A circular blade applied to ultrasonic machining and its design method

A design method and technology of round inserts, which are applied to tools for lathes, metal processing equipment, milling cutters, etc., can solve the problems of poor processing quality, high cutting temperature of the tool body, and low processing efficiency, and are easy to reflect and realize. , The effect of high surface processing quality and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

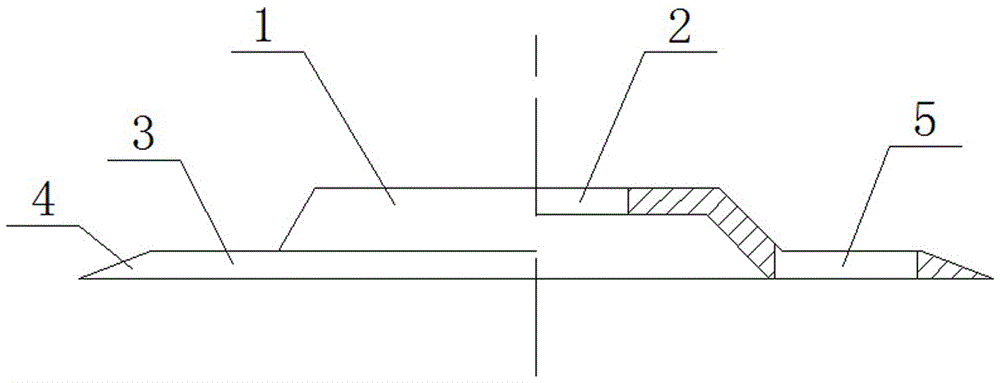

[0053] The resonant frequency of the ultrasonic vibration processing system is 20kHz, the diameter of the circular blade is D=52mm, the thickness of the circular blade is h=1.4mm, and the rake angle θ=14゜ of the circular blade rake angle 4 is a circular knife. The material of the tool is tool steel, and the material of the circular blade is The heat treatment should meet the work reliability requirements, and it can work normally within the specified cutting time without abnormal fracture. Elastic modulus E=2e11Pa, Poisson's ratio μ=0.3, density ρ=7800Kg / m 3 , you can get a radially grooved circular blade, the structure shows Figure 4 . The specific steps of slot design are as follows.

[0054] (1) Calculate the resonant frequency of a circular blade with a diameter of 52mm?; establish an ANSYS model for finite element analysis, and calculate the vibration mode of the circular blade.

[0055] In the cylindrical coordinate system, the free lateral vibration differential equat...

Embodiment 2

[0076] The resonant frequency of the ultrasonic vibration processing system is 20kHz, the diameter of the circular blade is D=25mm, the thickness of the circular blade is h=1.4mm, and the rake angle θ=14゜ of the circular blade rake angle 4 is a circular knife. The material of the tool is tool steel, and the material of the circular blade is The heat treatment should meet the work reliability requirements, and it can work normally within the specified cutting time without abnormal fracture. Elastic modulus E=2e11Pa, Poisson's ratio μ=0.3, density ρ=7800Kg / m 3 , you can get radial grooving circular inserts. The specific steps of slot design are as follows.

[0077] (1) Design the structural diagram of a circular blade with a diameter of 25 mm, establish an ANSYS model for finite element analysis, and calculate the vibration mode of the circular blade.

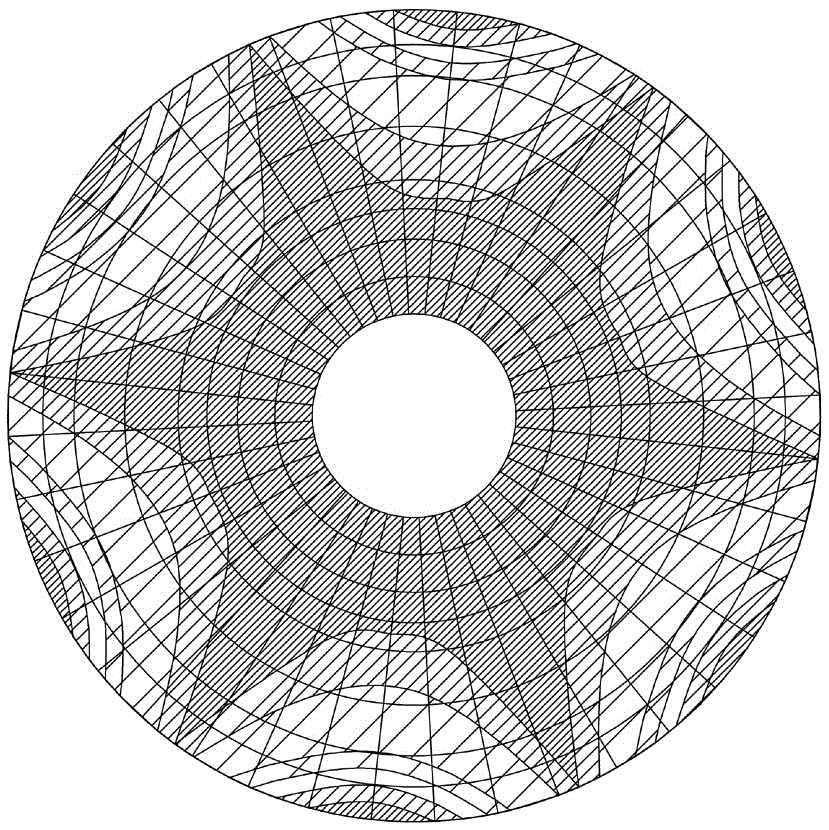

[0078] (2) From the vibration mode, it is determined that the number of nodal lines a distributed in the diameter of the circ...

Embodiment 3

[0087] The resonant frequency of the ultrasonic vibration processing system is 20kHz, the diameter of the circular blade is D=102mm, the thickness of the circular blade is h=9mm, the rake angle θ=18゜ of the circular blade rake angle 4 is a circular knife, the tool material is tool steel, and the elastic modulus E= 2e11Pa, Poisson's ratio μ=0.3, density ρ=7800Kg / m3, you can get circular blades with radial grooves. The specific steps of slot design are as follows.

[0088] (1) Design the structural diagram of the circular blade, establish the ANSYS model for finite element analysis, and calculate the vibration mode of the circular blade.

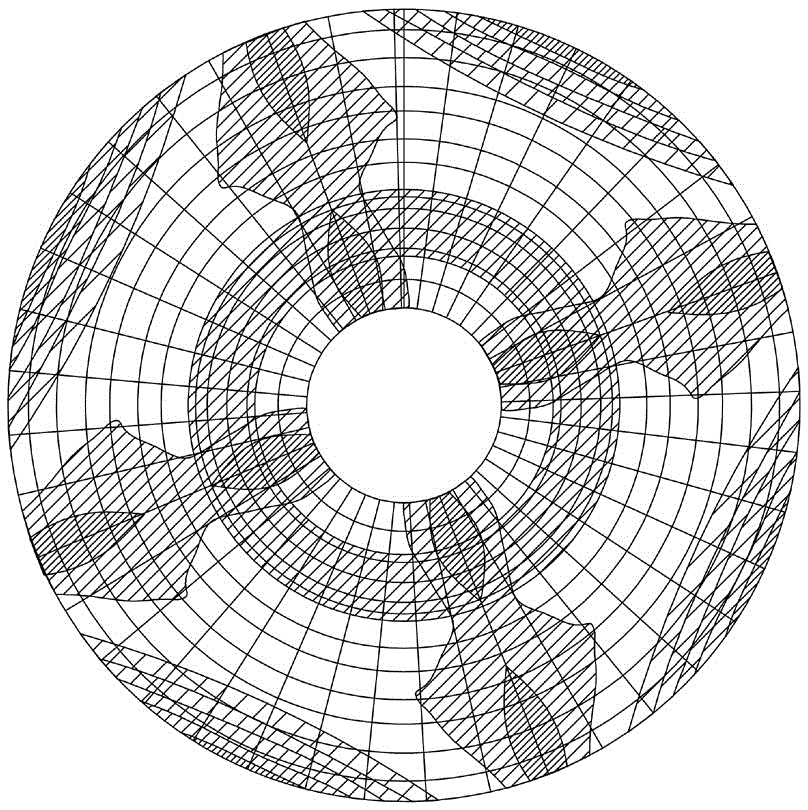

[0089] (2) From the vibration mode, it is determined that the nodal line a of the circular blade diameter distribution with a small vibration amplitude is 2, such as Figure 5 shown.

[0090] (3) In the vibration mode, there are two pitch circles b distributed on the circumference of the circular blade with relatively small vibration amplitu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com