Floating type garlic root cutting device guided in through roller

A floating, drum technology, applied in application, food processing, food science, etc., can solve the problems of short cutting effect, poor application effect, reduce the force of the cutter on the root system, etc., to achieve good adaptability and avoid garlic damage. , Reduce the effect of garlic damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

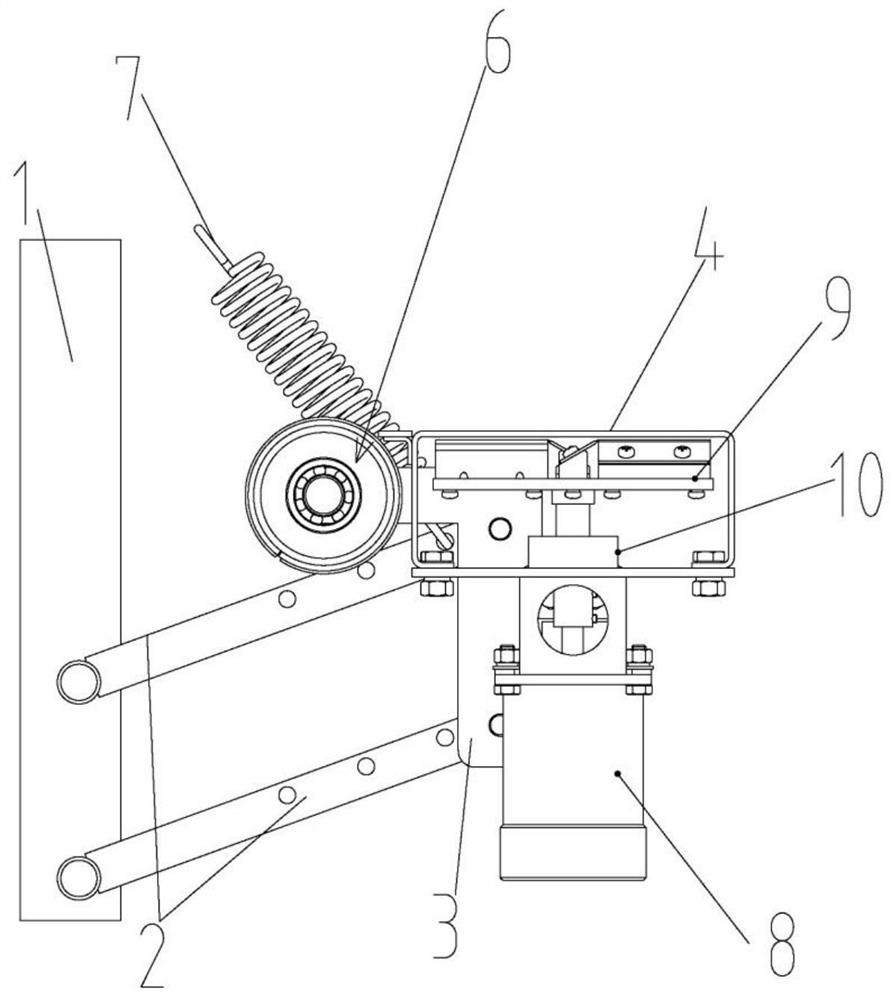

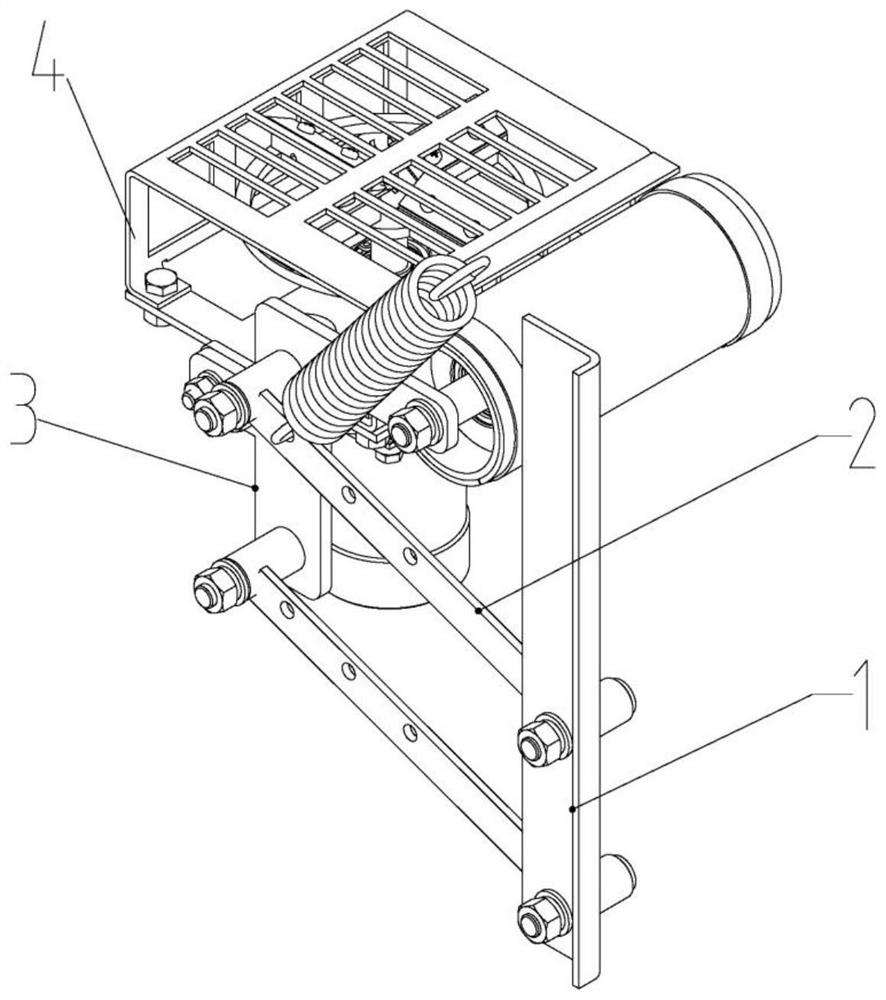

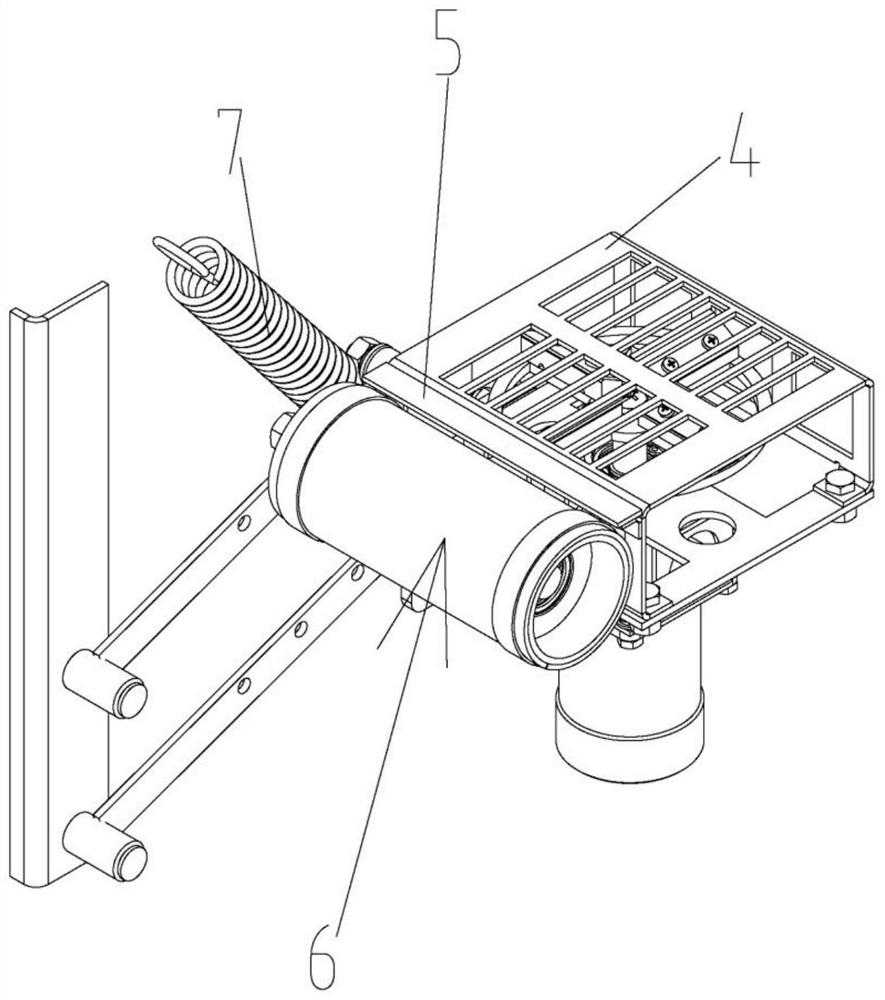

[0038] Attached below Figure 1-8 The present invention is further illustrated with specific examples. The front and rear mentioned in this embodiment are based on the conveying direction of the garlic, that is, the garlic is set to be arranged in a straight line from front to back for conveying.

[0039] Such as Figure 7 , 8 As shown, a floating garlic root-cutting device introduced by a roller includes a floating root-cutting main body part 11 between two alignment chains 13 (the two alignment chains 13 are directly below the two clamping chains 12), such as Figure 1-3 As shown, the floating root cutting body part 11 includes:

[0040] The riser 1 fixed on the alignment chain frame 14 and extending downward based on the alignment chain frame 14;

[0041] A parallelogram linkage mechanism that is composed of a pair of swing arms 2 that are parallel to each other and of equal length and that moves in the vertical direction. One end of the two swing arms 2 is rotatably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com