Glass tube cutting mechanism

A cutting mechanism and glass tube technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as easy to burst, and achieve the effect of increasing safety

Inactive Publication Date: 2018-11-13

爱克斯瑞真空技术(苏州)有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In view of this, the present invention proposes a glass tube cutting mechanis

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

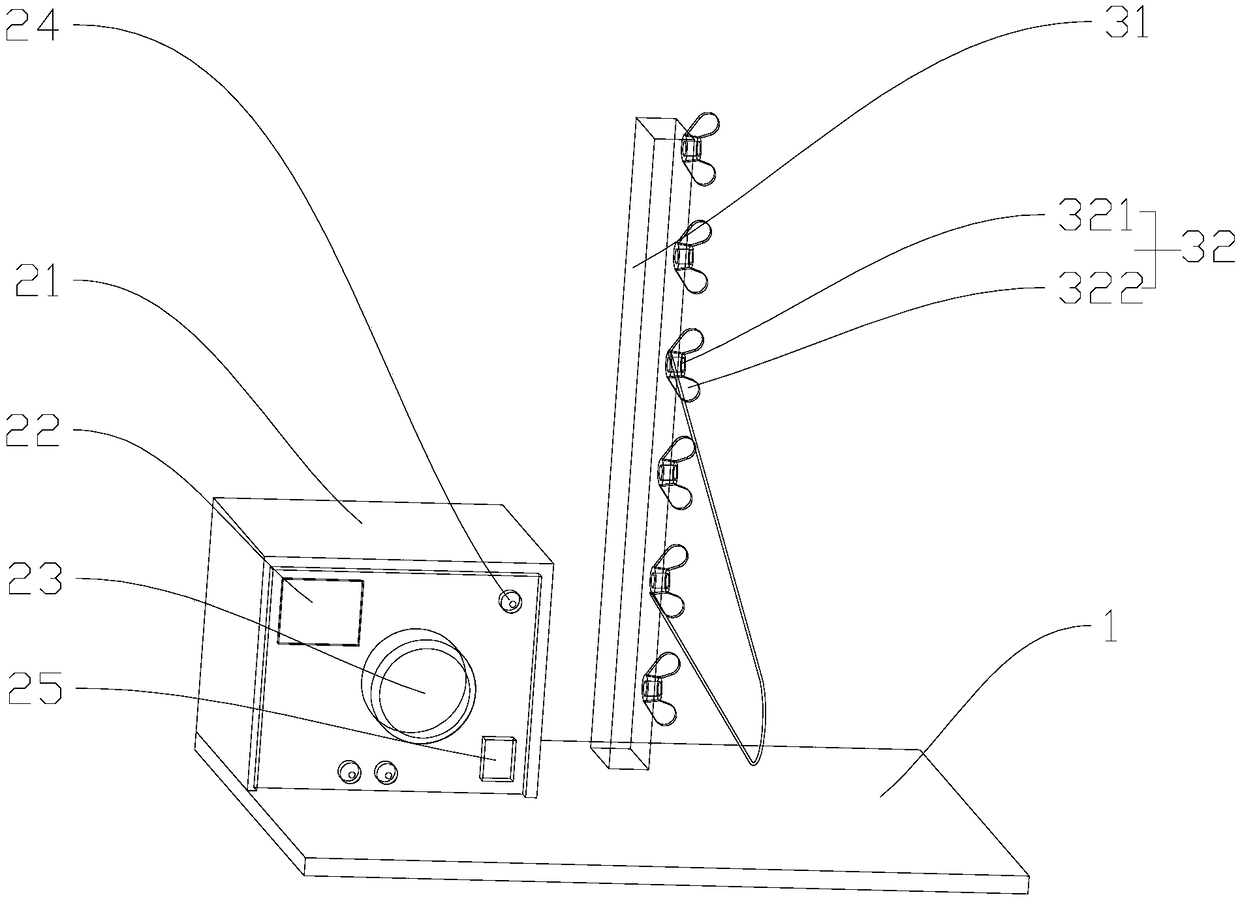

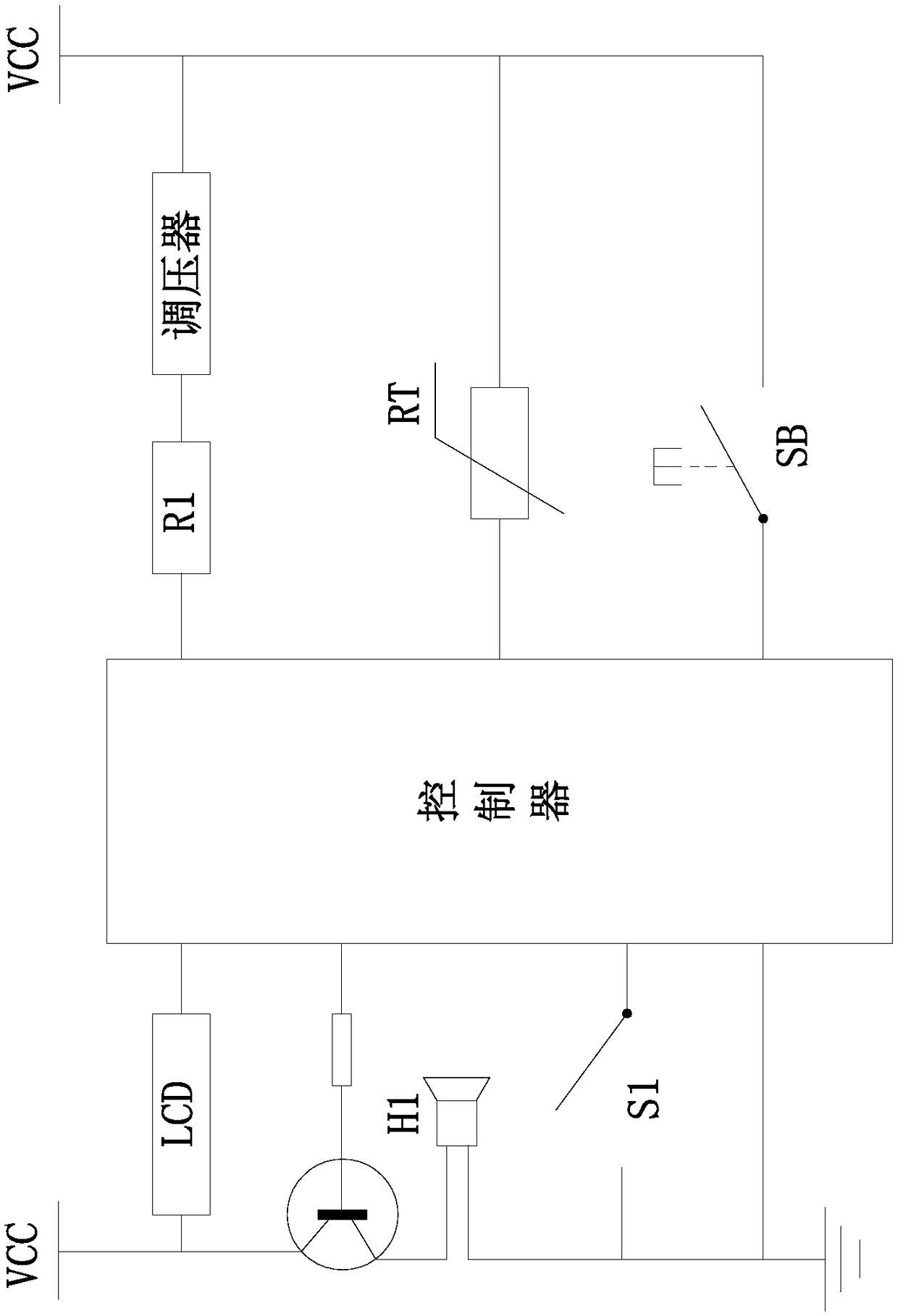

The invention relates to the technical field of glass tube cutting and in particular relates to a glass tube cutting mechanism which comprises a bottom plate, a heating device and a fixing adjustmentdevice, wherein the fixing adjusting device is arranged on the bottom plate; the heating device comprises a controller, an LCD (Liquid Crystal Display), a voltage adjusting knob, a switch button SB, apower supply switch S1, a temperature sensor RT, a voltage regulator and an electric heating wire R1, wherein the fixing adjusting device comprises a vertical column which is fixed on the bottom plate and a plurality of connecting interfaces; the LCD, the voltage adjusting knob, the switch button SB, the power supply switch S1 and the temperature sensor RT are arranged on the shell of the voltageregulator; the temperature sensor is used for sensing a current electric heating wire temperature. By adopting the glass tube cutting mechanism, the problem that a glass tube is liable to explode andcrack when being cut by using a conventional tool can be solved, the glass tube cut with the electric heating wire is tidy in cut section, and the cut section is not a matt side.

Description

technical field [0001] The invention relates to the technical field of glass tube cutting, in particular to a glass tube cutting and loading mechanism. Background technique [0002] X-ray tubes are vacuum diodes that operate at high voltages. Contains two electrodes: one is a filament for emitting electrons, as a cathode, and the other is a target for receiving electron bombardment, as an anode, both stages are sealed in a high-vacuum glass or ceramic shell. [0003] Glass tubes are an essential part of X-ray tubes. Currently, the glass tubes purchased in the market are all long lengths, which need to be divided into small pieces when used. [0004] Using traditional tools to cut glass tubes has problems such as irregular cutting, fogging on the cutting section, easy bursting during cutting, and unsafety. Contents of the invention [0005] In view of this, the present invention proposes a glass tube cutting mechanism to solve the problem of easy bursting of traditional t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03B33/095

CPCC03B33/095

Inventor 王炳唐天权颜加润毛燕王丽娟

Owner 爱克斯瑞真空技术(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com