Quartz glass slicing machine

A quartz glass and slicing machine technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of unguaranteed cutting uniformity, impact on the workshop, and waste falling on the ground to avoid movement, Improve the accuracy and make the cutting surface neat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

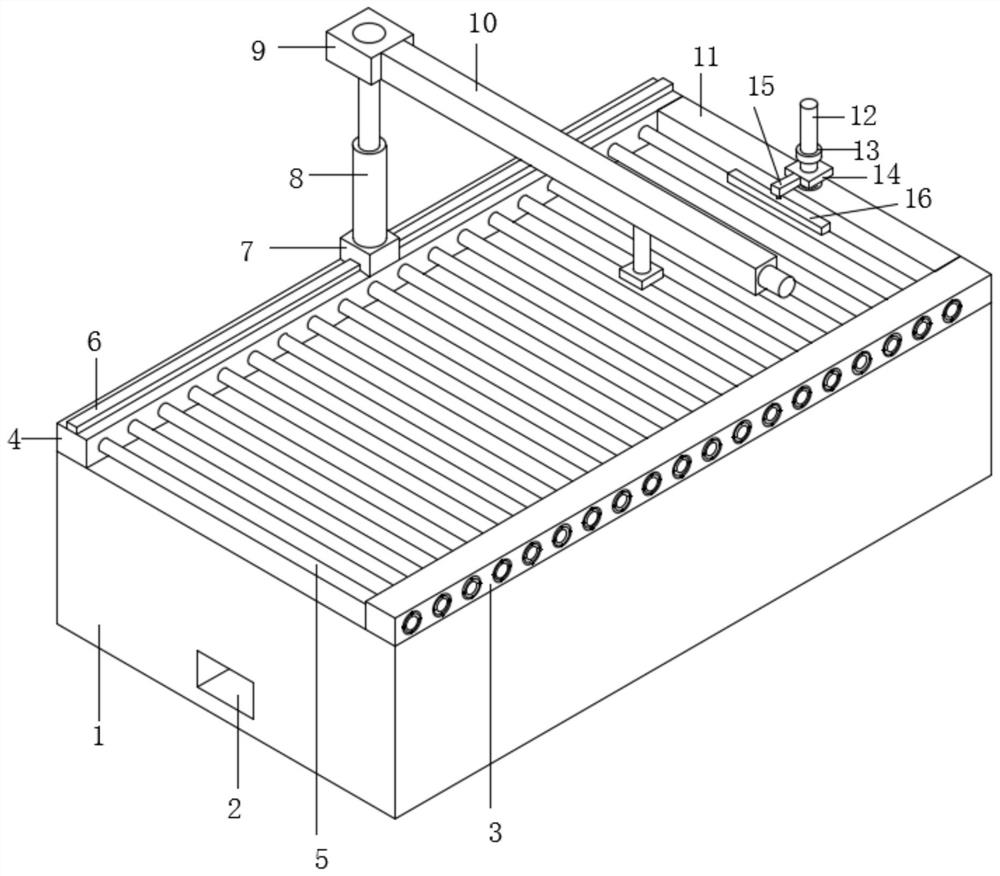

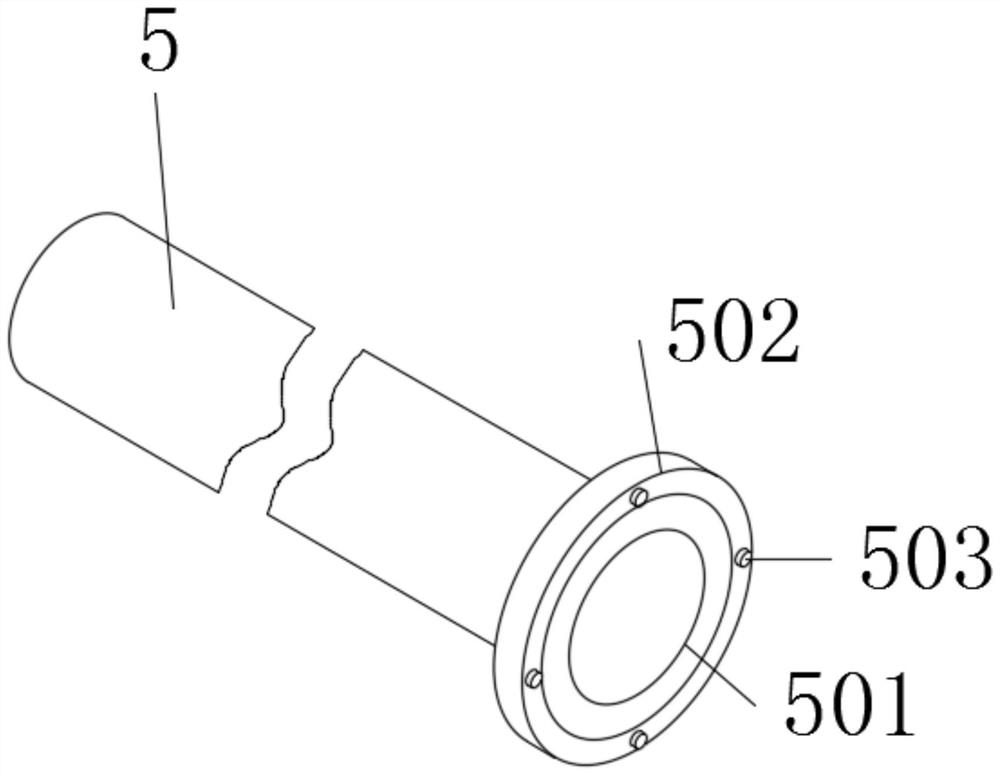

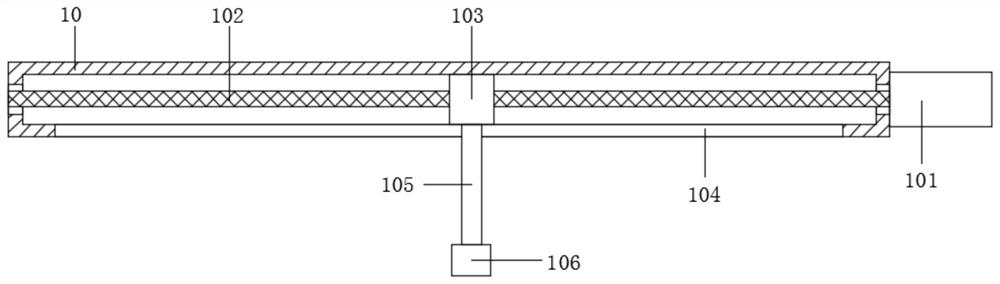

Embodiment 1

[0037] When working, the quartz glass is placed on the support roller 5 between the driving guardrail 3 and the rolling guardrail 4. Due to the rotation performance of the support roller 5, the quartz glass can be easily moved, and the quartz glass can be moved to the rear baffle. After being close to each other, adjust the pressing plate 16 again, and by turning the pressing nut 13, the pressing nut 13 is pressed against the lower pressing seat 14 and moves downward along the pressing screw rod 12, so that the pressing plate 16 is pressed against the quartz glass. Compression action, and then drive the fixed frame 9 and cutting mechanism 10 to move along the slide rail 6 through the electric slider 7, move to the cutting position, drive the cutting mechanism 10 to lift through the air pressure telescopic rod 8, so that the cutting knife 106 and Quartz glass is close to, when cutting, the drive screw 102 is driven by the drive motor 101 to rotate, so that the internal thread sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com