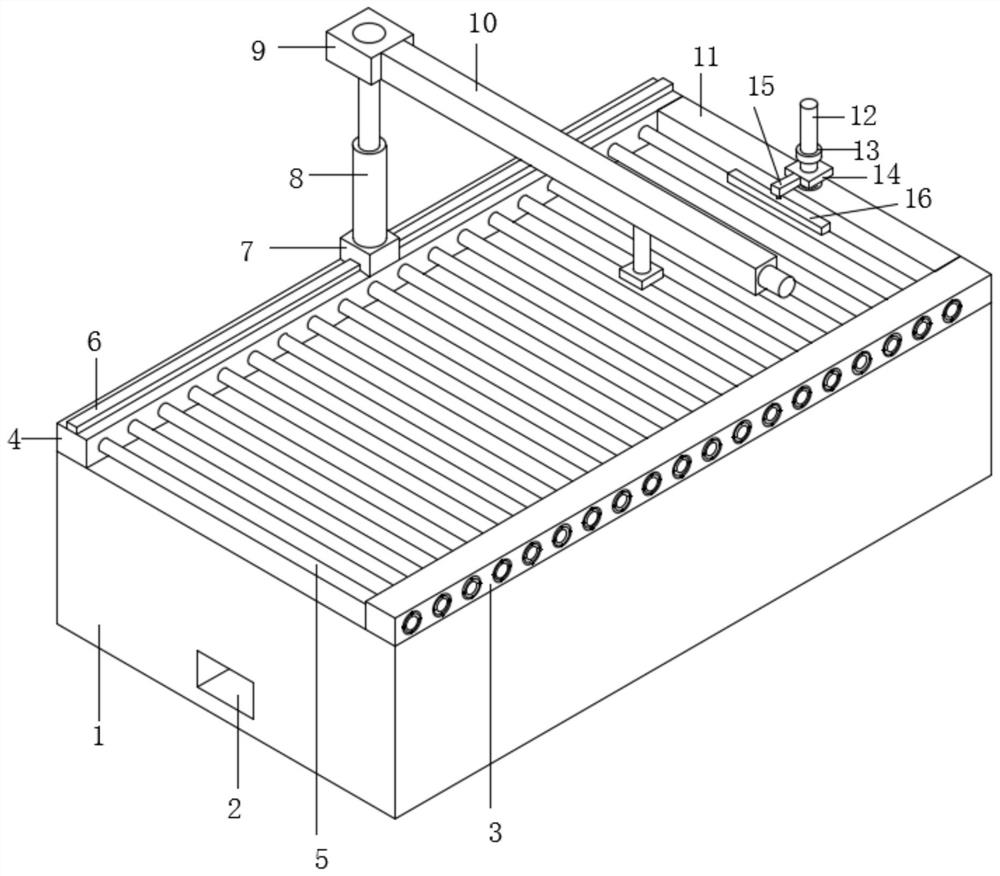

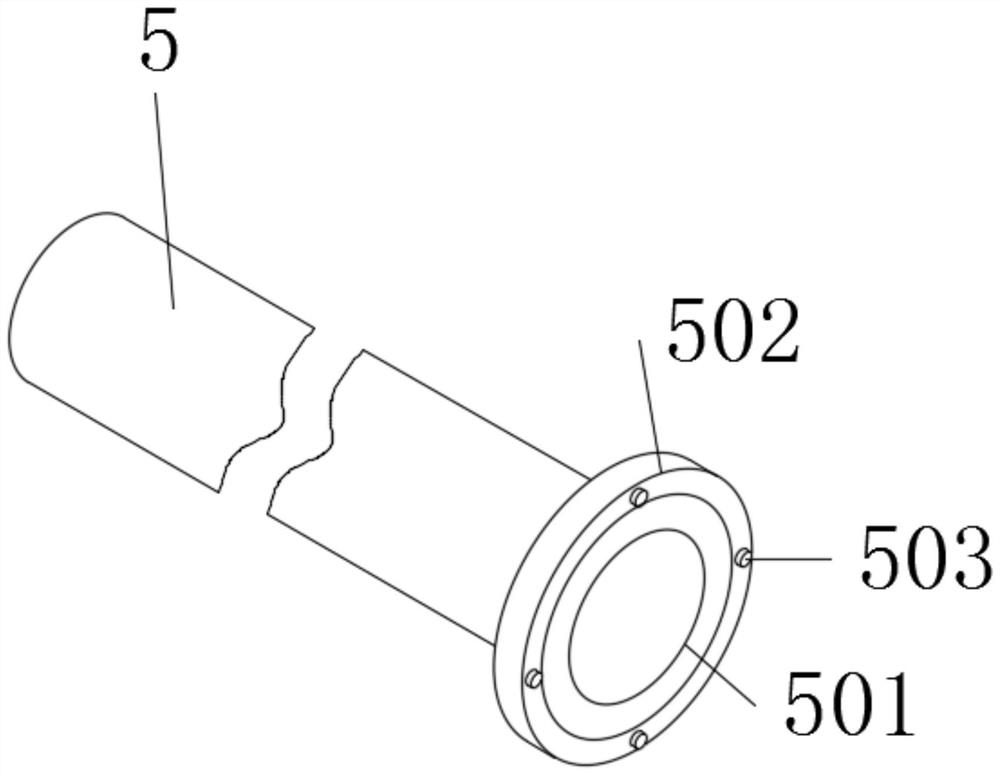

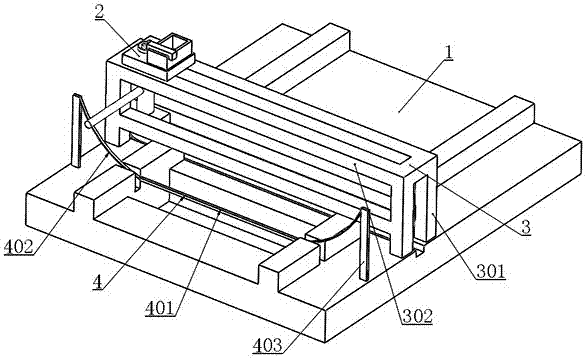

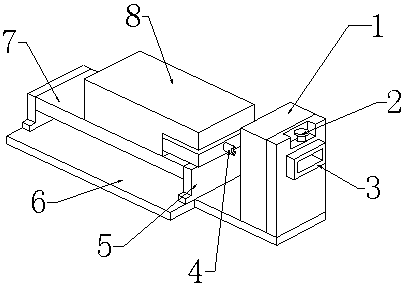

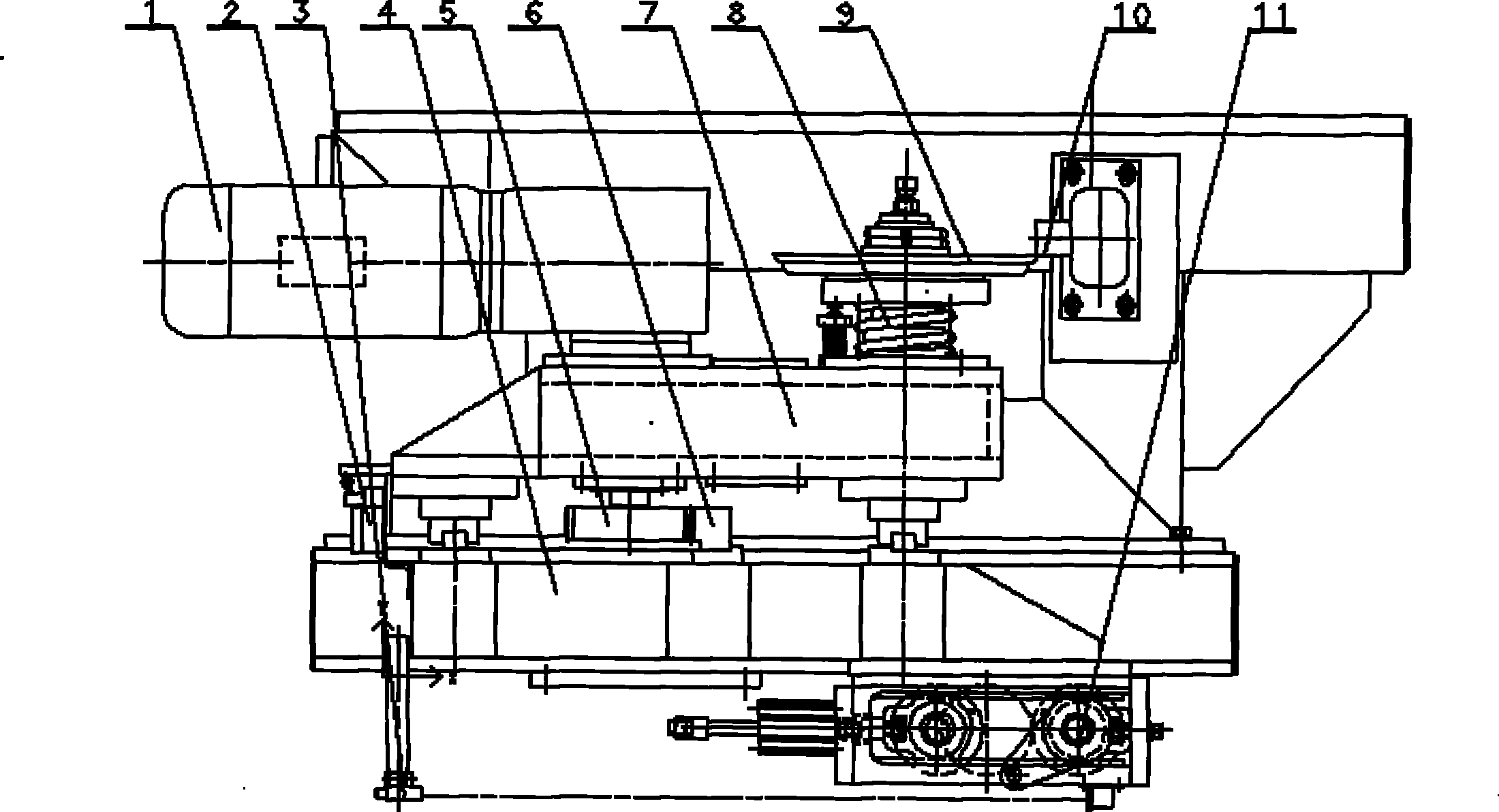

Aluminum profile integrated device

ActiveCN108655502AAvoid scratchesLow melting pointWork clamping meansMeasurement/indication equipmentsEngineeringIntegrated devices

The invention discloses an aluminum profile integrated device. The device comprises a water tank, a water cutting head and aluminum profiles; T-shaped grooves are formed in surrounding surfaces of thealuminum profiles; the water cutting head is mounted on the outer wall of the water tank; a side plate of the water tank is connected with a clamping plate; a second transmission plate is arranged atone end of the water tank; sliding chutes are formed in the second transmission plate; sliding blocks are clamped in the sliding chutes; motors are arranged outside the sliding blocks; the motors areconnected with baffles; the water tank is connected with positioning plates; positioning blocks are mounted in the positioning plates; the positioning plates are connected with guiding plates; the tops of the guiding plates are connected with guiding rolls; and one ends of the guiding plates are connected with first transmission plates. Through sliding the sliding blocks, the distance between thebaffle and the water cutting head is equal to a cutting length of the aluminum profiles, the aluminum profiles are transmitted to the guiding plates from the first transmission plates; the guiding rolls on the guiding plates rotate to adjust the aluminum profiles to a vertical state so that the aluminum profiles properly enter into the positioning plates, the positioning blocks on the positioningplates are glidingly clamped into the T-shaped grooves on the aluminum profiles, the clamping plates clamp the aluminum profiles, the water cutting head cuts the aluminum profiles, and after the cutting is finished, the aluminum profiles are transmitted away from the second transmission plates.

Owner:ANHUI AOYU CNC TECH

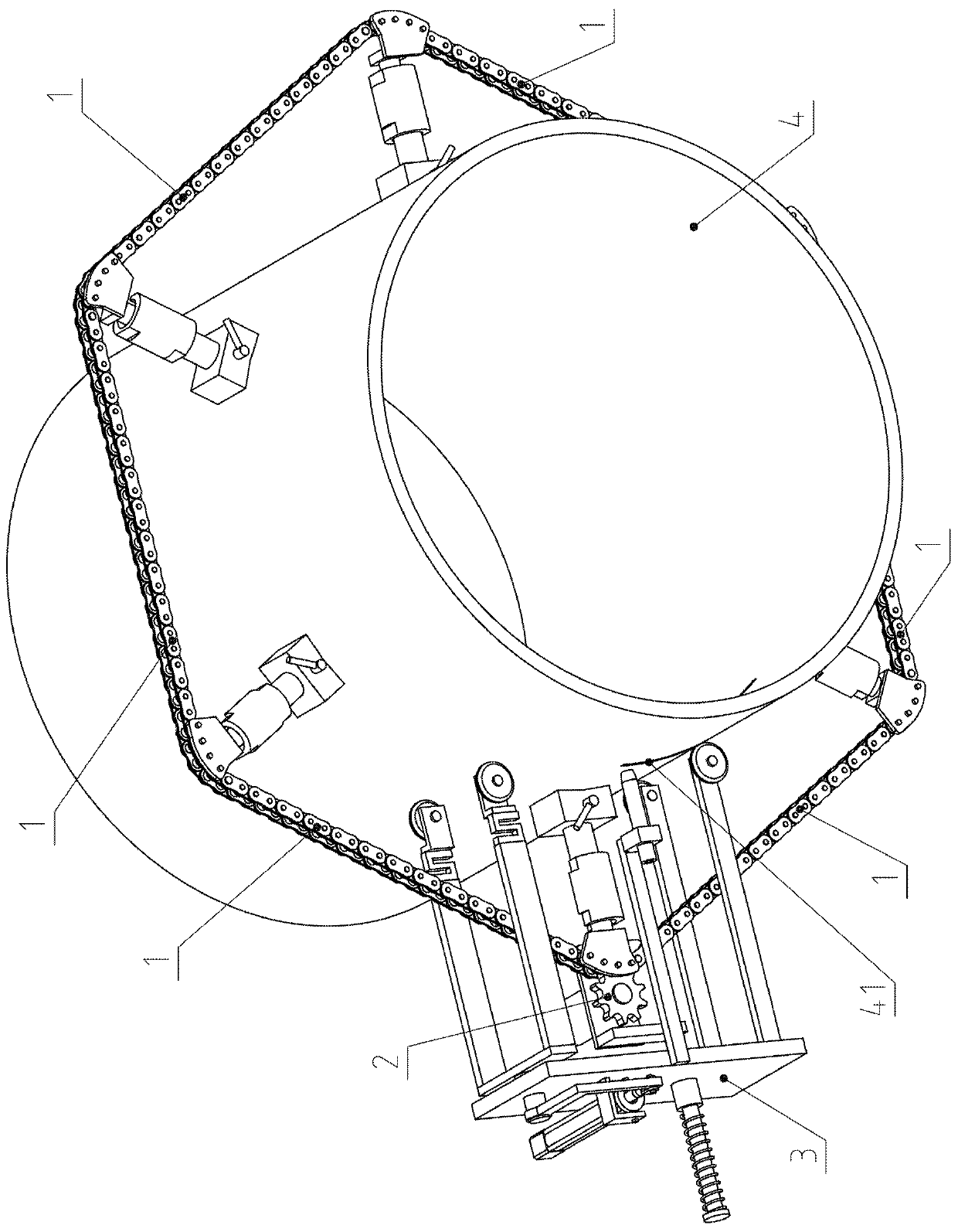

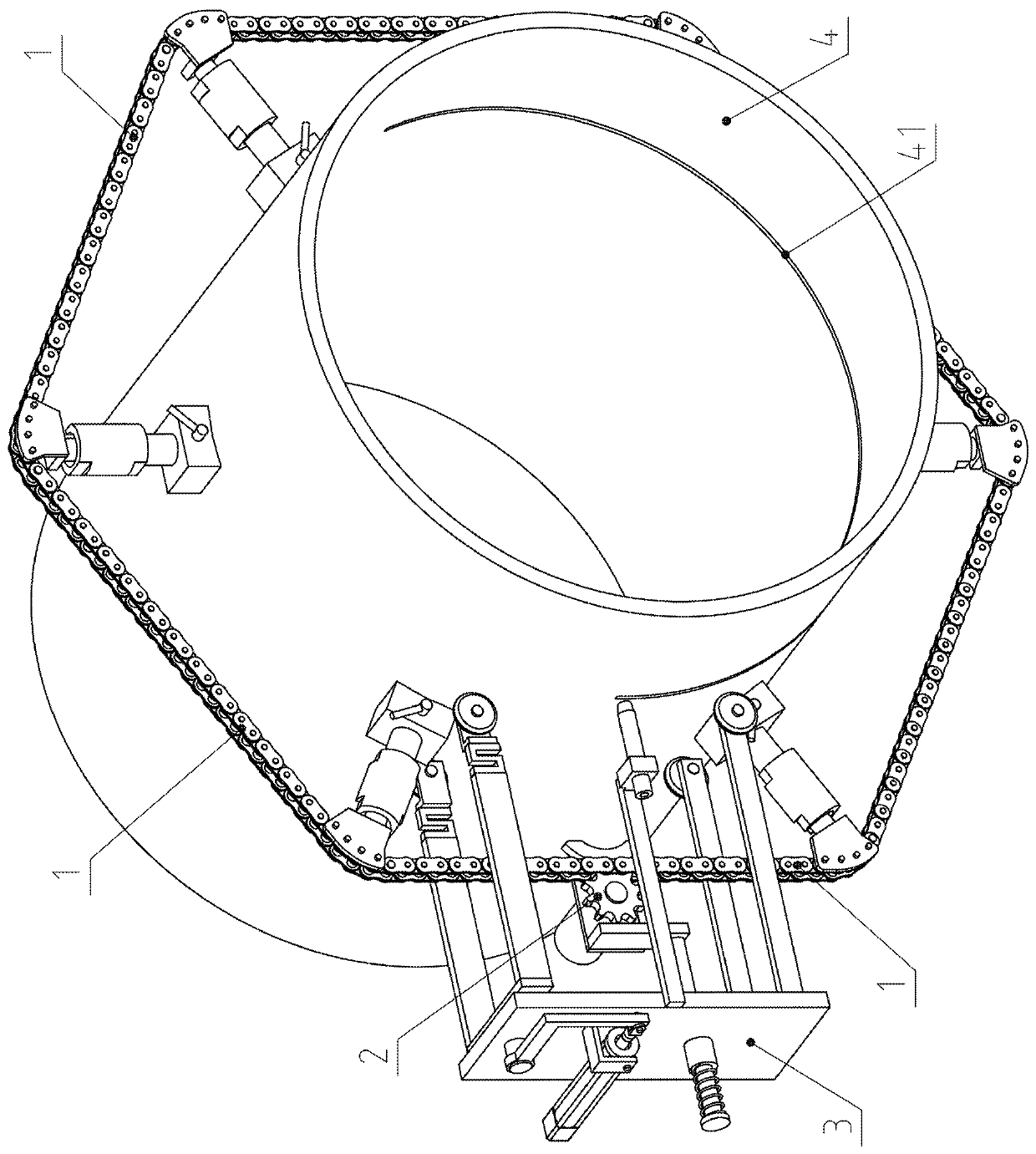

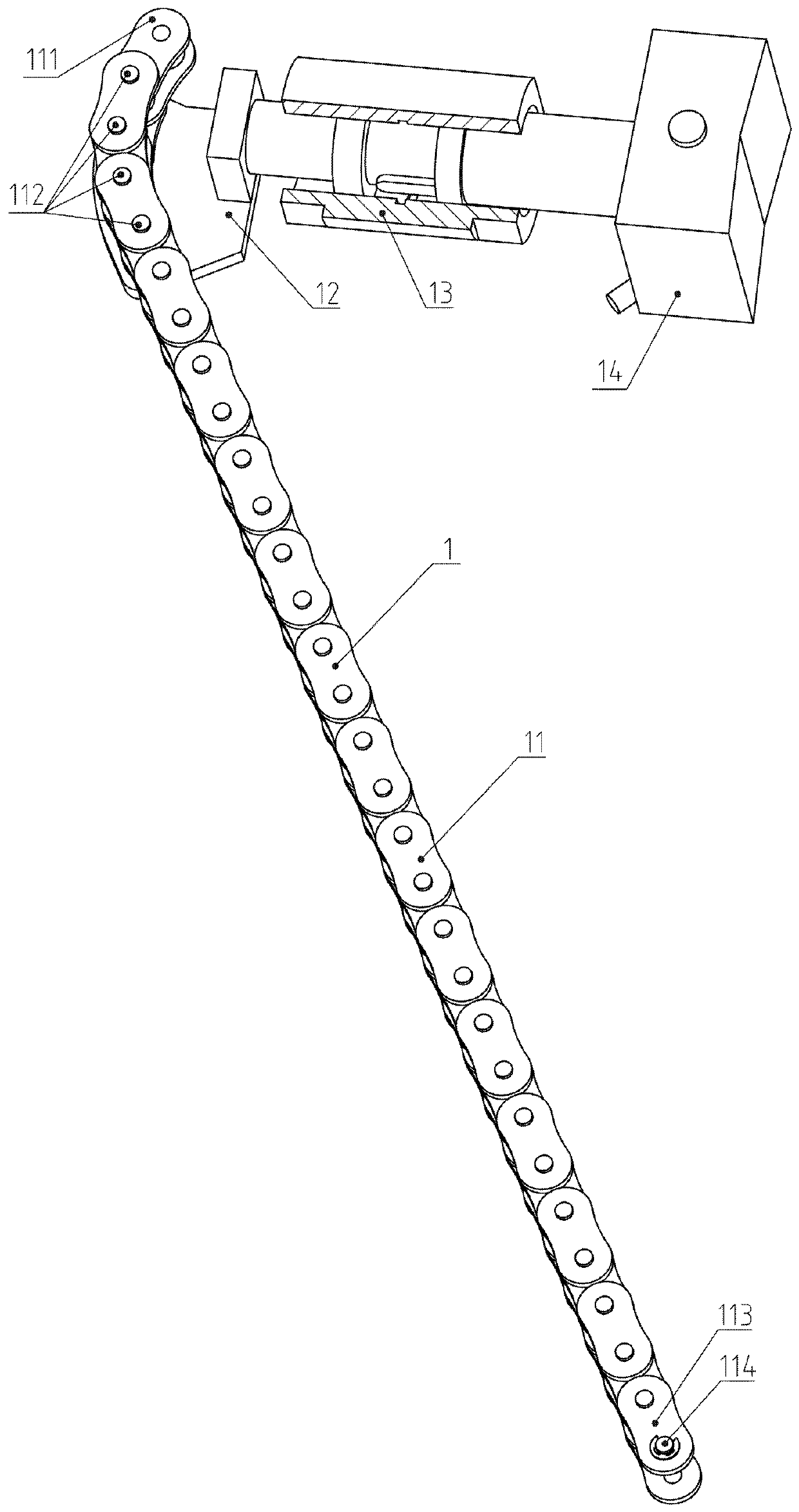

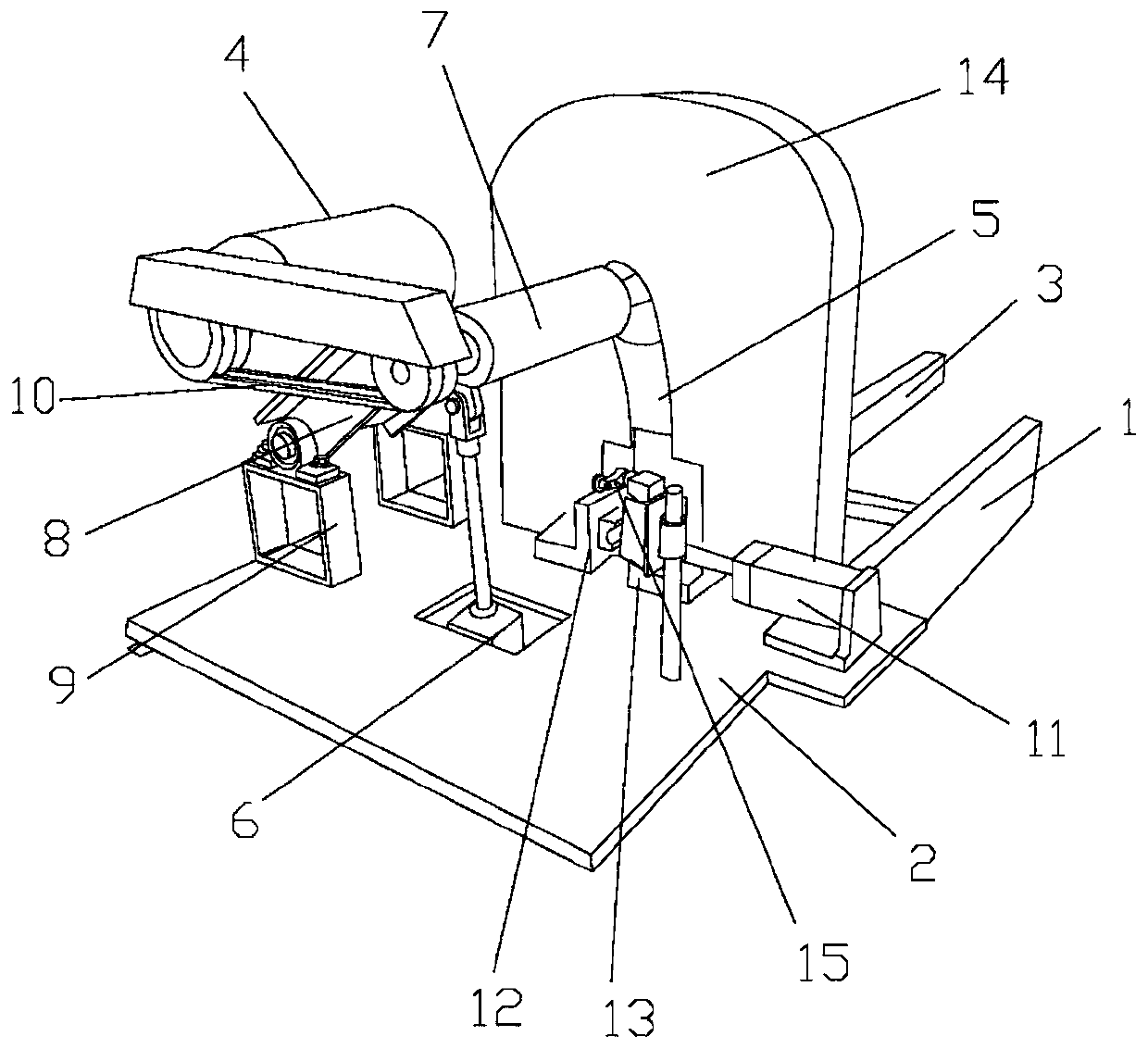

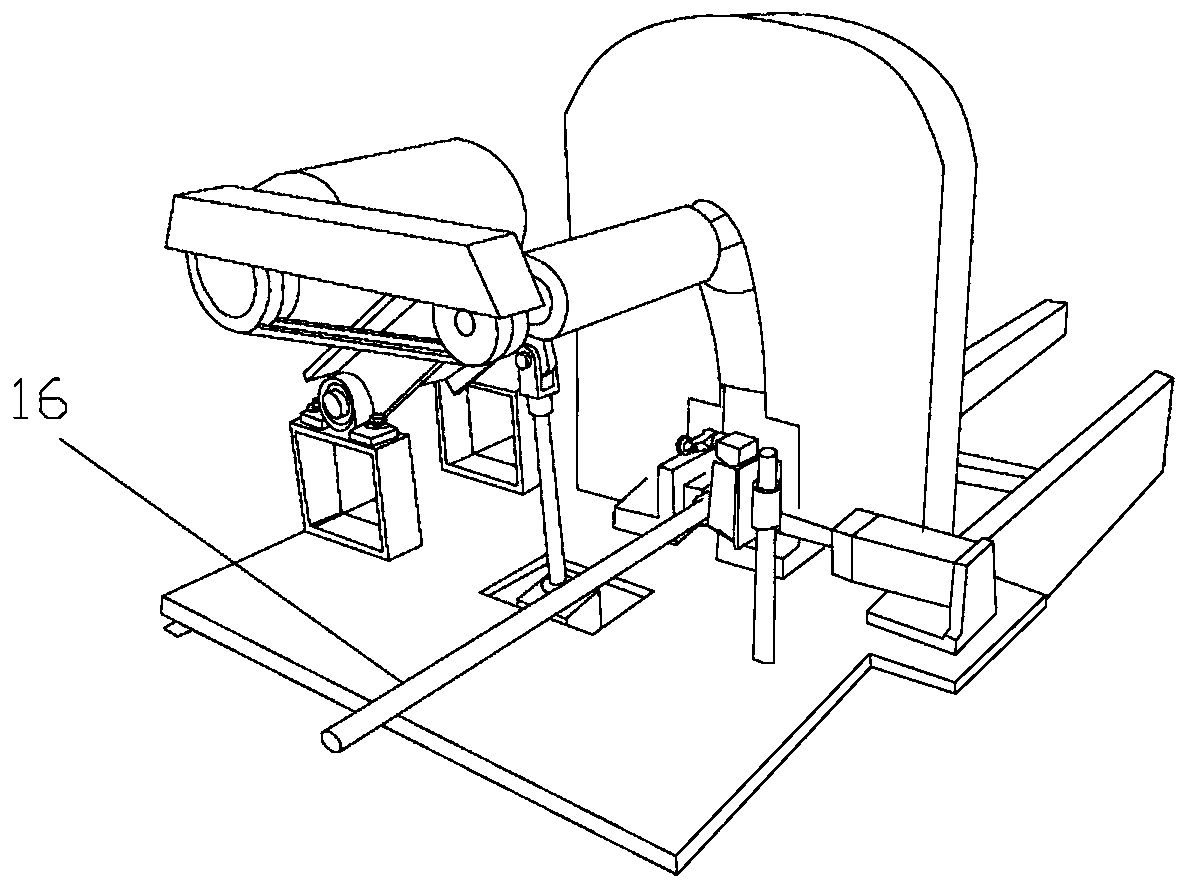

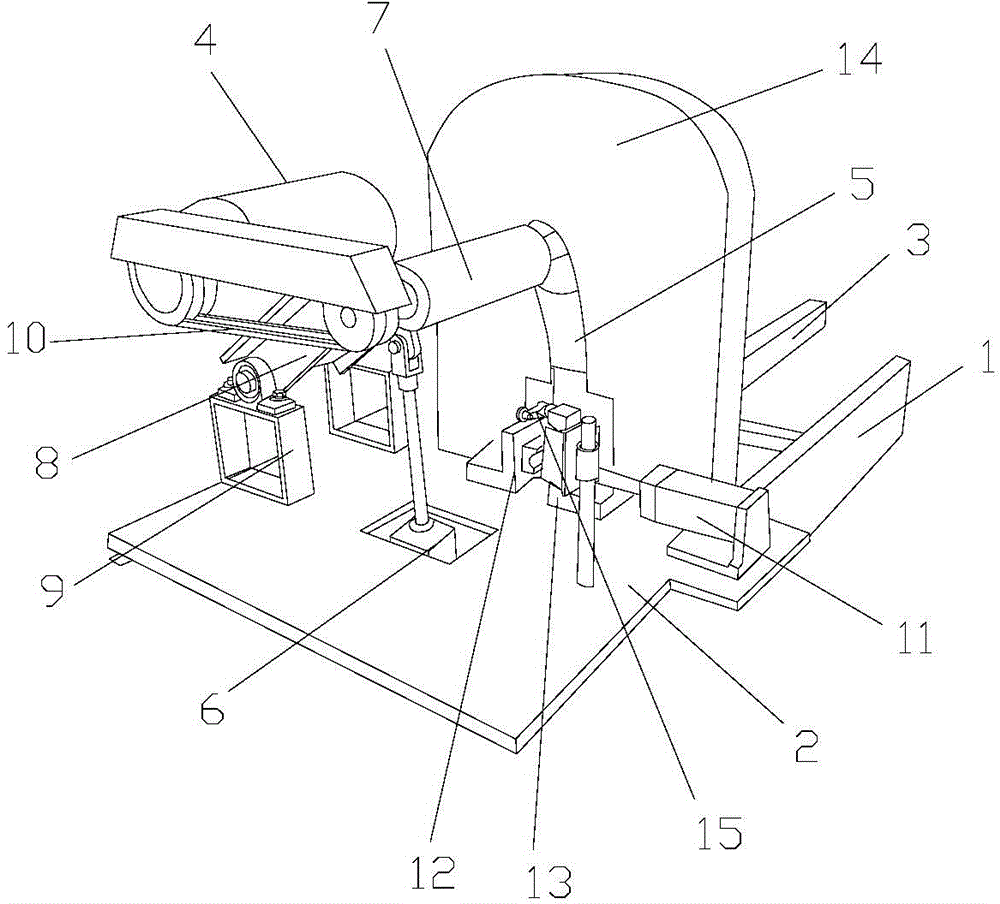

Portable laser cutting auxiliary device for large-diameter petroleum or natural gas transportation steel pipe

ActiveCN110315220AQuickly leave each otherQuickly approach each otherMetal working apparatusLaser beam welding apparatusSteering wheelMotor drive

The invention belongs to the technical field of laser cutting and relates to a portable laser cutting auxiliary device for a large-diameter petroleum or natural gas transportation steel pipe. The lower bottom surface of a permanent magnet attracting hanging apparatus of a chain assembly is attracted to the outer cylindrical surface of a large-diameter steel pipe, a free end I and a free end II which are adjacent are connected, and sleeve roller chain sections are combined into a sleeve roller chain ring. A servo motor drives a chain wheel to rotate, then a chain wheel assembly drives a trolleyassembly to run together, a rear left trolley wheel, a rear right trolley wheel, a left steering wheel and a right steering wheel roll on the outer cylindrical surface of the large-diameter steel pipe, and a laser cutting gun cuts the pipe wall of the large-diameter steel pipe. The running direction is adjusted through an electric cylinder when the difference of pressure values measured by two tension pressure sensors is large. According to the portable laser cutting auxiliary device for the large-diameter petroleum or natural gas transportation steel pipe, disassembling, transportation and carrying are convenient, the device is suitable for field operation, labor is saved, the labor intensity is relieved, the size accuracy is improved, the cut surface is neat, the working efficiency is improved, intelligent and automatic welding equipment can be adopted, and the working efficiency and the welding quality of the whole engineering are improved.

Owner:山东大图数控设备有限公司

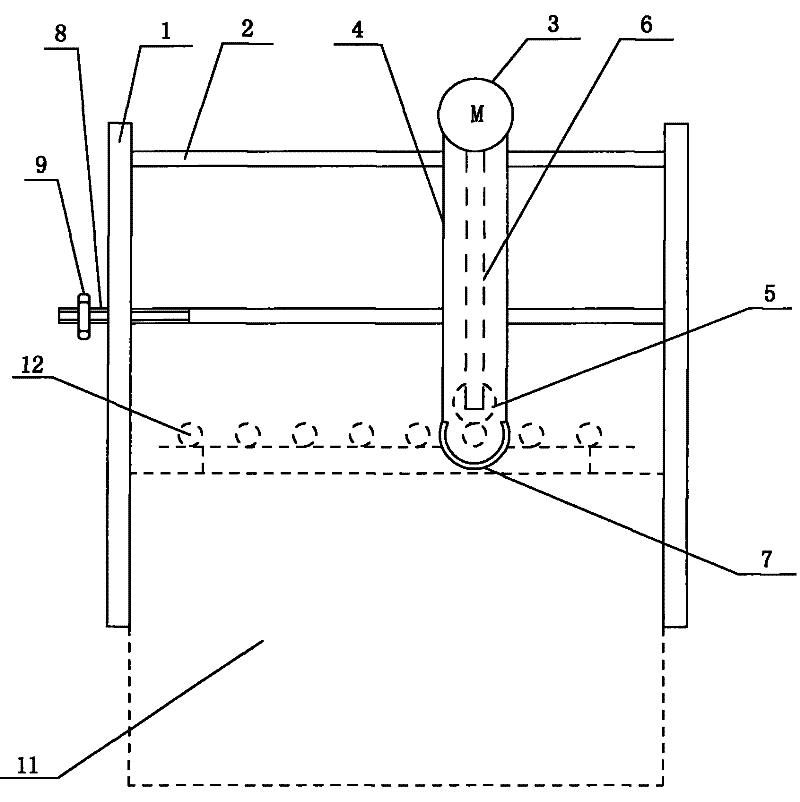

Stainless steel tube cutting machine

InactiveCN104588760ANeat cutting surfaceSimple structureTube shearing machinesShearing machine accessoriesManufacturing technologyEngineering

The invention relates to the technical field of manufacturing of stainless steel tubes, in particular to a stainless steel tube cutting machine. The stainless steel tube cutting machine comprises a machine frame, a bottom plate, a cutting mechanism and a clamping mechanism. A first cylinder is fixed on the machine frame, and a piston rod of the first cylinder is connected with one end of the bottom plate and drives the bottom plate to slide on the machine frame. The cutting mechanism and the clamping mechanism are arranged on the bottom plate, and the cutting mechanism is mainly composed of a motor, a cutting wheel and a second cylinder. The stainless steel tube cutting machine is simple in structure and rapid and convenient to use, the cutting faces of stainless steel tubes are tidy and free of burrs, and working efficiency is improved greatly.

Owner:TIANJIN SENKUOYUAN METAL PROD

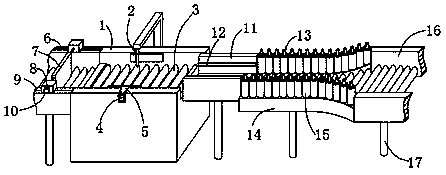

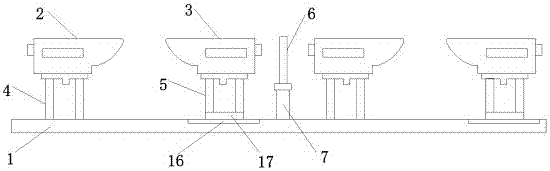

Ginger stem cutting machine

ActiveCN111791275AFast shippingEasy cutting workMetal working apparatusAgricultural engineeringSmall footprint

The invention discloses a ginger stem cutting machine, and belongs to the field of agricultural machinery. The ginger stem cutting machine is composed of a conveying device, a rotary table, a straightmoving mechanism, a steering device, a cutting device, a collecting device and a supporting table; the whole device can automatically achieve the work of ginger conveying, ginger steering, ginger stem cutting, ginger stem collecting and ginger collecting, and the labor intensity of workers is obviously relieved; the overall structure is in an L shape, the occupied area is small, and the device issuitable for ginger harvesting sites; the conveying device of the ginger stem cutting machine can convey ginger subjected to soil removal work to the rotary table, manpower is replaced with the mode,and if the ginger is manually placed on the rotary table, the hand of the worker can touch a cutter and get injured; and the conveying device composed of chains can further achieve falling of soil, and therefore subsequent work is facilitated.

Owner:福建龙植生物科技有限公司

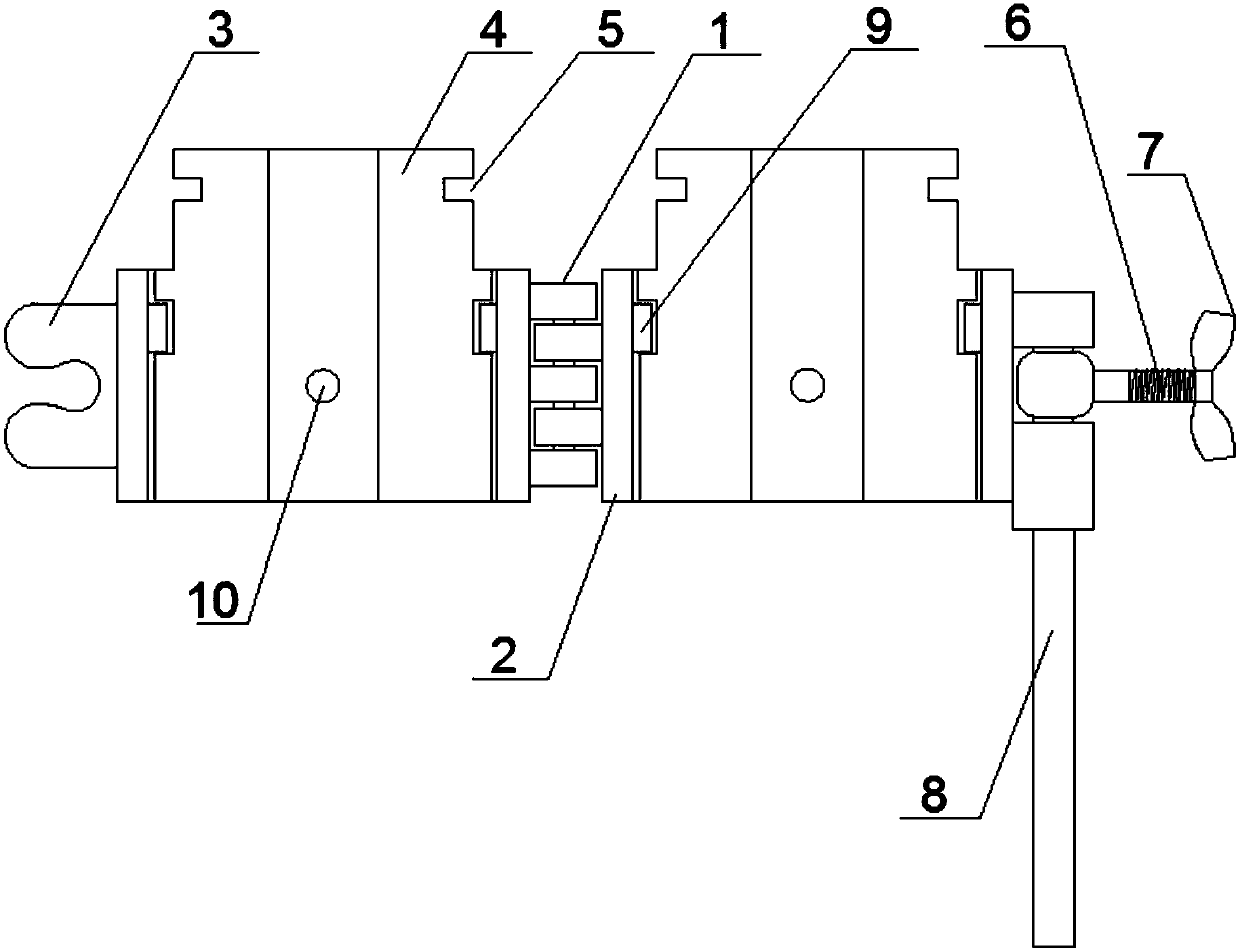

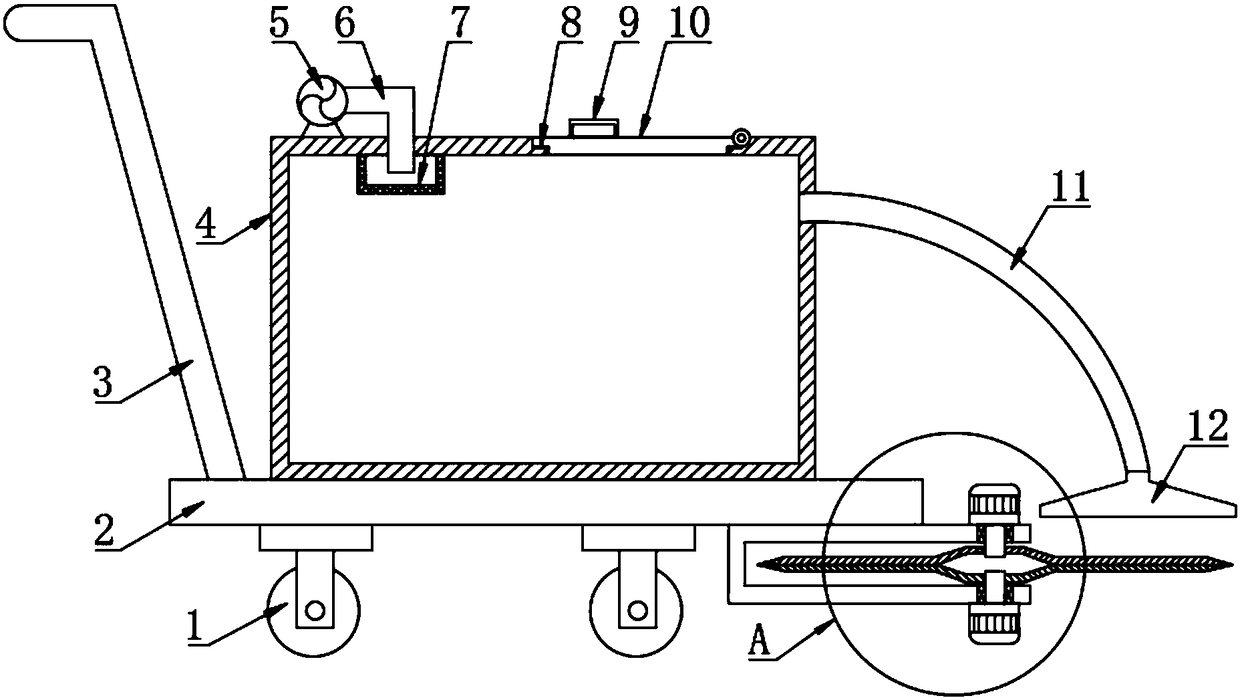

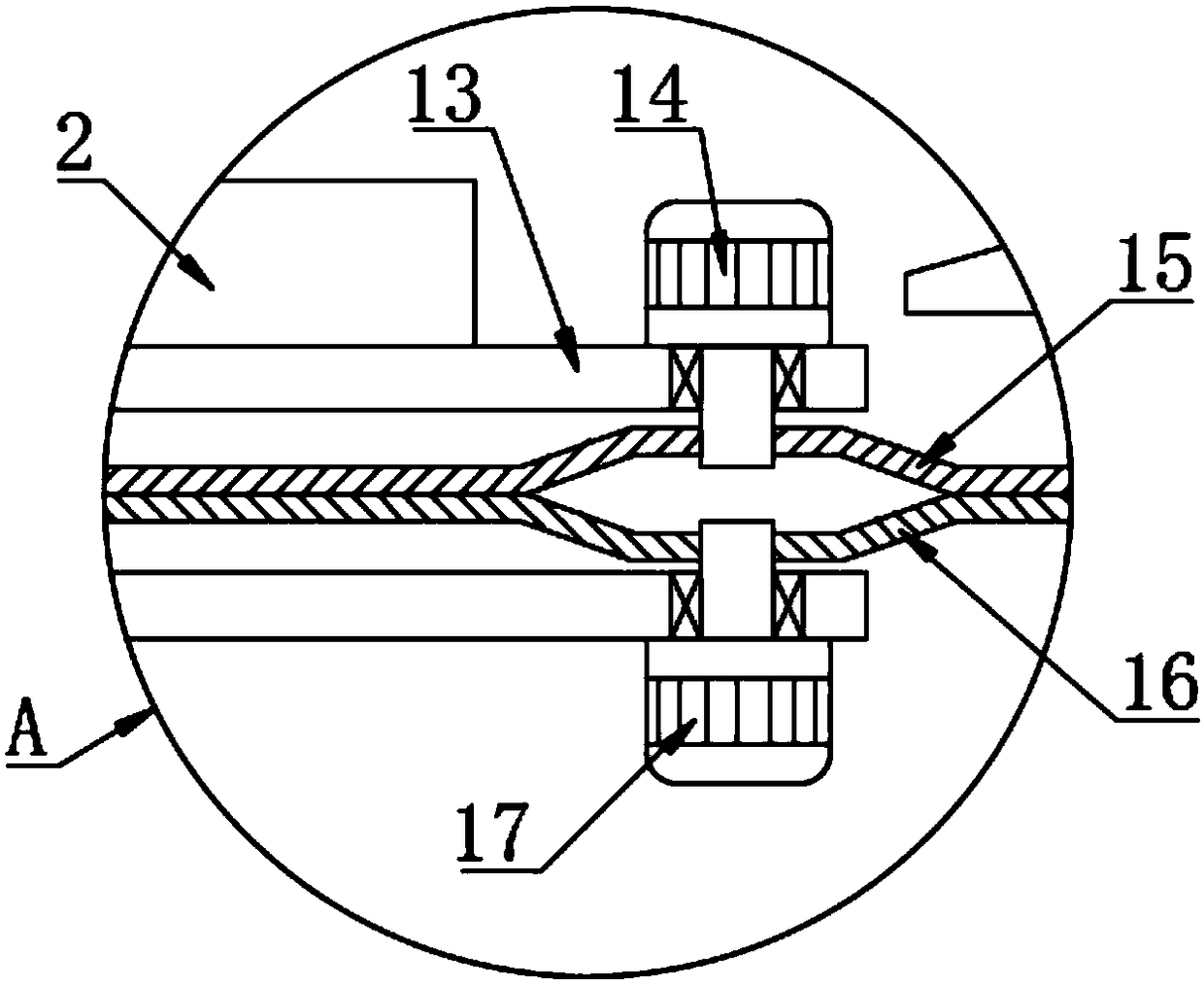

Portable LGJ-aluminum cable steel reinforced positioning holder

InactiveCN107947011ANeat cut surfaceAvoid looseApparatus for joining/termination cablesFastenerAluminium

The invention discloses a portable LGJ-aluminum cable steel reinforced positioning holder, and belongs to the technical field of power construction equipment. The device comprises two petal semi-annular positioning mode buckles which are hinged by a hinge shaft, wherein connection seats are respectively arranged at free ends of the positioning mode buckles, the two connection seats are fastened toform a whole by a fastening piece, semi-annular positioning modes are respectively fixed in the positioning mode buckles, the radius of an outer side surface of each positioning mode is equal to theradius of an inner side surface of each positioning mode buckle, the radius of an inner side surface of each positioning mode is equal to the radius of a steel core aluminum stranded wire, ends of thepositioning modes protrude out of the positioning mode buckles, and one of the positioning modes is used for fixing a groove of a turntable-type cuter cam. When a turntable-type cutter is used for cutting an outer-layer aluminum wire of the steel core aluminum stranded wire in a rotation way, the aluminum wire of a cross section of the end of the aluminum stranded wire of the positioning holder can be enabled not to be scattered, smooth twisting texture of the original wire is maintained, burr and crimping are prevented, the positioning holder is accurate and convenient to operate, and the construction quality is ensured.

Owner:STATE GRID CORP OF CHINA +2

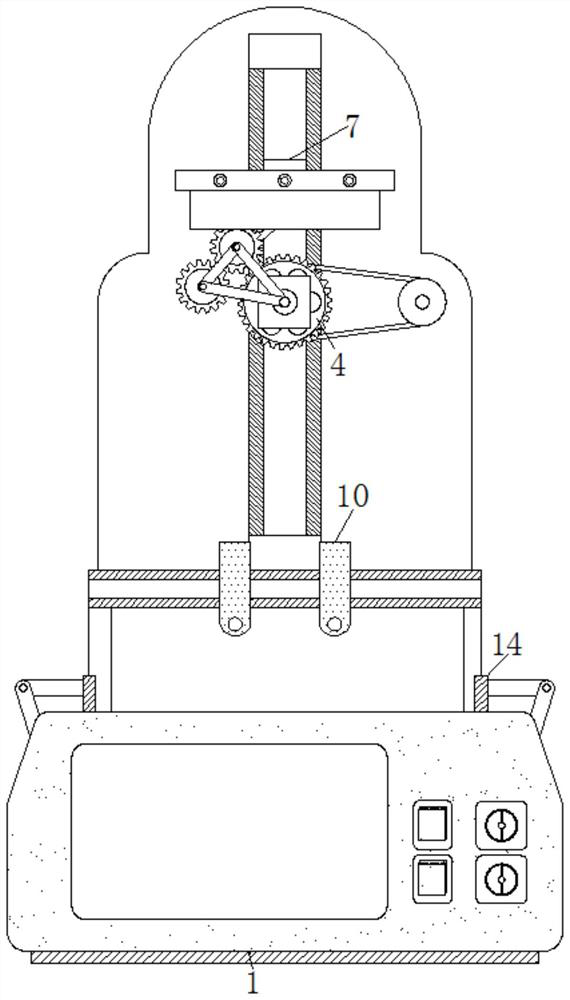

Printing paper cutting device capable of ensuring quantitative cutting and smoothing printing paper

InactiveCN111687897ASame sizeGuaranteed uniformityMetal working apparatusReciprocating motionIndustrial engineering

The invention relates to the technical field of printing, and discloses a printing paper cutting device capable of ensuring quantitative cutting and smoothing printing paper. The printing paper cutting device capable of ensuring the quantitative cutting and smoothing the printing paper comprises a base, the base is used for supporting and stabilizing the whole device, and a second gear, a third gear, a first connecting rod and a moving block match for use, so that a moving block is used for driving a cutting knife to do reciprocating motion to quantitatively cut the paper, it is guaranteed that the size of the cut paper is consistent, the uniformity of products is guaranteed, through cooperative use of a first gear, a first sliding sleeve, a second connecting rod and a smoothing block, thepaper can be smoothened when the printing paper is cut, the flatness of the paper is guaranteed, the situation that creases exist in a cutting process and influence the cutting effect is prevented, through cooperative use of a second sliding sleeve, a first supporting rod, a second supporting rod and a clamping plate, it is guaranteed that the folded paper is kept stable through the clamping plate when the paper is cut, and therefore shaking generated in the paper cutting process is avoided, and the cutting face is more neat.

Owner:熊浩浩

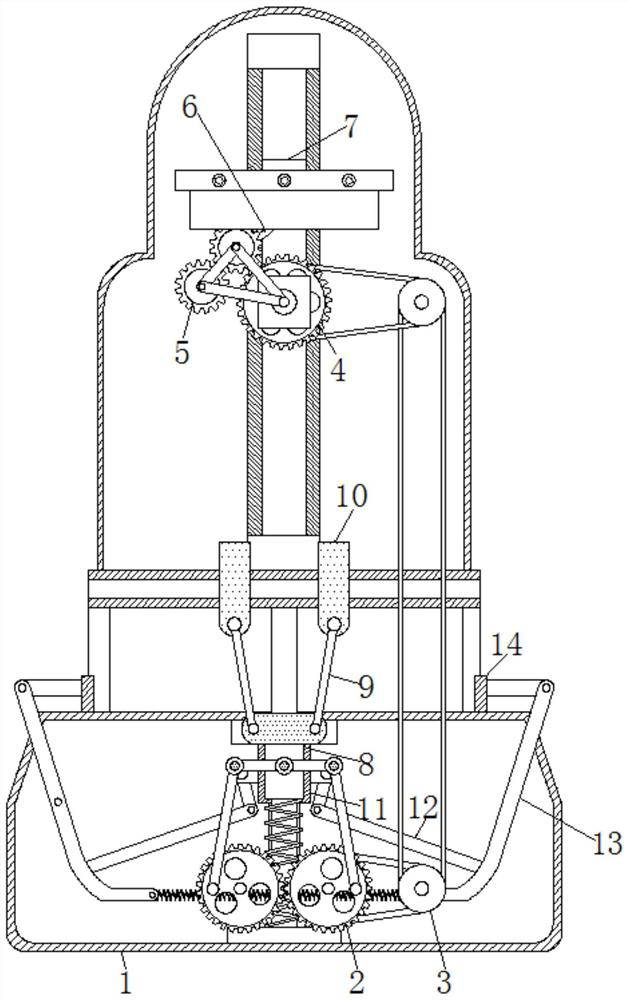

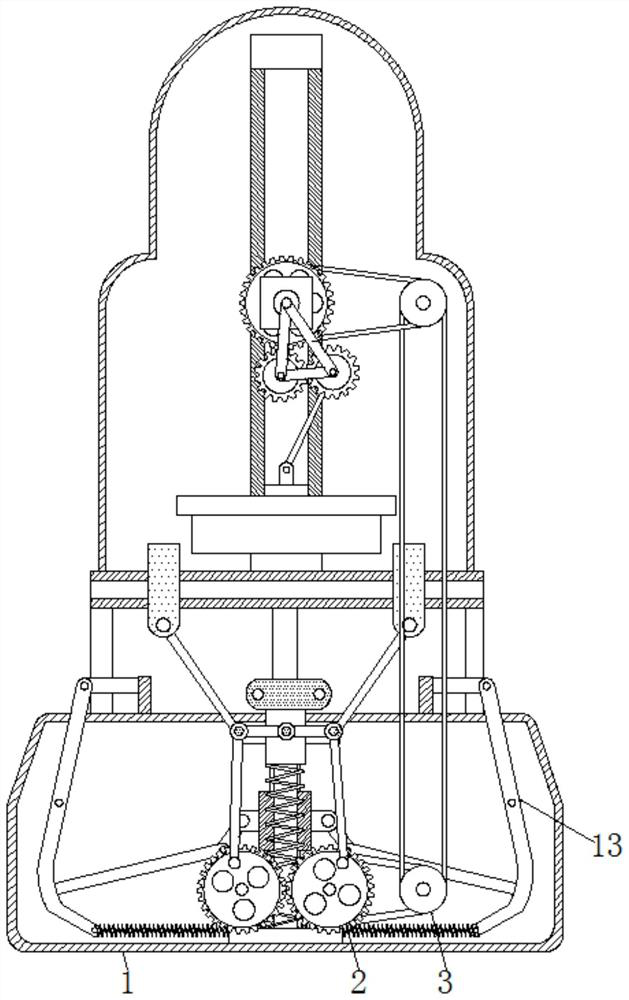

Garden weeding device with cut grass collecting function

The invention discloses a garden weeding device with a cut grass collecting function. The garden weeding device with the cut grass collecting function comprises a base, the right of the bottom of thebase is fixedly connected with a U-shaped plate, the top of the U-shaped plate is fixedly provided with a first reducing motor, and the motor shaft at the bottom end of the first reducing motor penetrates through the top of the U-shaped plate and is fixedly connected with an upper cutter; the bottom of the U-shaped plate is fixedly provided with a second reducing motor, and the motor shaft at thetop end of the second reducing motor penetrates through the U-shaped plate and is fixedly provided with a lower cutter; the top of the base is fixedly provided with a collecting tank, the top of the right wall of the collecting tank is fixedly connected with an elbow, which is communicated with the collecting tank and arranged on the right upper side of the upper cutter; the top left of the collecting tank is fixedly provided with a draught fan, and the right air inlet of the draught fan is connected with an air inlet pipe. The garden weeding device with the cut grass collecting function achieves a shear type weeding mode through the cutters rotating in opposite directions, so that the cut surface can be relatively orderly, and the cutters are low in rotating speeds and accordingly avoid splashing of cut grass; the top of the cutters is provided with a wind cover, and the cut grass is collected through air drafting by the draught fan.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

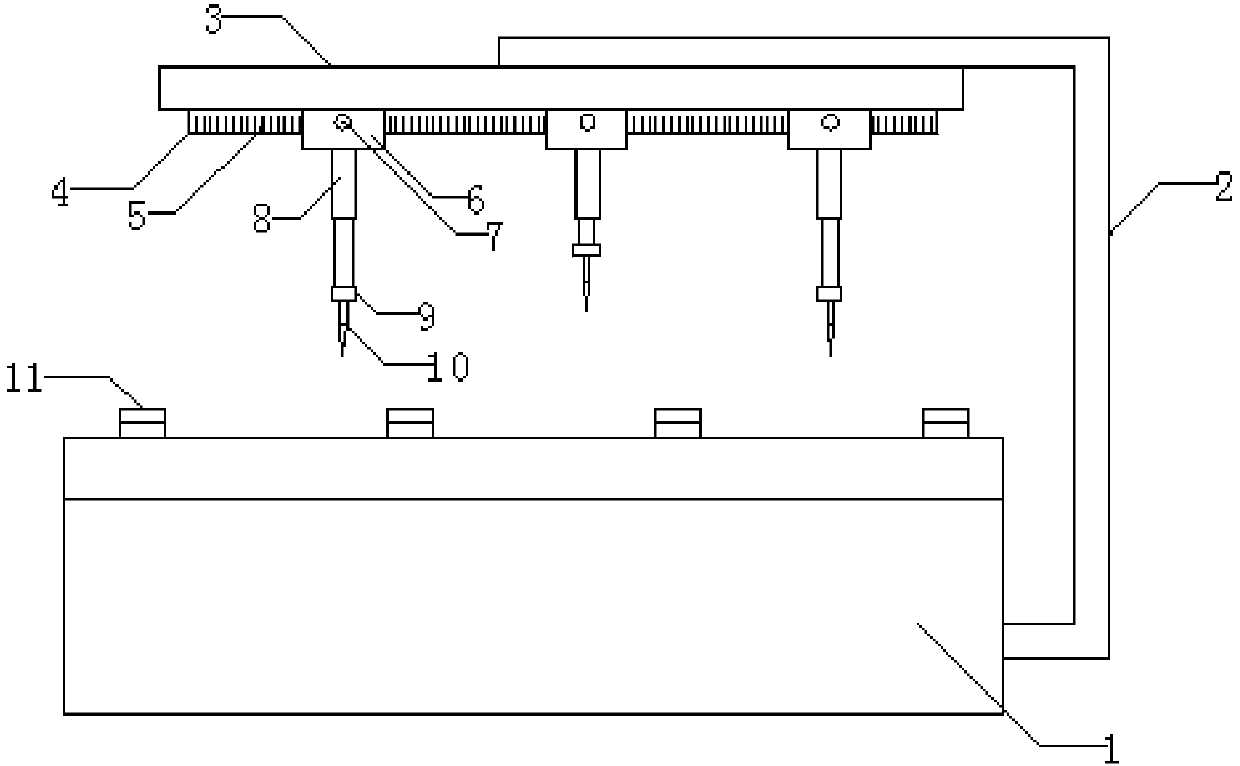

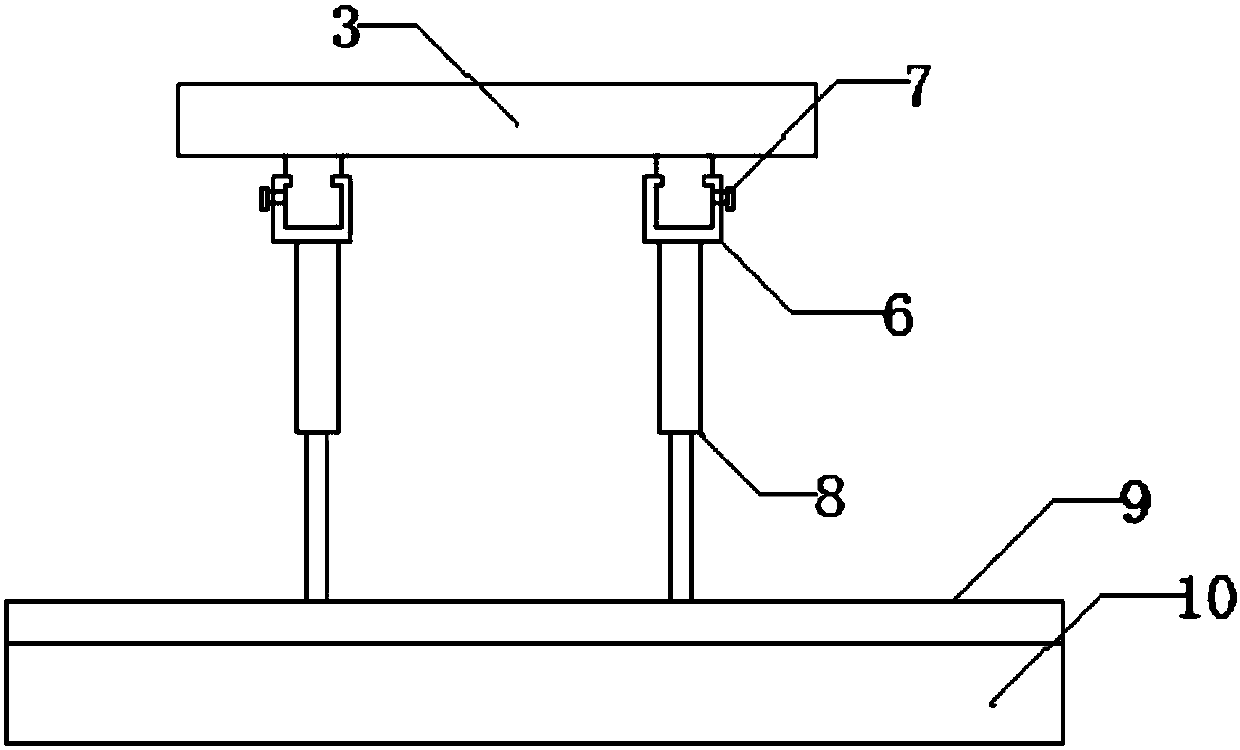

Novel data line cutting device

The invention provides a novel data line cutting device. A top plate is arranged over a cutting table through a support, a sliding rail is arranged at the bottom end of the top plate, length scales are marked on the sliding rail, at least two sliding blocks are arranged on the sliding rail, and aer in sliding connection with the sliding rail, a fastening bolt used for positioning is arranged on each sliding block, an air cylinder is arranged at the bottom end of each sliding block, a cutter holder is fixed to the tail end of an air cylinder piston rod, a cutting cutter plate is assembled on each cutter holder, multiple clamps are arranged at the top end of a cutting table, each clamp comprises a lower clamping base on the lower and an upper clamping plate arranged on the upper, one end ofeach lower clamping base and one end of the corresponding upper clamping plate are hinged through a hinge part, a buckle fixing structure and a buckle structure are arranged at the corresponding positions of the other ends of each lower clamping base and the corresponding upper clamping plate, multiple lower containing grooves are formed in the lower clamping bases, multiple upper containing grooves are formed in the upper clamping plate, and holes capable of containing data lines to penetrate are formed by the upper containing grooves and the lower containing grooves. The device has the beneficial effects of being high in work efficiency and high in use flexibility.

Owner:TIANJIN OULIN ELECTRONICS

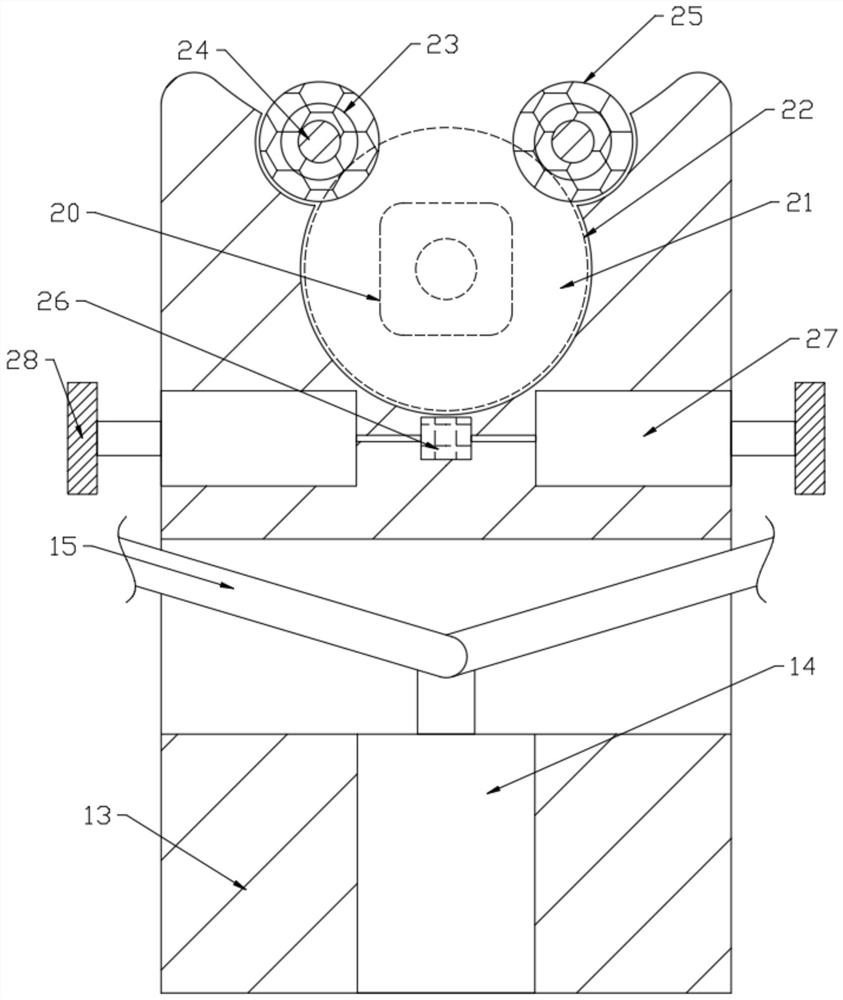

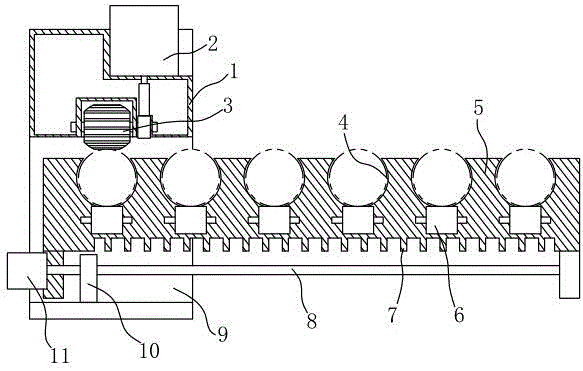

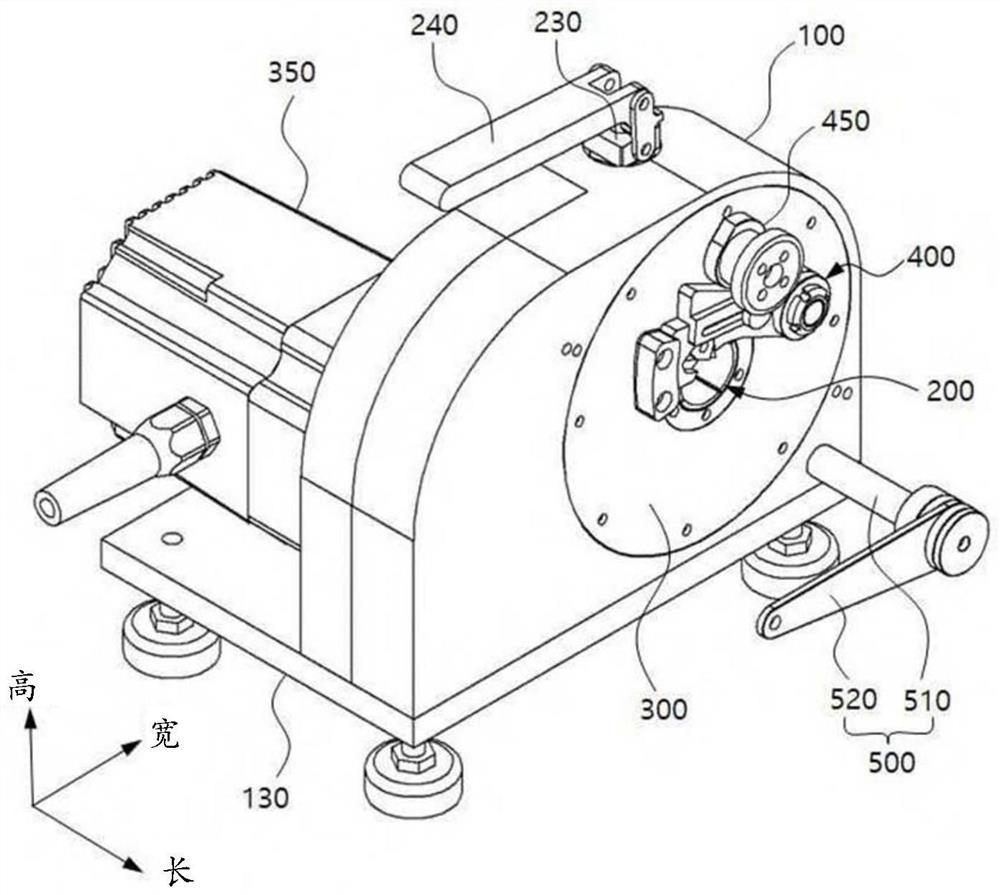

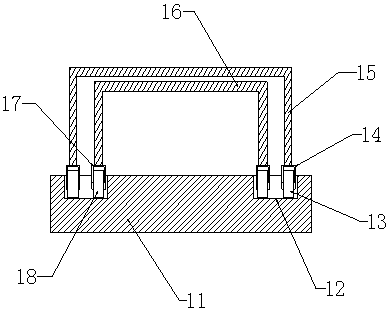

Mechatronic pipe fitting cutting device

ActiveCN112222520AGuaranteed normal rotationNeat cutting surfaceTube shearing machinesShearing machine accessoriesGear drivePipe fitting

The invention discloses a mechatronic pipe fitting cutting device. The cutting device comprises a frame body, wherein a cutting assembly used for cutting a pipe fitting is arranged at the upper end inthe frame body, fixing bases are fixedly connected to the two sides in the frame body respectively, fixing assemblies used for fixing the pipe fitting are arranged on the fixing bases, a stand columnis arranged at the lower end of the frame body, a driving assembly used for driving the fixing assemblies to work is arranged in the frame body, a rotating assembly for driving the pipe fitting to rotate is arranged in the stand column, and a failure assembly for driving the fixing assemblies to temporarily fail is arranged in the frame body. According to the cutting device, a second motor drivesa driving gear to rotate, then driven gears meshed with the driving gear drive rotating shafts to rotate, the rotating shafts rotate to enable rotating rollers to drive the pipe fitting to rotate after primary cutting, an inductor drives electric push rods to drive contact blocks to apply pressure to vertical columns during operation of the second motor, and then the clamping work of clamping blocks fails through moving columns under the action of springs, rotation of the pipe fitting is guaranteed, and then the cut face of the pipe fitting is neat without burrs after cutting.

Owner:ZHUZHOU HUAXIN PRECISION IND

Glass tube cutting mechanism

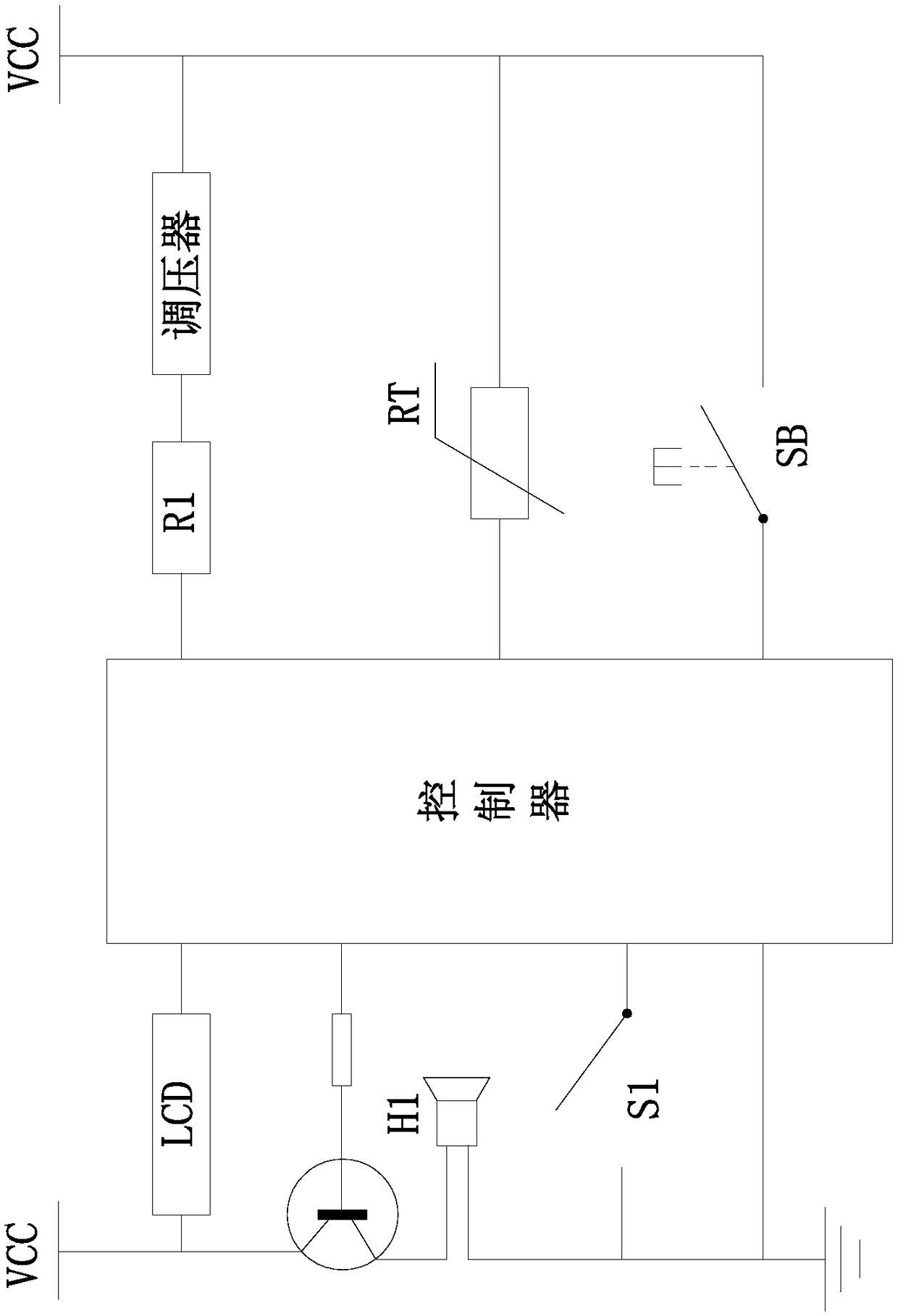

InactiveCN108793717ASolve the explosiveEasy to control temperatureGlass severing apparatusVoltage regulationElectric heating

Owner:爱克斯瑞真空技术(苏州)有限公司

Novel plastic pipe cutting machine

PendingCN108214608AFlat cutting surfaceNeat cutting surfaceMetal working apparatusEngineeringMechanical engineering

The invention relates to a novel plastic pipe cutting machine, which comprises a working table. A rotary shaft, a rotary motor and a clamping sleeve are arranged on the upper part of the working table; one end of the rotary shaft is connected with a cutting sleeve pipe; the cutting sleeve pipe is a tubular shell with one sealed end; and the center of the sealed end of the cutting sleeve pipe is connected with the end part of the rotary shaft. According to the novel plastic pipe cutting machine provided by the invention, a cutter is utilized for circumferentially cutting a macromolecule pipe, so that compared with saw blade cutting, a cutting surface of the macromolecule pipe cut by using the cutter is smoother, and the occurrence of the phenomenon of excessive coarseness is avoided. With an inclined surface of a taper sleeve, horizontal sliding of the taper sleeve is converted into up-and-down movement of a movable sliding block, so that the sufficient pressure can exist between the cutter and the macromolecule pipe, and the cutter can conveniently cut the macromolecule pipe.

Owner:JINAN SOARING ABRASION PROOF MATERIAL

Stainless steel pipe cutting machine capable of reducing kerf burrs

InactiveCN111215685ANeat cutting surfaceSimple structureFeeding apparatusTube shearing machinesElectric machinerySS - Stainless steel

The invention relates to the technical field of stainless steel pipe manufacturing, in particular to a stainless steel pipe cutting machine capable of reducing kerf burrs. The machine comprises a rack, a bottom plate, a cutting mechanism and a clamping mechanism, wherein a first air cylinder is fixed on the rack, a piston rod of the first air cylinder is connected with one end of the bottom plateto drive the bottom plate to slide on the rack, the cutting mechanism and the clamping mechanism are arranged on the bottom plate, and the cutting mechanism is mainly composed of a motor, a cutting wheel and a second air cylinder. The machine is simple in structure, rapid and convenient, a cutting face of a stainless steel pipe is neat and free of burrs, and the working efficiency is greatly improved.

Owner:湖南超宇科技有限公司

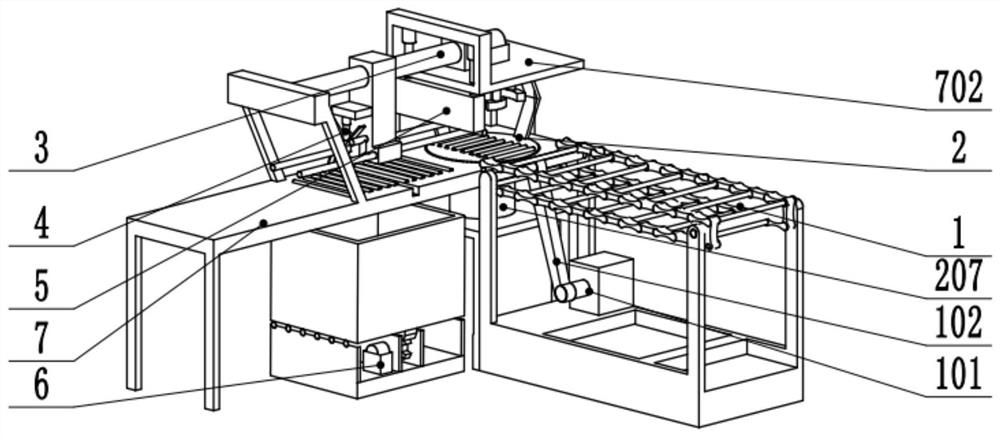

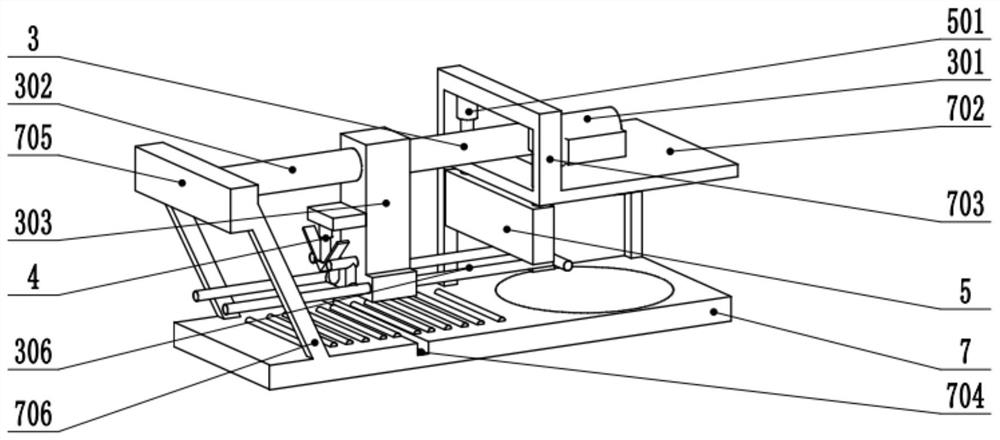

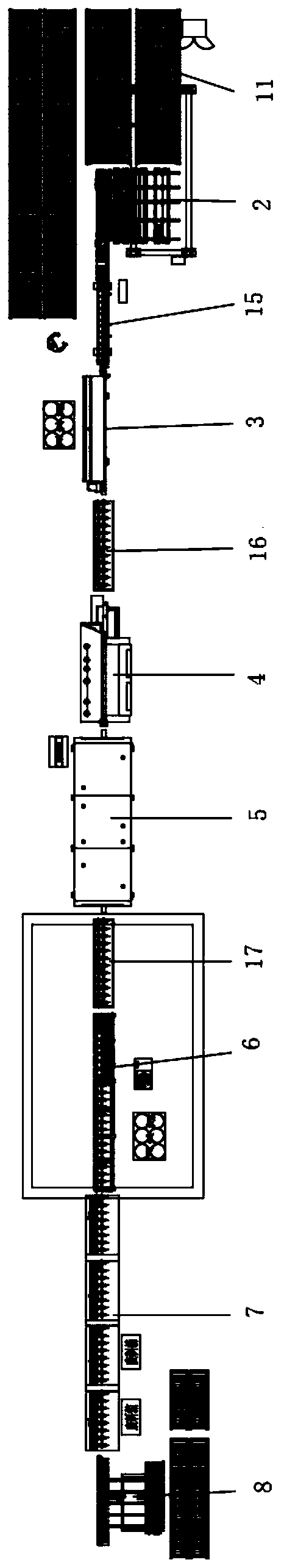

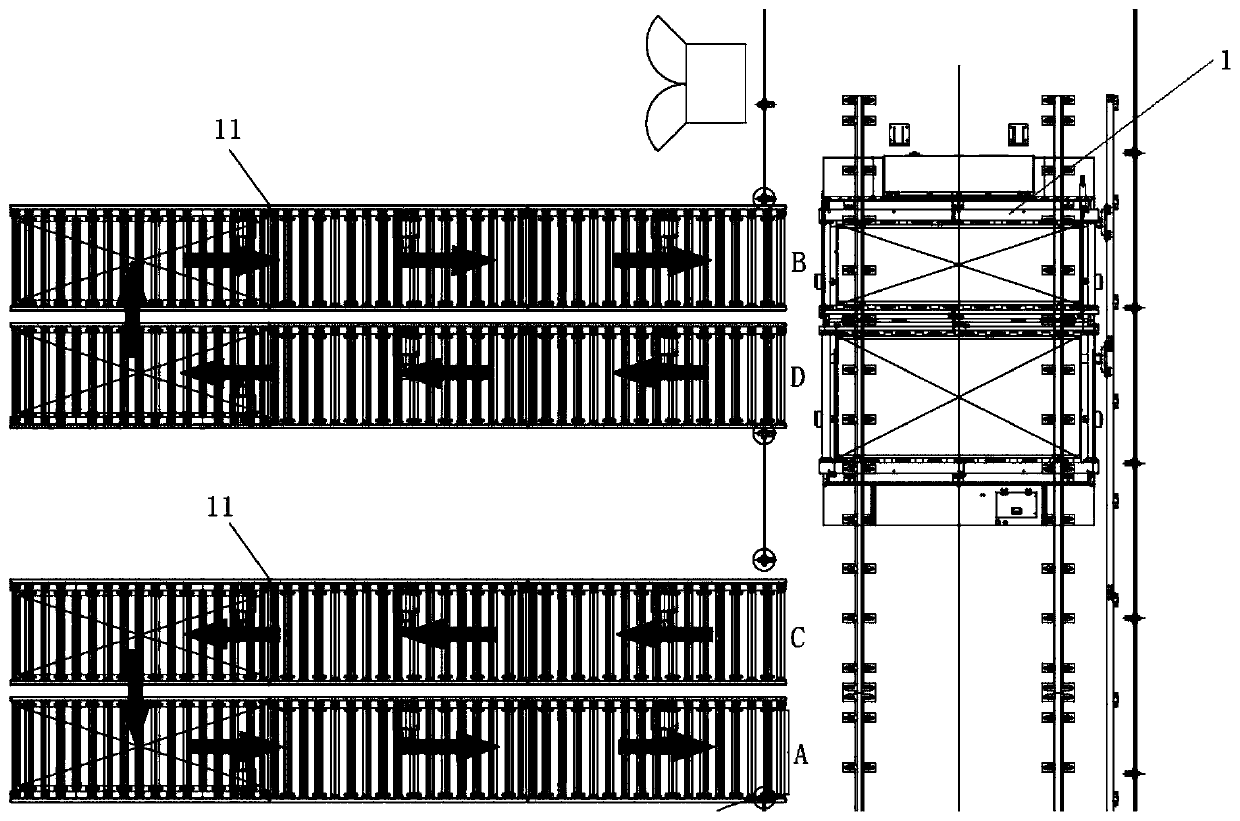

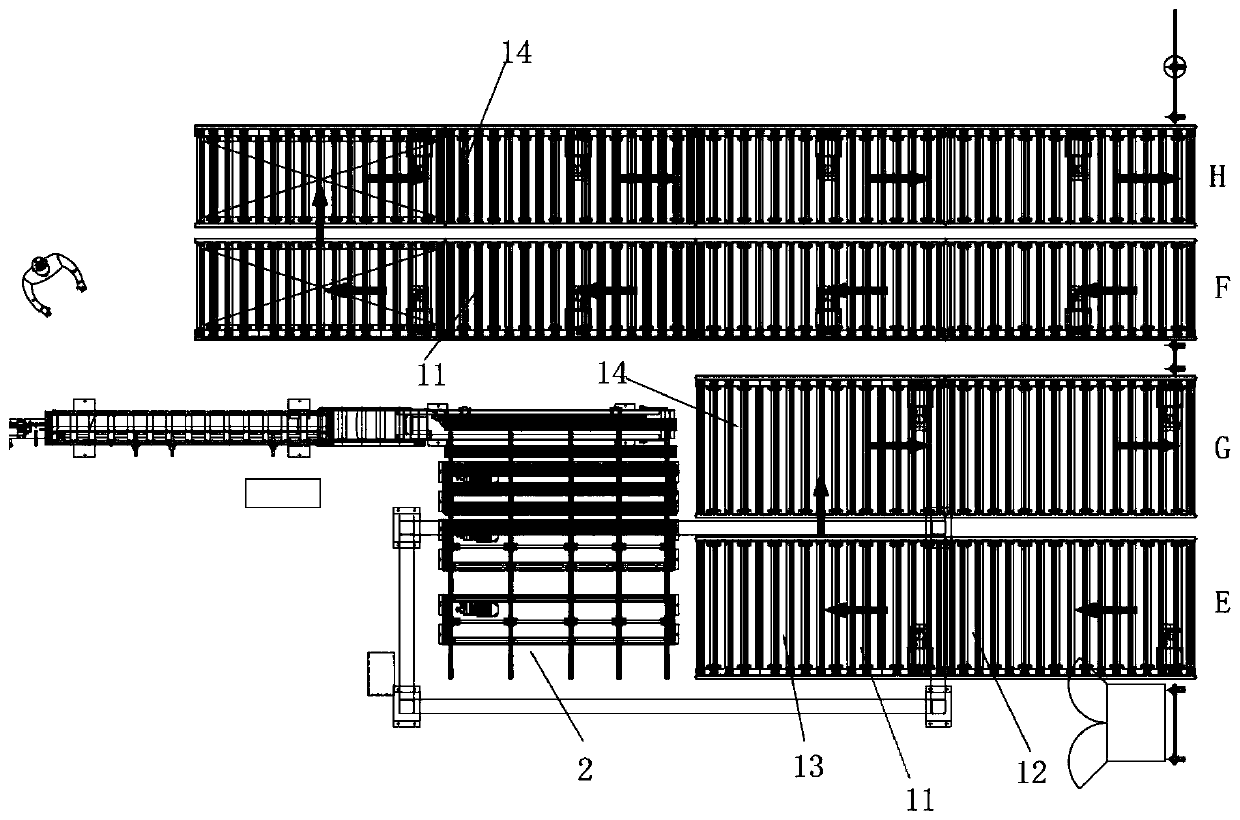

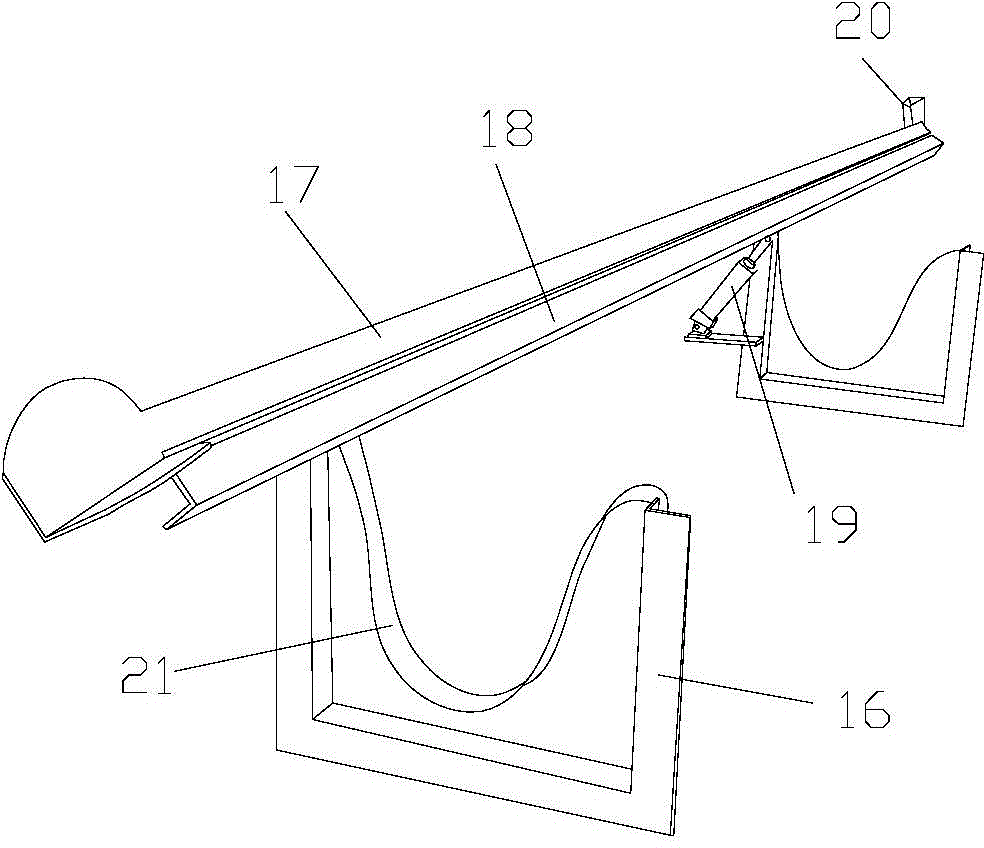

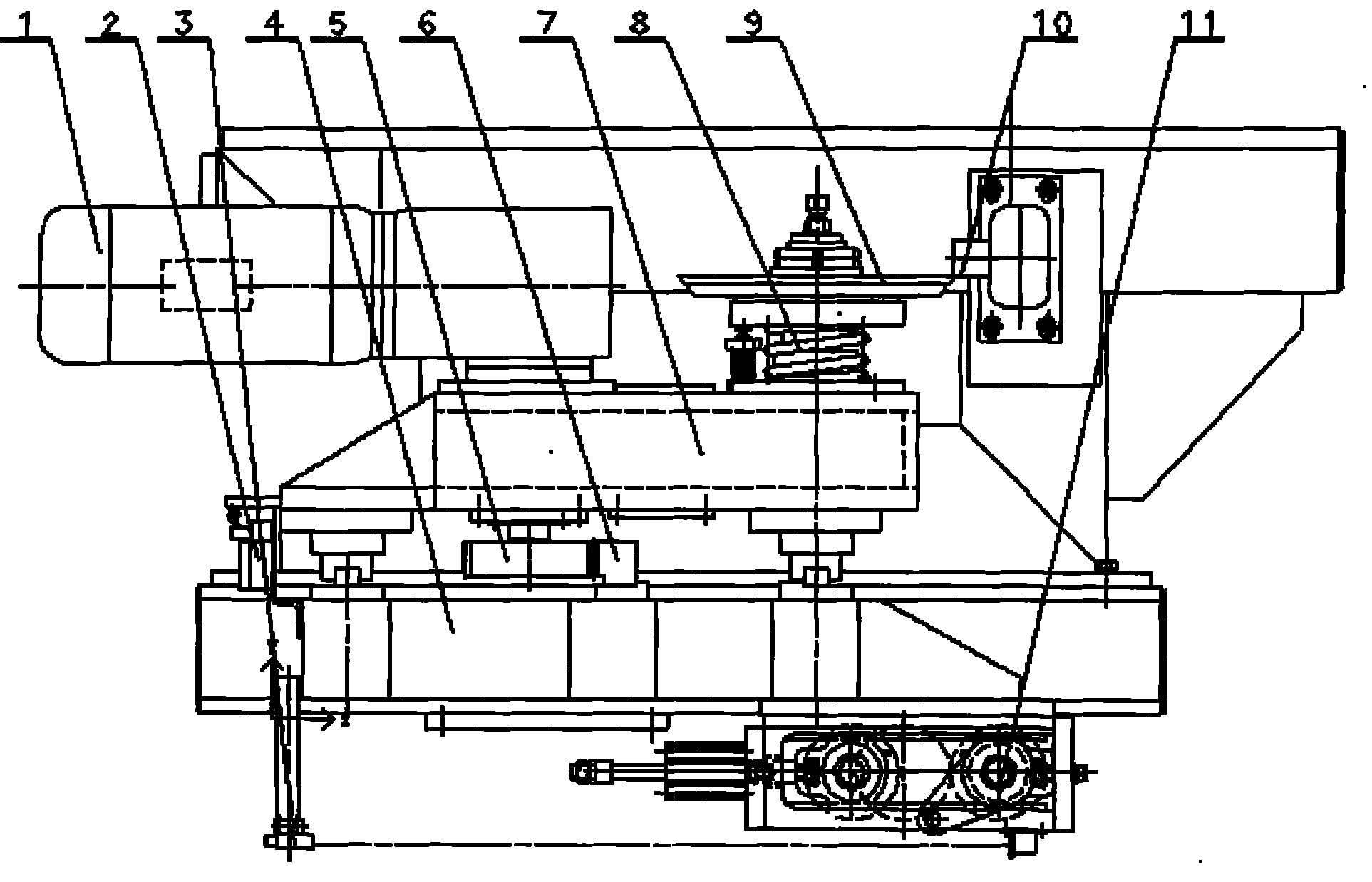

Intelligent line production system and cutting process thereof

InactiveCN110181605AHigh degree of automationIncrease productivityConveyorsWood veneer joiningProduction lineAutomation

The invention relates to the technical field of wood door line production, and aims to provide an intelligent line production system and a cutting process thereof. The characteristic of being automatic, high in intelligent degree, high in production efficiency and low in labor cost are achieved. The intelligent line production system comprises material conveying equipment and a feeding machine, aline laminating machine, a five-shaft four-side planing machine, a line sanding machine, a line wrapping machine, a cutting machine and a discharging machine sequentially connected with a production line, wherein the cutting machine comprises four groups of tracking cutting devices connected with each other, saw blade angle of the first group of tracking cutting devices is 45 degrees, saw blade angle of the second and third groups of tracking cutting devices is 90 degrees, and the saw blade angle of the fourth group of tracking cutting devices is +45 degrees. The intelligent line production system solves the problems of low automation degree, low intelligent degree, low production efficiency and high labor cost in the prior art.

Owner:江山花木匠家居有限公司

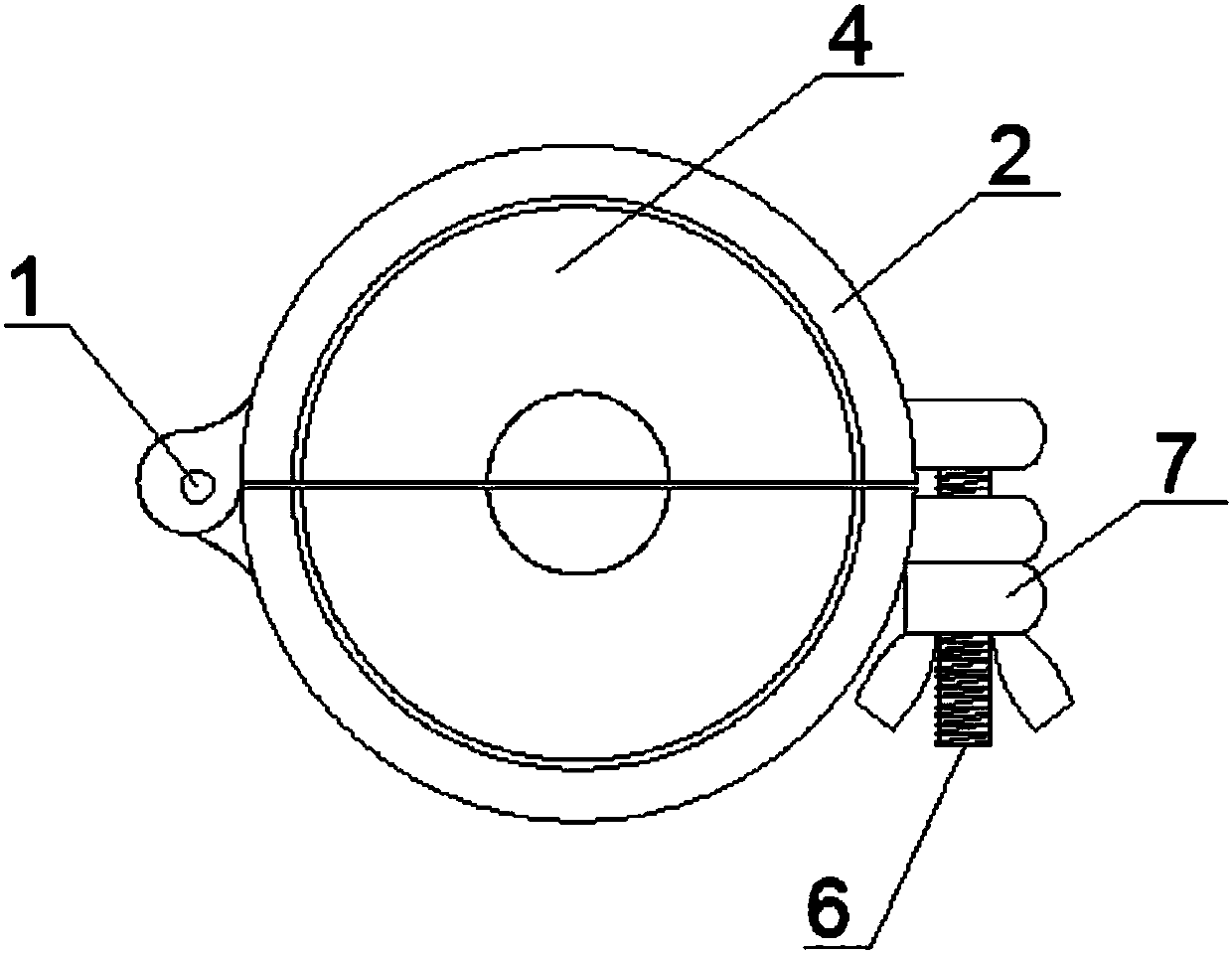

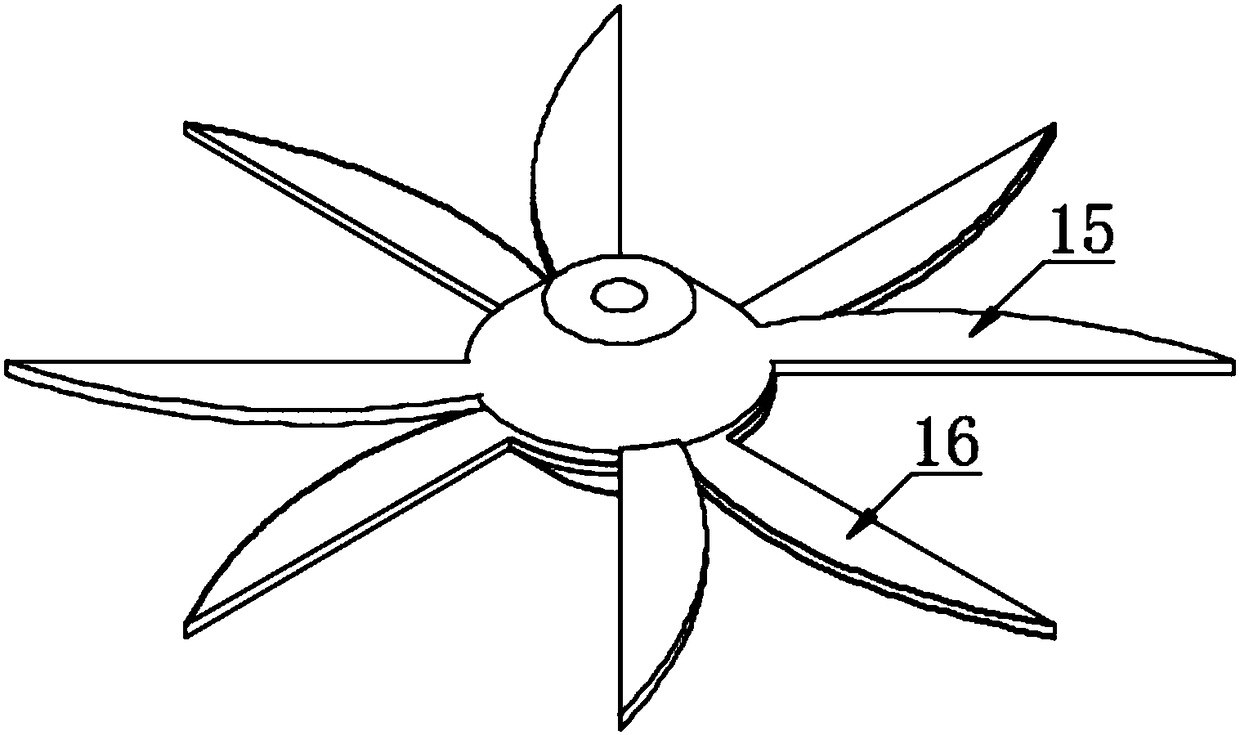

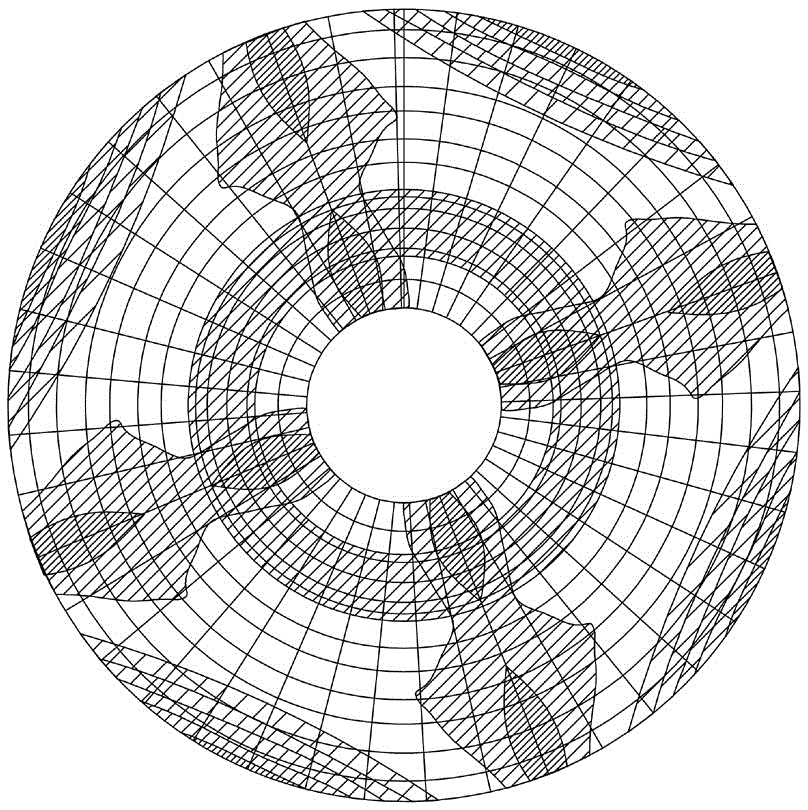

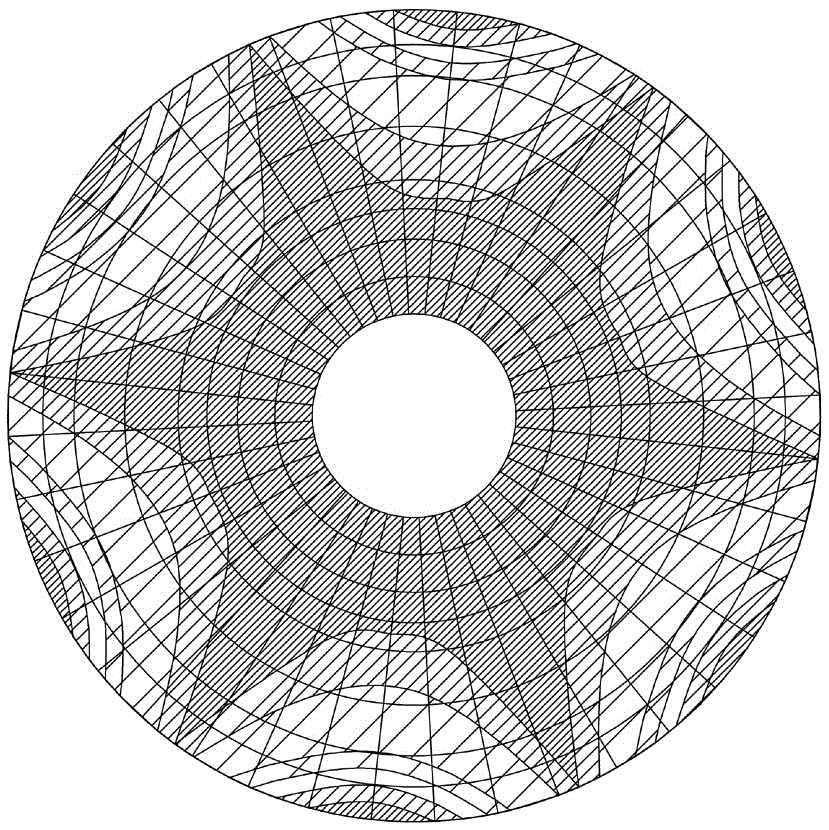

A circular blade applied to ultrasonic machining and its design method

InactiveCN103111645BReduce scrap rateNeat cutting surfaceMilling cuttersTurning toolsElement analysisResonance

The invention discloses a circular blade applied to ultrasonic machining and a method for designing the circular blade, and belongs to the technical field of ultrasonic cutters and methods for designing the same. Through grooves are radially and uniformly distributed on the circular blade, and the quantity of the through grooves is an even number. The method includes steps of (A), computing the resonance frequency of the circular blade, creating an ANSYS model to perform finite element analysis, and computing a vibration mode of the circular blade; (B), determining pitch lines; and (C), arranging the through grooves at positions where the pitch lines are overlapped with pitch circles if the pitch circles exist, and arranging the through grooves on the pitch lines if the pitch circles do not exist. The circular blade and the method have the advantages that a cutting tip of the circular blade with the radial grooves can realize an excellent ultrasonic vibration effect, accordingly, composite materials can be precisely cut and machined, and the superiority of ultrasonic vibration machining can be embodied and realized easily.

Owner:杭州辉昂科技有限公司

Quartz glass slicing machine

PendingCN111662006AImprove clamping effectPrevent movementGlass severing apparatusEngineeringStructural engineering

The invention discloses a quartz glass slicing machine, which comprises a collecting box, a discharging opening is formed in the bottom of the front side wall of the collecting box; a driving guardrail is arranged on the left side of the top of the collecting box; a rolling guardrail is arranged on the right side of the top of the collecting box; a supporting roller is rotationally connected between the driving guardrail and the rolling guardrail; a sliding rail is arranged at the top of the driving guardrail; the top of the sliding rail is slidably connected with an electric sliding block, anair pressure telescopic rod is arranged at the top of the electric sliding block; a fixing frame is arranged at the top of the pneumatic telescopic rod; a cutting mechanism is arranged on the right side of the fixing frame; according to the quartz glass slicing machine, the problems that most of existing quartz glass slicing machines directly place quartz glass on a table top and then directly cut the quartz glass manually, the cutting uniformity cannot be guaranteed, and scraps generated by cutting directly fall on the ground and affect workshops are solved.

Owner:新沂市铭达玻璃有限公司

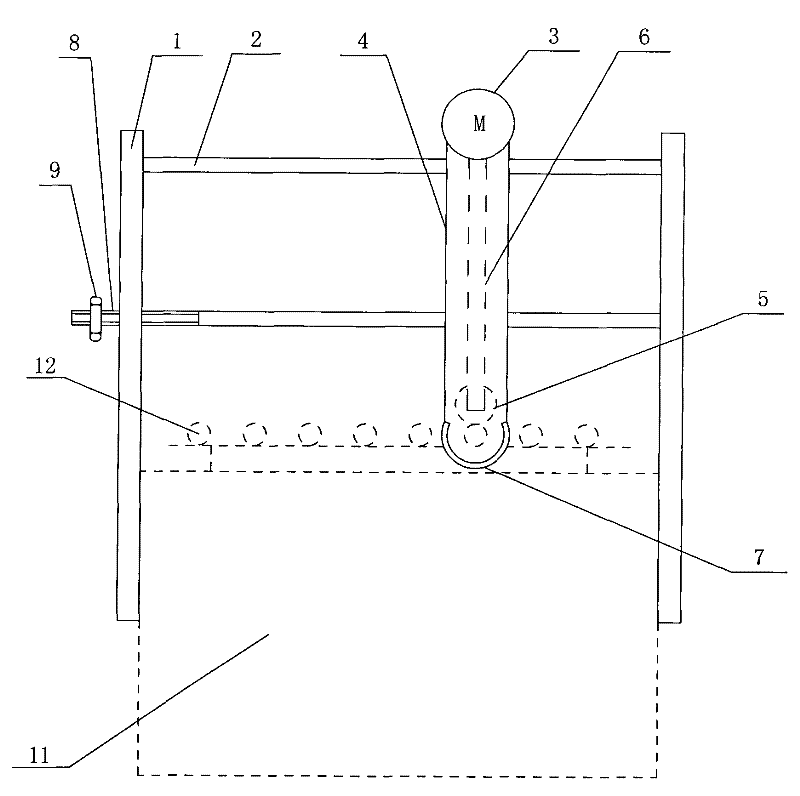

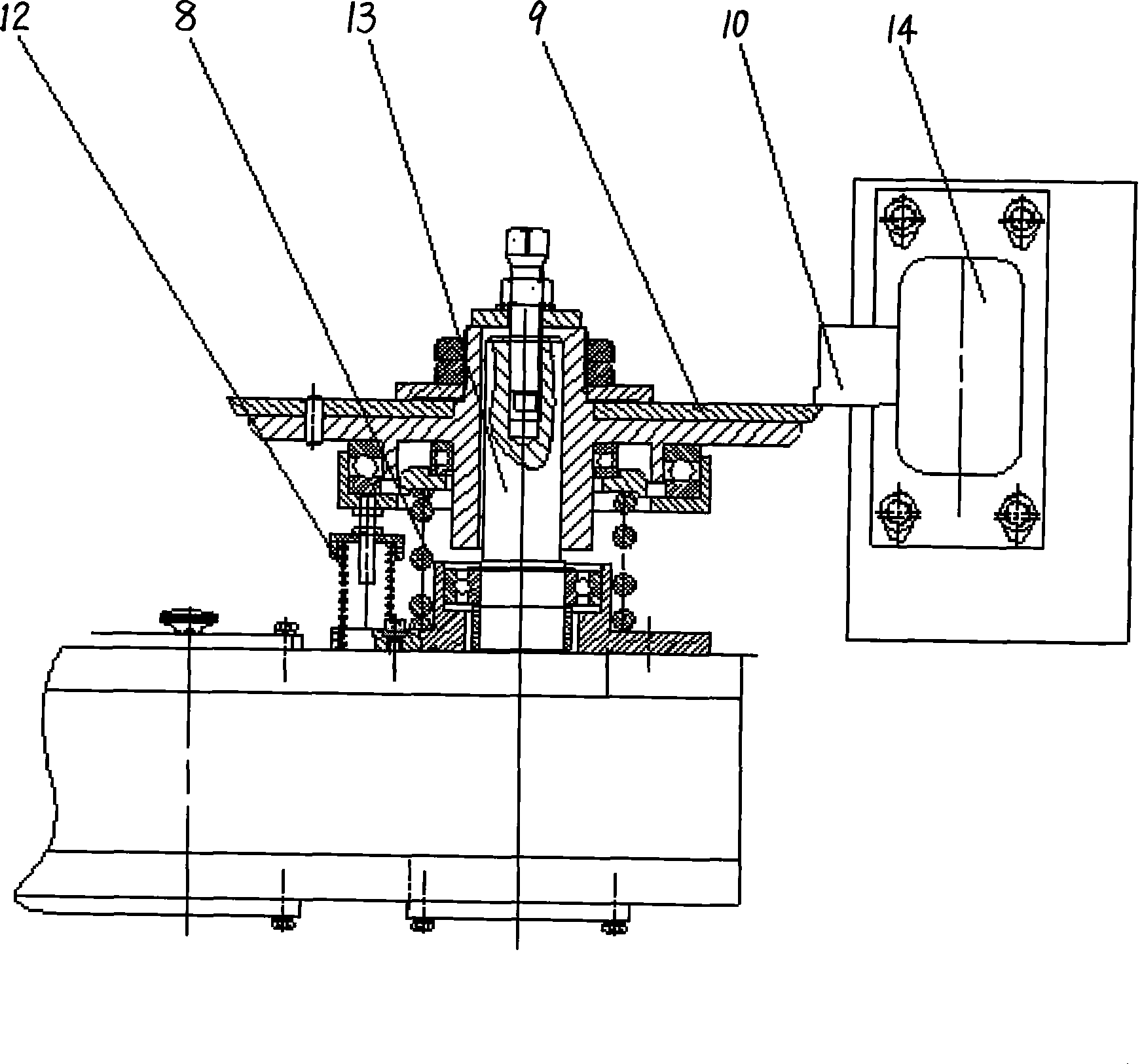

Stainless steel tube cutting and discharging system

InactiveCN104588761ANeat cutting surfaceSimple structureTube shearing machinesShearing machine accessoriesSteel tubePiston rod

The invention relates to the technical field of manufacturing of stainless steel tubes, in particular to a stainless steel tube cutting and discharging system. The stainless steel tube cutting and discharging system comprises a machine frame, a bottom plate, a cutting mechanism and a clamping mechanism. A first cylinder is fixed on the machine frame, and a piston rod of the first cylinder is connected with one end of the bottom plate and drives the bottom plate to slide on the machine frame. The cutting mechanism and the clamping mechanism are arranged on the bottom plate, and the cutting mechanism is mainly composed of a motor, a cutting wheel and a second cylinder. The stainless steel tube cutting and discharging system is simple in structure and rapid and convenient to use, the cutting faces of stainless steel tubes are tidy and free of burrs, and working efficiency is improved greatly.

Owner:TIANJIN SENKUOYUAN METAL PROD

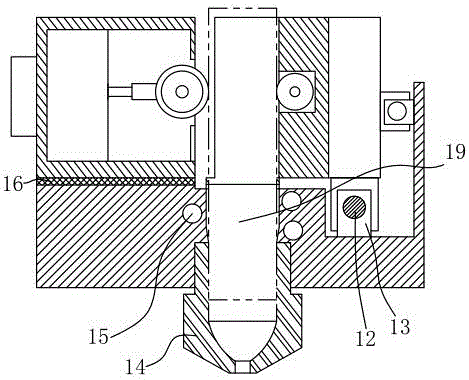

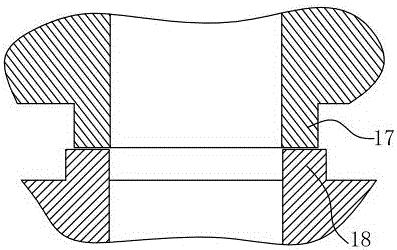

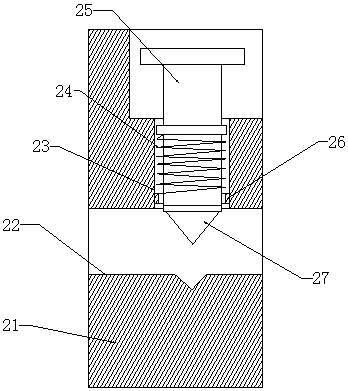

Multi-material three-dimensional printer nozzle

PendingCN106799834AAvoid separationSimple structureManufacturing heating elements3D object support structuresMulti material3D printing

The invention relates to a multi-material three-dimensional printer nozzle. The multi-material three-dimensional printer nozzle comprises a nozzle seat and a nozzle body. A clamping and conveying bin is arranged on one side of the top of the nozzle seat. A clamping and conveying motor is arranged on the clamping and conveying bin. A main clamping and conveying wheel is arranged on the clamping and conveying bin. A diversion hole is formed in the nozzle seat. Heating pipes are arranged on the nozzle seat. A guide block is arranged on the other side of the top face of the nozzle seat. Guide grooves are formed in the guide block. An opening is formed in the side, facing the clamping and conveying bin, of each guide groove. The cross section of each guide groove is in a sector shape. An auxiliary clamping and conveying wheel is arranged in each guide groove. A guide column is arranged at the bottom of the guide block. A guide sleeve is arranged on the nozzle seat. A screw and a material switching stepping motor are arranged on the side face of the guide block. A nut matched with the screw is arranged on the nozzle seat. An annular boss is arranged at the bottom of the guide block. Strip-shaped bosses are arranged on the two sides of the diversion hole in the top face of the nozzle seat. The strip-shaped bosses and the annular boss form a shearing blade. According to the multi-material three-dimensional printer nozzle, different raw materials are switched through the horizontally-moving guide block and enter the diversion hole, the structure is simple, continuous printing can be achieved, the efficiency is high, the shearing faces are level, and it is not necessary to additionally arrange heat dissipation equipment on the guide block.

Owner:苏州肯美威机械制造有限公司

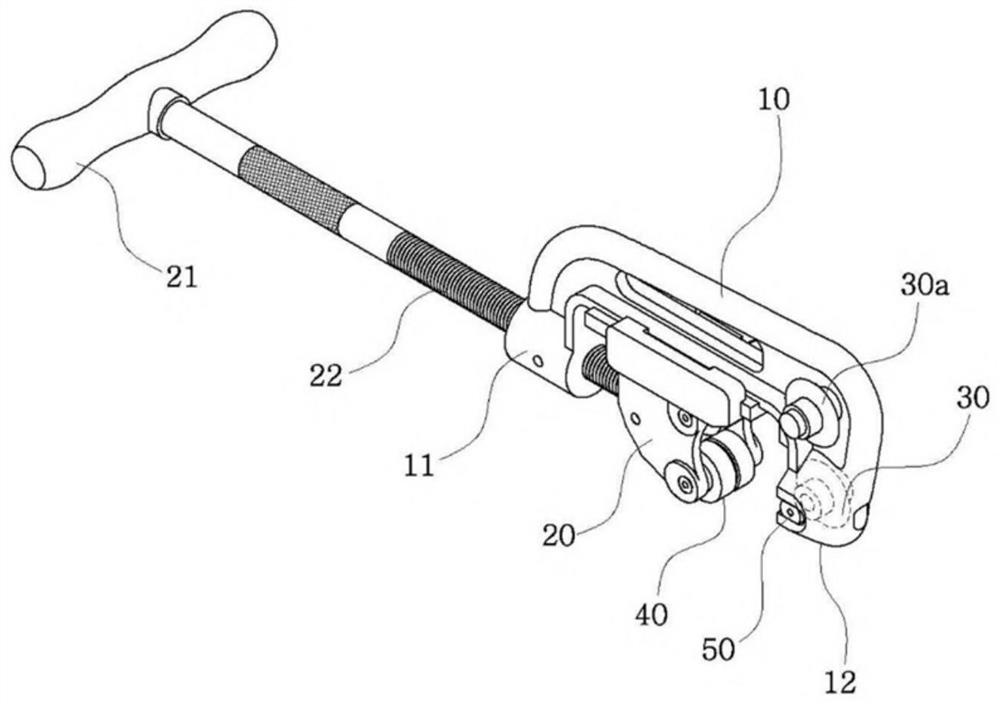

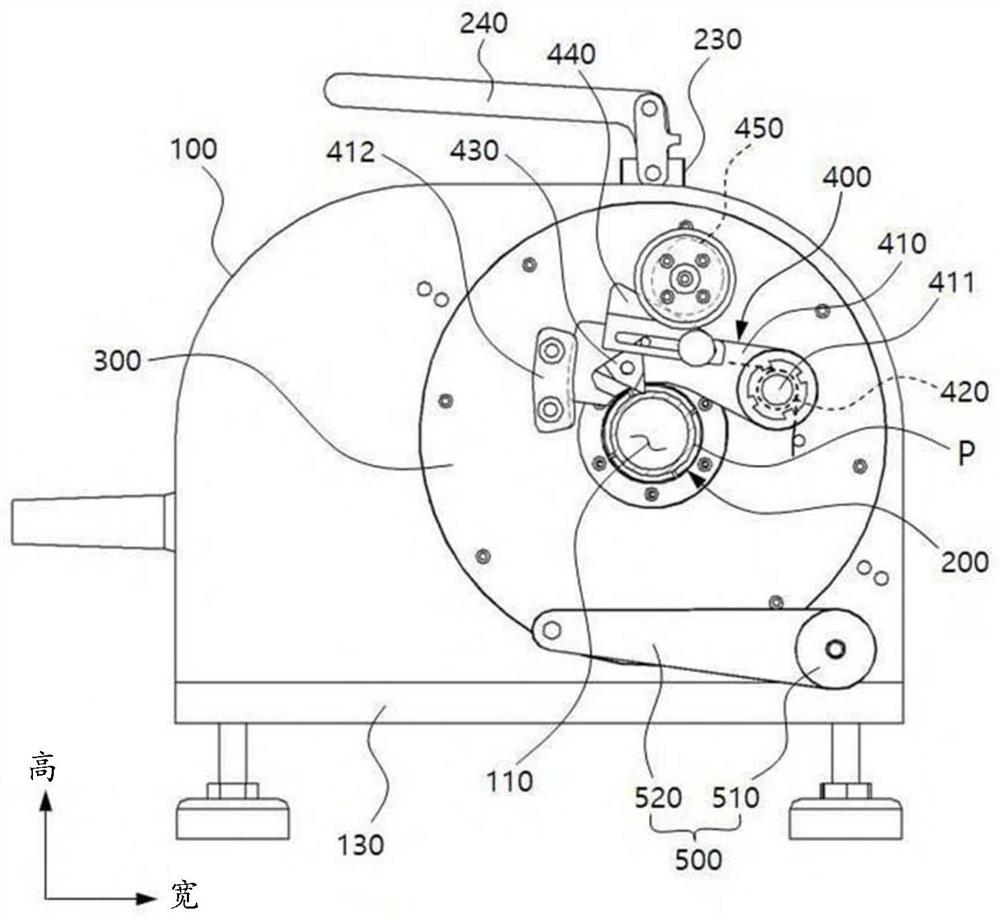

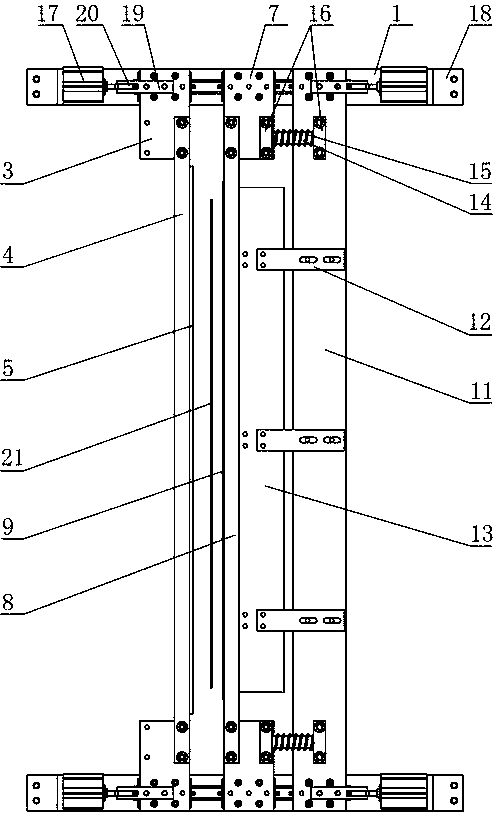

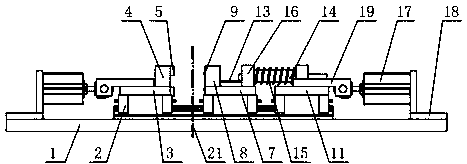

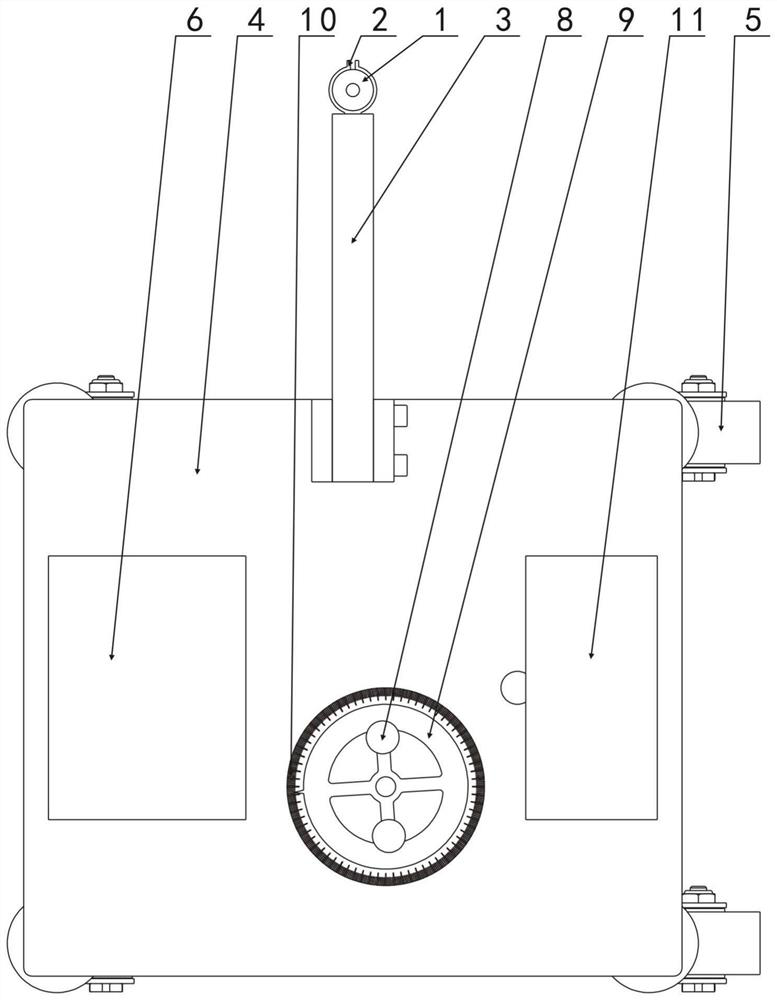

Pipe cutting device

PendingCN114473020AReduce distortionNeat cutting surfaceTube shearing machinesTurning machinesRotational axisEngineering

A pipe cutting device comprises a body, a pipe fixing part, a rotating disc, a cam and a cutting part. A tube fixing portion disposed adjacent to the hollow hole and capable of fixing a tube; a rotating disk coupled to the body so as to be rotatable about the central axis of the hollow hole, and connected to a first driving unit such that the rotating disk is controlled to rotate; a cam coupled to the rotating disk so as to be rotatable about a rotation axis at a point spaced apart from the central axis, rotating together with the rotating disk, and connected to a second drive unit so that the cam is rotationally controlled; a cutting part coupled to the rotating disk so as to rotate together with the rotating disk, and in contact with the cam, so that a cutting tip advances or retreats in the direction of the center shaft according to the rotation of the cam; the pipe cutting device can minimize the deformation of the pipe to be cut, does not need to perform additional surface processing on the cutting surface of the pipe, and can automatically cut the pipe.

Owner:DCSENG CO LTD

Efficient cutting and cooling integrated device for rubber

InactiveCN107225603AEfficient cuttingSimple structureMetal working apparatusEngineeringMechanical engineering

The invention belongs to the technical field of rubber production equipment and particularly relates to an efficient cutting and cooling integrated device for rubber. The efficient cutting and cooling integrated device comprises a cutting table and also comprises a cutting knife part used for cutting and cooling the rubber, a cutting frame arranged on the cutting table and used for sliding the cutting knife part in a limiting way and a lifting stopping part arranged on the cutting table, matched with the cutting knife part to carry out fixed-length cutting on the rubber in a rubber stopping way and discharging the cut rubber in a pulling-up way of the cutting knife part. Due to the adoption of the way that the cutting table is additionally provided with the cutting knife part, the cutting frame and the lifting stopping part, the aim of effective cutting is achieved. The efficient cutting and cooling integrated device has the advantages of simple and effective structure, convenience and rapidness in cooling and cutting operation, good cooling and cutting effects and neat cutting surface.

Owner:ANHUI HANCAI SEALING ELEMENT

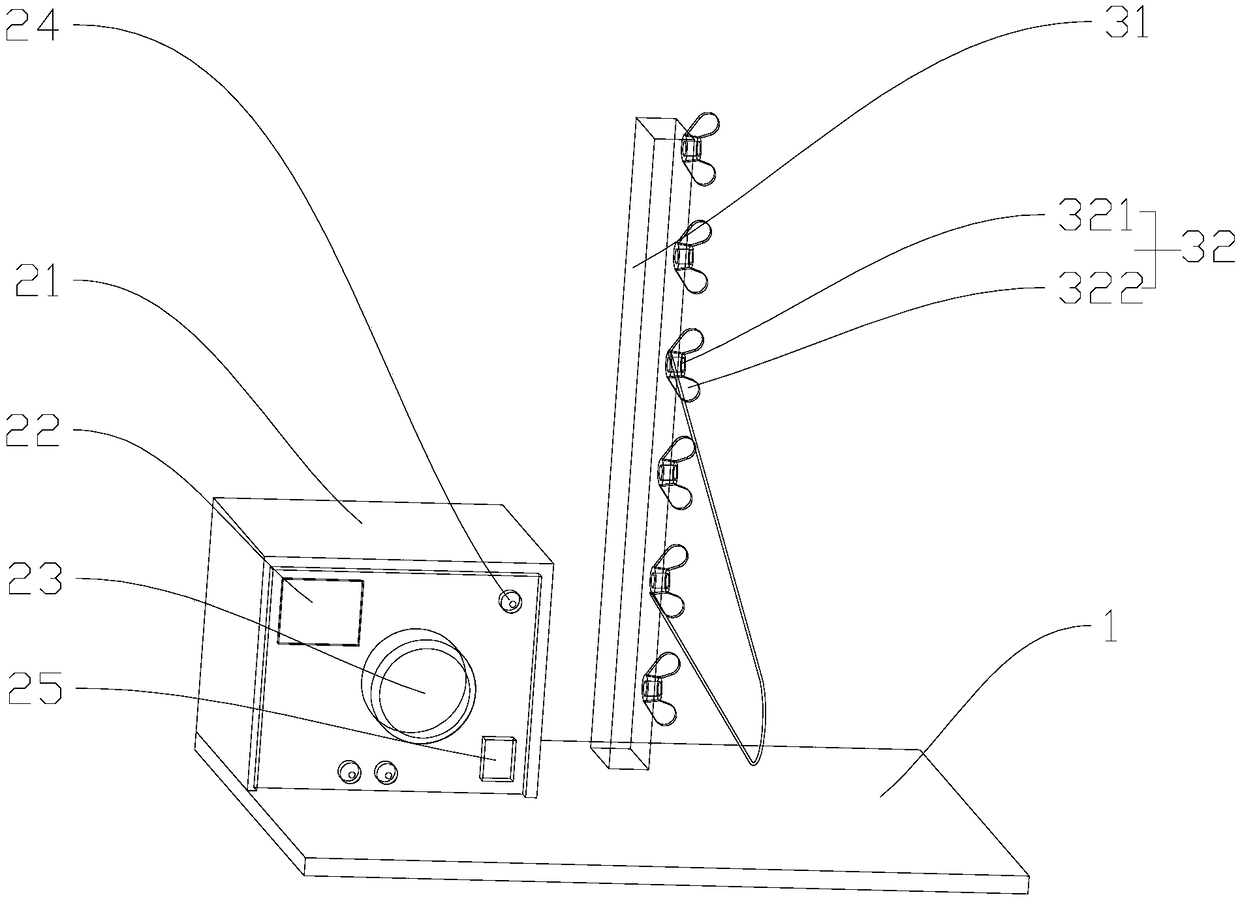

Motor wire end and outgoing wire twisting device

PendingCN107565769AAffect conductivitySolve conductive problemsManufacturing dynamo-electric machinesEngineeringOperational safety

The invention provides a motor wire end and outgoing wire twisting device, comprising rollers I, frame plate I, frame plate II, rollers II, a press rod, a cutter head, round-orifice posts, positioningbolts and pulleys. The motor wire end and outgoing wire twisting device has the advantages that the frame plate I is connected with the rollers I through mounting racks I, the frame plate II is connected with the rollers II through mounting racks II, a protective function is provided for wire twisting operation, and operational safety is enhanced; the press rod is arranged in a mounting hole, thecutter head is mounted on the lower end face of the press rod, a quick cutting function is provided for outgoing wires, cuts are neat, and next wire twisting is facilitated; the positioning bolts aremounted on the round-orifice posts, the pulleys are mounted in the round-orifice posts, a tension adjusting function is provided for the outgoing wires, and it is ensured that the outgoing wires aretensioned during twisting; the motor wire end and outgoing wire twisting device is convenient to use and operate, good in stability, and high in reliability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

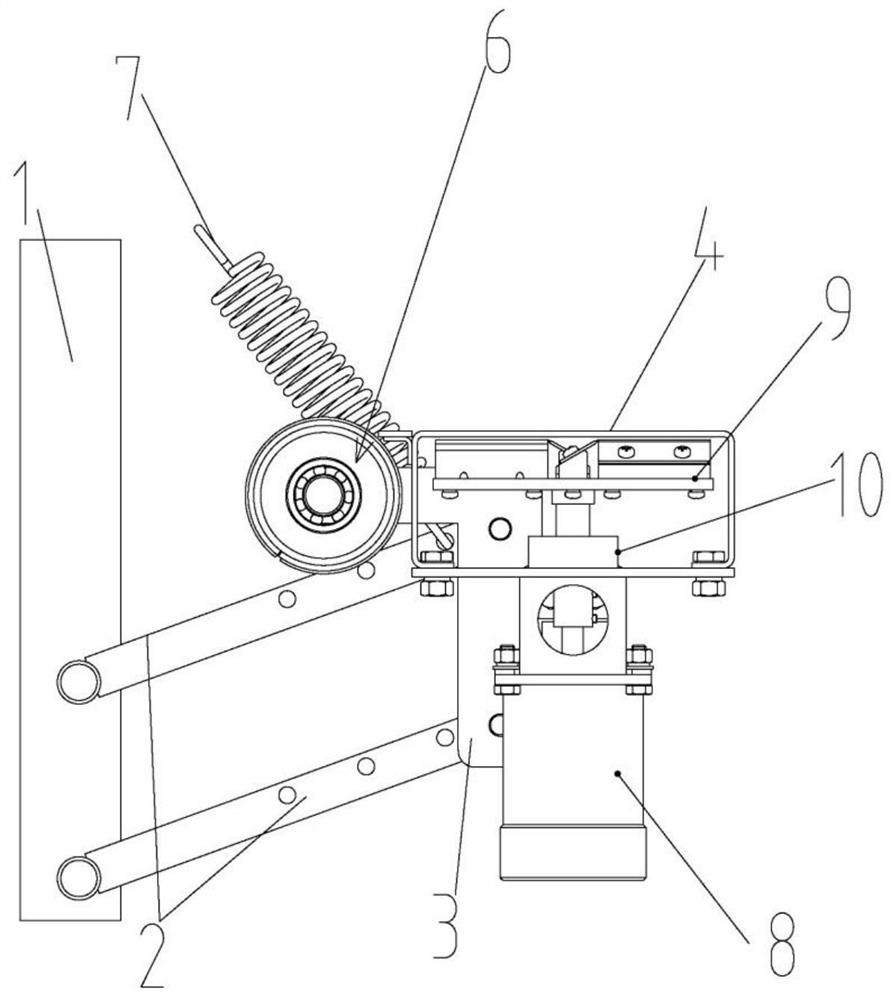

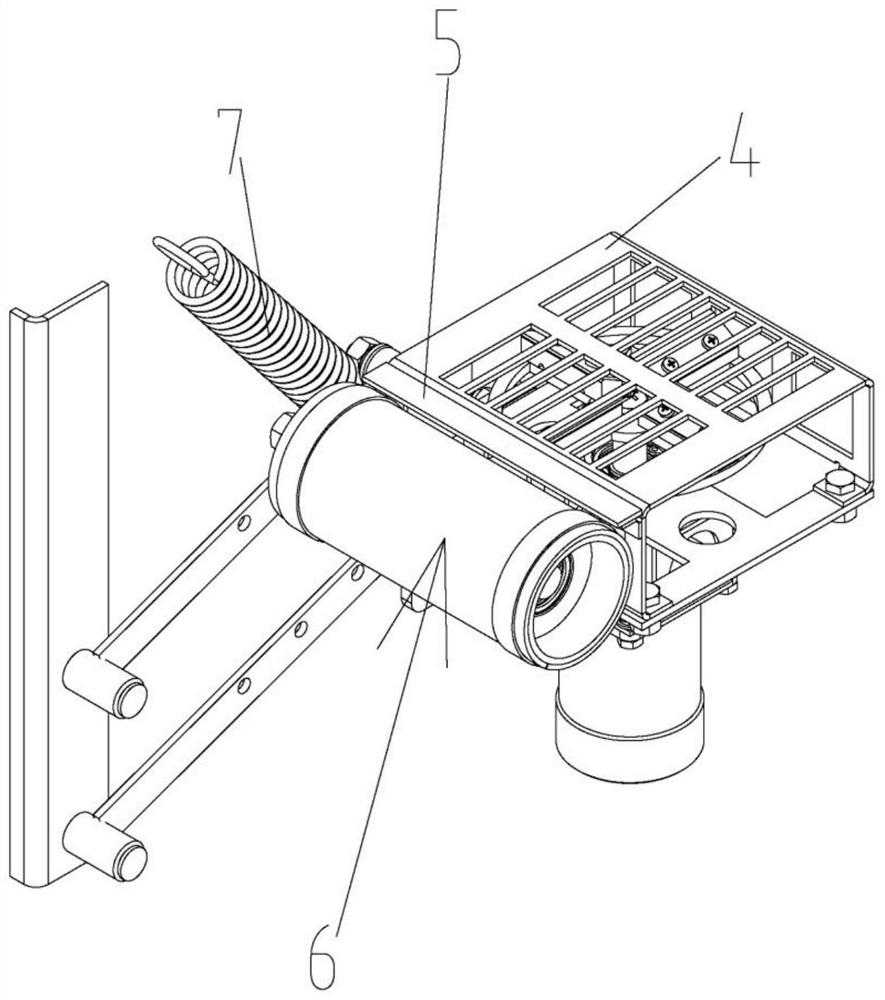

Floating type garlic root cutting device guided in through roller

ActiveCN112042974AGood orientationAvoid damageFood treatmentAgricultural engineeringElectric machinery

The invention relates to the field of agricultural machinery, in particular to a floating type garlic root cutting device guided in through a roller. The floating type garlic root cutting device comprises a floating root cutting main body part, wherein the floating root cutting main body part comprises a vertical plate, a parallelogram connecting rod mechanism, a base, a shell seat, a motor, a cutter, a profiling roller and an extension spring, wherein the vertical plate is fixed on an alignment chain rack; the parallelogram connecting rod mechanism is composed of a pair of swing arms, and oneends of the two swing arms are rotationally connected with the vertical plate; the other ends of the two swing arms are rotationally connected with the base; the upper side of the shell seat is of ahorizontal plane structure, a net-shaped structure is arranged on the horizontal plane of the upper side of the shell seat, and one side of the shell seat is fixedly connected with the base; the cutter is arranged in an inner cavity of the shell seat; the profiling roller is horizontally arranged, and rotationally connected with the base and located in front of the front side of the shell seat, and the central axis of the profiling roller is the rotating axis of the profiling roller and is perpendicular to the garlic bulb conveying direction; and one end of the extension spring is connected with the alignment chain rack and obliquely pulls the swing arms. Collision damage between garlic bulbs and the root cutting device during root cutting can be effectively reduced, and the root system cutting rate and the root system cutting uniformity are improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

A kind of cutting device of pearl cotton

ActiveCN105460308BSimple structureThe processing technology is easy to realizePackaging automatic controlShock-sensitive articlesEngineeringMechanical engineering

The invention discloses a pearl wool cutting device. The pearl wool cutting device comprises two linear guide rail pairs arranged in parallel, two pressing mechanisms which are arranged on the linear guide rail pairs and move oppositely along guide rails, a cutting mechanism connected with one pressing mechanism through a buffering part, and a power mechanism connected with the pressing mechanisms and the cutting mechanism. The pressing mechanisms and the cutting mechanism are fixed to sliders of the linear guide rail pairs. Each pressing mechanism comprises a pressing plate. The pressing plates are perpendicular to the two linear guide rail pairs. The pressing plates are driven by the power mechanism to oppositely move along the guide rails. The pressing plates are provided with cutting ports. The cutting mechanism is provided with a cutter. The cutter penetrates the cutting ports to cut off pearl wool pressed by the pressing mechanisms. The pearl wool cutting device is simple in structure, the machining technology is easy to achieve, the cutting quality is high, and the pearl wool can be automatically cut off in the cladding rotating process of the pearl wool.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Portable shielding top copper bar bus cutting machine

InactiveCN101695840BImprove reliabilityImprove power supply reliabilityMetal working apparatusPower gridCopper

The invention discloses a portable shielding top copper bar bus cutting machine which comprises a base. A support sliding bar is arranged at the upper part of the base; an electric motor is connected to the support sliding bar slidably; the bottom end of the electric motor is fixedly connected with an isolation drum in which a grinding wheel cutter is arranged; and the electric motor is in transmission connection with the grinding wheel cutter through a telescopic transmission component. The invention has simple structure and convenient use, no many persons are needed for careful cooperation and a cable caliber is not needed manipulating manually in the cutting process, thereby improving the working efficiency, saving the labor cost and the working time, shortening the replacing time of arelay protection device and improving the reliability of a mains supply; meanwhile, the cut surface of a bus is even, thereby avoiding the short circuit caused by the unevenness of the cut surface. In addition, operators do not need to directly use the cable caliber to cut the bus, thereby preventing the operators from electric shock.

Owner:XUCHANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER +1

Calendered products horizontal cutting device

ActiveCN101422909BReduce noiseExtended service lifeTyresMetal working apparatusLow noiseElectrical control

The invention relates to a cutting device for steel wire calendaring products and provides a novel transverse cutting device for calendaring products, wherein, a cutting knife tackle system is that a moving knife rotates relatively to a fixed knife and is driven by a driving motor of a cutting transmission system, the bottom of which is provided with an electrical control positioning and detecting system; the electrical control positioning and detecting system and a product pneumatic clamping and positioning system are all fixed on a base which is provided with a gear case in a sliding way; and a spring pre-loading device is arranged between the gear case and the moving knife. In the invention, the moving knife and the fixed knife are tightly jointed through a pre-pressing force, and the cutting stroke motion and the knife edge cutting motion are ensured to be synchronously carried out by a mechanical synchronous structure, thus solving the problems of fast cutter speed, large discontinuous cutting impact and easy tipping. The invention has the advantages of low noise in the working atmosphere, no flying chip and environmental protection, and as the moving knife and the fixed knife structure of the smooth knife edge is adopted, the knife tackle can carry out low-speed cutting with small impact and long service life.

Owner:大连橡胶塑料机械有限公司

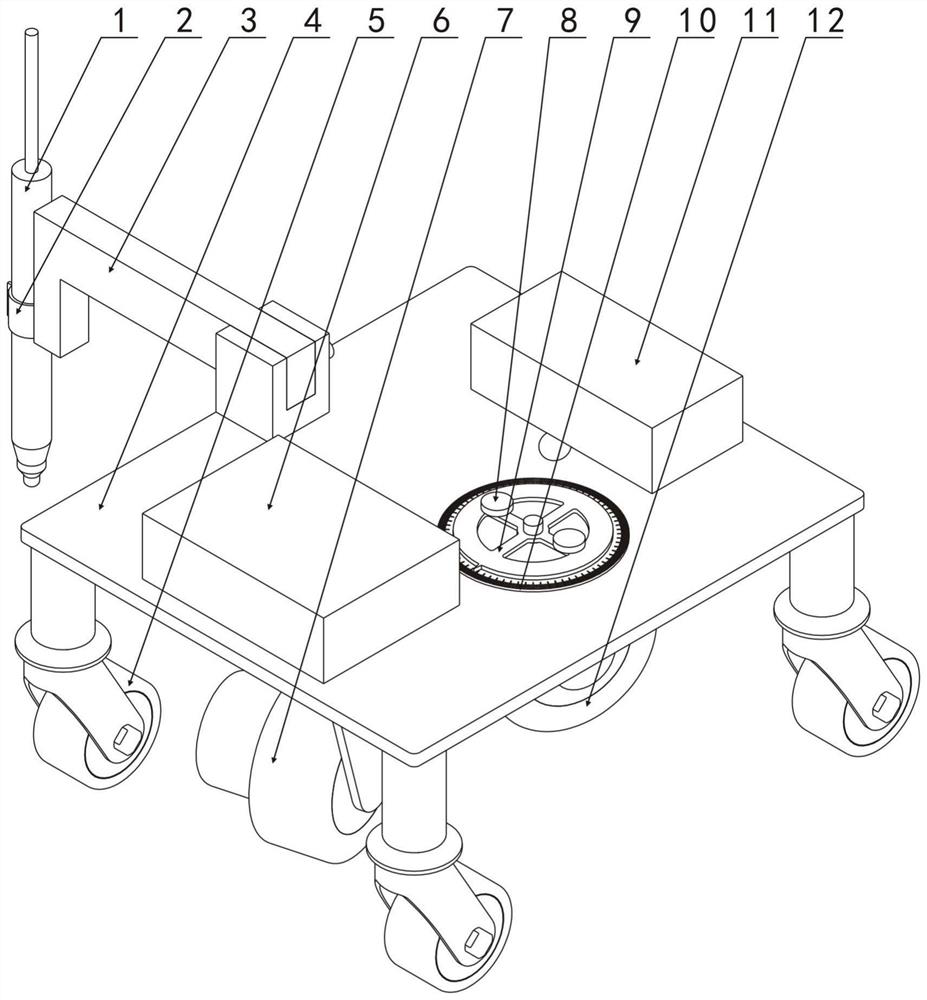

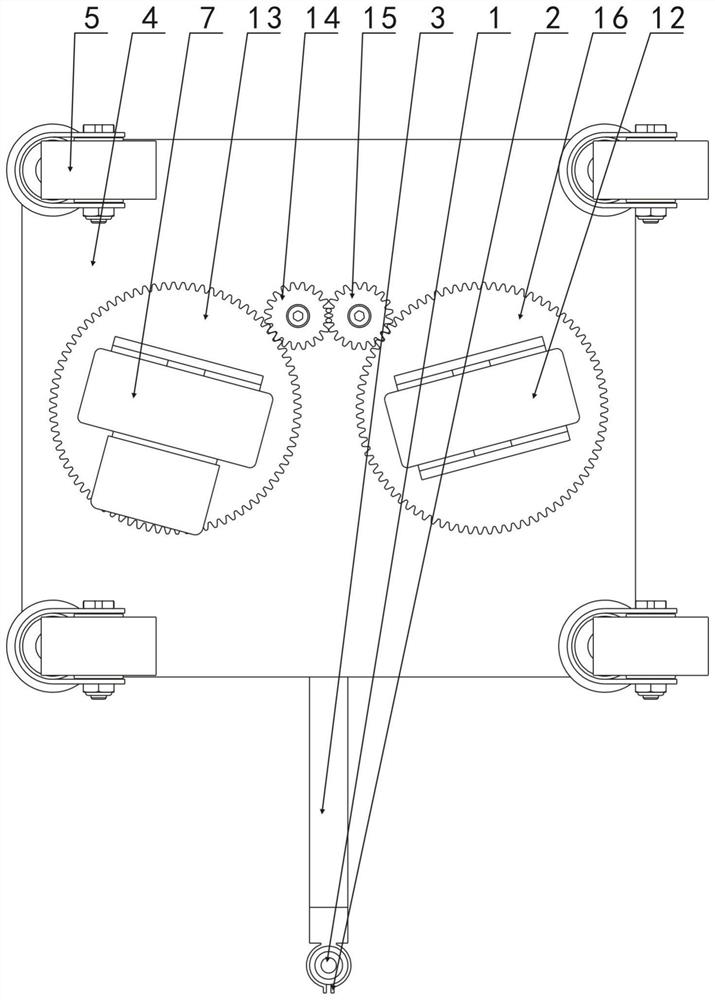

Automatic plasma cutting device capable of realizing high-quality cutting and convenient to operate

The invention discloses an automatic plasma cutting device capable of realizing high-quality cutting and convenient to operate. The automatic plasma cutting device comprises a plasma cutting gun, a base, universal rollers, a driving steering gear, a driven steering gear, a driving roller, a driven roller, an adjusting gear and a transmission gear, wherein a plurality of universal rollers, the driving steering gear and the driven steering gear are respectively mounted below the base, the driving roller is fixedly mounted below the driving steering gear, the driven roller is fixedly mounted below the driven steering gear, the adjusting gear and the transmission gear which are connected in a meshed mode are mounted below the base and located between the driving steering gear and the driven steering gear, and the adjusting gear and the transmission gear are connected with the driving steering gear or the driven steering gear in a meshed mode. Accurate linear, circular, arc-shaped and other cutting can be achieved, the cutting face is neat, the high-quality plasma cutting task is completed with low manpower and financial cost, and the automatic plasma cutting device is suitable for application and popularization.

Owner:CHENGDU AEROSPACE FENGHUO PRECISION ELECTROMECHANICAL

A wide-width cloth splitter

ActiveCN105332258BReduce workloadImprove cut qualitySevering textilesEngineeringMechanical engineering

The invention provides a broad cloth cutting device which mainly comprises a breast beam, wherein a temple combined cutter mechanism is arranged at the upper end of the breast beam; a temple group comprises a first temple and a second temple; the first temple is opposite to the second temple; a first temple support is arranged at the bottom of the first temple; a second temple support is arranged at the bottom of the second temple; the first temple support is fixedly arranged at the upper end of the breast beam; a cutter mechanism is fixedly arranged between the two temple groups and comprises a weft yarn cutter device and a driving device; the weft yarn cutter device is connected with the driving device; a sliding rail and a slide block are arranged at the upper end of the breast beam; the slide block is connected with the sliding rail in a sliding manner; and the second temple support is fixedly arranged on the slide block. The broad cloth cutting device disclosed by the invention is simple in structure principle and convenient to operate, cloth cutting operation can be automatically finished, the workload of workers is alleviated, and the working efficiency is improved. Meanwhile, the cut surface of the cut cloth is neat, and the cloth cutting quality is improved.

Owner:南通康禾新材料有限公司

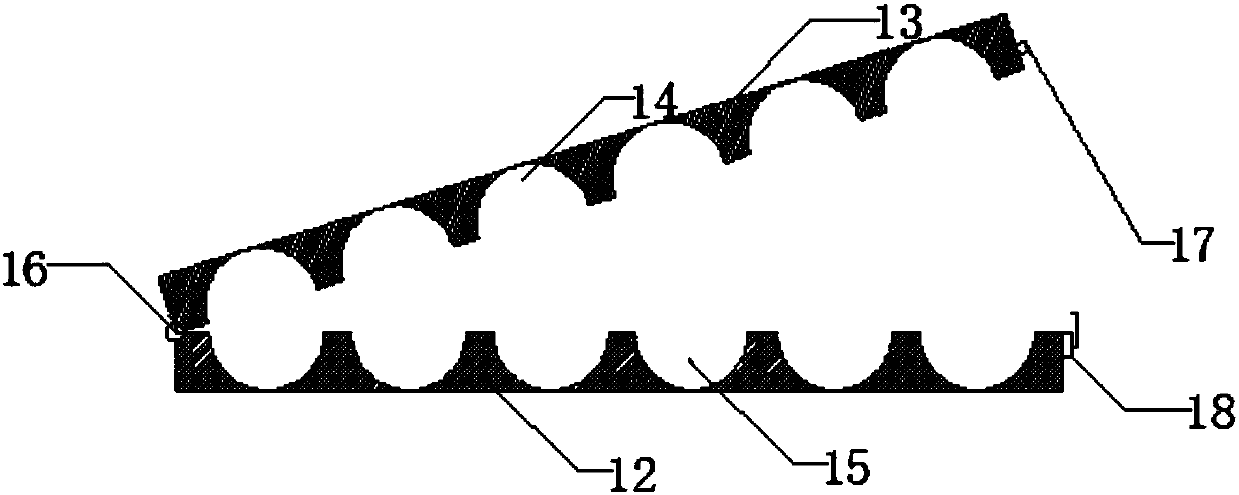

Cutting die and method for sound absorption cotton

Disclosed is a cutting die for sound absorption cotton. The cutting die comprises a fixing plate, a cutter and an upper plate surface, wherein the cutter is fixed to the fixing plate, and the upper plate surface is located above the cutter and can move up and down. The shape, needing to be processed, of the sound absorption cotton is defined by the cutter on the fixing plate. The cutting die has the advantages that the number of bursting edges is small, and the production efficiency is high.

Owner:上海柳清复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com