Mechatronic pipe fitting cutting device

A cutting device and technology for pipe fittings, applied in the field of pipe fittings processing, can solve the problems of poor quality and a large number of burrs on the cutting surface of pipe fittings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

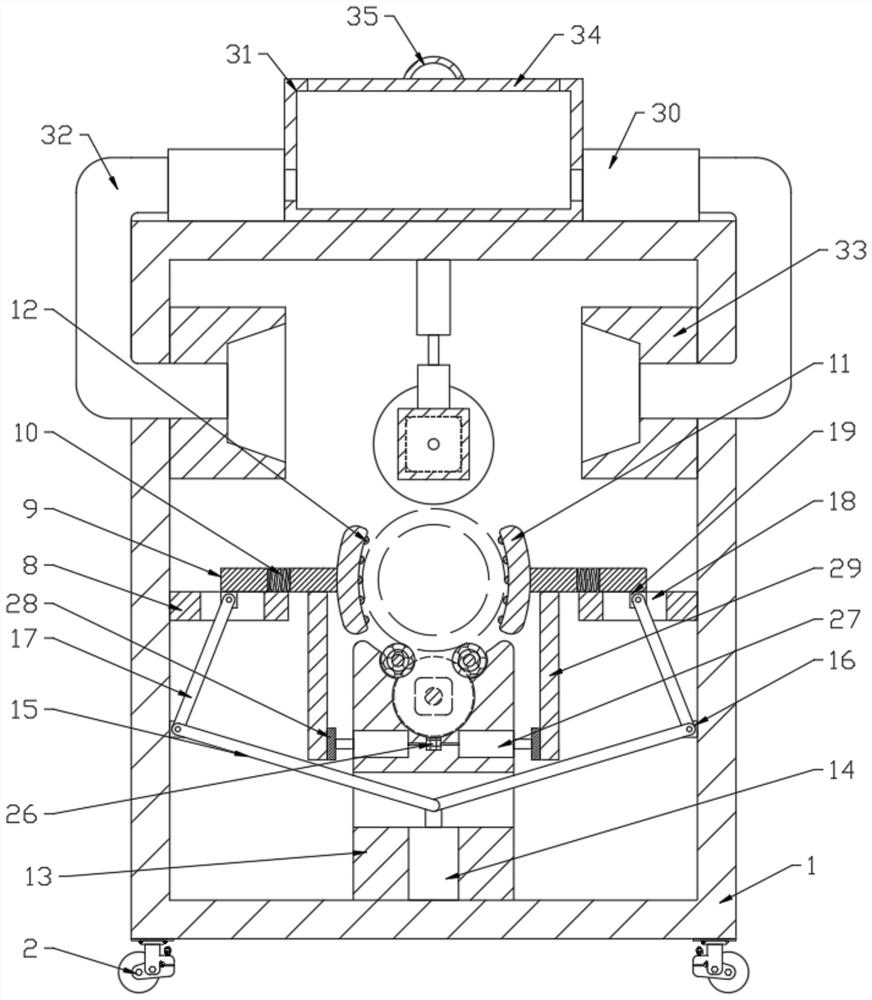

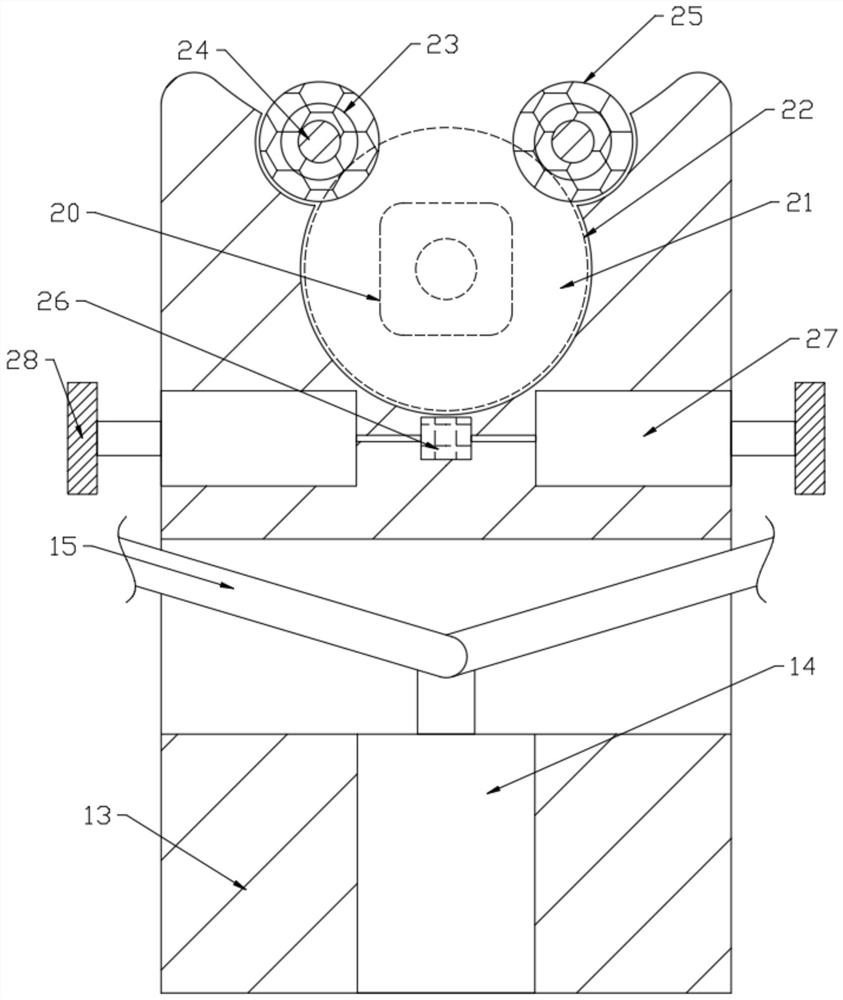

[0025]SeeFigure 1-5, An electromechanical integrated pipe cutting device, comprising a frame body 1, characterized in that the upper end of the frame body 1 is provided with a cutting assembly for cutting pipe fittings, and the inner sides of the frame body 1 are respectively fixedly connected with a fixing seat 8 and the fixing seat 8 There is a fixing assembly for fixing the pipe fittings. The frame body 1 is equipped with a column 13 at the lower end. The frame body 1 is provided with a driving assembly for driving the fixing assembly to work. The column 13 is provided with a rotating assembly for driving the pipe to rotate. There are failed components that drive fixed components temporarily failed.

[0026]Further, the lower end of the frame body 1 is provided with four rollers 2 with brake blocks to facilitate the device to move to different positions for work;

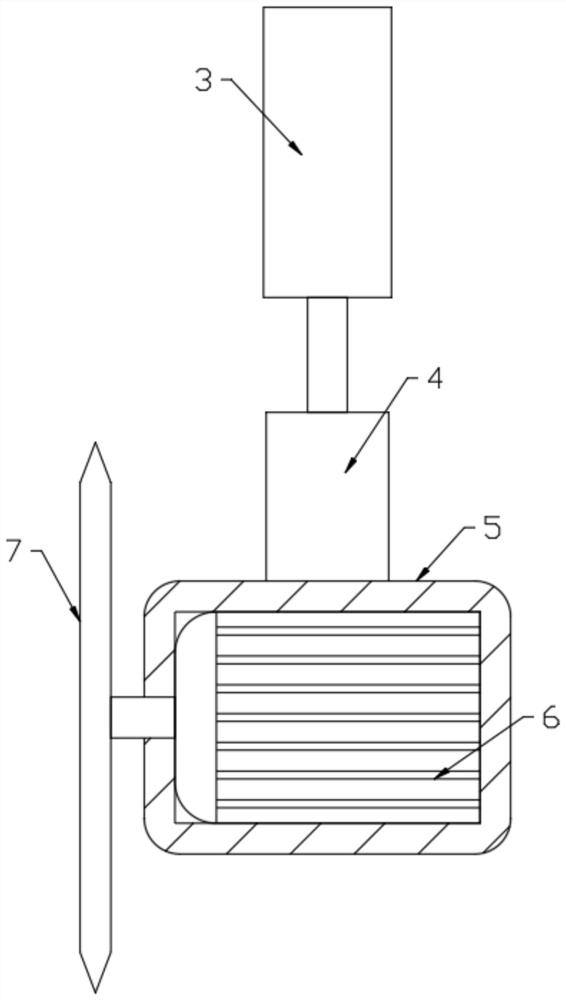

[0027]The cutting assembly includes a first hydraulic component 3, a connecting column 4, a case 5, a first motor 6, and a...

Embodiment 2

[0040]Further improvements are made on the basis of Embodiment 1, and the improvements are as follows: Fans 30 are provided on both sides of the upper end of the frame 1, and one end of the fan 30 is connected to the slag suction block 33 fixedly connected in the frame 1 through a connecting pipe 32. The other end of the fan 30 communicates with the slag storage cylinder 31 fixedly connected to the upper end of the frame body 1. The upper end of the slag storage cylinder 31 is threadedly connected with a cylinder cover 34, and the upper end of the cylinder cover 34 is fixedly connected with a grip ring 35. The fan 30 works through the connecting pipe 32 and the suction The slag block 33 absorbs the waste generated during the cutting work, and then is stored in the slag storage cylinder 31, and the grip ring 35 is rotated so that the cylinder cover 34 is removed from the slag storage cylinder 31 to clean the inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com