Portable LGJ-aluminum cable steel reinforced positioning holder

A steel-cored aluminum stranded wire and holder technology, which is applied in the installation of cables, electrical components, equipment for connecting/terminating cables, etc. The effect of waste, neat cut surface and safety guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

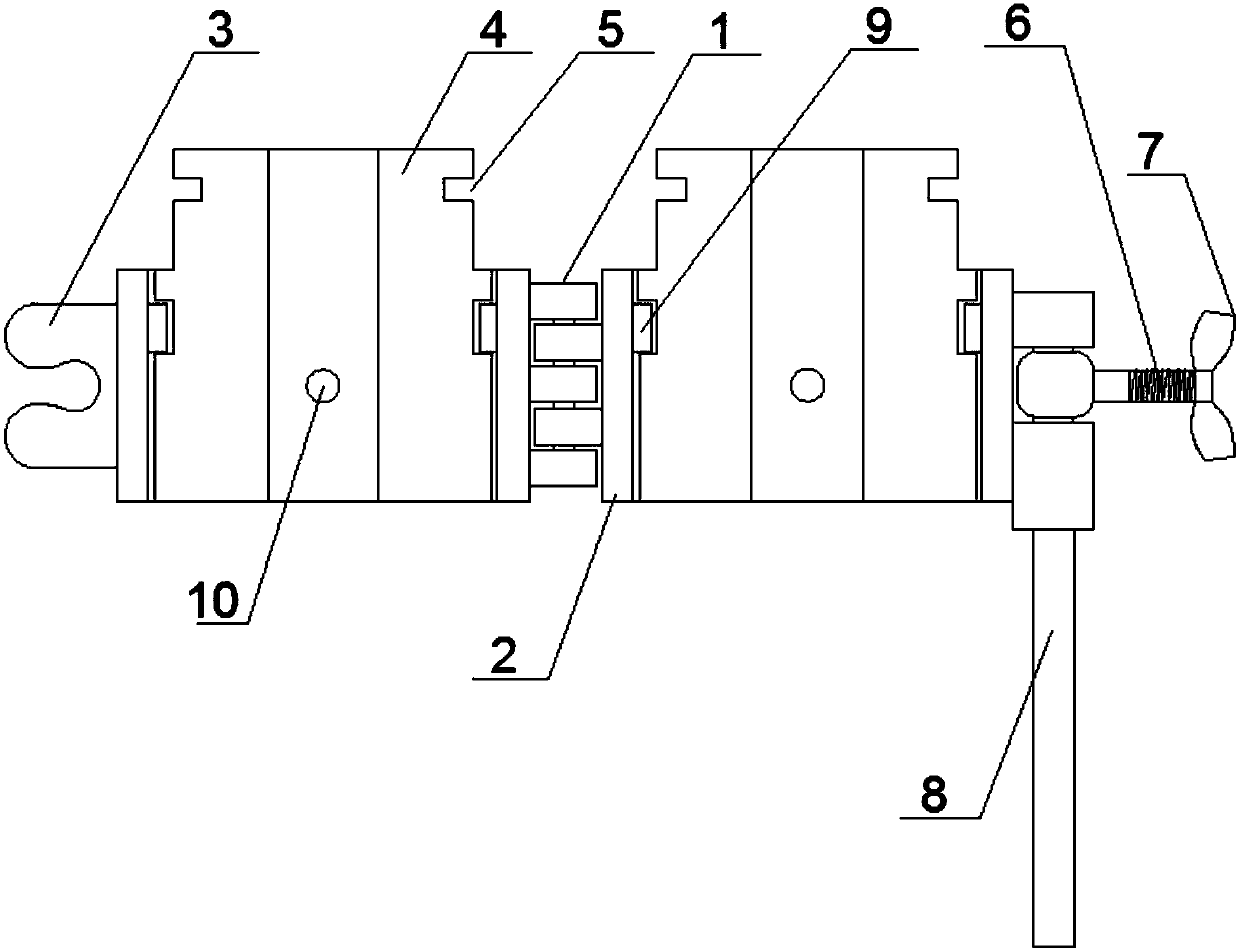

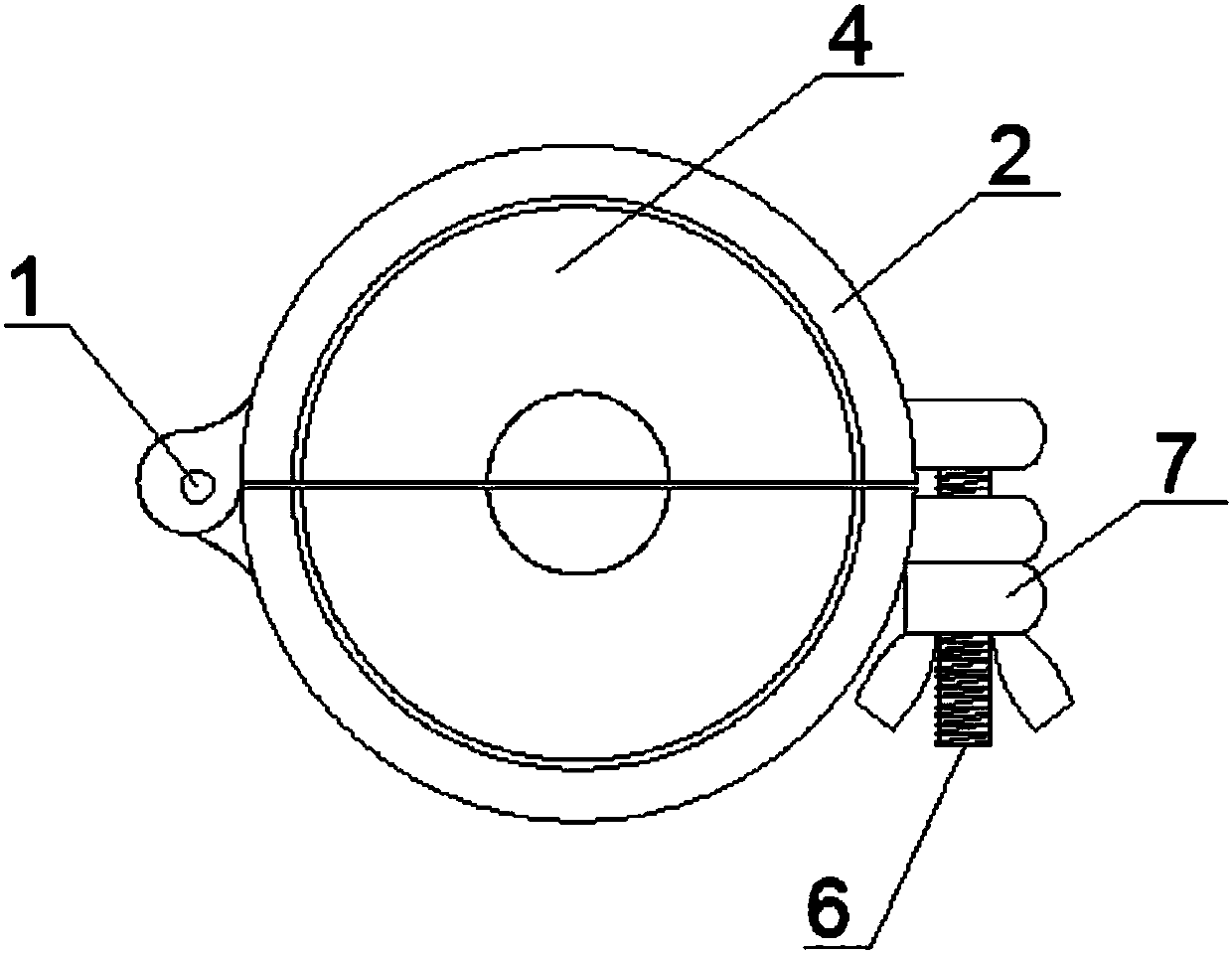

[0014] The present invention is a portable LGJ-steel-reinforced wire positioning gripper, the device includes a two-lobed semi-annular positioning mold buckle 2 hinged by means of a hinge 1, the free ends of the positioning mold buckle 2 are respectively provided with connecting seats, and the Fasteners fasten the two connecting seats into a whole. The key point is that the inside of the positioning die buckle 2 is respectively fixed with a semi-circular positioning die 4, and the radius of the outer surface of the positioning die 4 is equal to that of the positioning die buckle 2. The radius of the inner surface, the radius of the inner surface of the positioning die 4 is equal to the radius of the steel-cored aluminum stranded wire, the end of the positioning die 4 protrudes from the buckle 2 of the positioning die and is provided with a groove for fixing the rotary disc cutter cam 5.

[0015] The present invention will be further described below in conjunction with the acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com