Portable laser cutting auxiliary device for large-diameter petroleum or natural gas transportation steel pipe

A large-diameter, portable technology, used in laser welding equipment, tubular items, applications, etc., can solve problems such as reducing engineering work efficiency, hidden dangers of engineering quality, and uneven cutting surface workload, saving work time and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

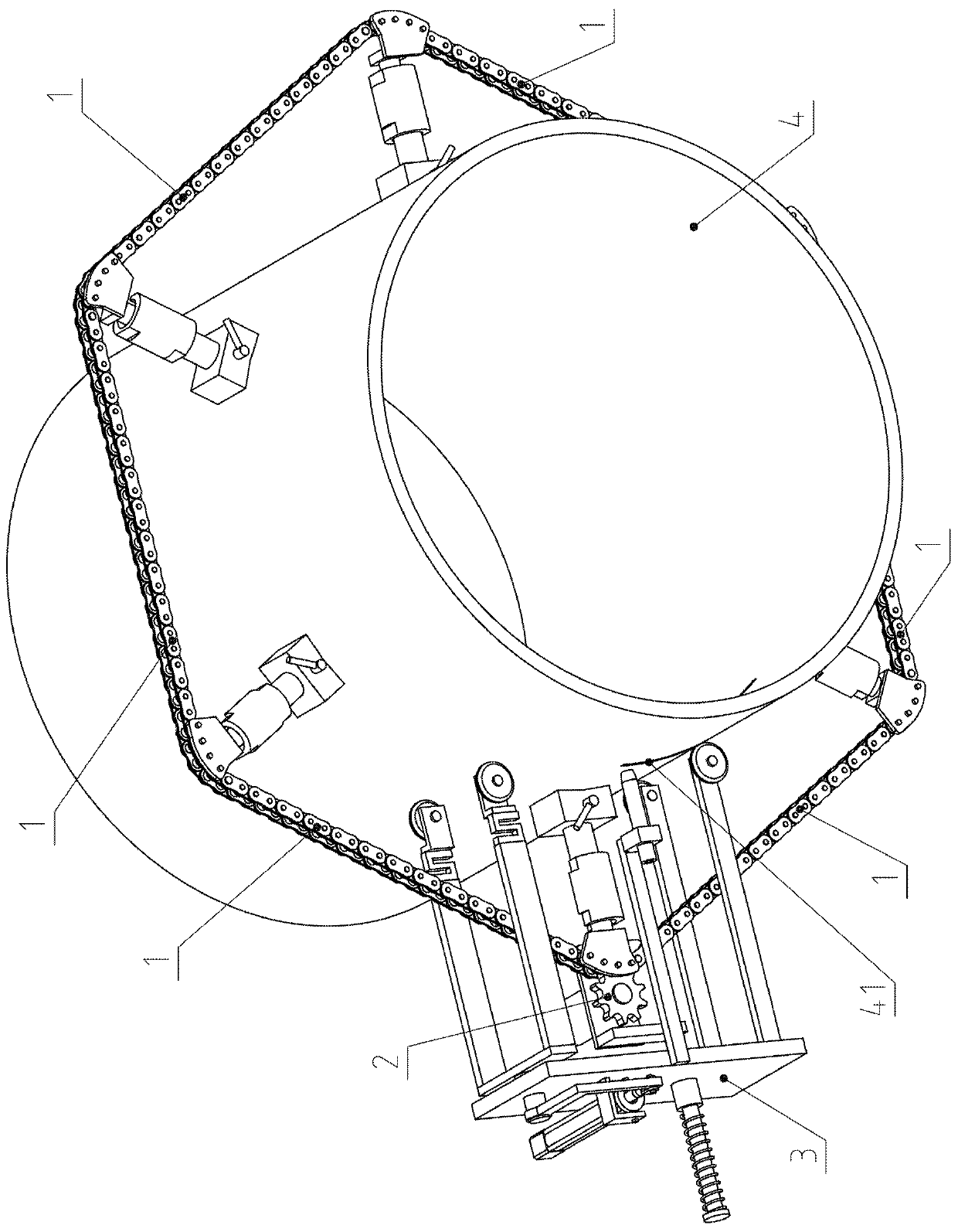

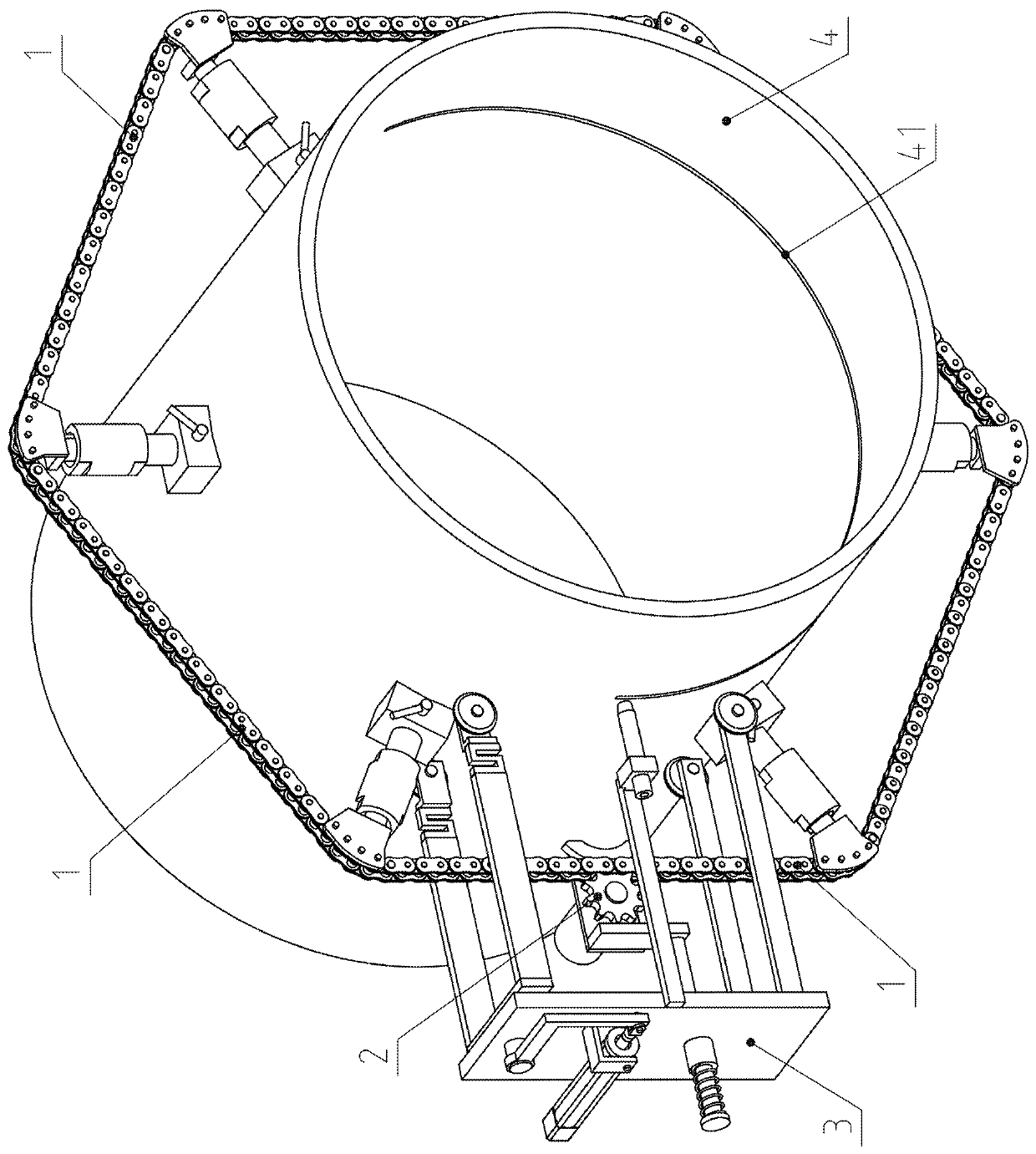

[0049] Example: see Figure 1 to Figure 11 .

[0050] A portable laser cutting auxiliary device for large-diameter oil or natural gas transmission steel pipes, including a sprocket assembly 2, a trolley assembly 3 and a six-piece chain assembly 1;

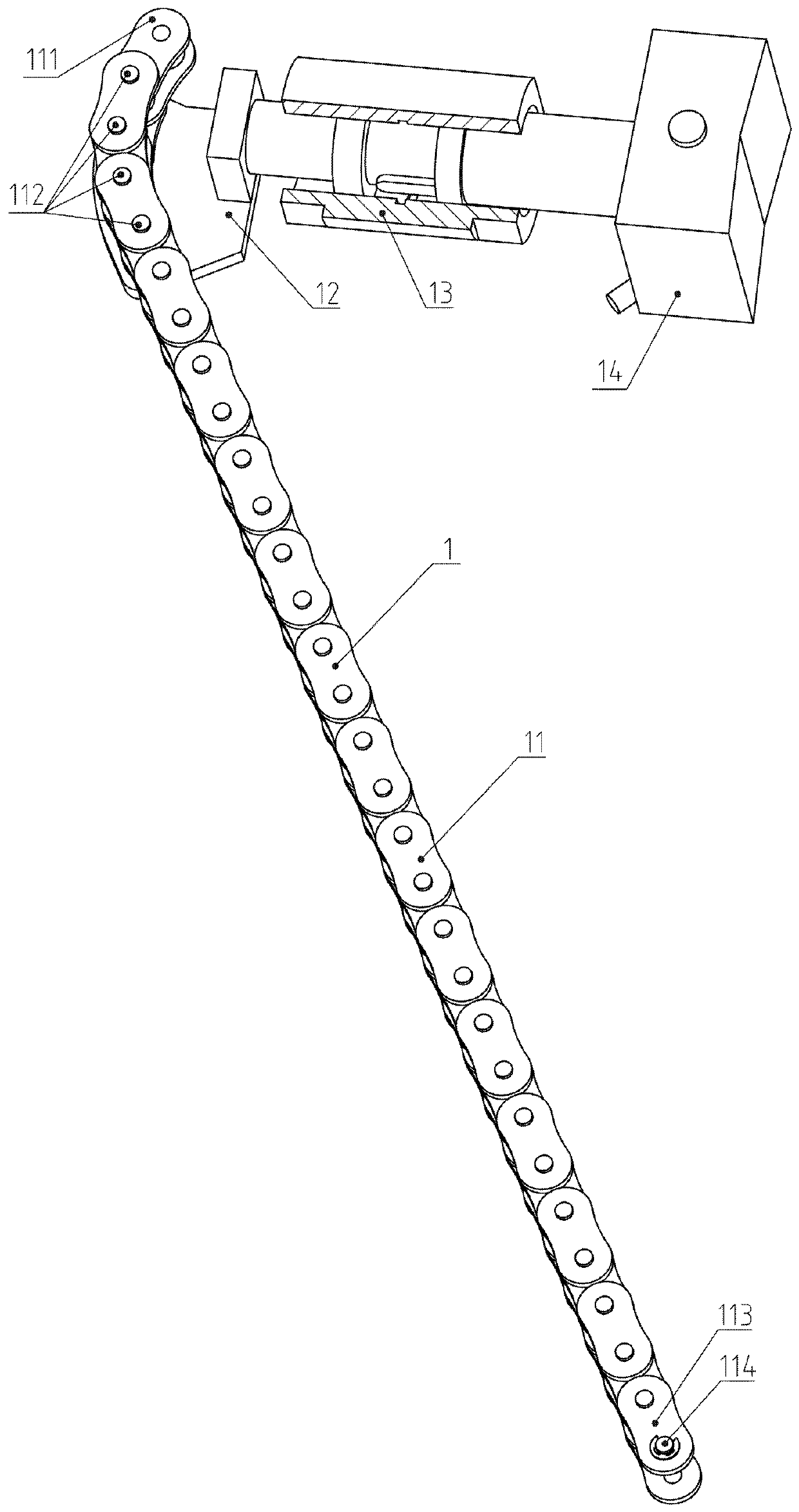

[0051] The chain assembly 1 includes a sleeve roller segment 11, a chain holder 12, a threaded sleeve 13 and a magnetic base 14;

[0052] The sleeve roller chain segment 11 includes two free ends, the two free ends are respectively free end one 111 and free end two 113; the sleeve roller chain segment 11 also includes a combination 114 of a pin and an open retaining ring; the sleeve roller The sub-chain segment 11 refers to the bush roller chain described in GB1243.1-83; each pin shaft of the bush roller chain segment 11 is covered with a roller 115;

[0053] Chain holder 12 includes guide shaft 1211, guide flat key 1212, right-handed external thread convex ring 122 and pin shaft fixing plate 123; guide flat key 1212 is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com