Stainless steel tube cutting and discharging system

A stainless steel pipe blanking technology, which is applied in the direction of pipe shearing devices, shearing devices, and accessories of shearing machines, can solve the problems of easy generation of burrs, low work efficiency, and high manufacturing costs, and achieve neat and burr-free cutting surfaces. The effect of improving work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

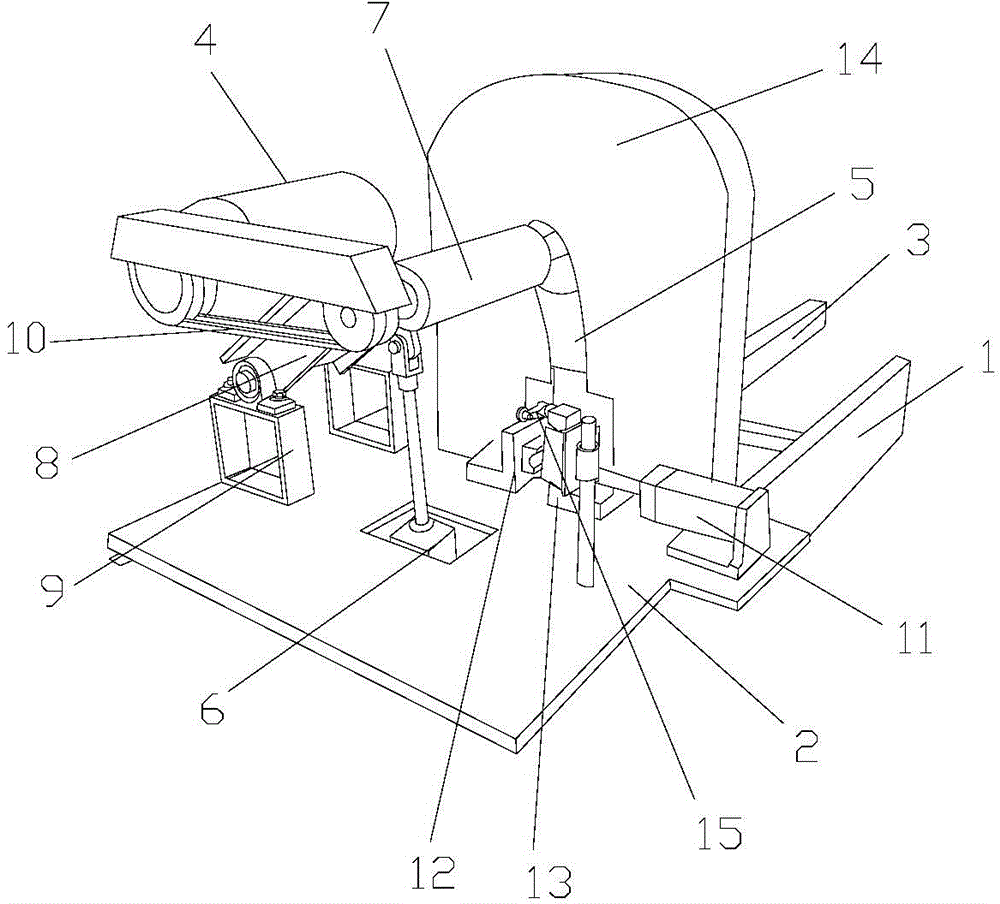

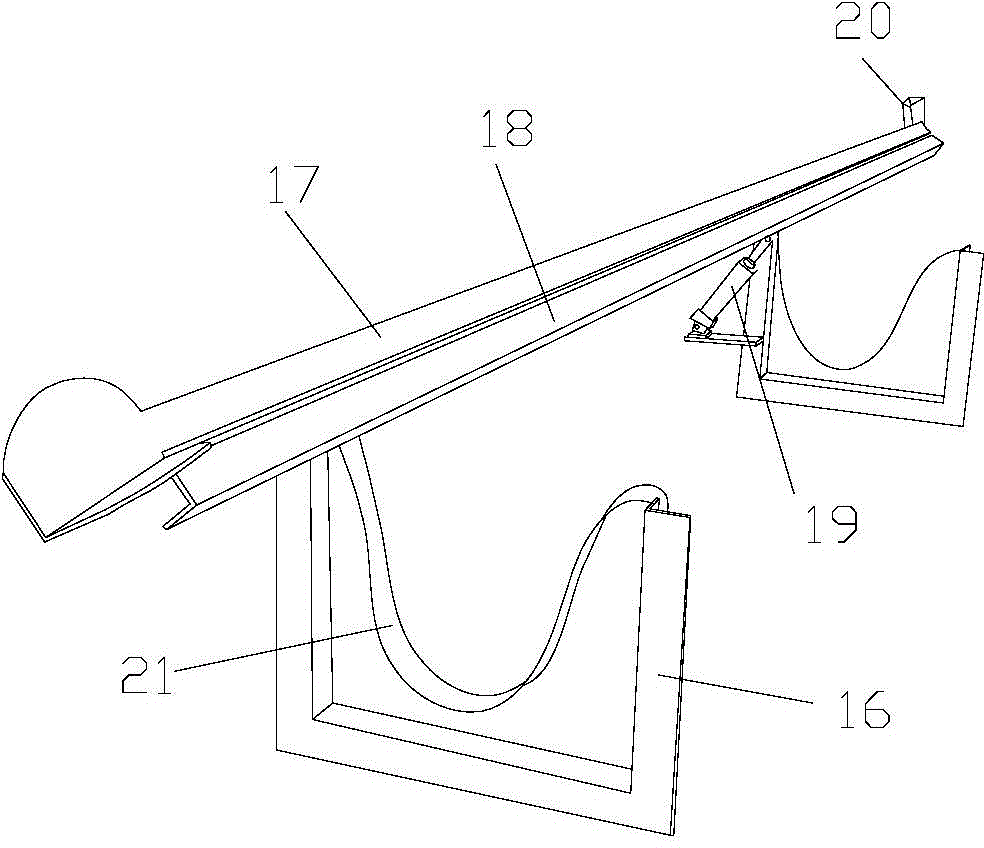

[0016] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 As shown, a stainless steel pipe cutting and blanking system includes a frame 1, a base plate 2, a cutting mechanism and a clamping mechanism, the frame is fixed with a first cylinder 3, and the piston rod of the first cylinder is connected to the One end of the bottom plate is connected to drive the bottom plate to slide on the frame. Since the stainless steel pipe will move forward at a certain speed when cutting, the bottom plate is set to a sliding structure in order to keep a synchronous speed with the stainless steel pipe.

[0017] The cutting mechanism and the clamping mechanism are respectively arranged on the base plate. The cutting mechanism is mainly composed of a motor 4, a cutting wheel 5, and a second cylinder 6. The cutting wheel is keyed to one end of the rotating shaft, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com