Automatic plasma cutting device capable of realizing high-quality cutting and convenient to operate

An automatic cutting device and plasma technology, applied in plasma welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of irregular cutting surface, excessive auxiliary time, disproportionate cost and return, and achieve low manpower and financial costs , The effect of neat cutting surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

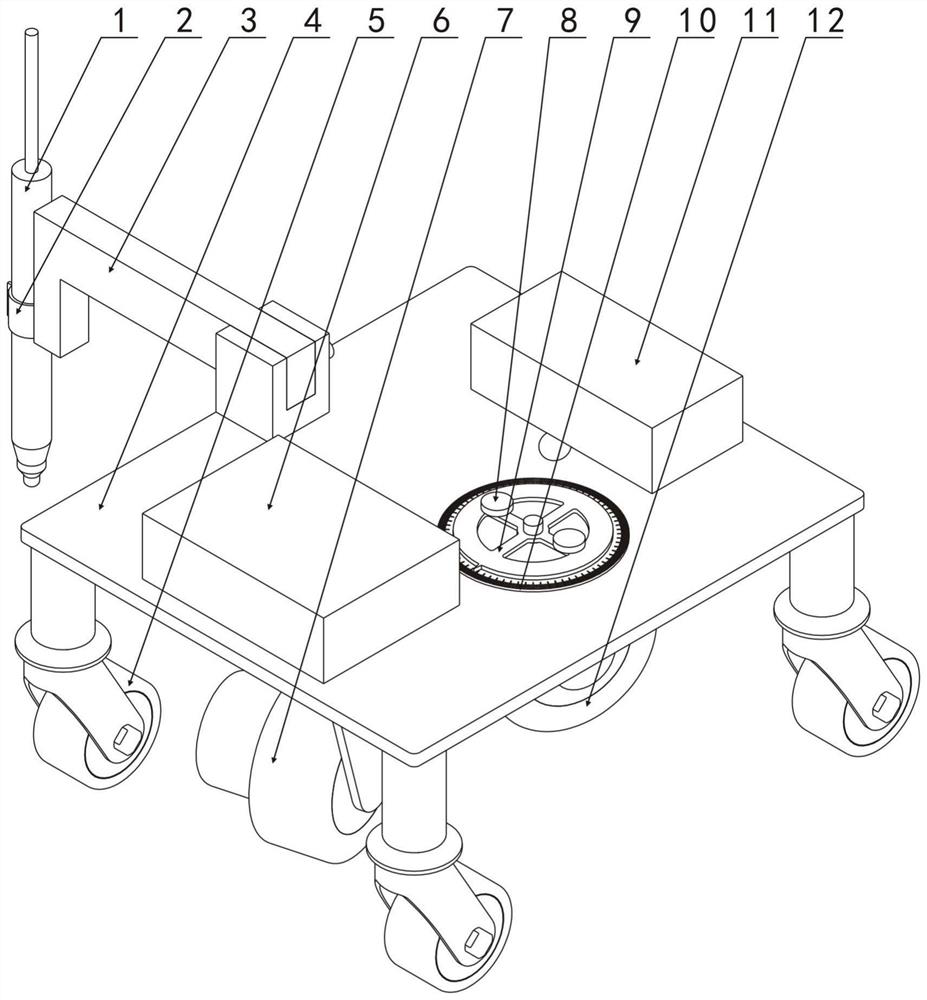

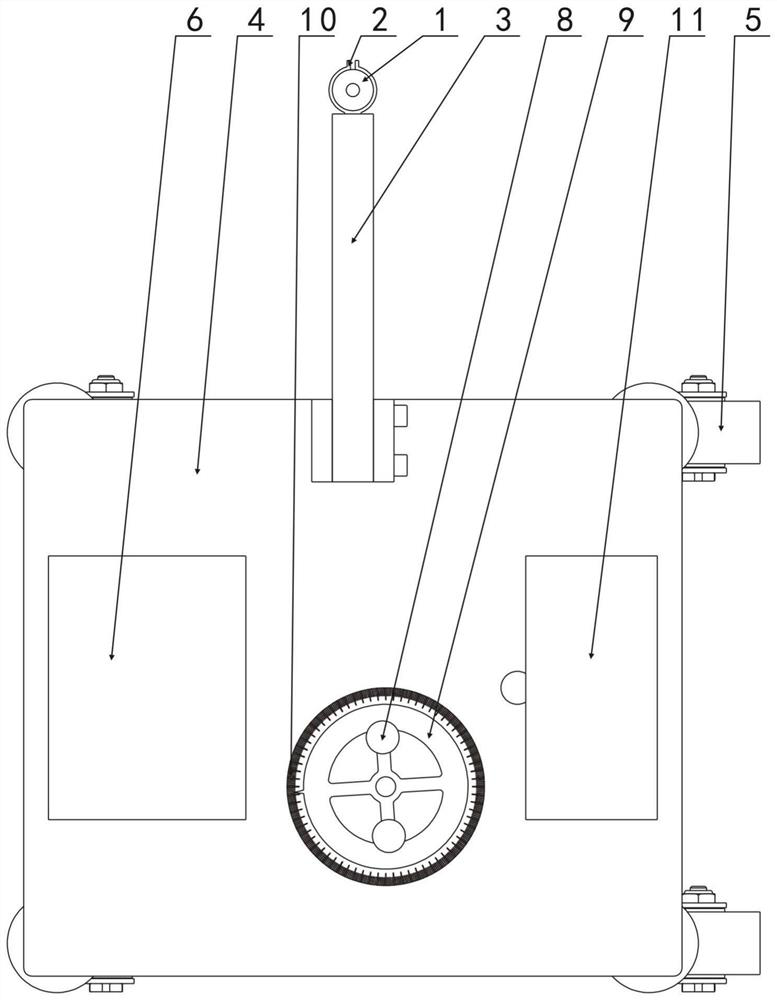

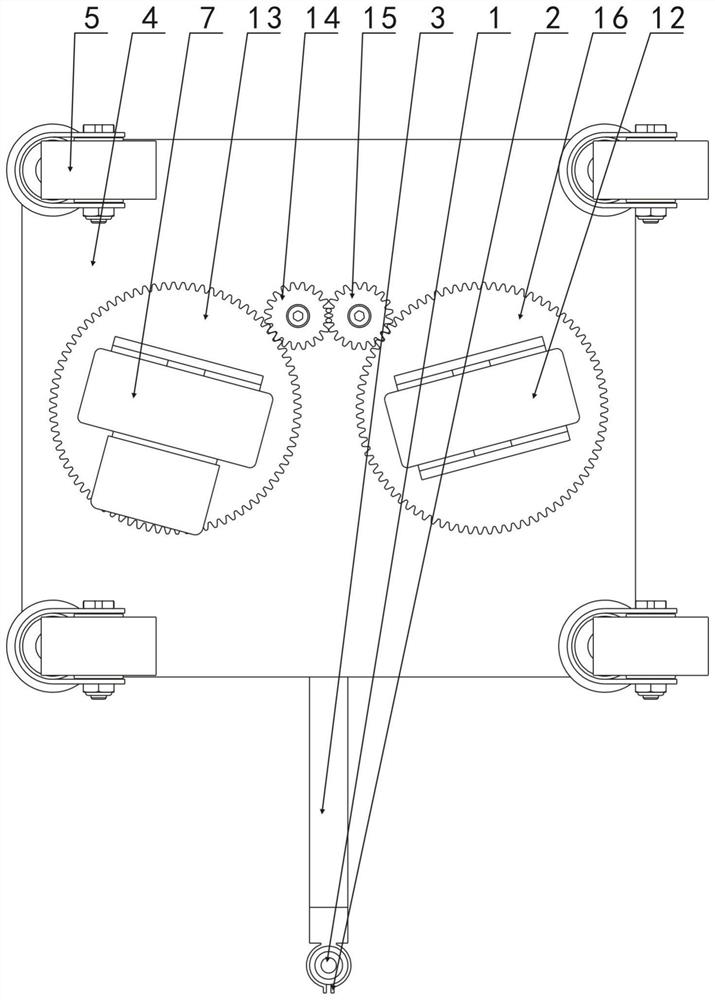

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] Such as Figure 1-Figure 4 As shown, the plasma automatic cutting device that can realize high-quality cutting and is easy to operate according to the present invention includes a plasma cutting torch 1, a base 4, a universal roller 5, a driving steering gear 13, a driven steering gear 16, a driving roller 7, Driven roller 12, adjustment gear 15 and transmission gear 14, a plurality of universal rollers 5 are installed below the base 4, and horizontal driving steering gear 13 and horizontal driven steering gear 16 are respectively installed below the base 4 and Can rotate, the driving roller 7 that has driving motor (unmarked among the figure) is fixedly installed below driving steering gear 13, the driven roller 12 that does not have driving motor is fixedly installing below driven steering gear 16, driving roller 7, The following of the driven roller 12 and a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com