Underwater ventilation cavity assisted high-pressure water jet cutting device

A high-pressure water jet and cutting device technology, applied in the direction of explosion generation device, abrasive feeding device, used abrasive processing device, etc., can solve the problems of reduced cutting efficiency, unstable high-pressure pump, high energy consumption, etc. Achieve the effect of neat cutting surface, guarantee of safety and high water jet speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

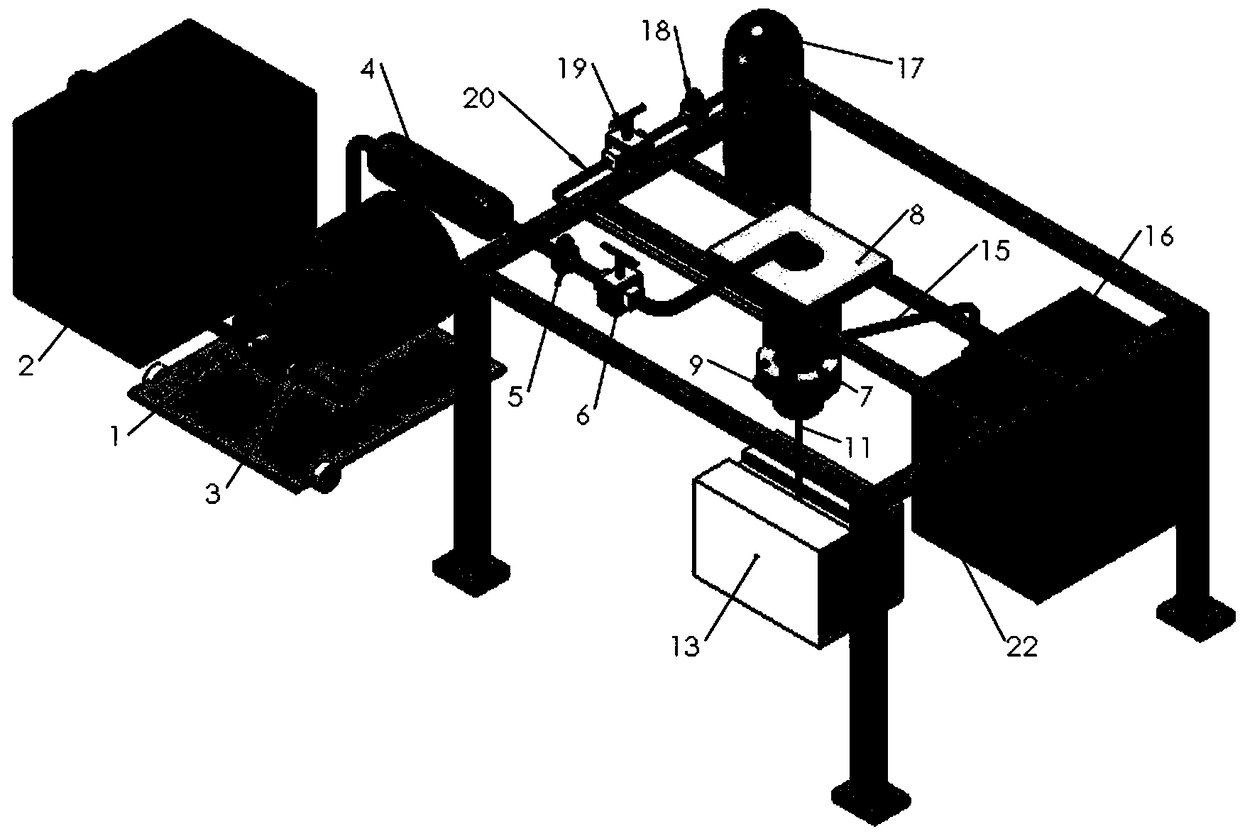

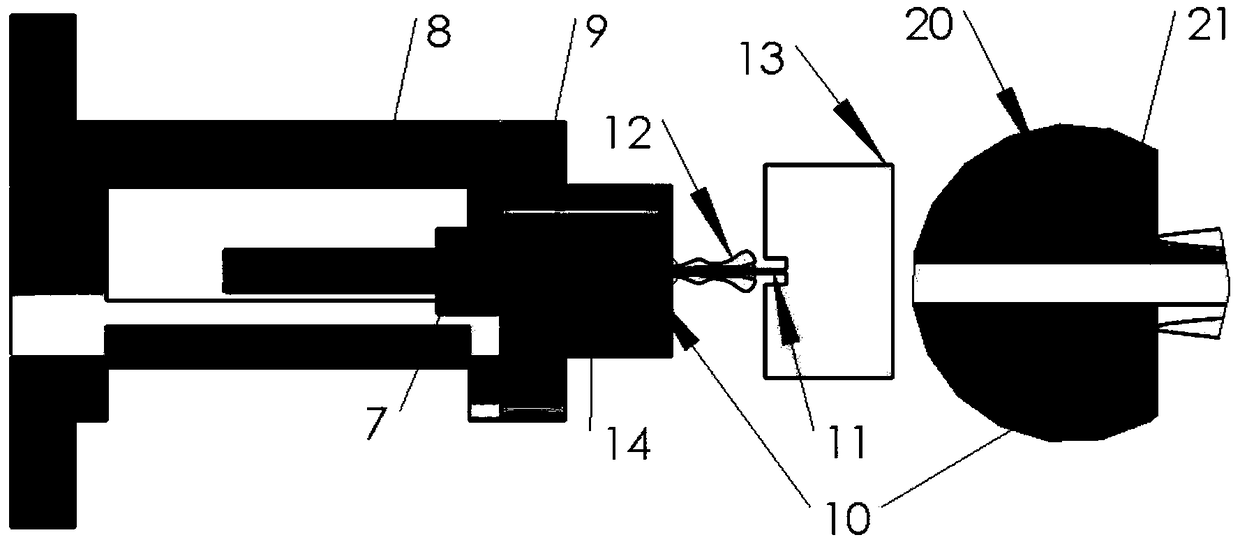

[0018] as attached figure 1 Shown is the system structure diagram of the present invention, attached figure 2 Shown is a partially enlarged view of the water injection part of the present invention. An underwater ventilation cavitation assisted high-pressure water jet cutting device, including a high-pressure water pump 1, a water tank 2, a high-pressure water pipe 3, an accumulator 4, a pressure regulating valve 5, a flow meter 6, a water pipe joint 7, and a water knife fixed slider 8 , water jet reactor 9, ruby nozzle 10, high-speed water jet 11, air bubble 12, workpiece to be cut 13, frosted mixing pipe 14, frosted delivery pipe 15, frosted 16, high-pressure gas cylinder 17, gas pressure regulating valve 18 , gas 19, air pipe 20, air cavity 21, water jet CNC guide rail mounting frame 22; the high-pressure water tank is located on the far left side of the device, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com