Multi-material three-dimensional printer nozzle

A 3D printer and nozzle technology, which is applied in the fields of additive manufacturing, coating devices, processing heating elements, etc., can solve the problems of unsmooth material change, complex structure, and easy softening of consumables in advance, so as to prevent material jams and reduce equipment volume. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

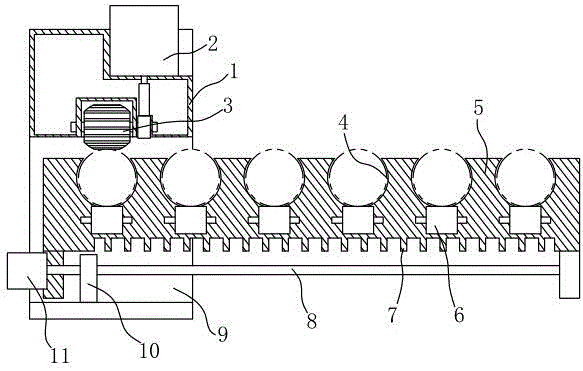

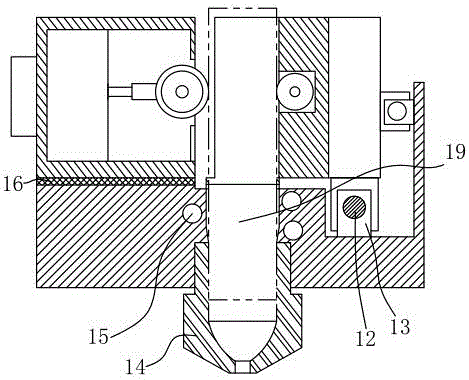

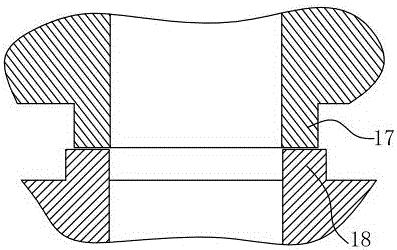

[0020] Embodiment: A multi-material three-dimensional printer nozzle, including a nozzle seat 9, a nozzle body 14 arranged at the bottom of the nozzle seat 9, a pinch chamber 1 is provided on the top side of the nozzle seat 9, and the pinch chamber 1 A pinch motor 2 is provided on the pinch chamber 1, and a main pinch wheel 3 is provided on the pinch chamber 1, and the main pinch wheel 3 is connected to the pinch motor 2 by transmission. The nozzle body 14 communicates with the vertical guide hole 19, the nozzle seat 9 is provided with a heating pipe 15, and the other side of the top surface of the nozzle seat 9 is provided with a guide block 5, and the guide block 5 is provided with a vertical There are at least two guide grooves 4, the guide grooves 4 open towards the side of the pinch chamber 1, the cross section of the guide grooves 4 is fan-shaped and its central angle is greater than 180°, the guide grooves 4 is provided with a secondary pinch wheel 6 opposite to the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com