Portable shielding top copper bar bus cutting machine

A portable cutting machine technology, which is applied in metal processing and other directions, can solve the problems of small bus bar spacing, irregular shearing section, manual operation deviation, etc., to achieve neat cutting surface, improve safety, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

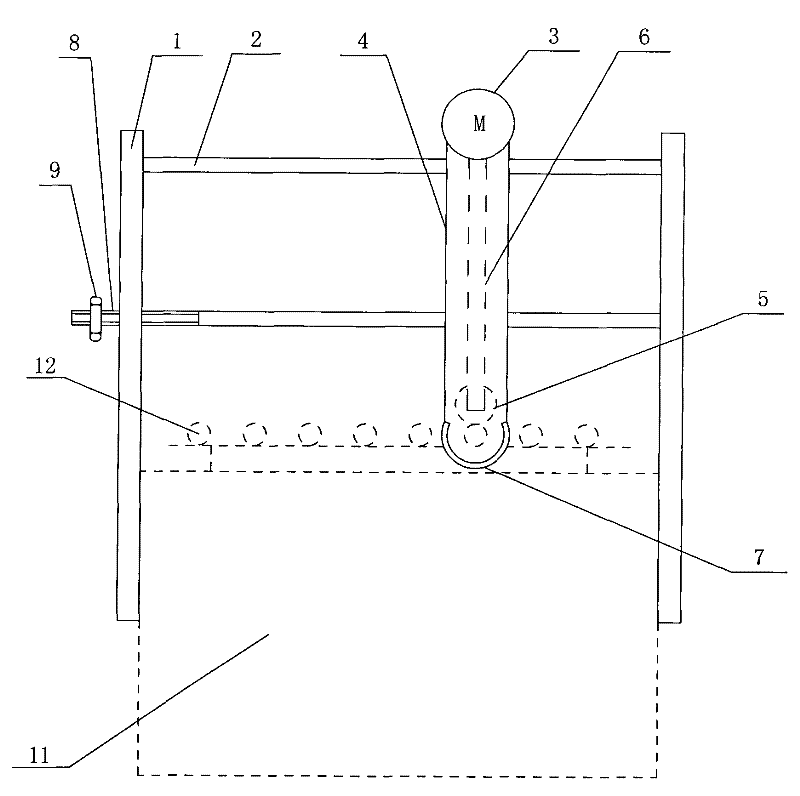

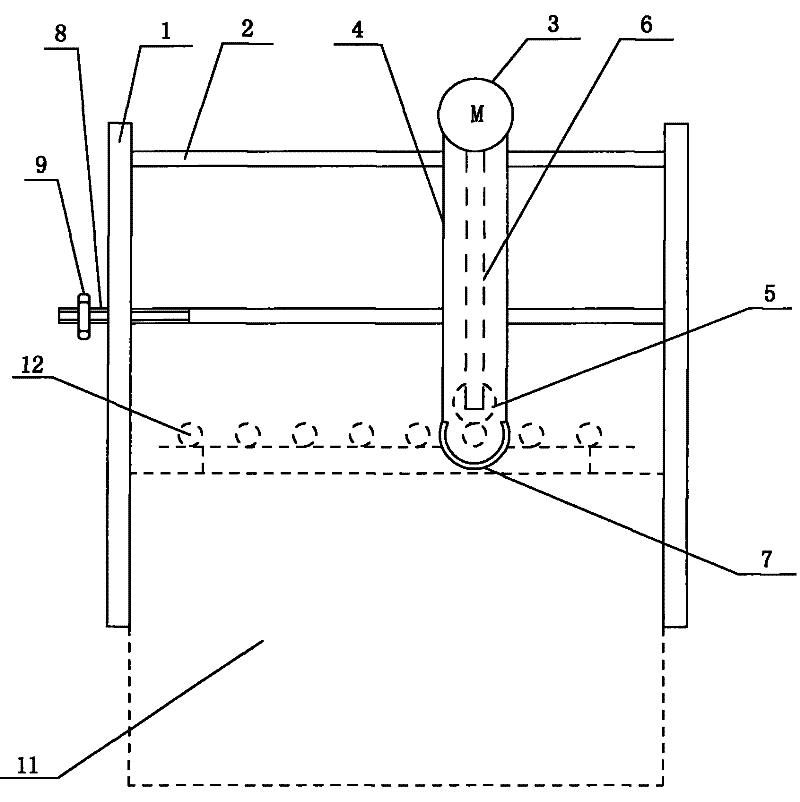

[0012] Such as figure 1 As shown, the portable screen-top copper rod busbar cutting machine of the present invention includes a base 1, a support slide bar 2 is provided on the upper part of the base 1, a motor 3 is slidably connected to the support slide bar 2, and an insulating The cylinder 4 and the insulating cylinder 4 are provided with a grinding wheel cutter 5 , and the motor 3 is connected to the grinding wheel cutter 5 through a telescopic transmission member 6 . The bottom end of the insulating cylinder 4 is hinged with a closed box body 7 . The middle part of the base 1 is provided with a tension screw 8, and one end of the tension screw 8 protrudes from the base 1 and is provided with a nut 9. Wherein, the pulling screw rod 8 can be provided with an outer wire on the whole rod, and also can be provided with an outer wire only on one side of the nut 9 .

[0013] Such as figure 1 As shown, when cutting the copper bar busbar 12, the base 1 and the whole cutting mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com