A kind of cutting device of pearl cotton

A cutting device, the technology of pearl cotton, applied in the directions of packaging, packaging protection, transportation and packaging, can solve the problems of unfavorable production line automation level, difficult to improve cutting efficiency, difficult to cut pearl cotton, etc., to reduce labor costs, simple structure, The effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

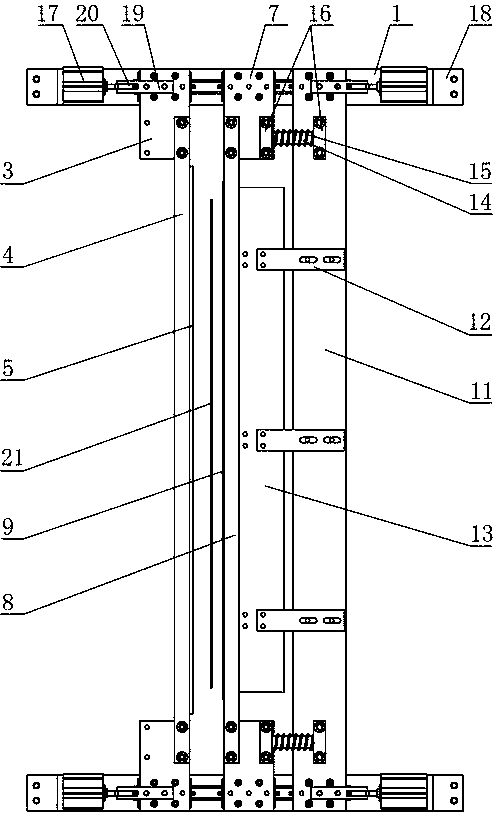

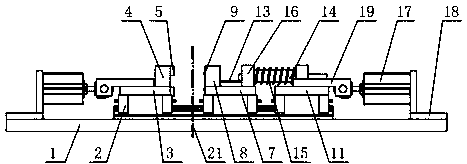

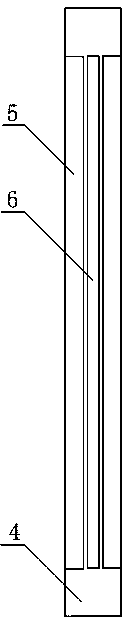

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. It is only stated here that the words for directions such as up, down, left, right, front, back, inside, and outside that appear or will appear in the text of the present invention are only based on the accompanying drawings of the present invention, and are not specific to the present invention. limited.

[0028] Existing stacked wall and floor tiles often use pearl cotton placed between the brick surfaces to avoid scratches on the brick surfaces, but due to the thickness, toughness, flammability and other reasons of pearl cotton, it cannot be cut by a cutting device using ordinary cutting paper. And the present invention provides a kind of device that is applied to the equipment that covers the pearl cotton on the surface of the adobe before the stacker and cuts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com