Efficient cutting and cooling integrated device for rubber

A rubber and high-efficiency technology, used in metal processing and other directions, can solve the problems of poor cutting effect and complex structure, and achieve the effect of neat cutting surface, simple and effective structure, and effective cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

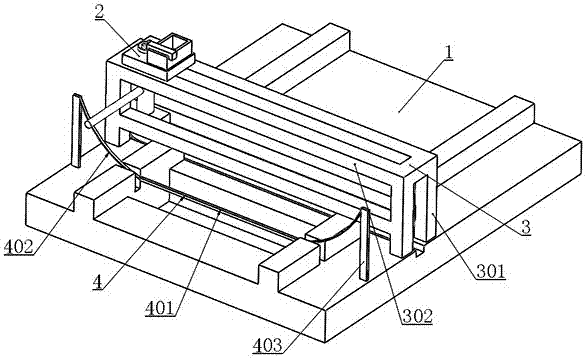

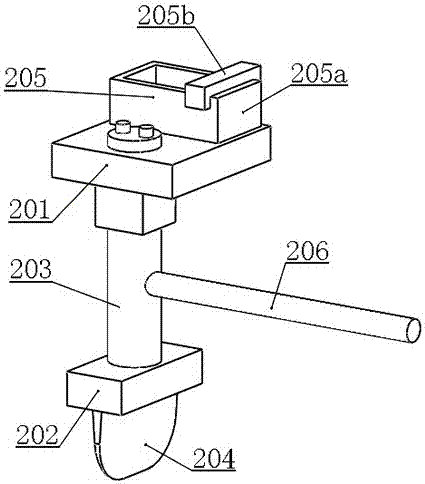

[0023] Example: as attached figure 1 , 2 , 3 and attached Figure 4 As shown, a highly efficient rubber cutting and cooling integrated device includes a cutting table 1, and also includes a cutting knife part 2 for cutting and cooling the rubber, which is arranged on the cutting table 1 and used for the cutting The cutting frame 3 that the knife part 2 performs limited sliding, and is arranged on the cutting table 1 and is used to cooperate with the cutting knife part 2 to cut the rubber to a fixed length by blocking the rubber; through the The pulling and pulling up method of the cutting blade part 2 is used for lifting and lowering the blocking part 4 for cutting the rubber.

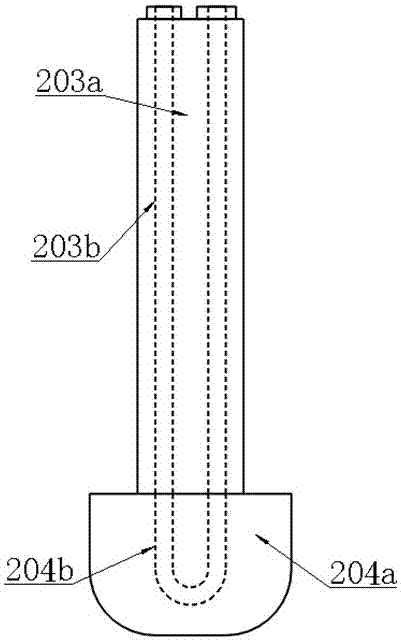

[0024] In this embodiment, on the basis of the cutting function, the cutting blade part 2 also has its own internal circulating water cooling effect, so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com