A wide-width cloth splitter

A slitting and wide-width technology is applied in the field of fabric cutting devices, which can solve the problems of inability to meet production requirements, labor intensity of workers, and complicated operation process, so as to reduce the workload of workers, improve the quality of cutting, and have a simple structure and principle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

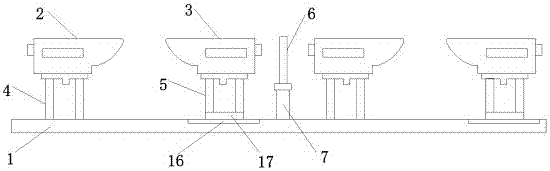

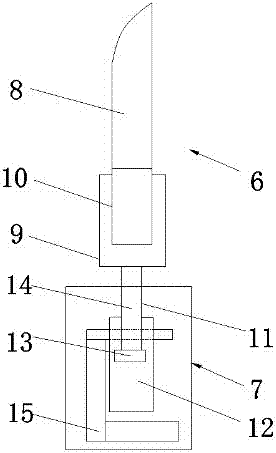

[0016] Such as figure 1 , figure 2 As shown, a wide-width cloth splitting device mainly includes a chest beam 1, a temple set and a cutter mechanism are arranged at the upper end of the chest beam 1, and a cloth rolling support is provided outside the temple set, and the side The support group includes a first temple 2 and a second temple 3, and the first temple 2 and the second temple 3 are arranged oppositely, and the bottom of the first temple 2 is provided with a first temple stand 4 , the bottom of the second temple 3 is provided with a second temple support 5, the first temple support 2 is fixedly arranged on the upper end of the chest beam 1, and the cutting is fixedly arranged between two groups of temples. knife mechanism. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com