Calendered products horizontal cutting device

A calendered product, horizontal technology, applied in the field of cutting devices, can solve the problems of high tool speed, large cutting impact, large intermittent cutting impact, etc., and achieve the effects of improved cutting quality, long service life and small impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

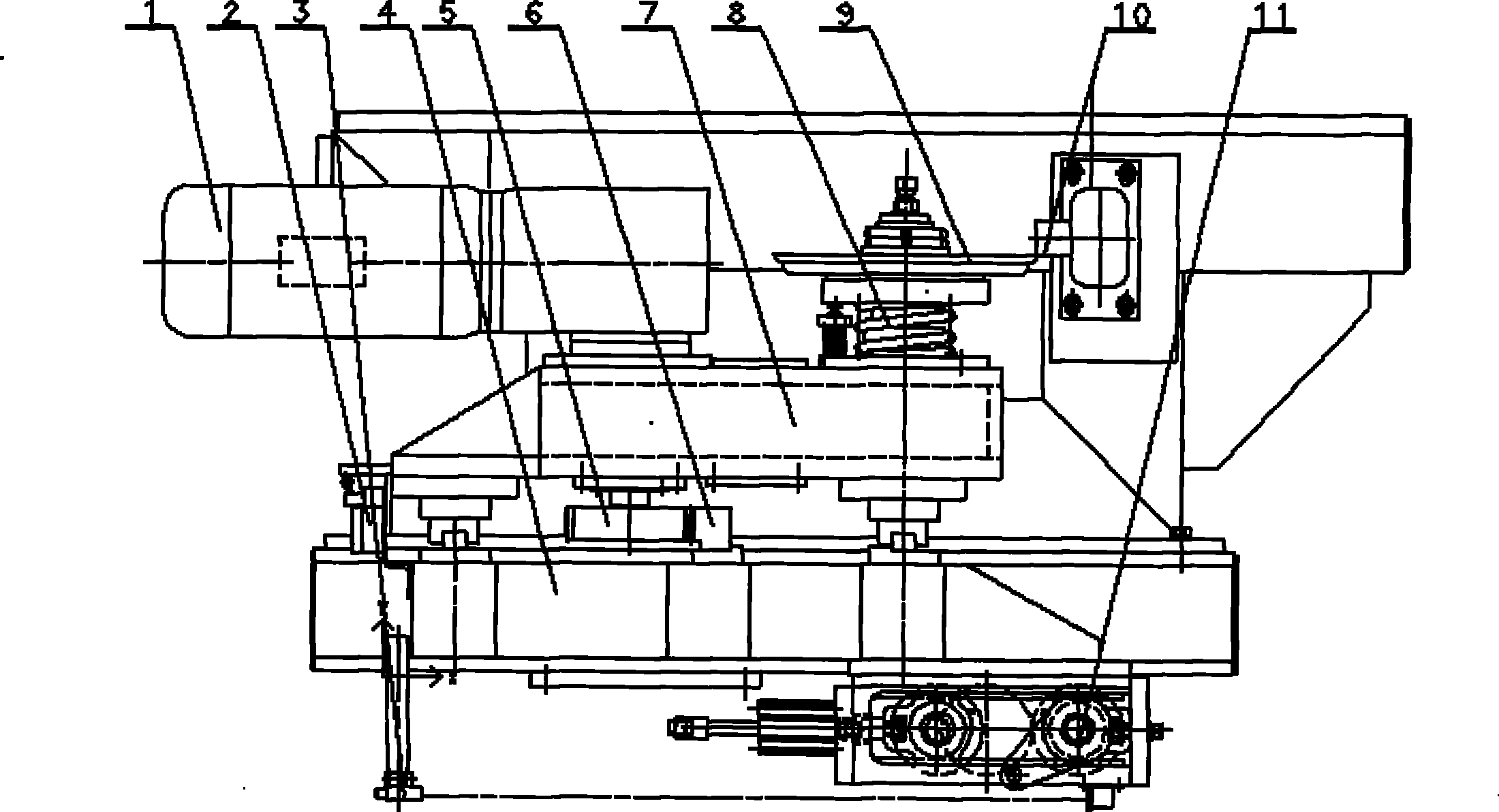

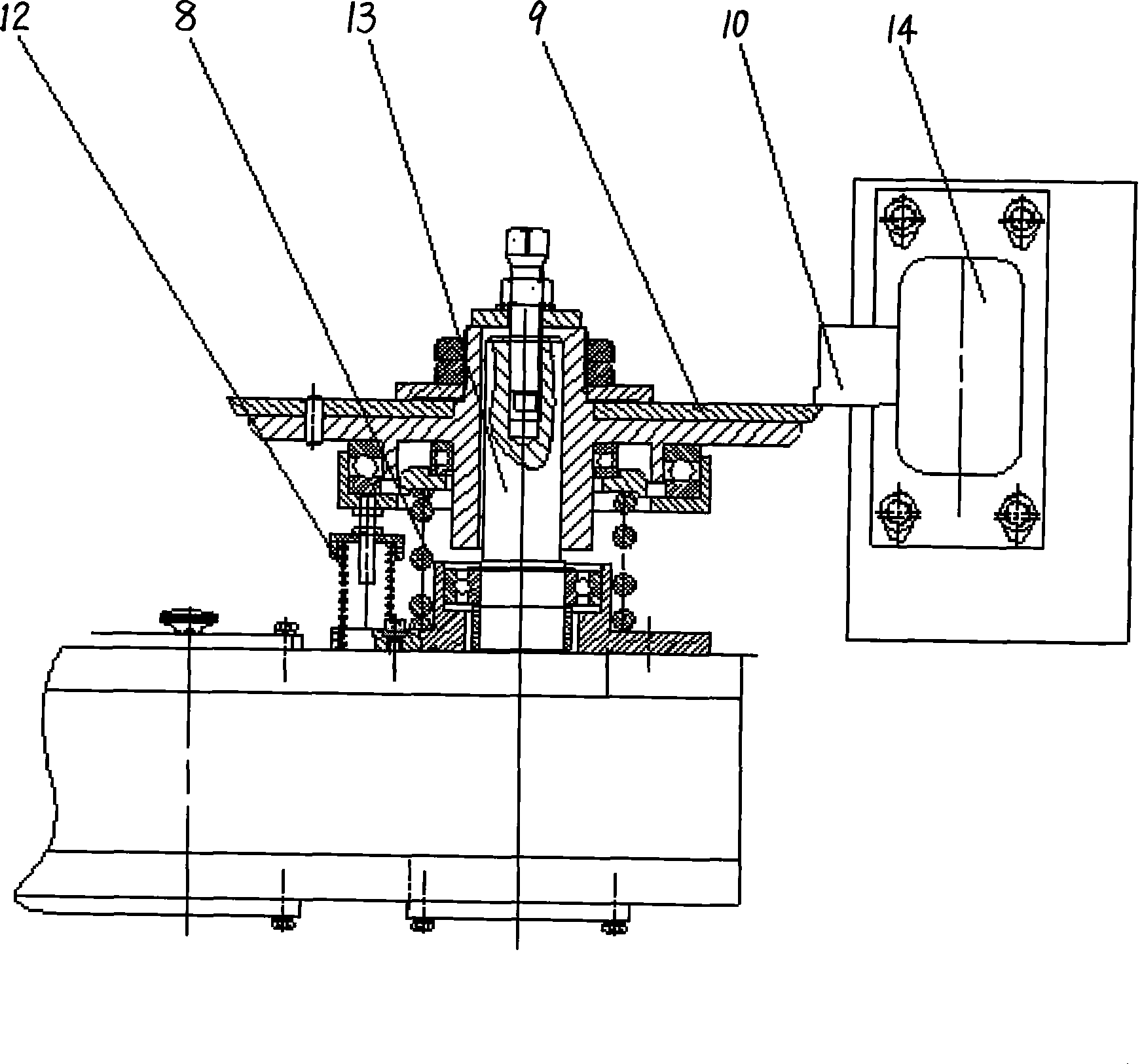

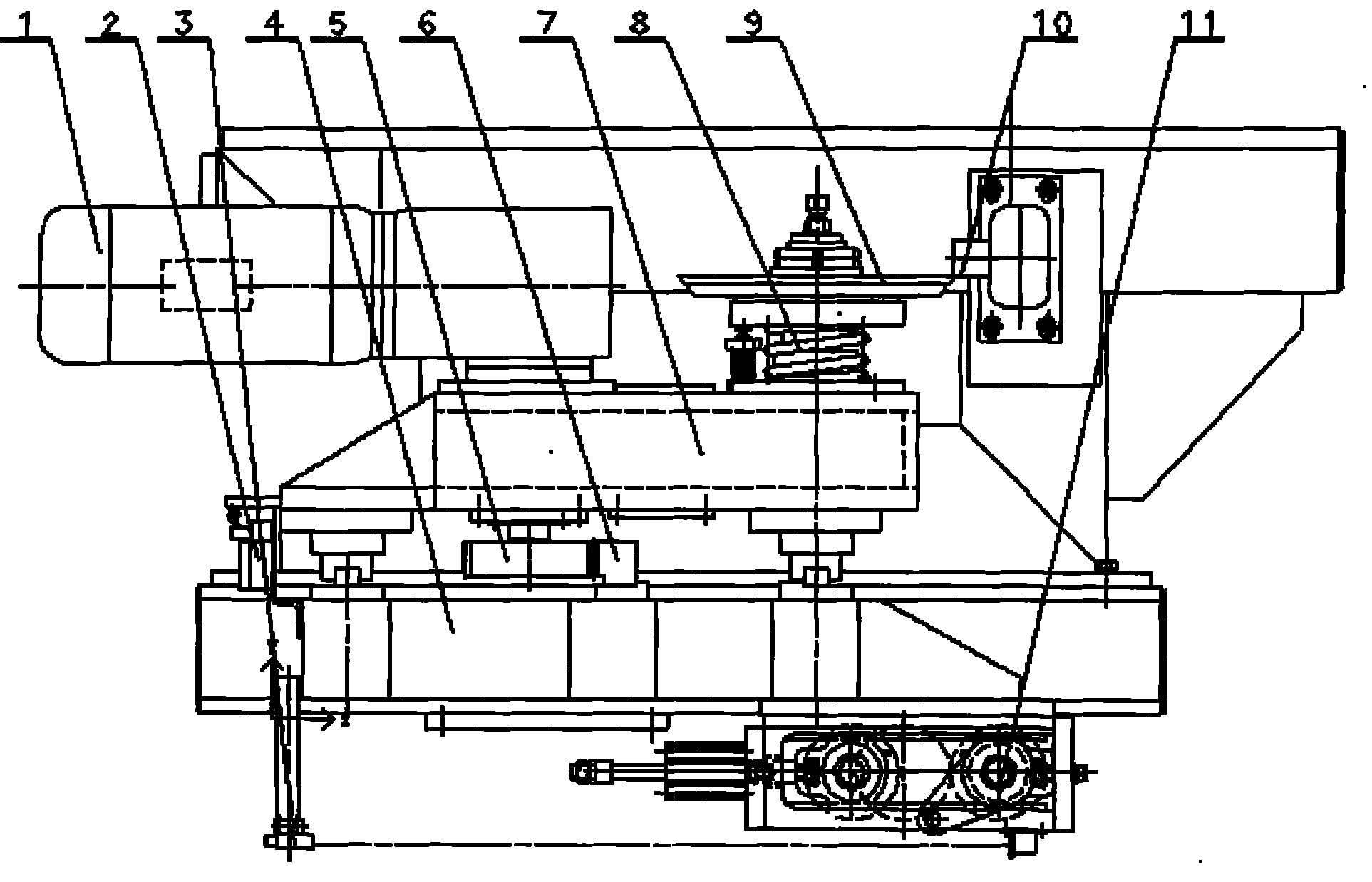

[0015] Such as figure 1 , 2 The one shown is mainly composed of a cutting device, a new type of horizontal cutting device for rolled products, which is mainly composed of a cutting knife set system, a cutting transmission system, a product pneumatic clamping and positioning system 11 and an electric control positioning detection system. The cutting knife set system is a moving knife 9 Rotate relative to the fixed knife 10, the moving knife is driven by the drive motor 1 of the cutting transmission system, the bottom of the transmission system is equipped with an electronically controlled positioning detection system, the electronically controlled positioning detection system and the product pneumatic clamping and positioning system 11 are fixed on the base 4 , a gearbox 7 is slidably installed on the base, the motor 1 is a mechanical automatic brake motor, the output shaft of the motor is connected to the input shaft of the gearbox 7, and a spring preloading device is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com