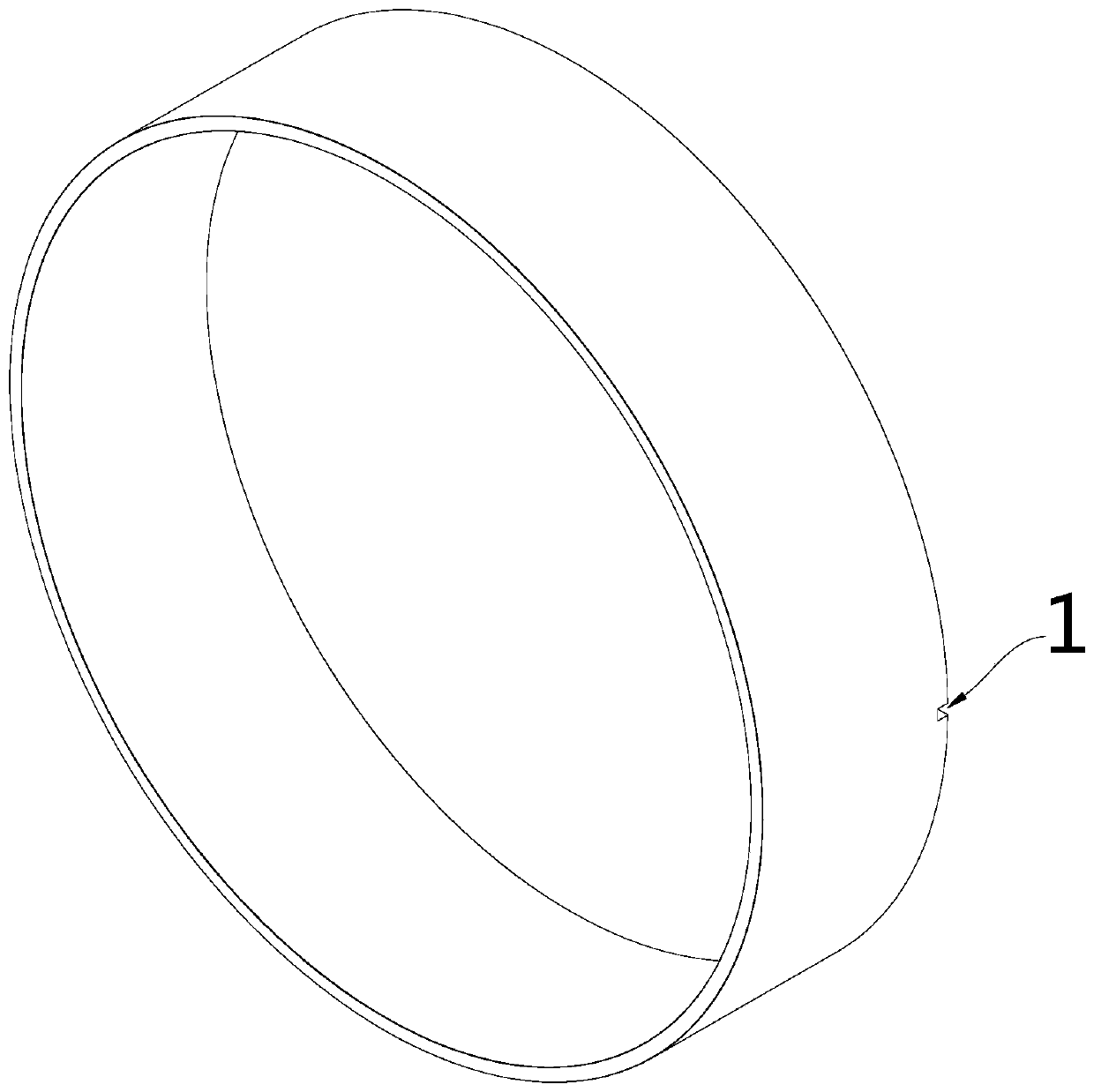

Notched Quartz Macroring Polishing Process

A technology of quartz and notch, which is applied in the polishing process of quartz macrorings, can solve problems such as easy bursting, and achieve the effects of reducing the probability of bursting, reducing subsequent bursting, and reducing polishing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the quartz macroring polishing process with notch, comprises the following steps:

[0034] A. Grinding outer diameter;

[0035] B. Clean the polished quartz ring;

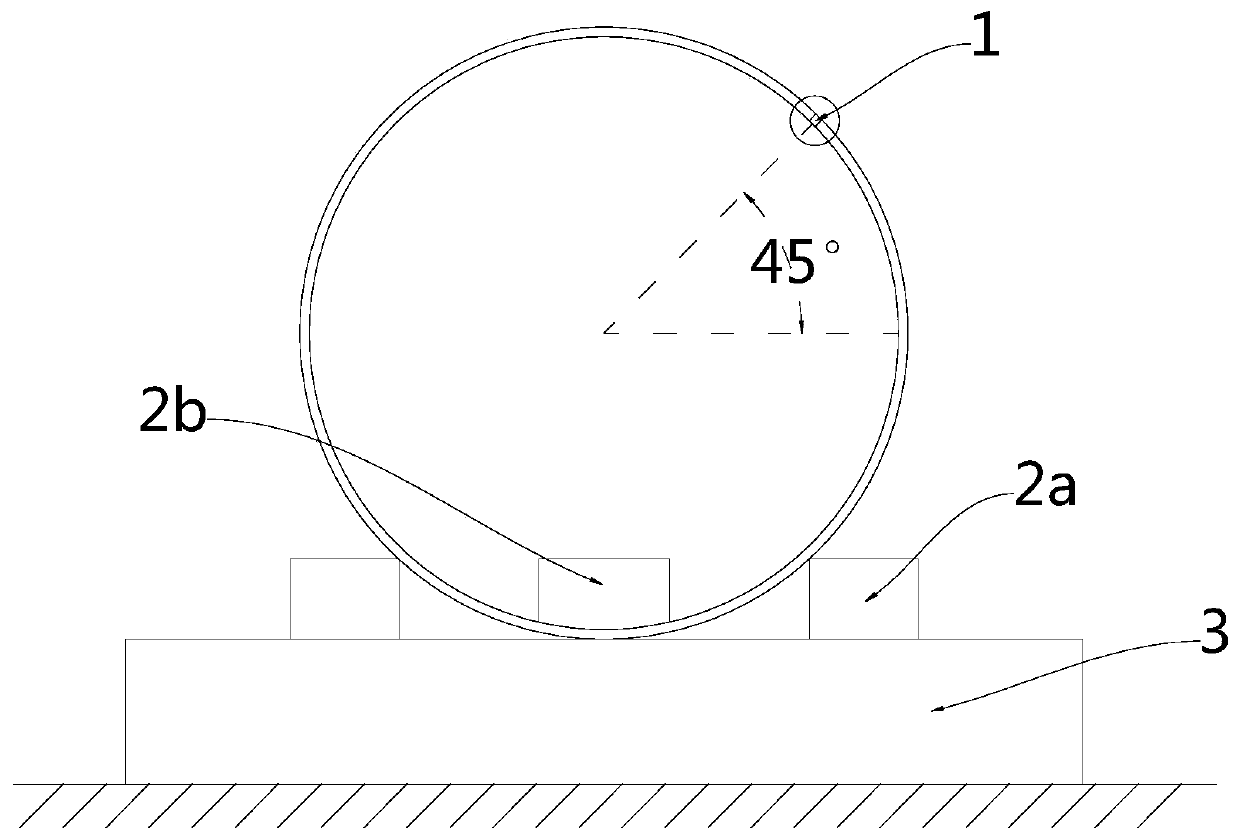

[0036] C. Keep the axis of the large quartz ring horizontal and place it on the workbench, so that the notch of the large quartz ring is at the midpoint of the quarter arc with the highest point of the large quartz ring as the endpoint;

[0037] D. Slowly push the large quartz ring into the annealing furnace for heating. When the temperature of the annealing furnace rises to 950°C, stop heating and slowly drag the large quartz ring out;

[0038] E. Perform high-temperature polishing on the half circumference of the upper part of the large quartz ring by means of flame jetting, first polish the notch, then polish the edges on both sides, and finally polish the inner and outer walls;

[0039] F. Slowly push the quartz macroring into the annealing furnace for annealing;

[0040] G. To check the...

Embodiment 2

[0052] Embodiment 2: the quartz macroring polishing process with notch, comprises the following steps:

[0053] A. Grinding outer diameter;

[0054] B. Clean the polished quartz ring;

[0055] C. Keep the axis of the large quartz ring horizontal and place it on the workbench, so that the notch of the large quartz ring is at the midpoint of the quarter arc with the highest point of the large quartz ring as the endpoint;

[0056] D. Slowly push the large quartz ring into the annealing furnace for heating. When the temperature of the annealing furnace rises to 950°C, stop heating and slowly drag the large quartz ring out;

[0057] E. Perform high-temperature polishing on the half circumference of the upper part of the large quartz ring by means of flame jetting, first polish the notch, then polish the edges on both sides, and finally polish the inner and outer walls;

[0058] F. Slowly push the quartz macroring into the annealing furnace for annealing;

[0059] G. To check the...

Embodiment 3

[0071] Embodiment 3: the quartz macroring polishing process with notch, comprises the following steps:

[0072] A. Grinding outer diameter;

[0073] B. Clean the polished quartz ring;

[0074] C. Keep the axis of the large quartz ring horizontal and place it on the workbench, so that the notch of the large quartz ring is at the midpoint of the quarter arc with the highest point of the large quartz ring as the endpoint;

[0075] D. Slowly push the large quartz ring into the annealing furnace for heating. When the temperature of the annealing furnace rises to 950°C, stop heating and slowly drag the large quartz ring out;

[0076] E. Perform high-temperature polishing on the half circumference of the upper part of the large quartz ring by means of flame jetting, first polish the notch, then polish the edges on both sides, and finally polish the inner and outer walls;

[0077] F. Slowly push the quartz macroring into the annealing furnace for annealing;

[0078] G. To check the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com