Patents

Literature

34results about How to "Increased tensile and shear capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

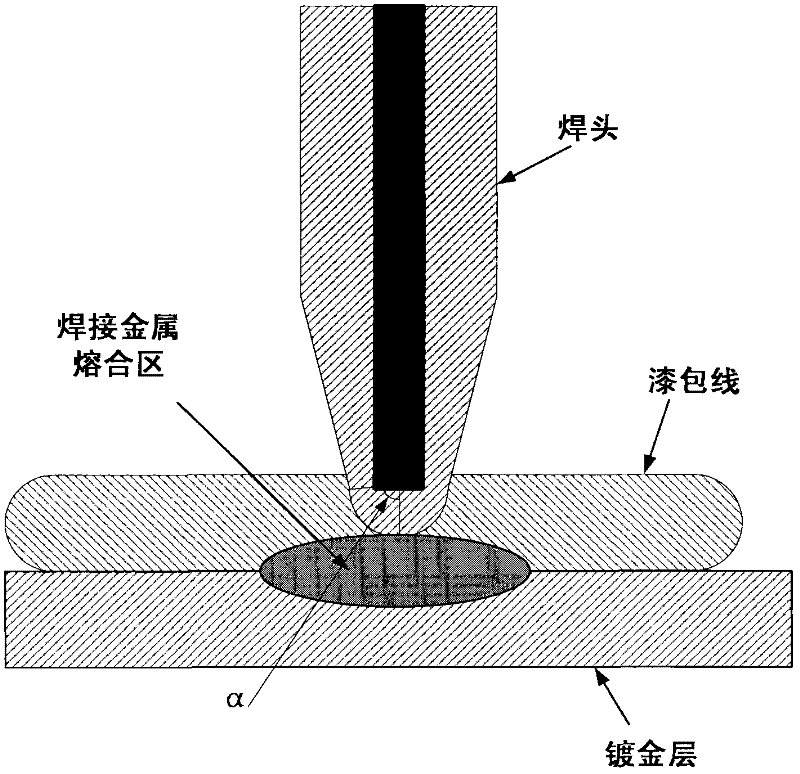

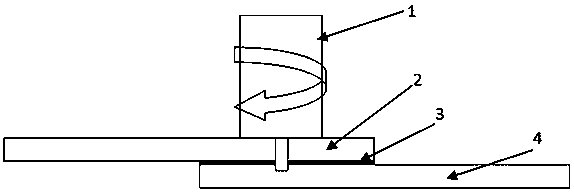

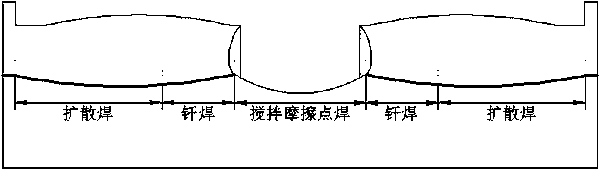

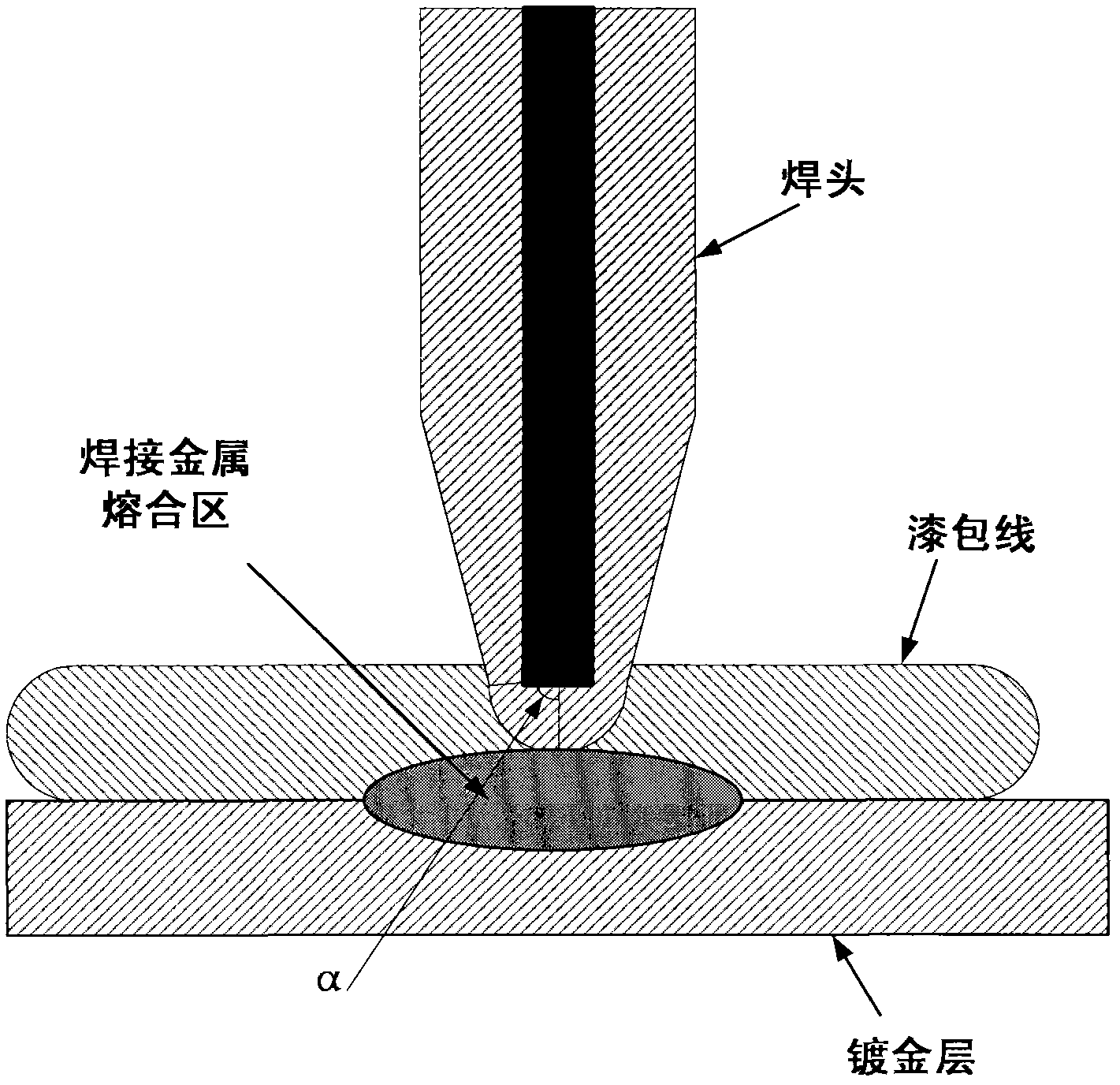

Method for synchronously implementing friction stir spot welding, soldering and diffusion welding of aluminum and magnesium dissimilar materials

ActiveCN105834608AIncrease the effective bearing areaIncreased tensile and shear capacitySoldering apparatusWelding/soldering/cutting articlesMagnesiumAluminium

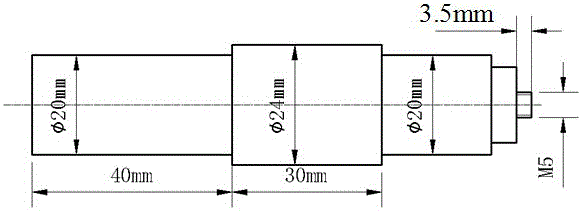

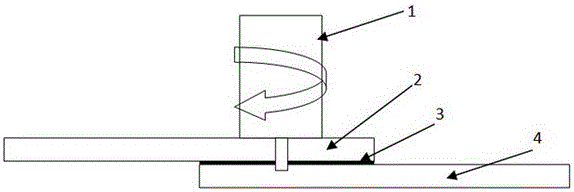

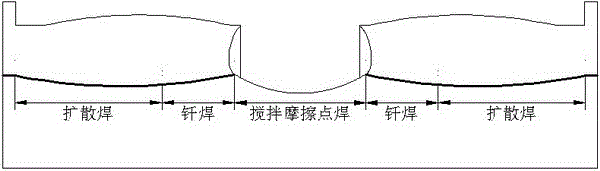

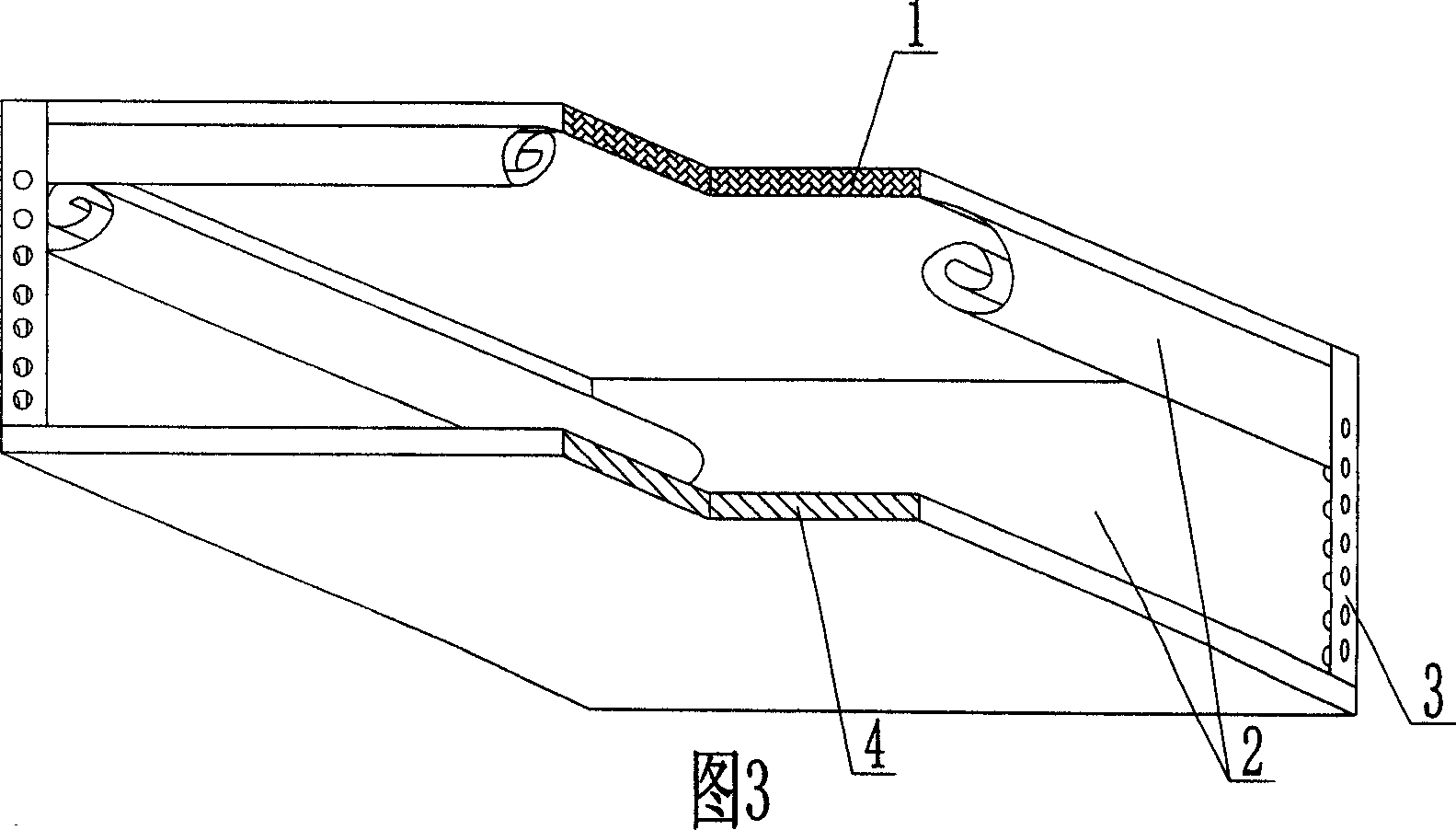

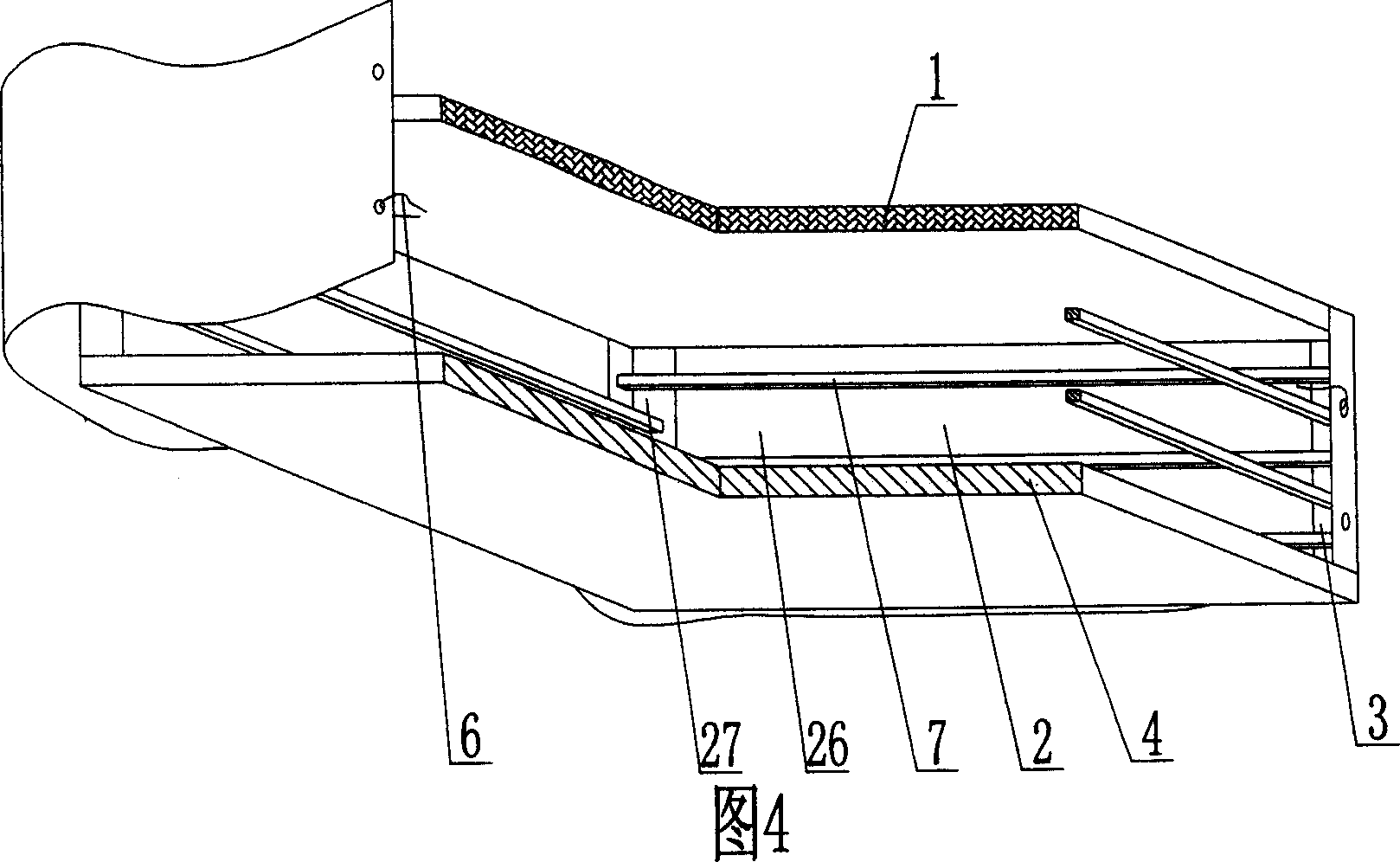

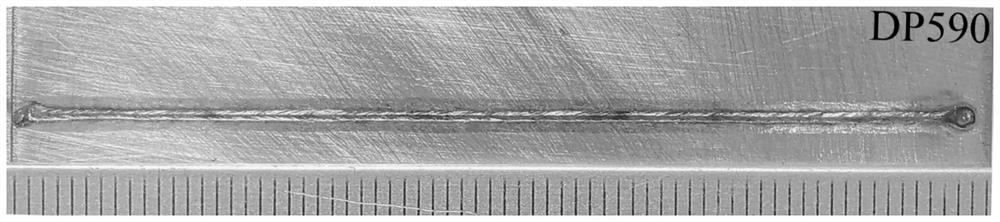

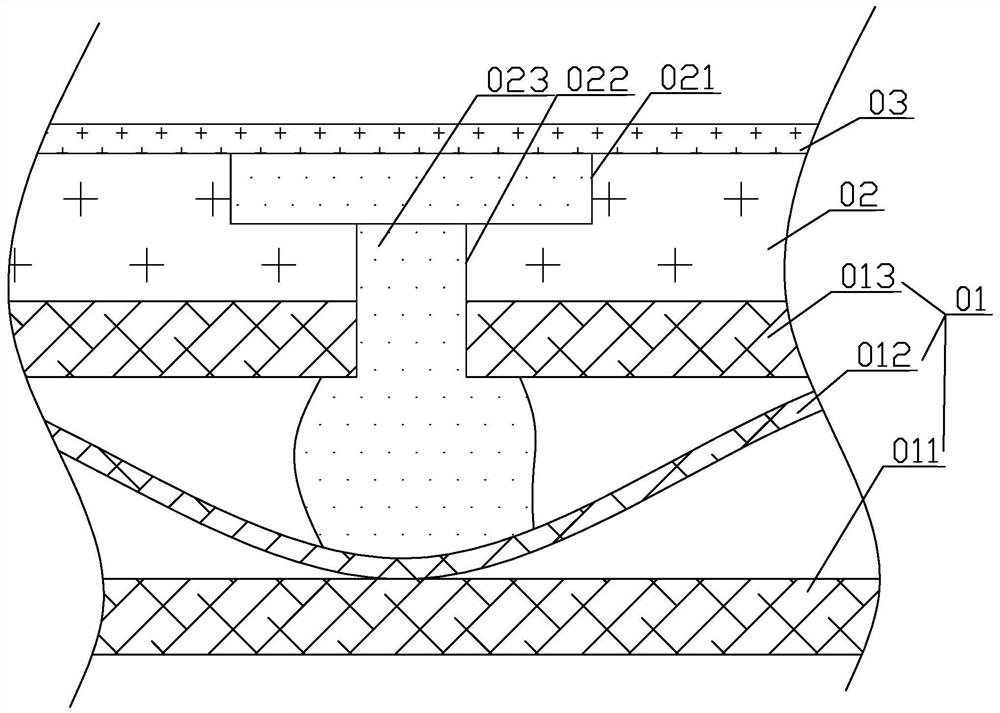

The invention discloses a method for synchronously implementing friction stir spot welding, soldering and diffusion welding of aluminum and magnesium dissimilar materials. The operation process includes the following steps of fixing a clean aluminum plate to a clean magnesium plate in an overlap joint mode, adding a solder piece between the two plates with both sides of the solder piece in contact with the aluminum plate and the magnesium plate, and implementing friction stir spot welding on the fixed overlap joint structure. In the welding process, on the one hand, the friction stir spot welding of the aluminum plate and the magnesium plate is realized through the action of a stirring pin on a stirring head with the plates below; on the other hand, under the action of friction heat of a shaft shoulder of the stirring head and forging force, the surrounding area near the stirring pin is high in temperature, the solder piece is melted, and soldering connection is formed between the aluminum plate and the magnesium plate; while in the area far away from the stirring pin, atomic diffusion occurs between the aluminum plate and the solder piece as well as between the magnesium plate and the solder piece under the action of heat of stirring friction, so that diffusion welding is formed. The method can form soldering and diffusion welding connectors at the same time of friction stir spot welding, increase the effective bearing area of welding spots and improve the anti-tensioning shear force of the connectors.

Owner:NANCHANG HANGKONG UNIVERSITY

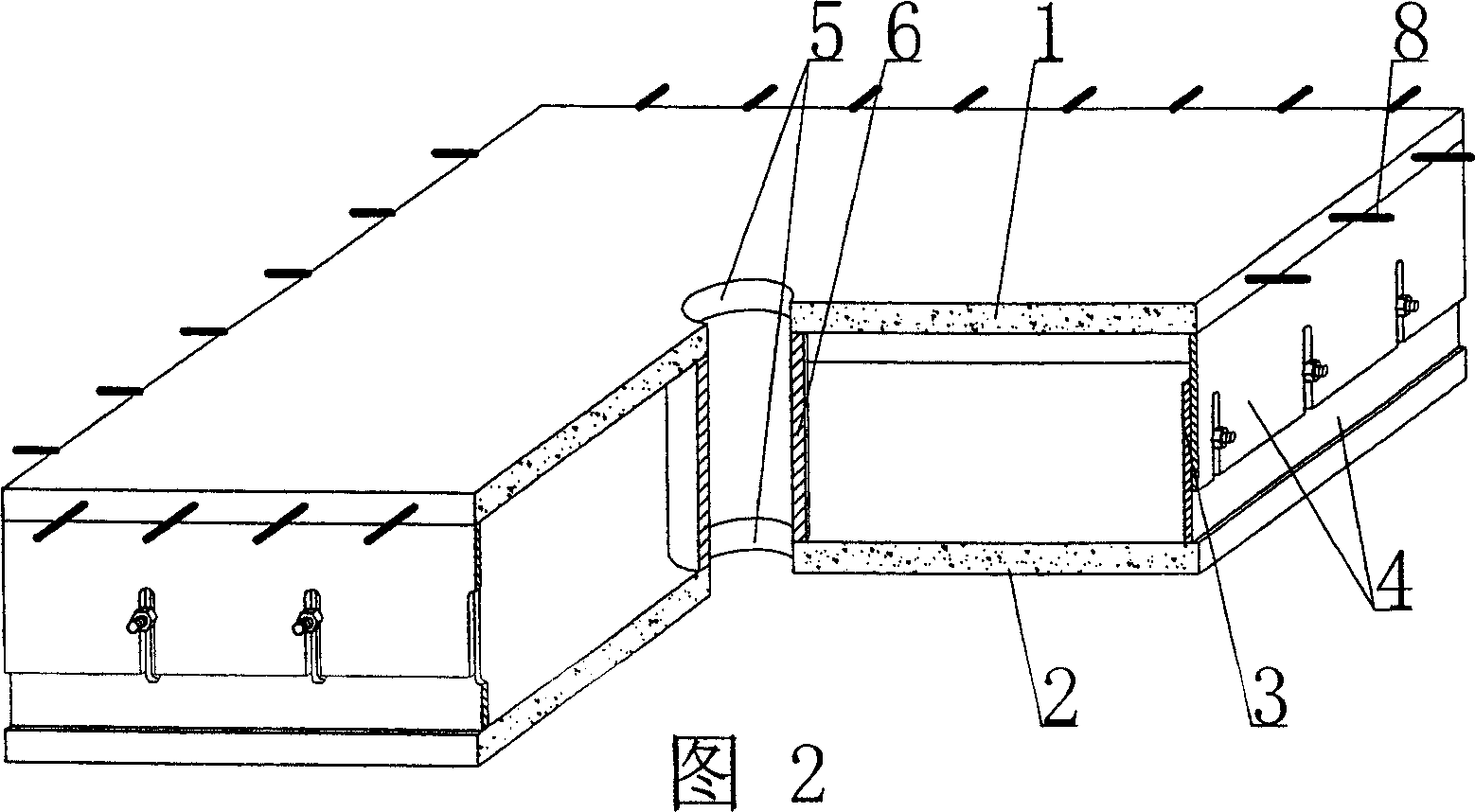

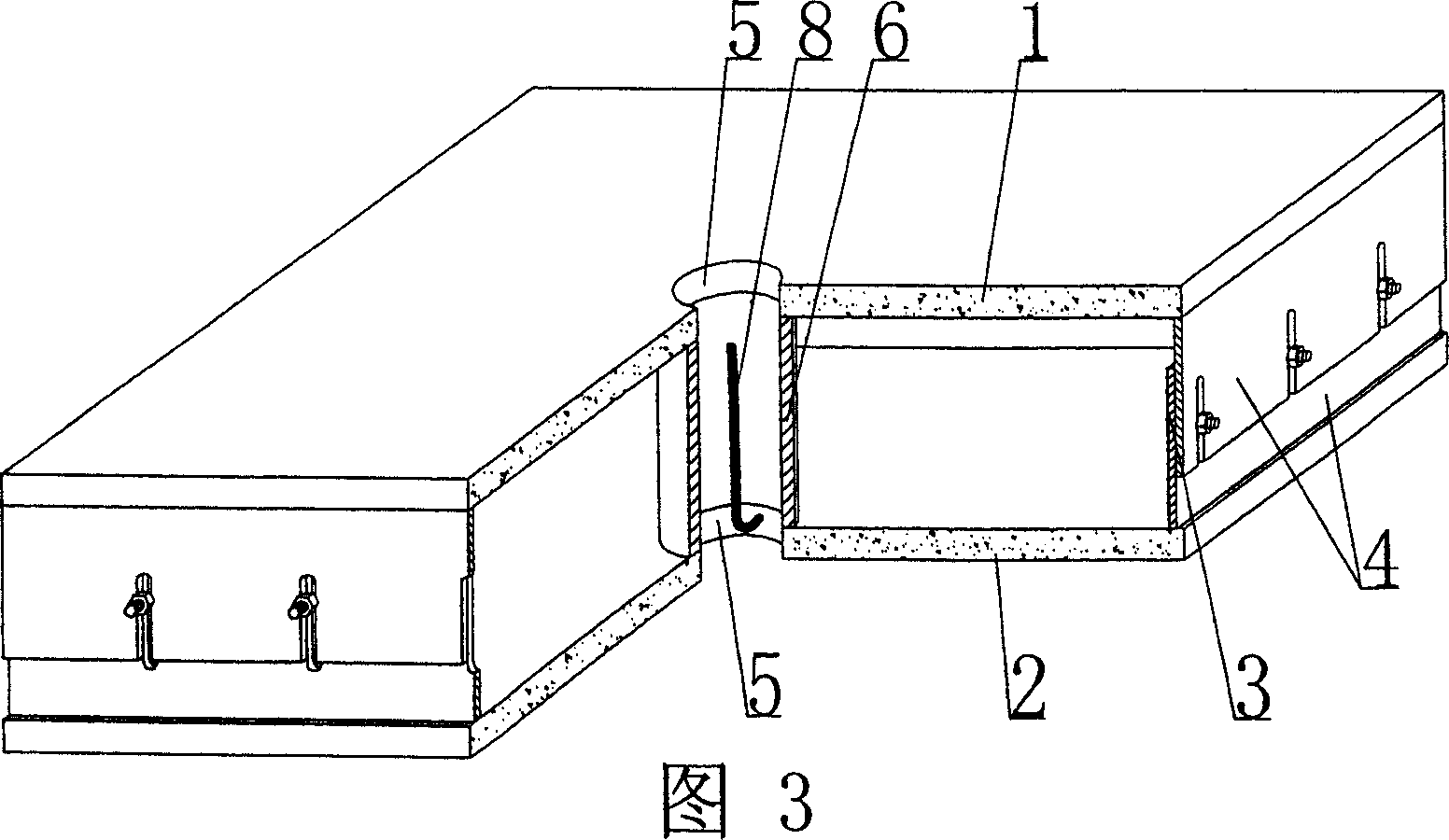

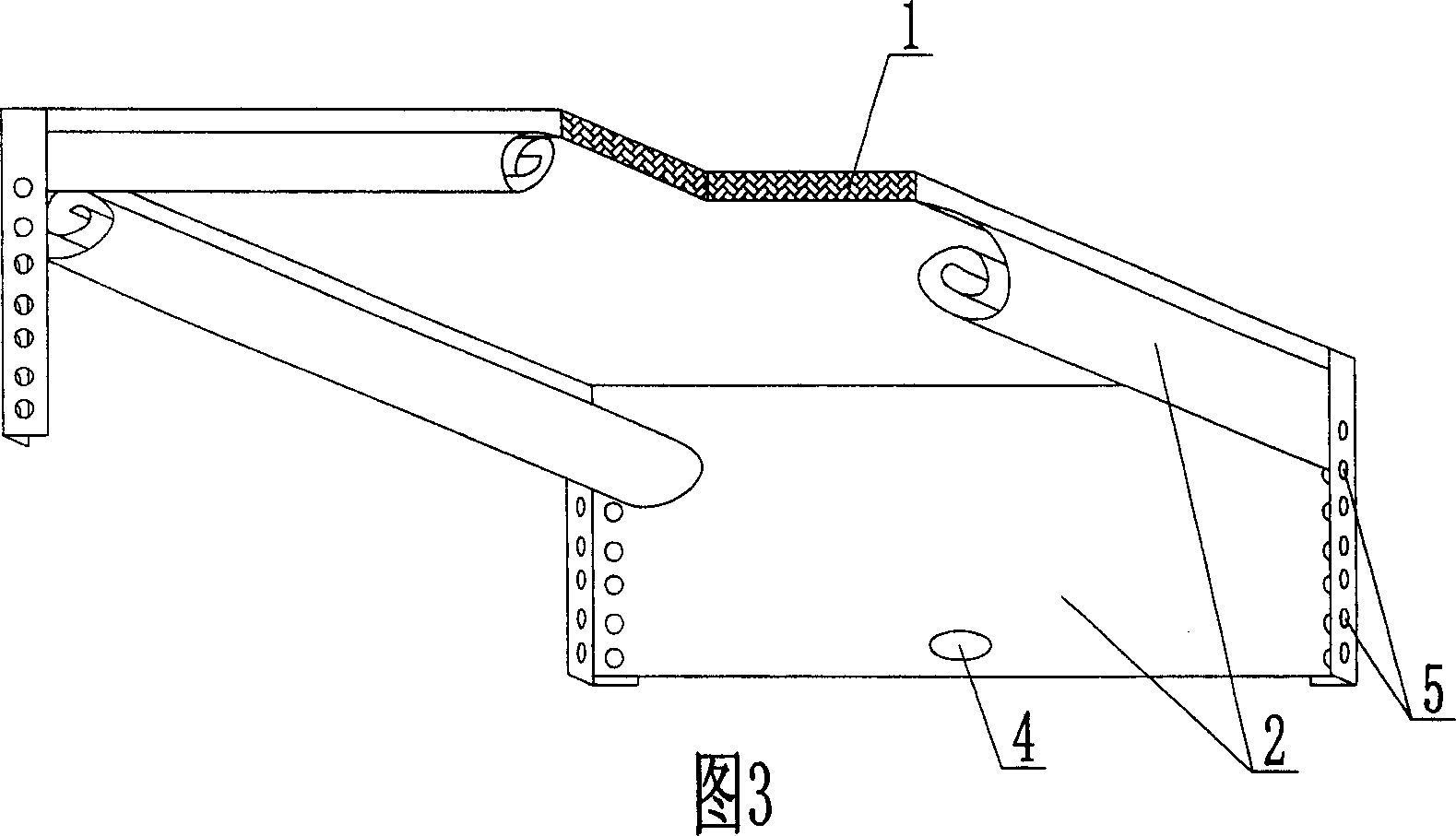

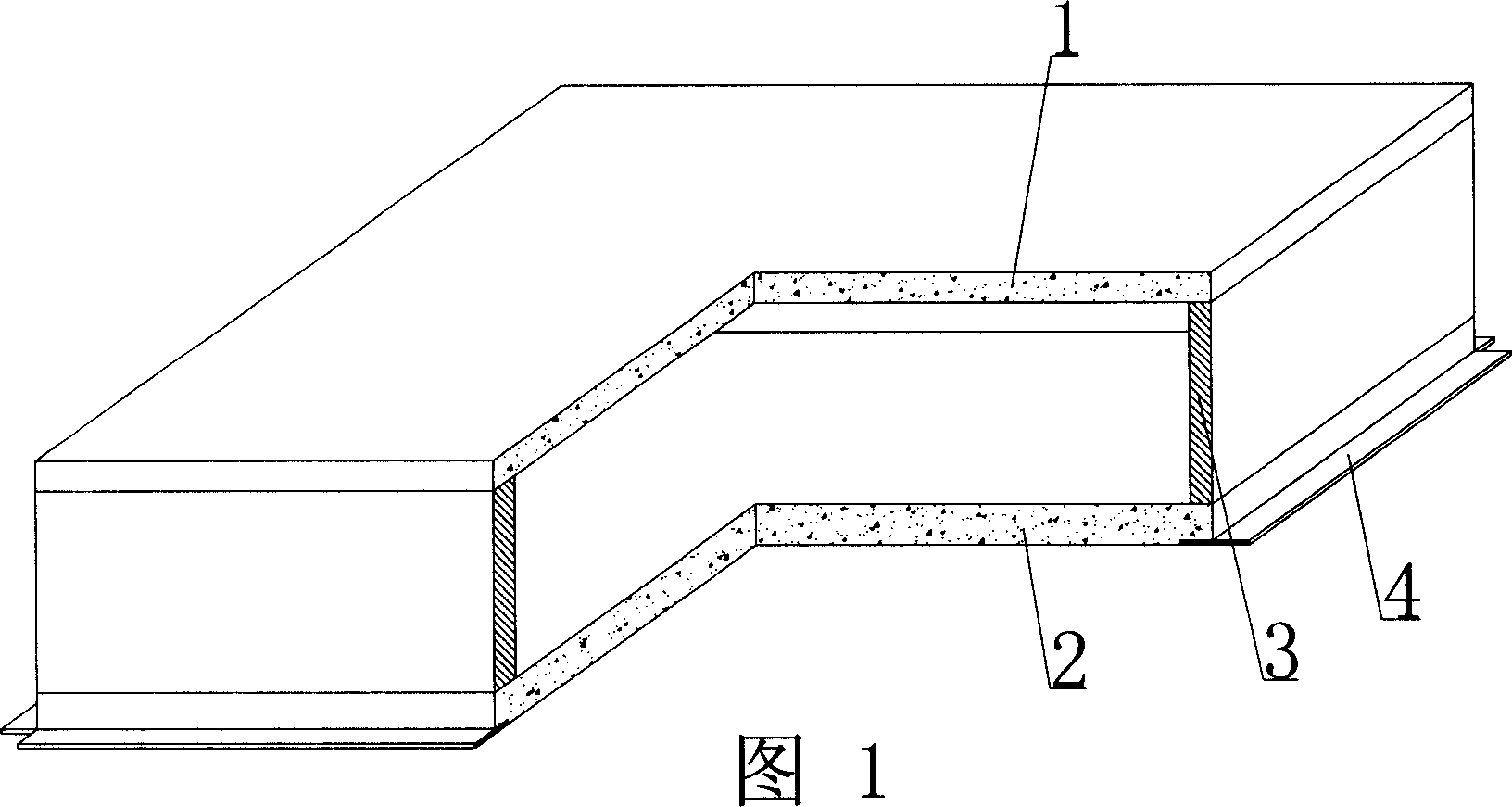

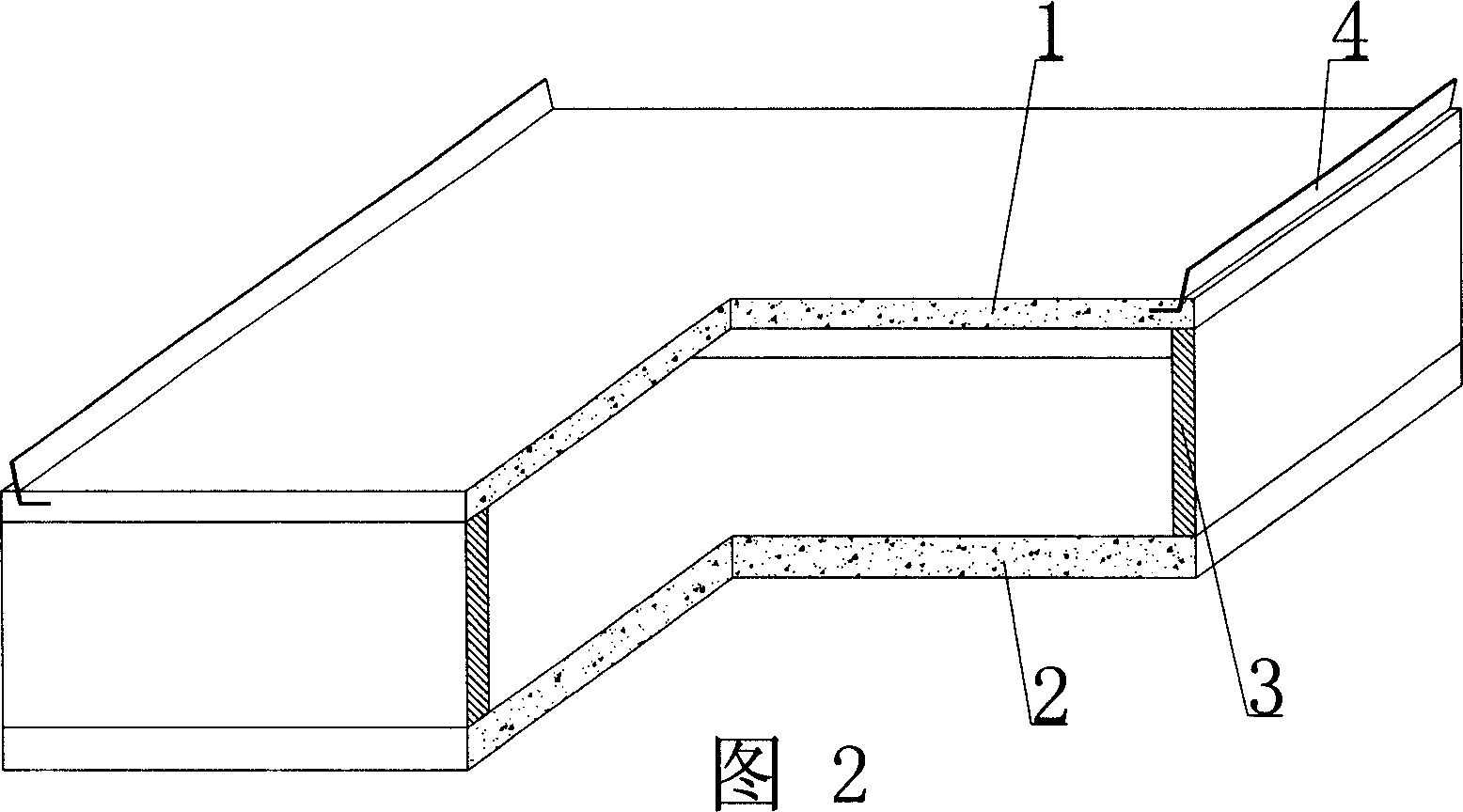

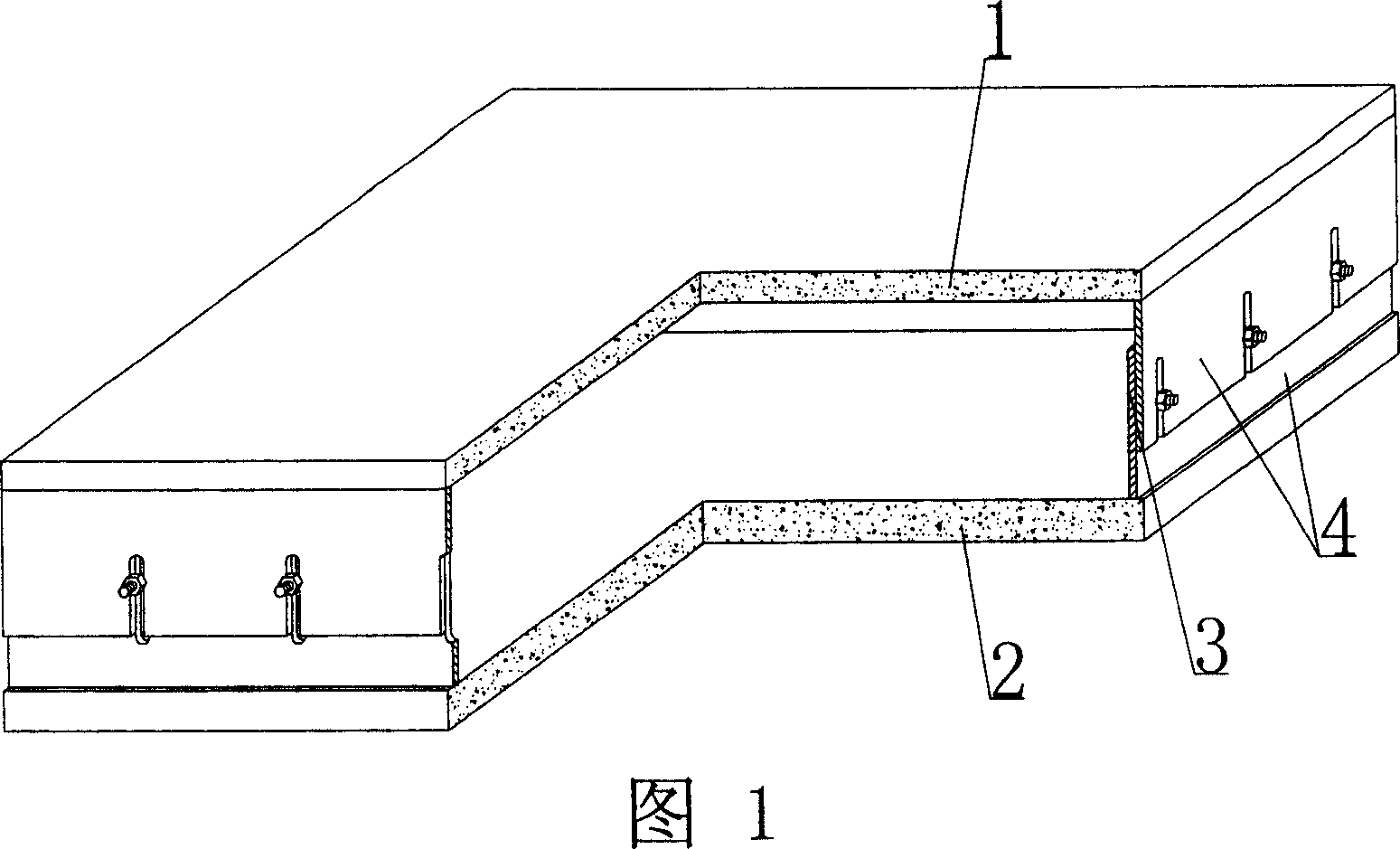

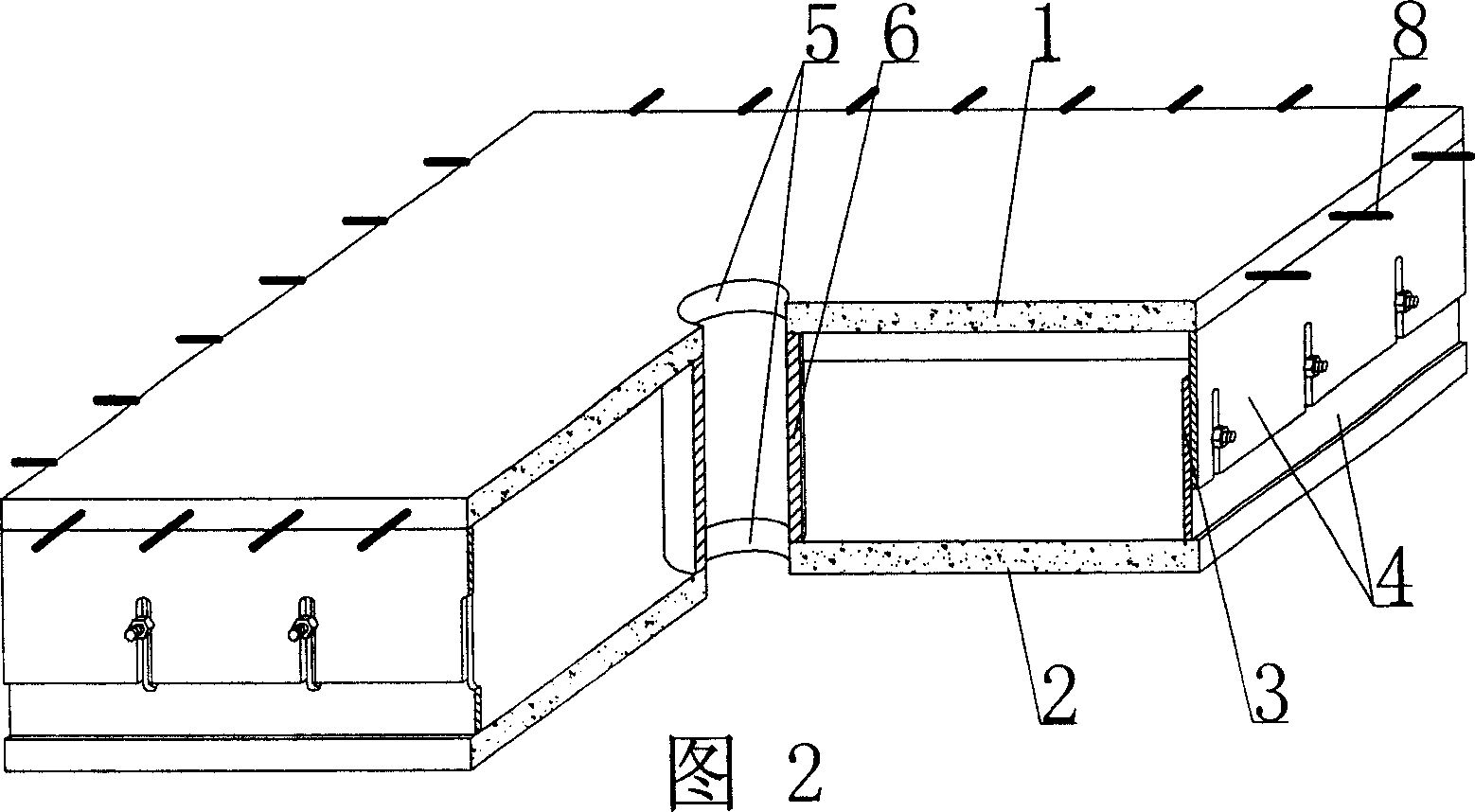

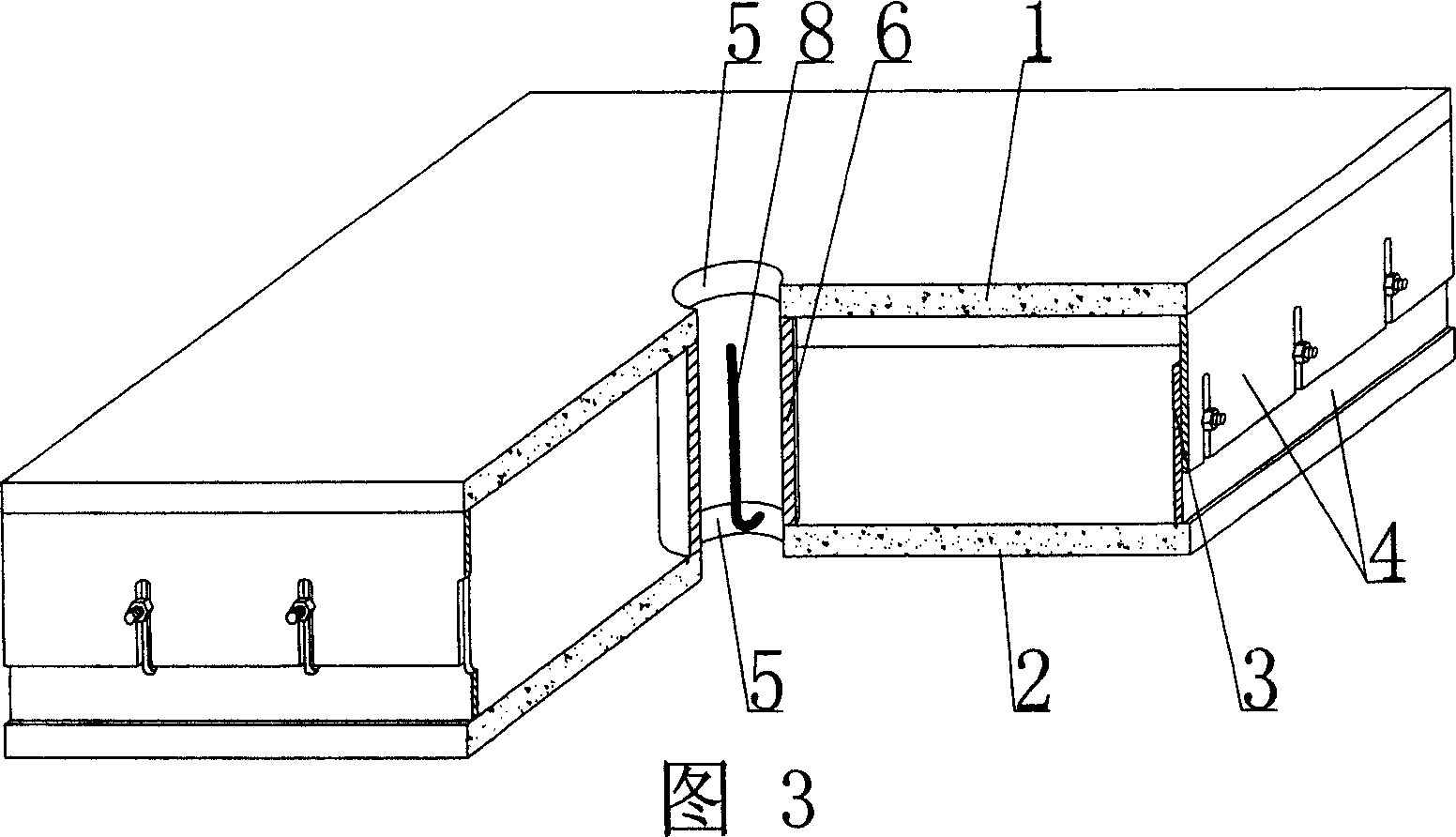

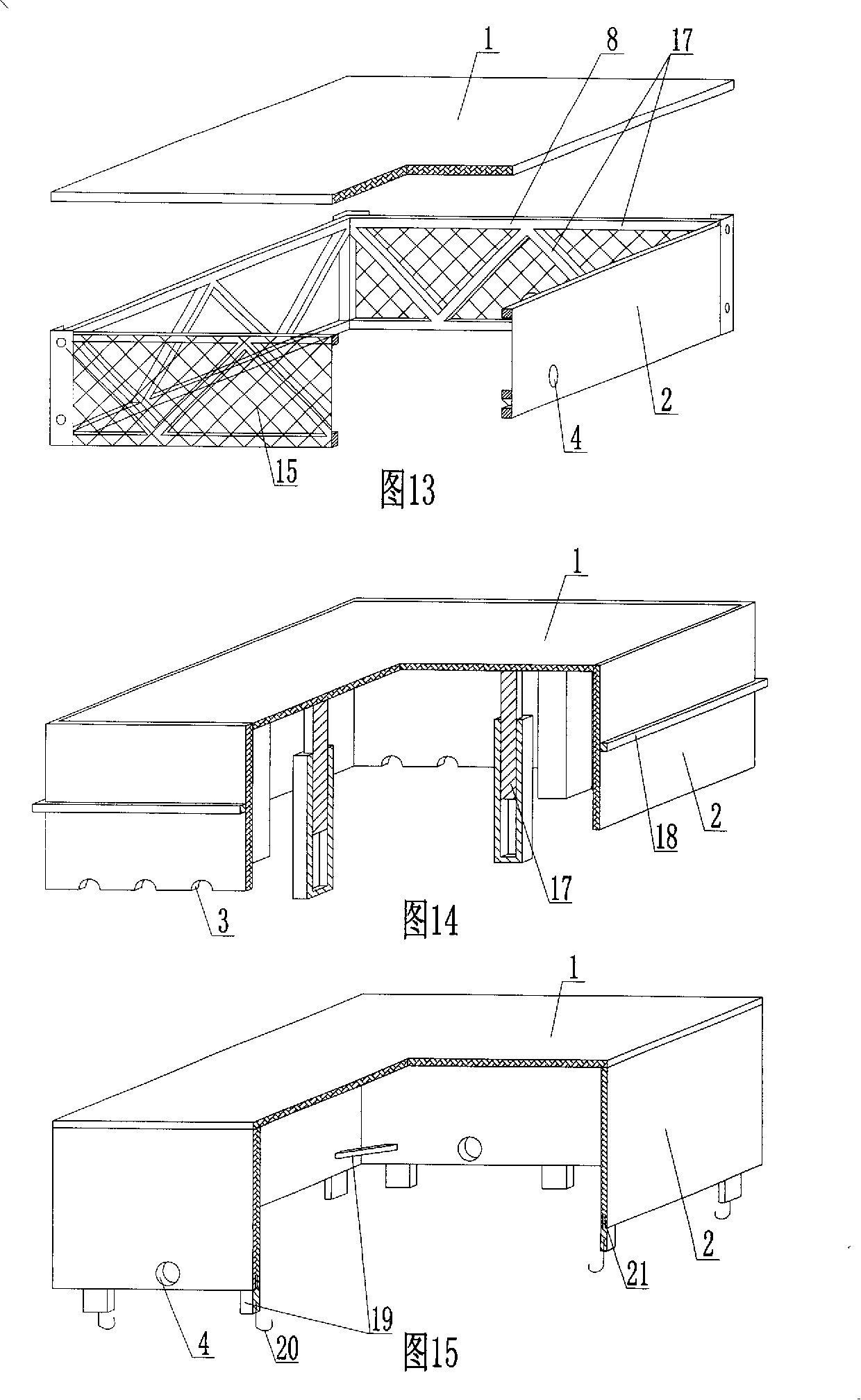

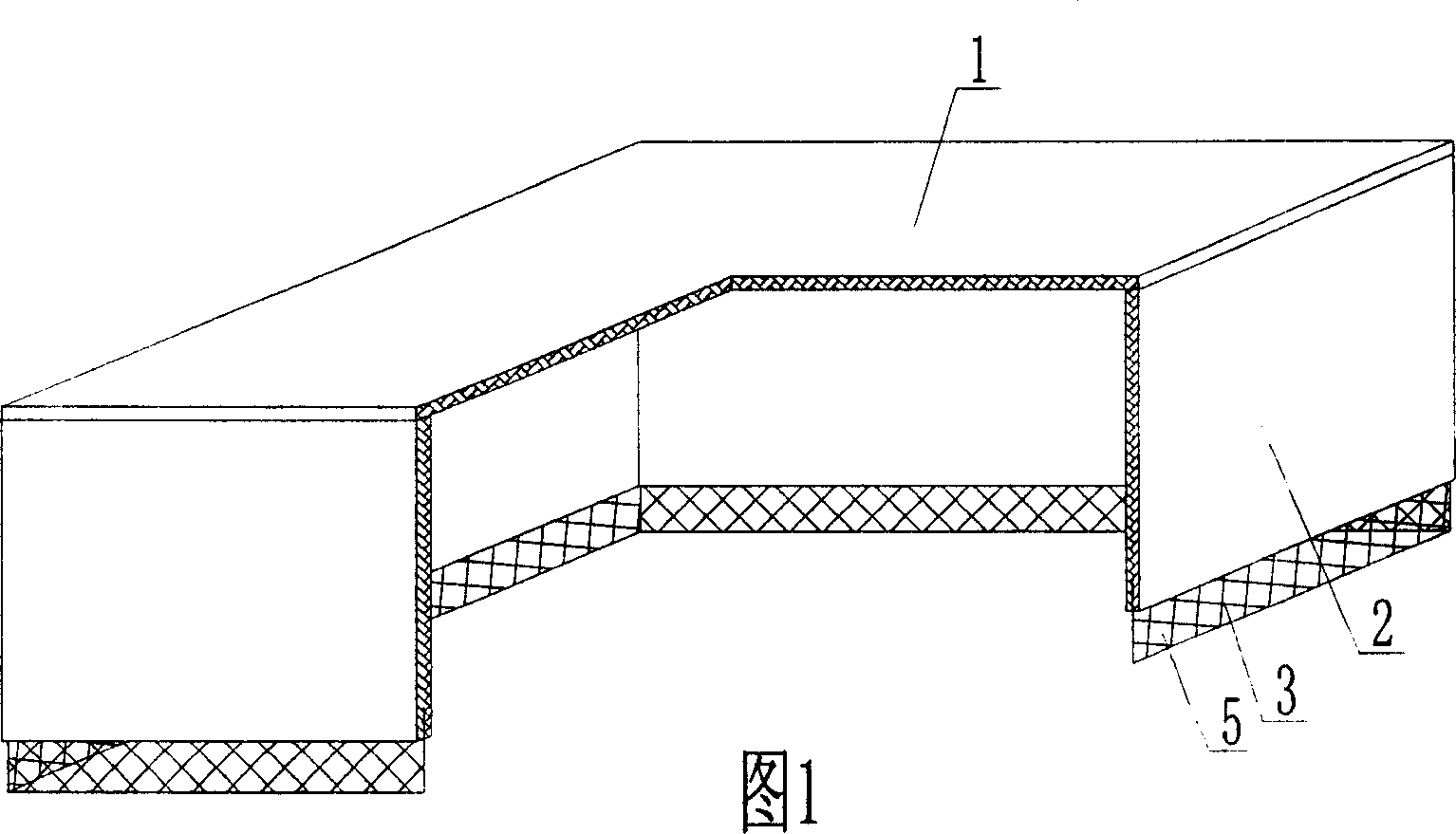

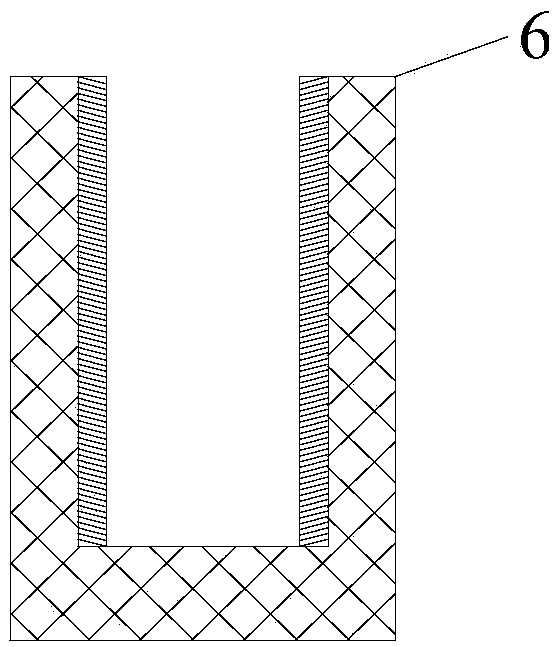

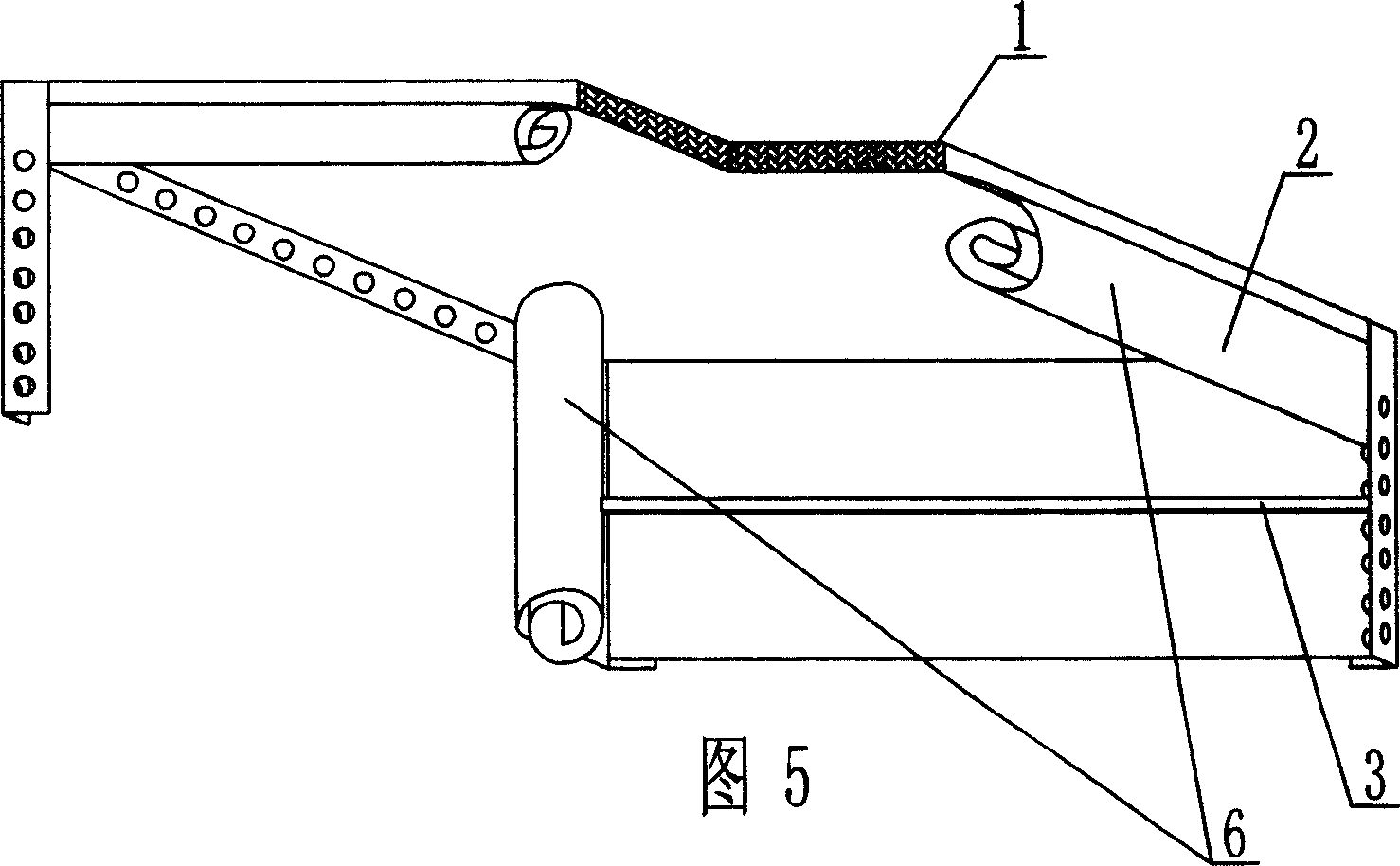

Sandwich member for concrete use

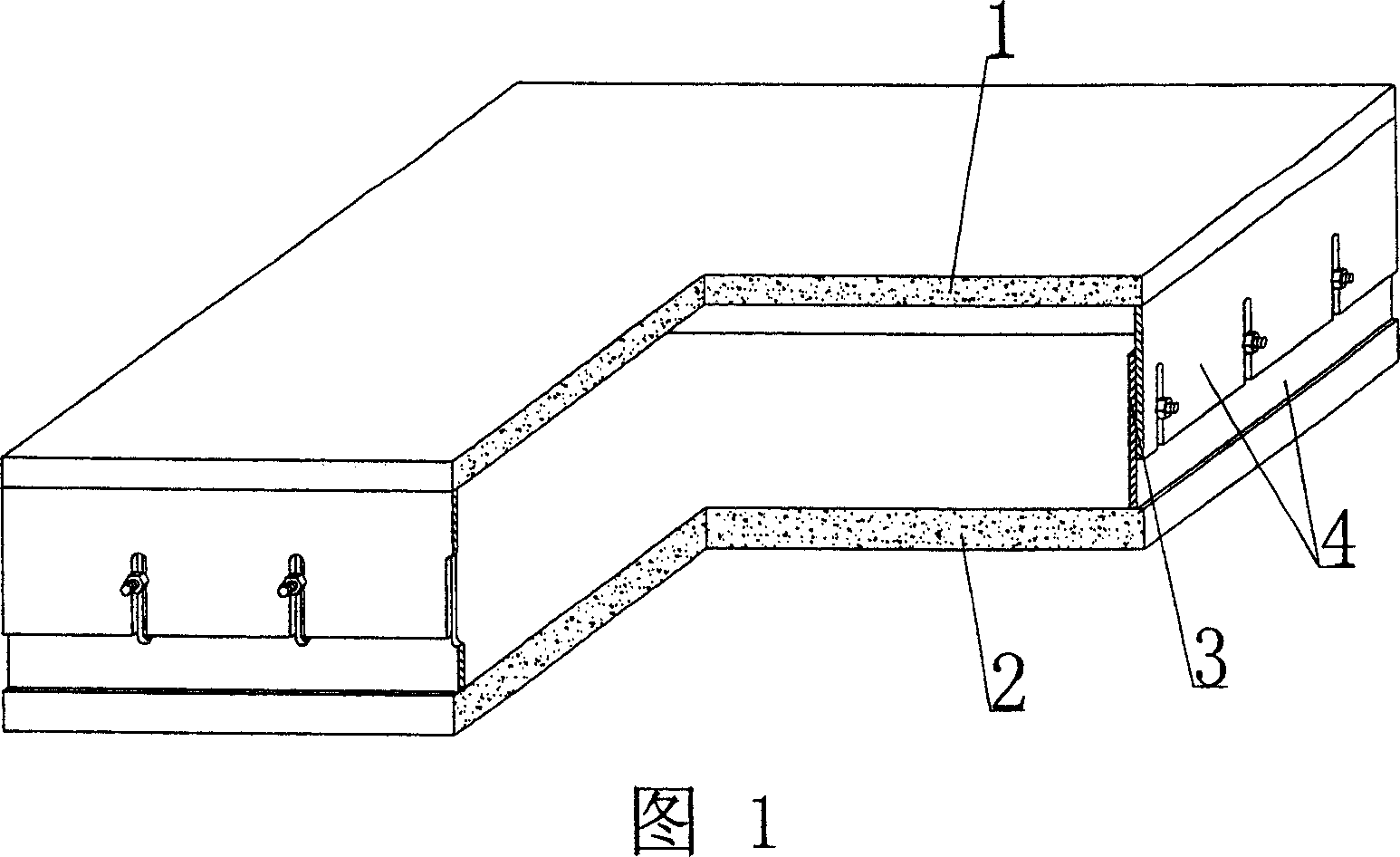

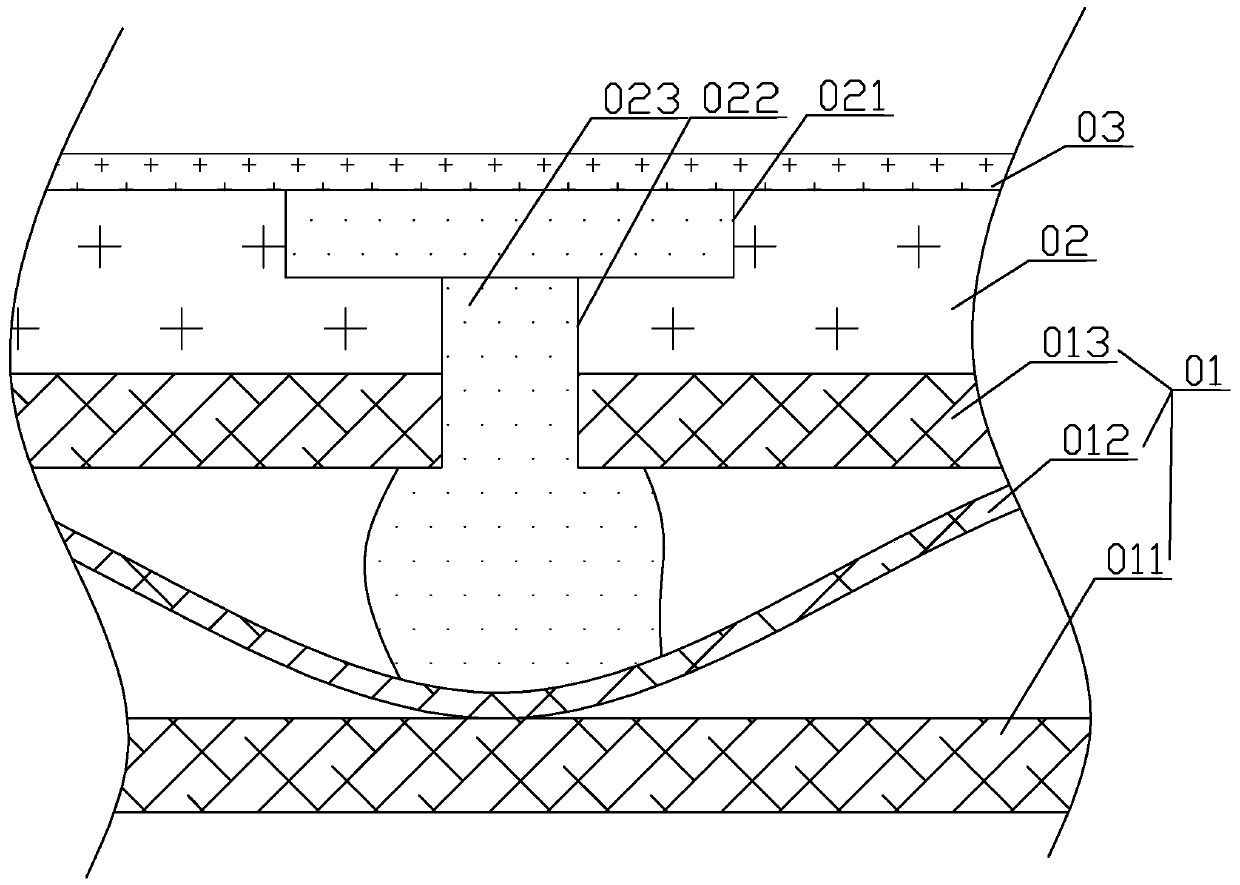

The sandwiched member for concrete includes one upper box board, one lower box board and one filling formwork between the upper box board and the lower box board, and features that the height or the width of the filling formwork is adjustable or the height of the upper box board or the lower box board is adjustable. The present invention is suitable for in-situ cast or pre-stressed reinforced concrete hollow floor slab, roof, wall, foundation slab and hollow bridge, especially hollow flat floor slab.

Owner:湖南邱则有专利战略策划有限公司

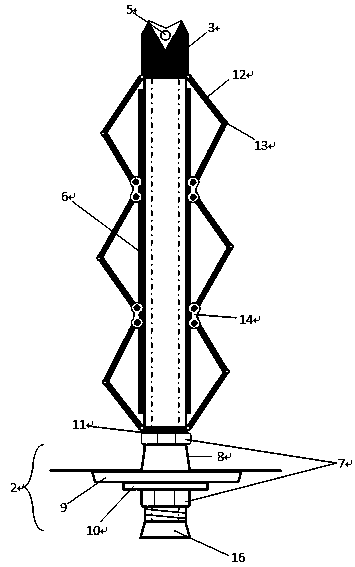

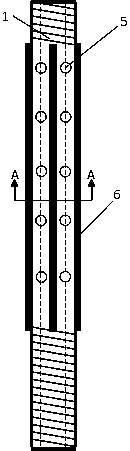

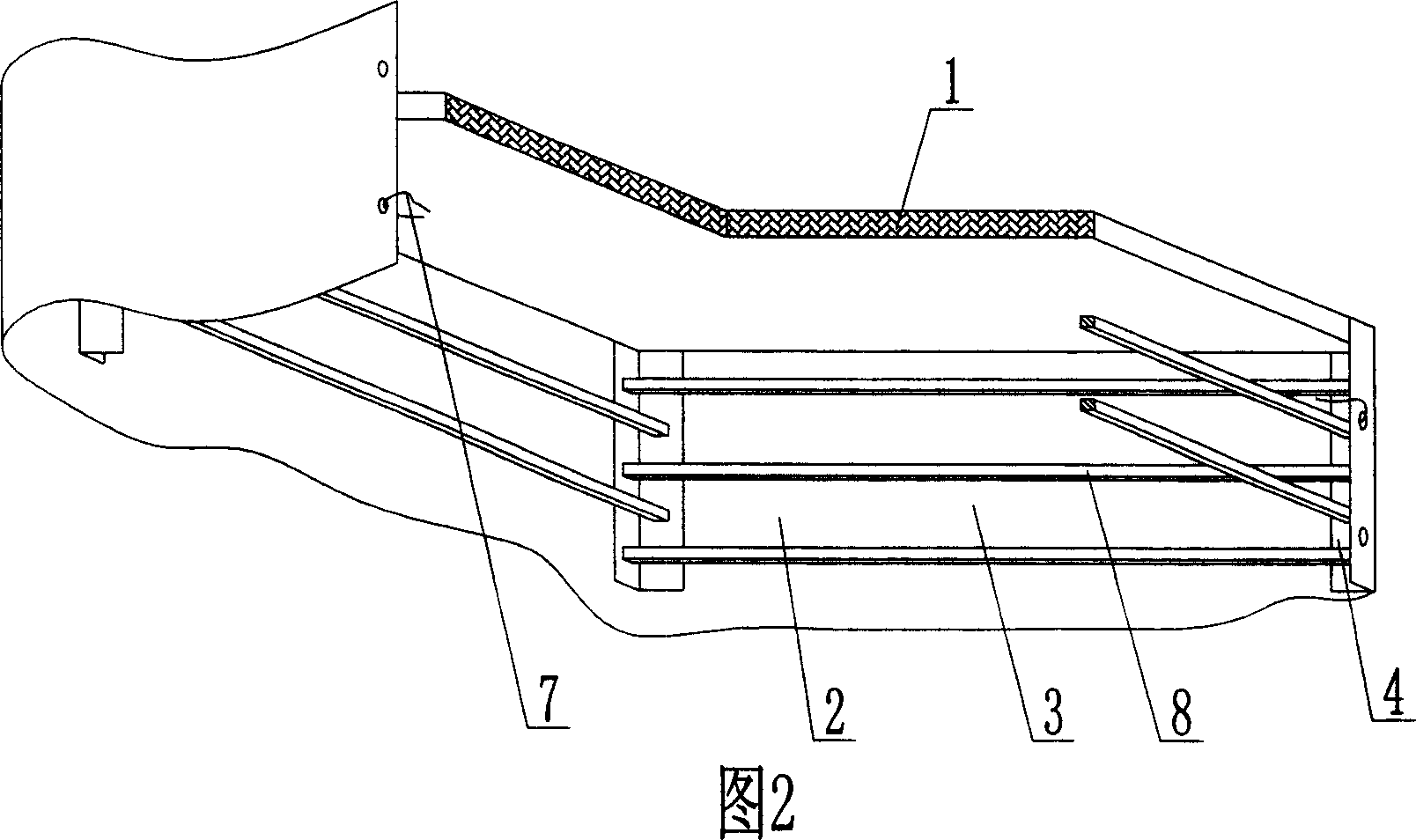

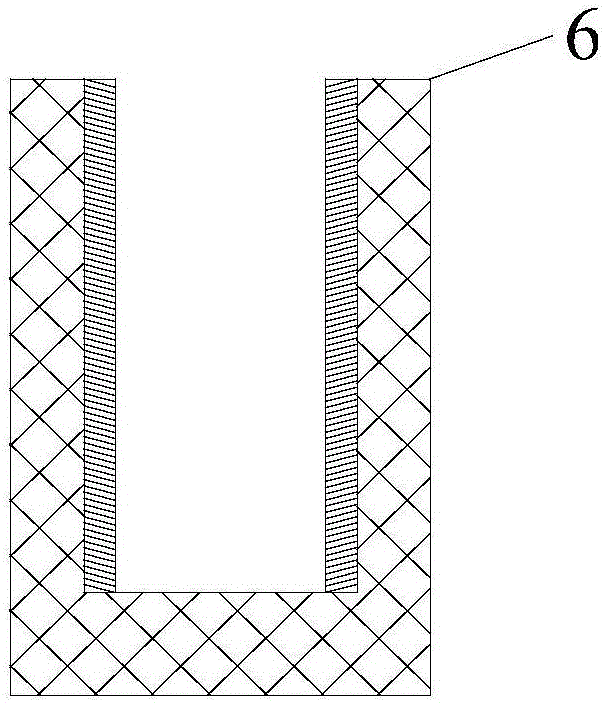

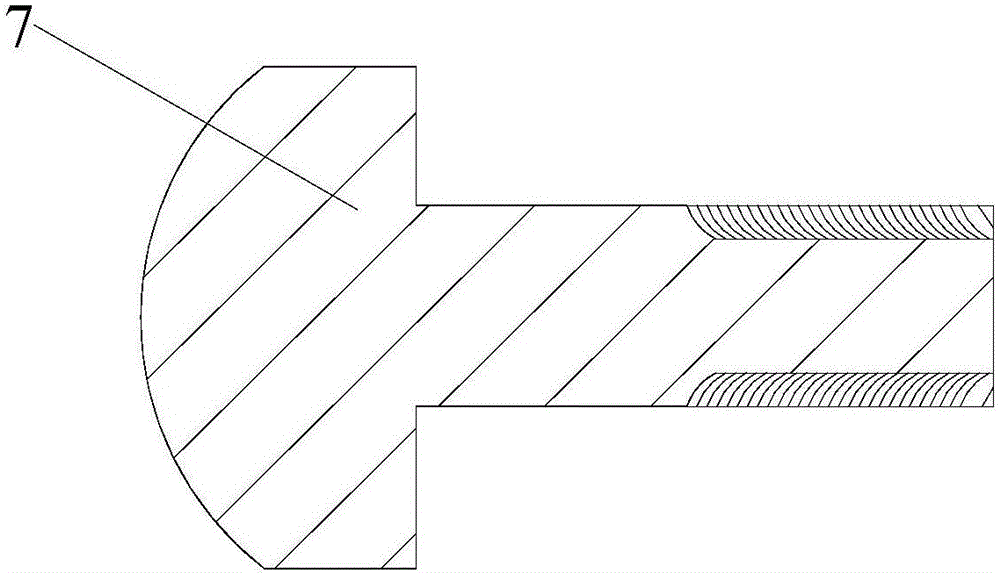

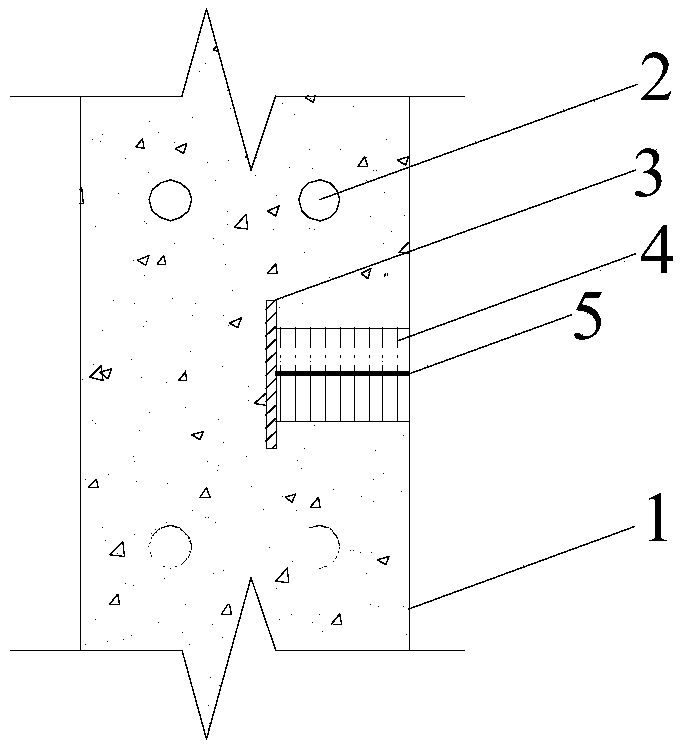

Novel grouting anchoring rod with steel sleeve rod

PendingCN107620603AIncreased tensile and shear capacityGuaranteed stabilityAnchoring boltsClimate change adaptationDrill holeBiomedical engineering

The invention relates to a novel grouting anchoring rod with a steel sleeve rod. The novel grouting anchoring rod comprises a rod body, an anchoring end, an anchoring head and a rod-sleeving device, wherein the anchoring end and the anchoring head are located at the two ends of the rod body correspondingly, and the rod-sleeving device is arranged outside the rod body. The novel grouting anchoringrod with the steel sleeve rod is characterized in that guide rails are circumferentially and evenly distributed on the rod body; the rod-sleeving device is of a multi-section type cage-shaped structure, the rod body is sleeved with the rod-sleeving device, and the rod-sleeving device comprises a joint and a cage body; the joint portion is in slidably matched connection with the guide rails of therod body, and the cage body is hinged to the joint; and each section of the cage body adopts a two-section type hinging structure, and when the novel grouting anchoring rod is mounted in a drill holeand pressed in a fastened mode through the anchoring head, the cage body is compressed axially and expanded radially and makes contact and supports the drill hole wall. Through the mode of additionally arranging the steel sleeve rod, a hollow threaded steel anchoring rod is transformed, the steel sleeve rod is pressed by means of a nut, and the steel rod is supported open to make direct contact with a supported rock body so as to generate certain friction force, and the stability of the anchoring rod in the grouting process is ensured; and meanwhile after grouting, the anti-tensile-and-shearing capacity of the whole of a grouting material and the anchoring rod is improved, and the support strength of the anchoring rod is improved.

Owner:CHINA UNIV OF MINING & TECH

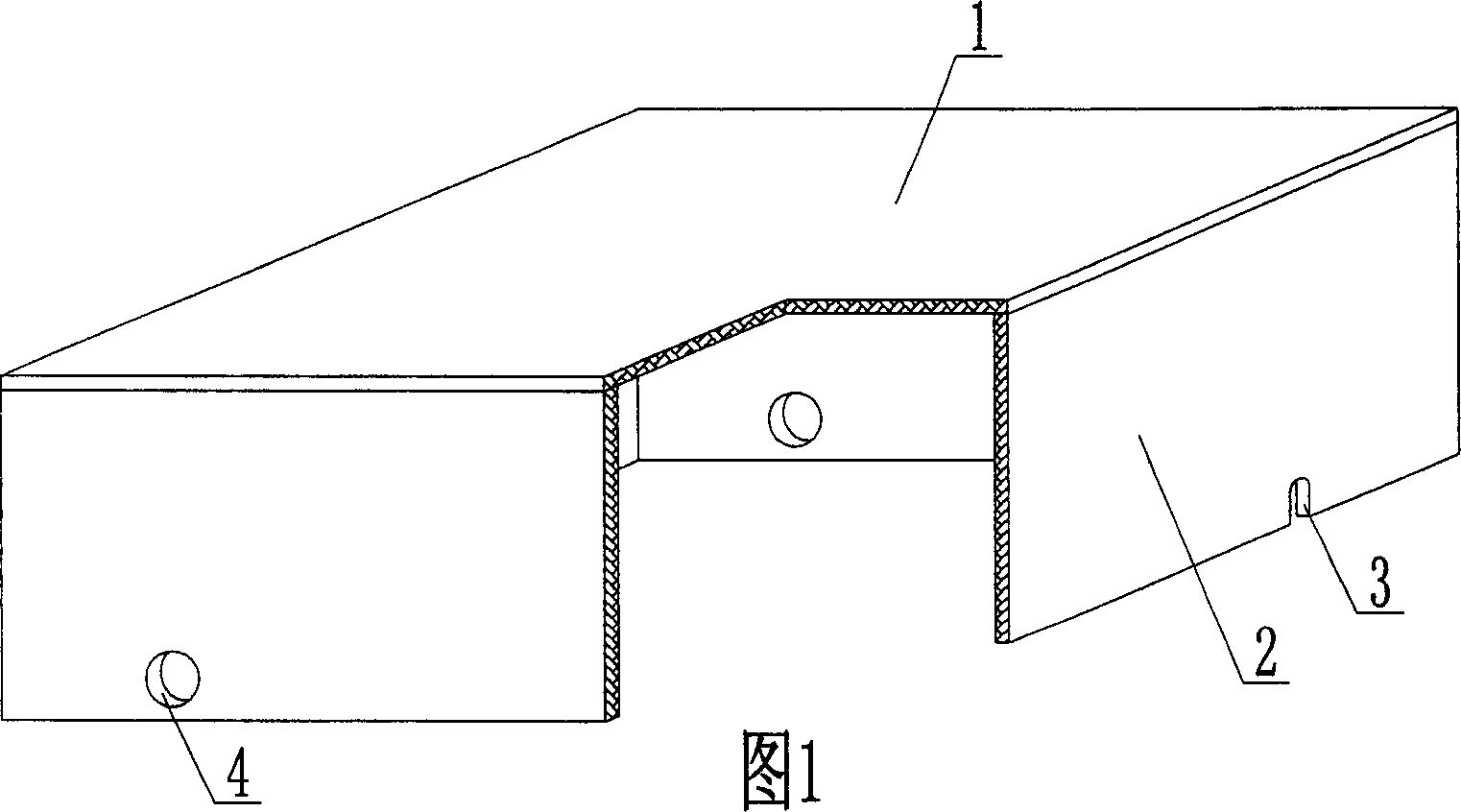

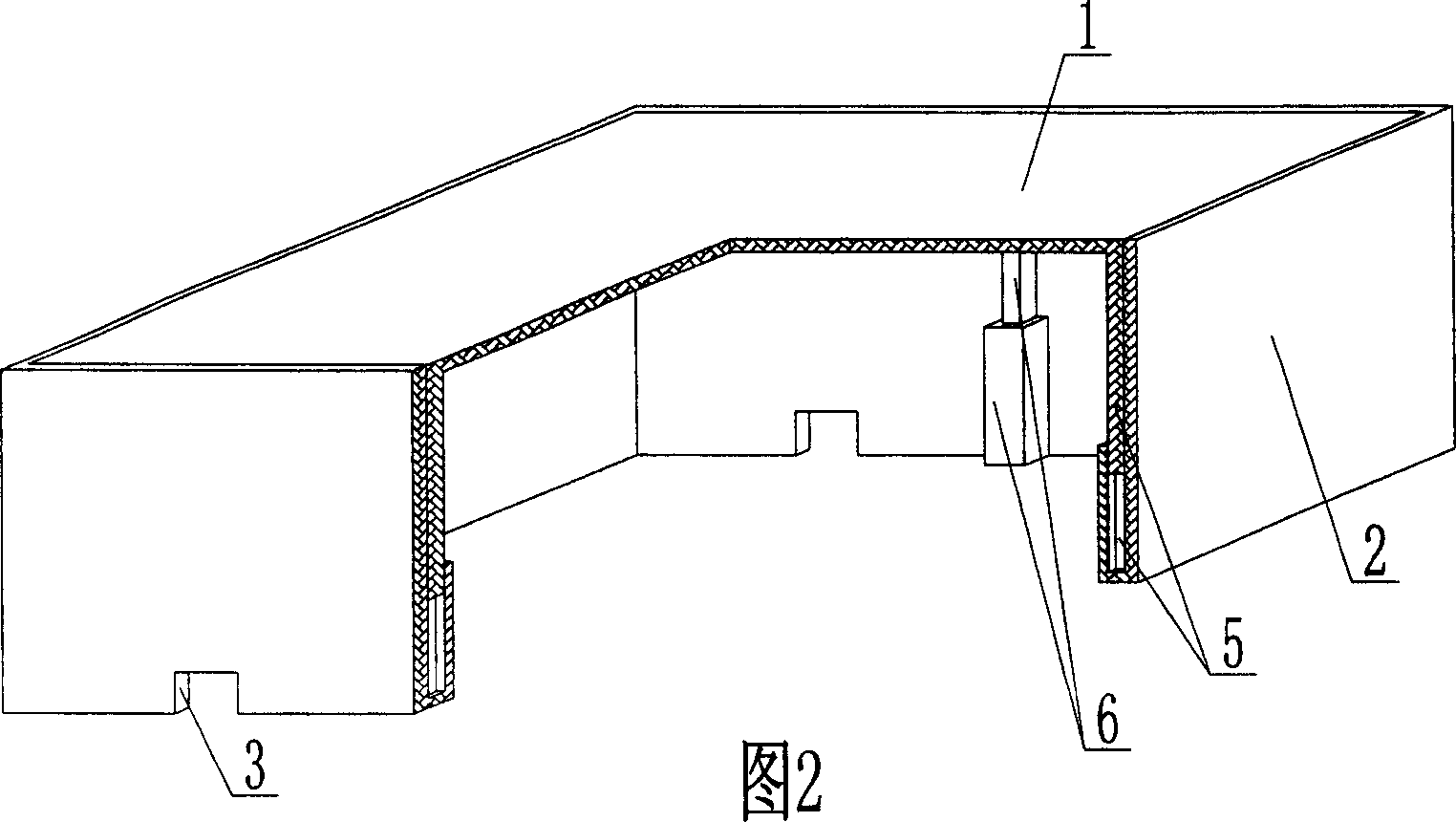

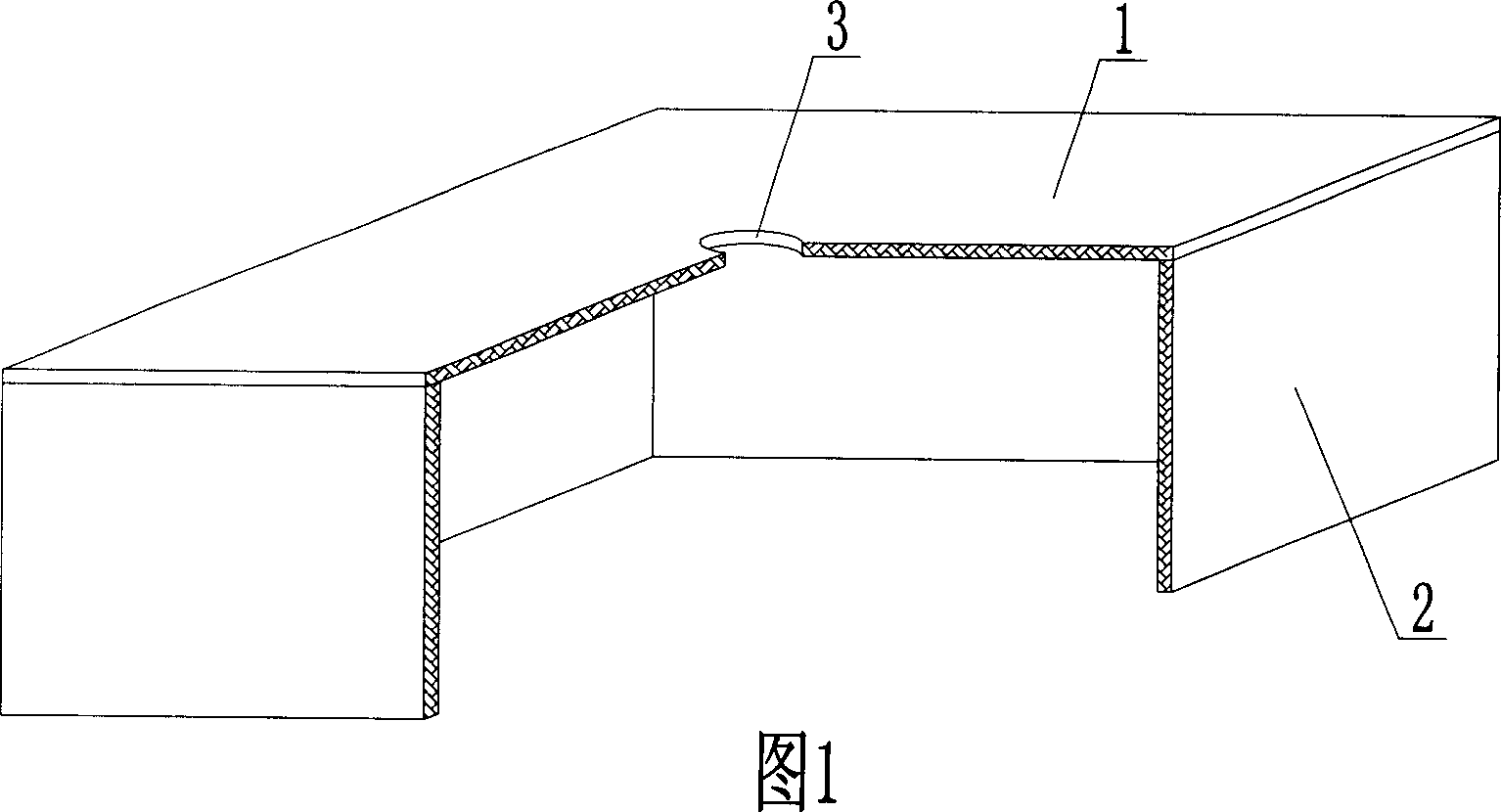

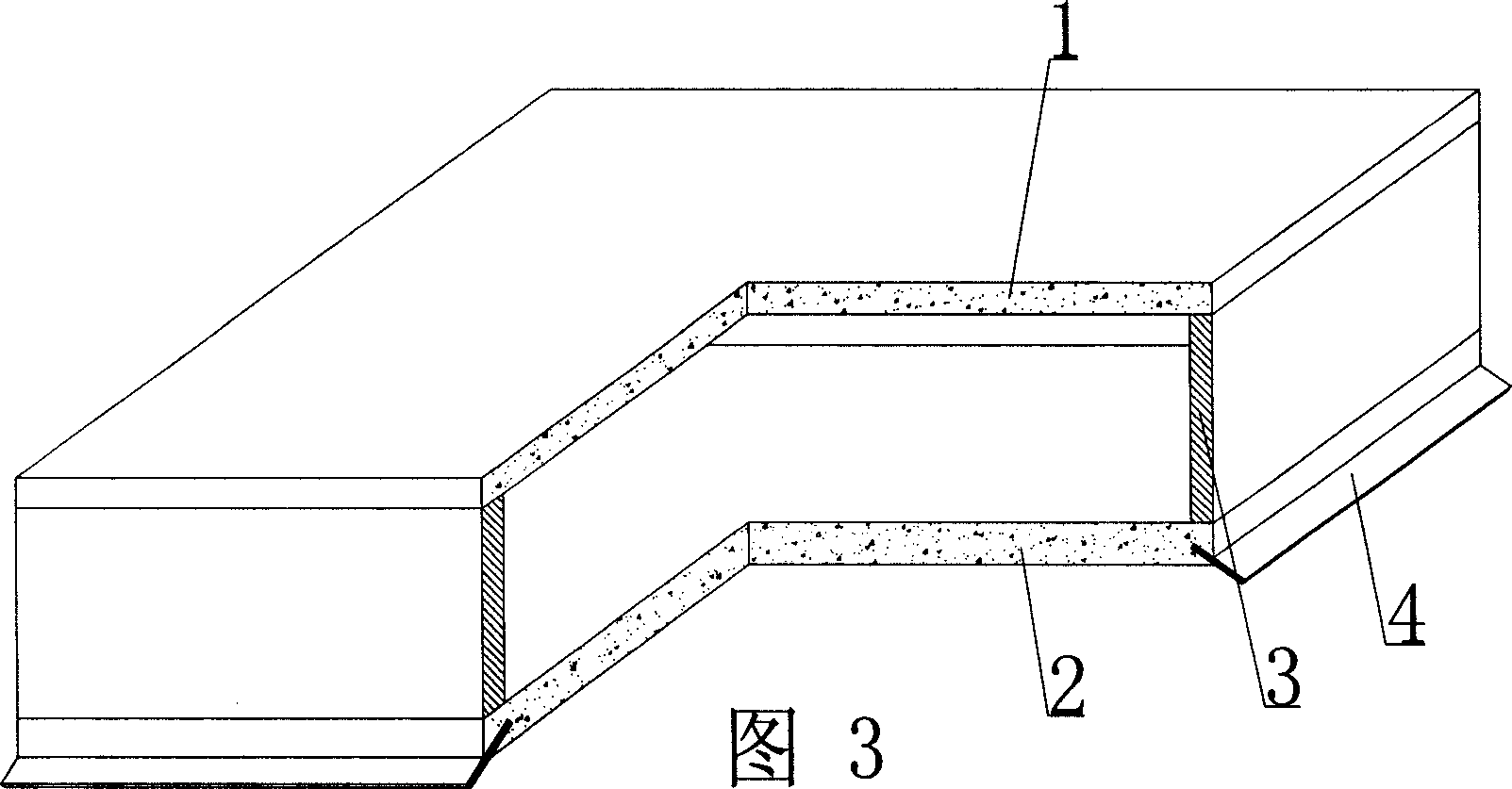

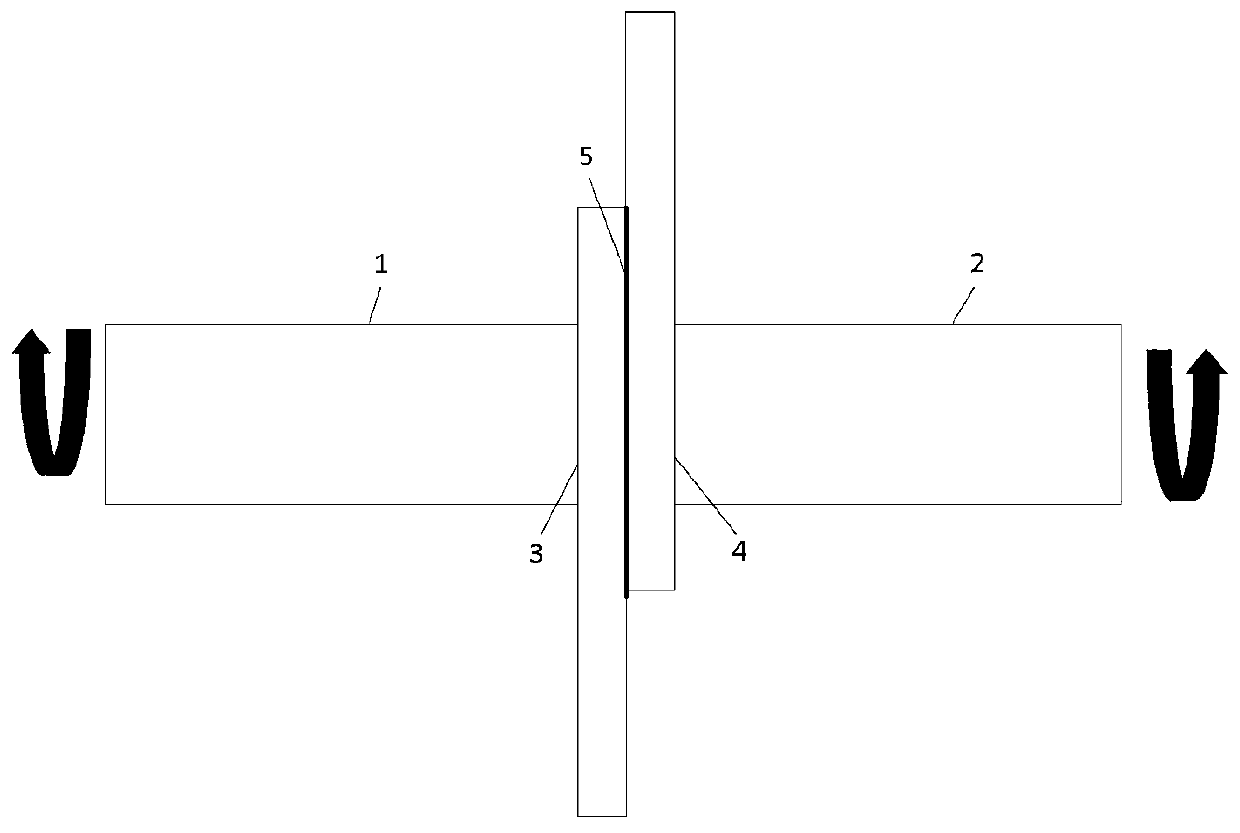

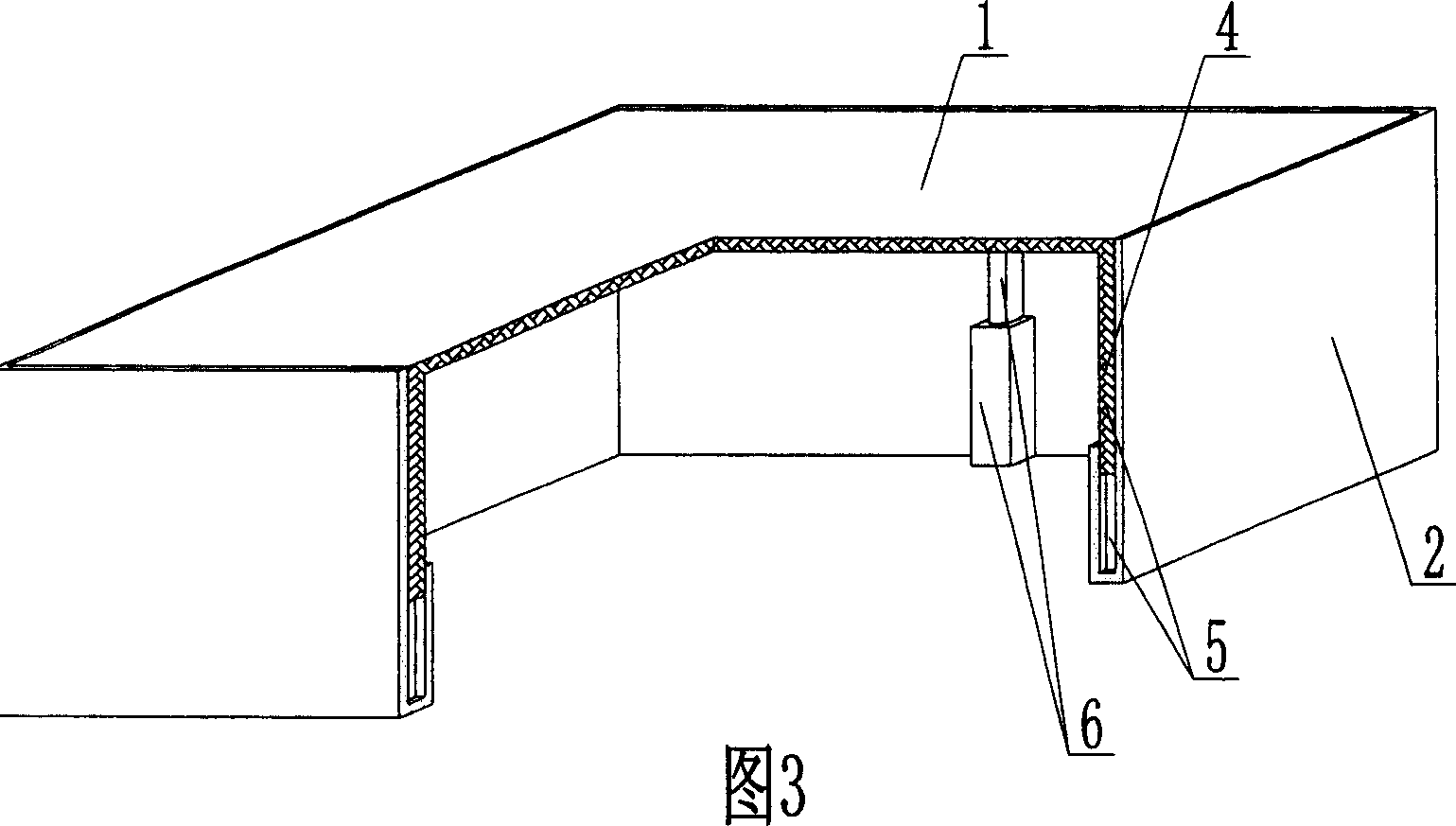

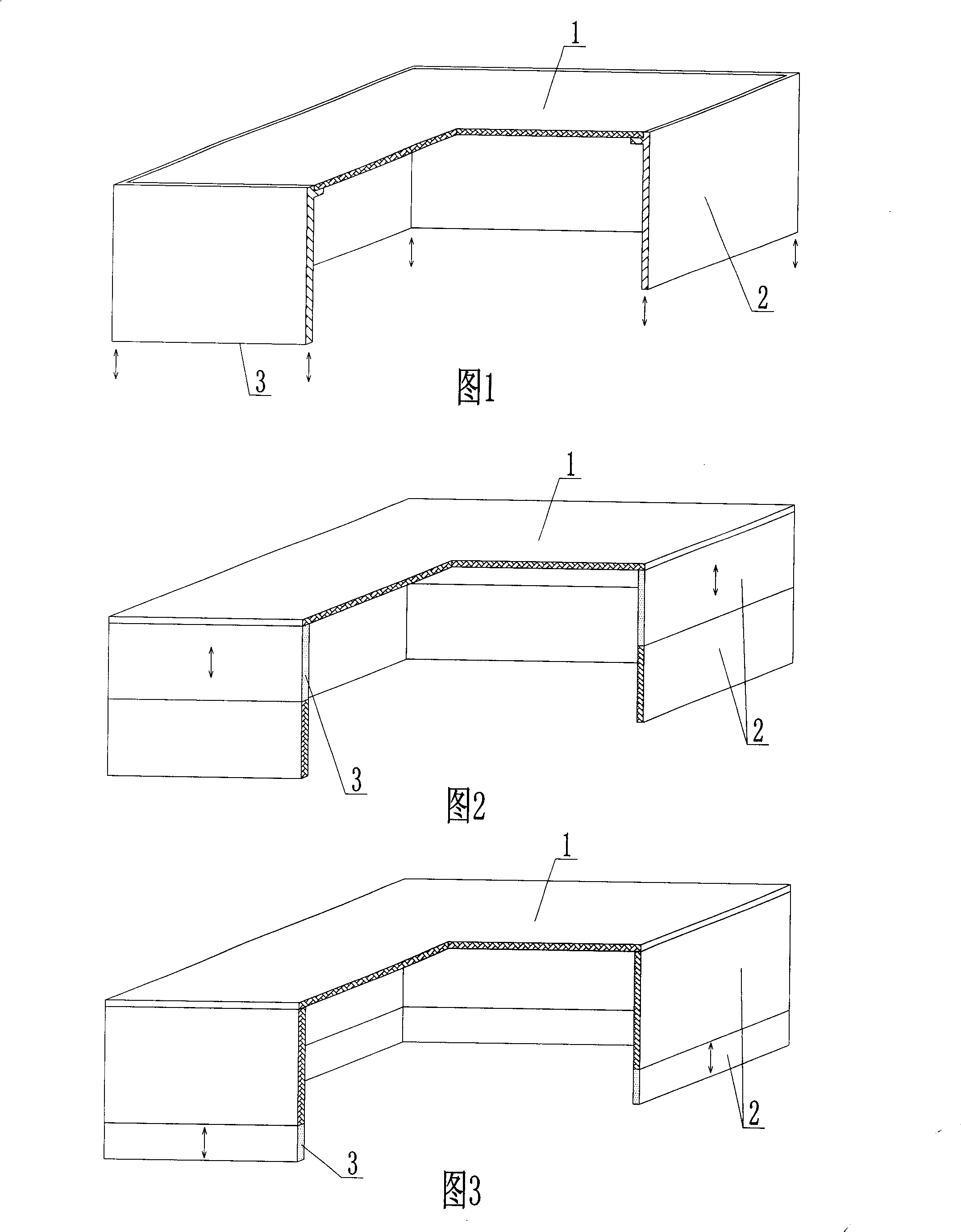

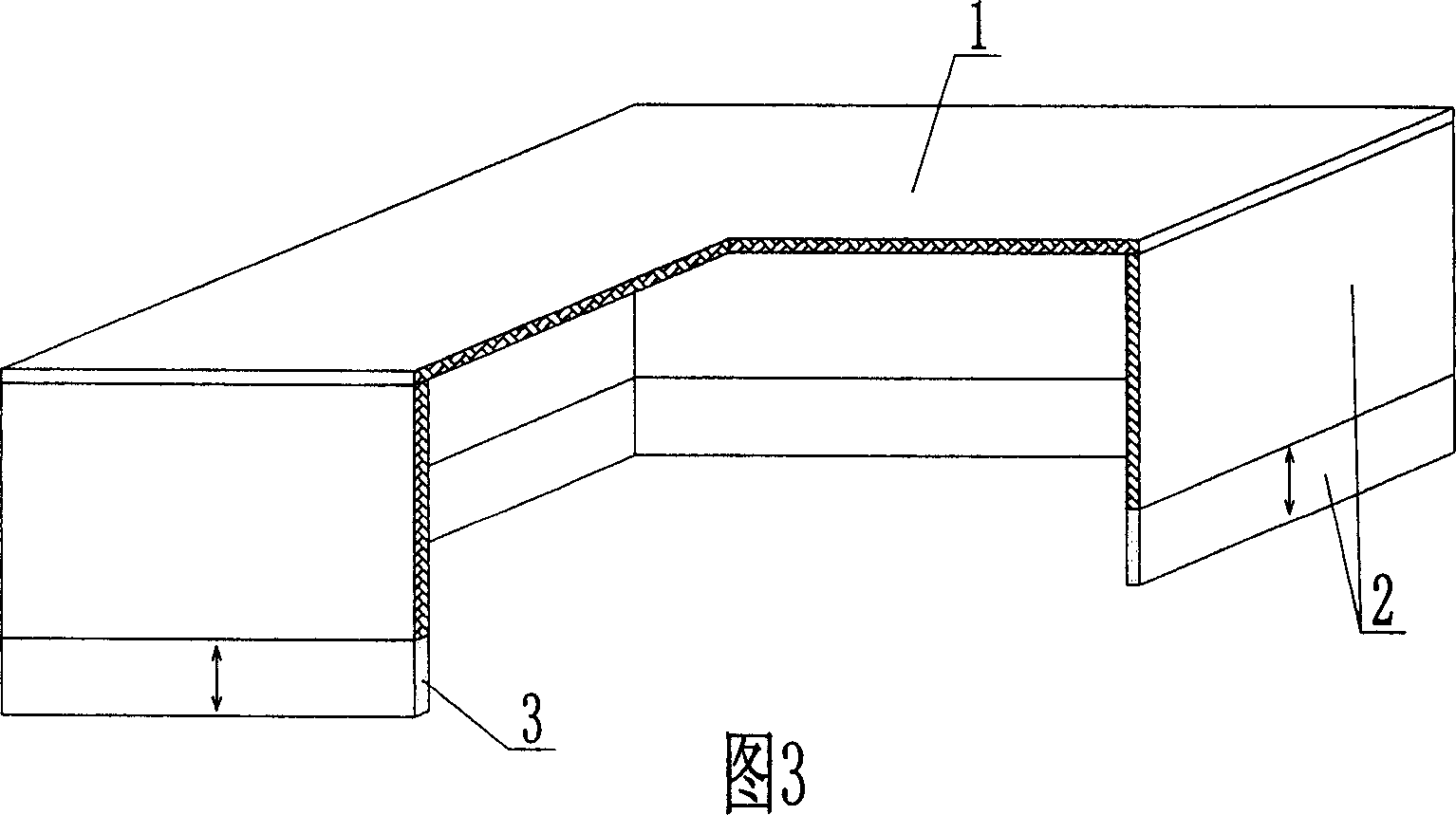

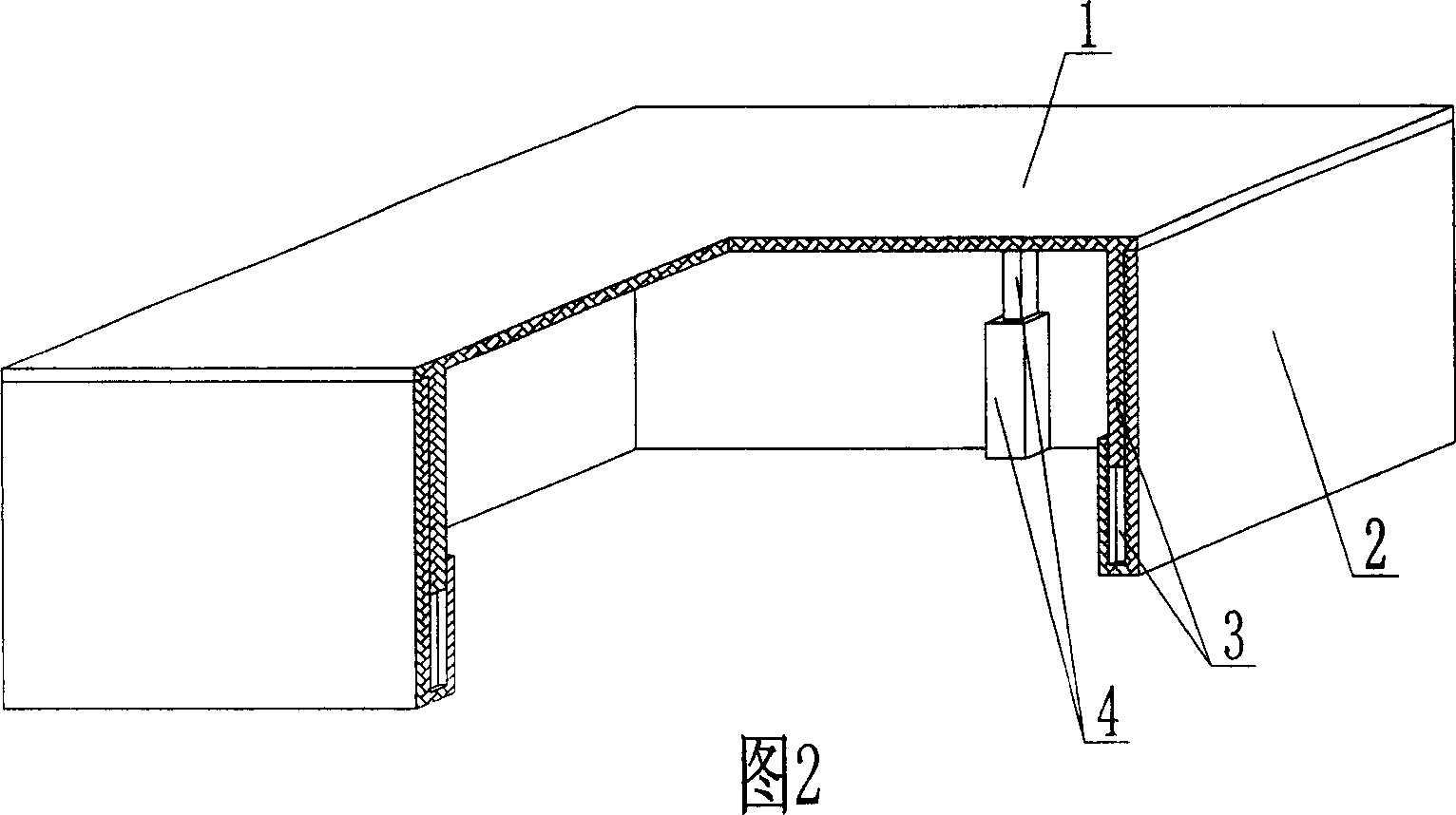

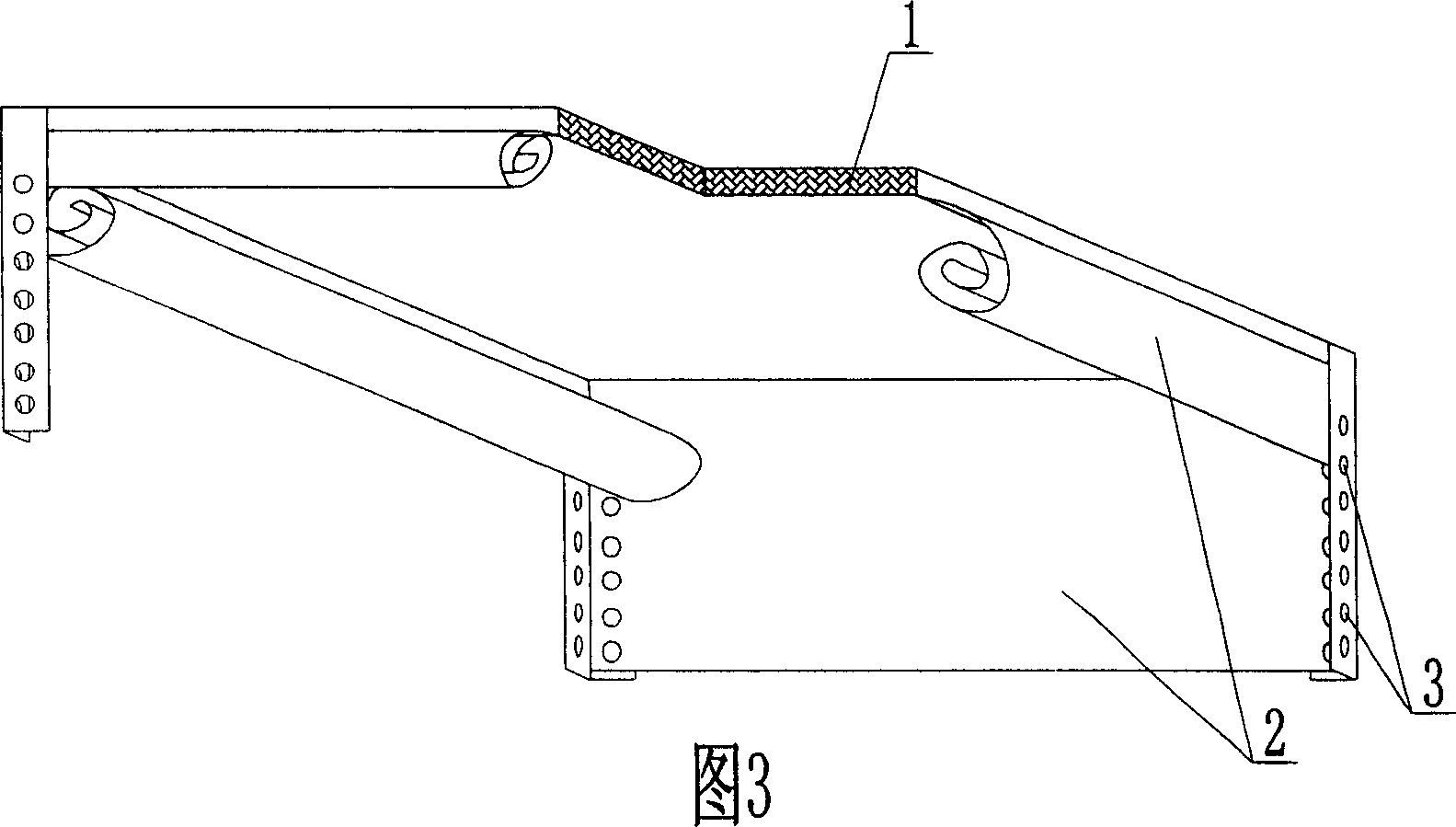

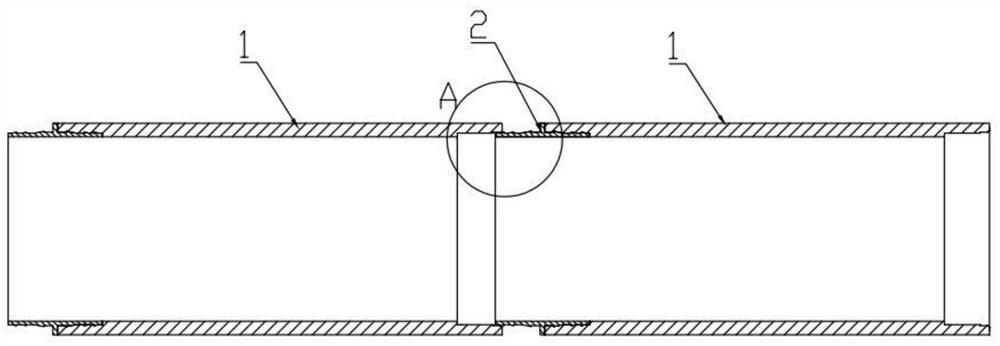

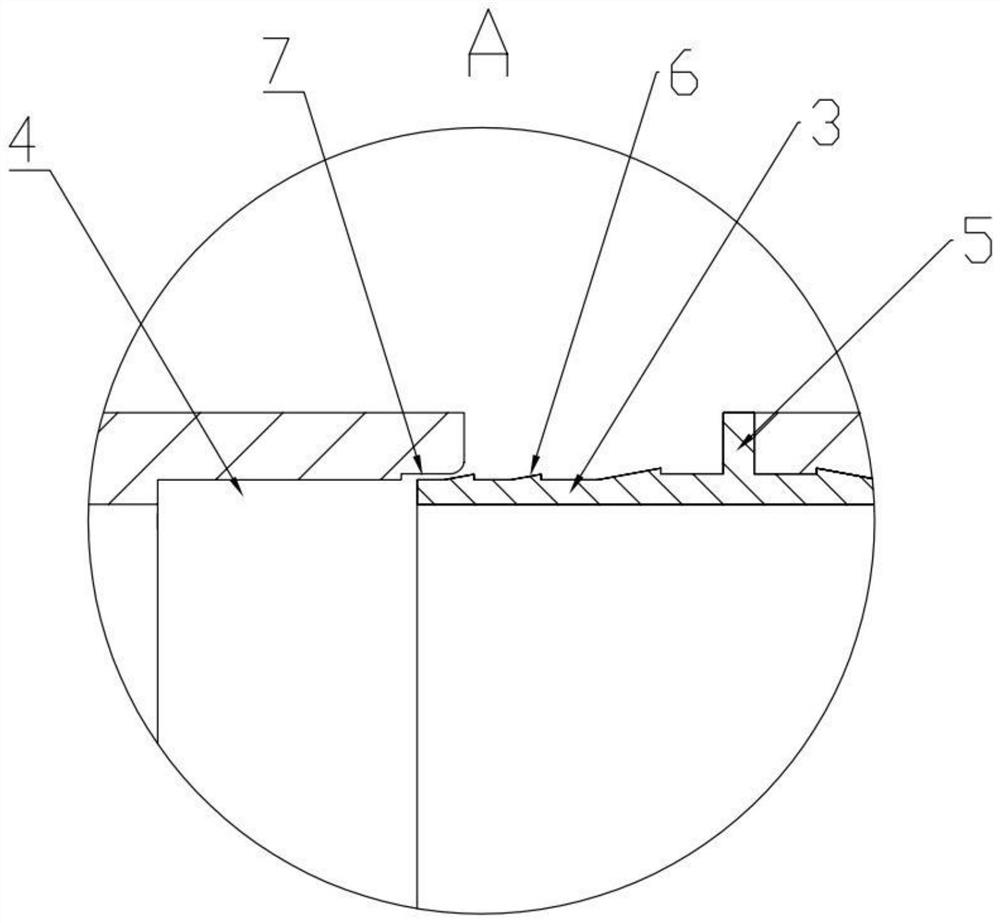

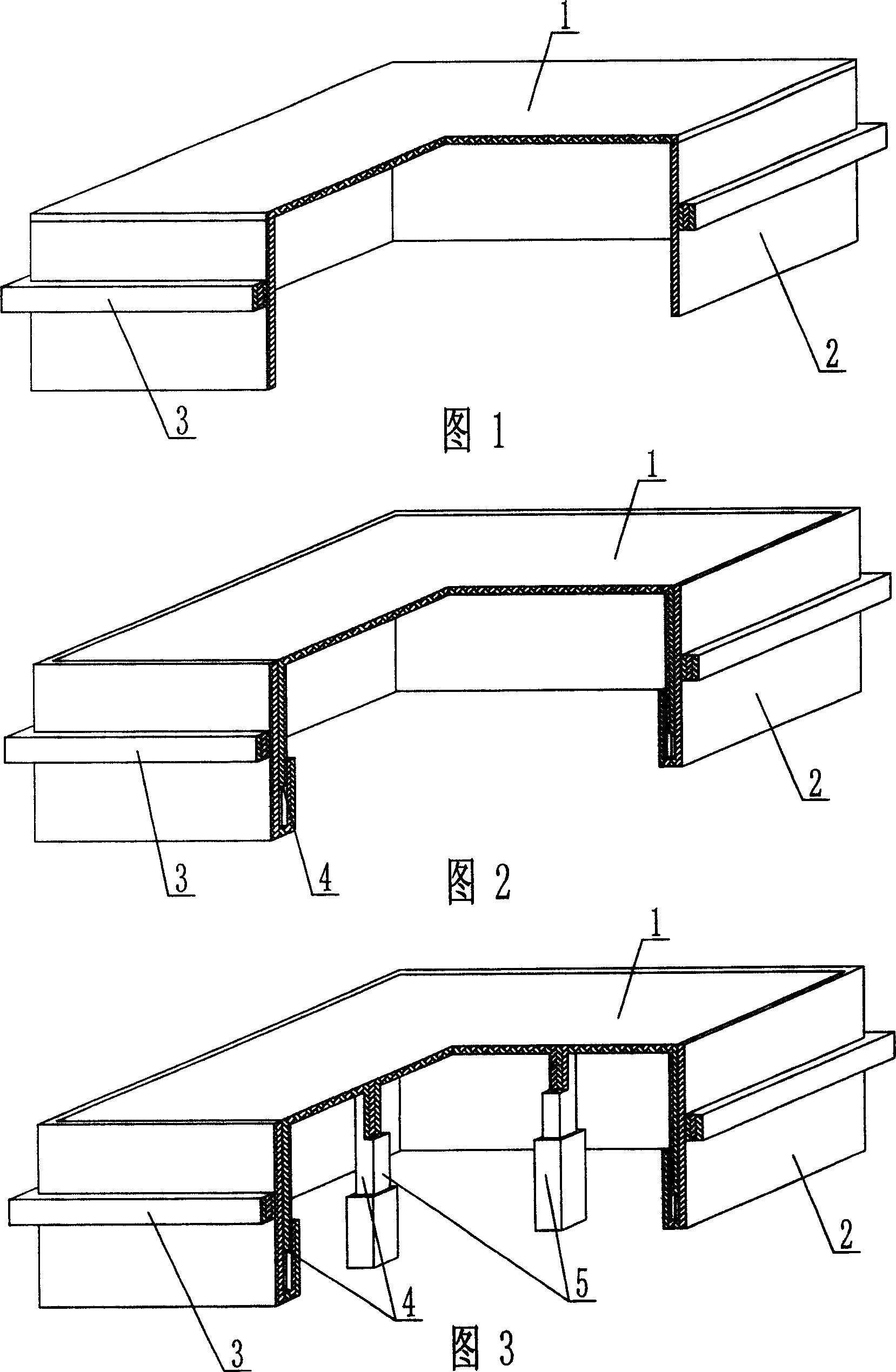

Opening box for concrete structure

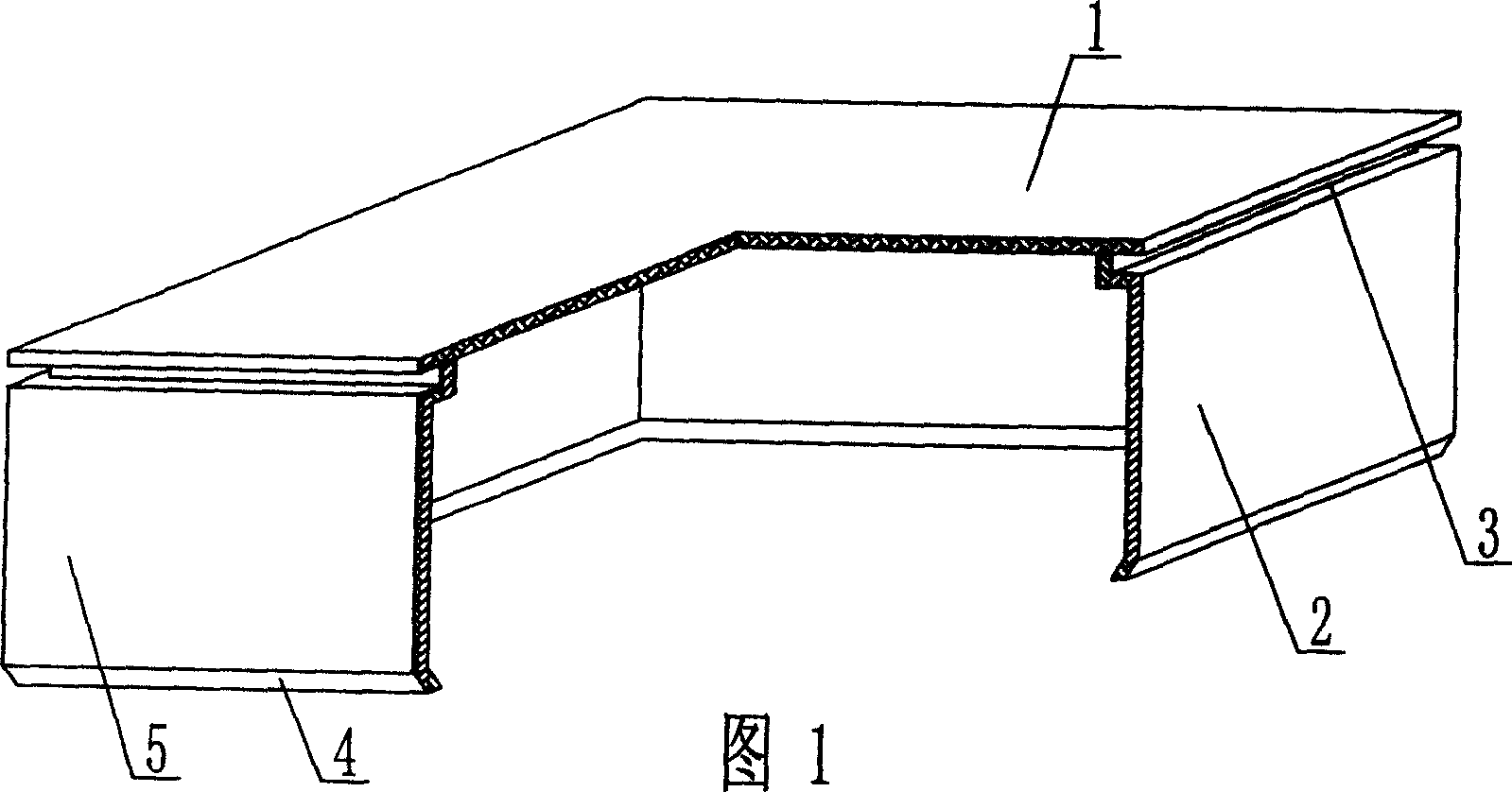

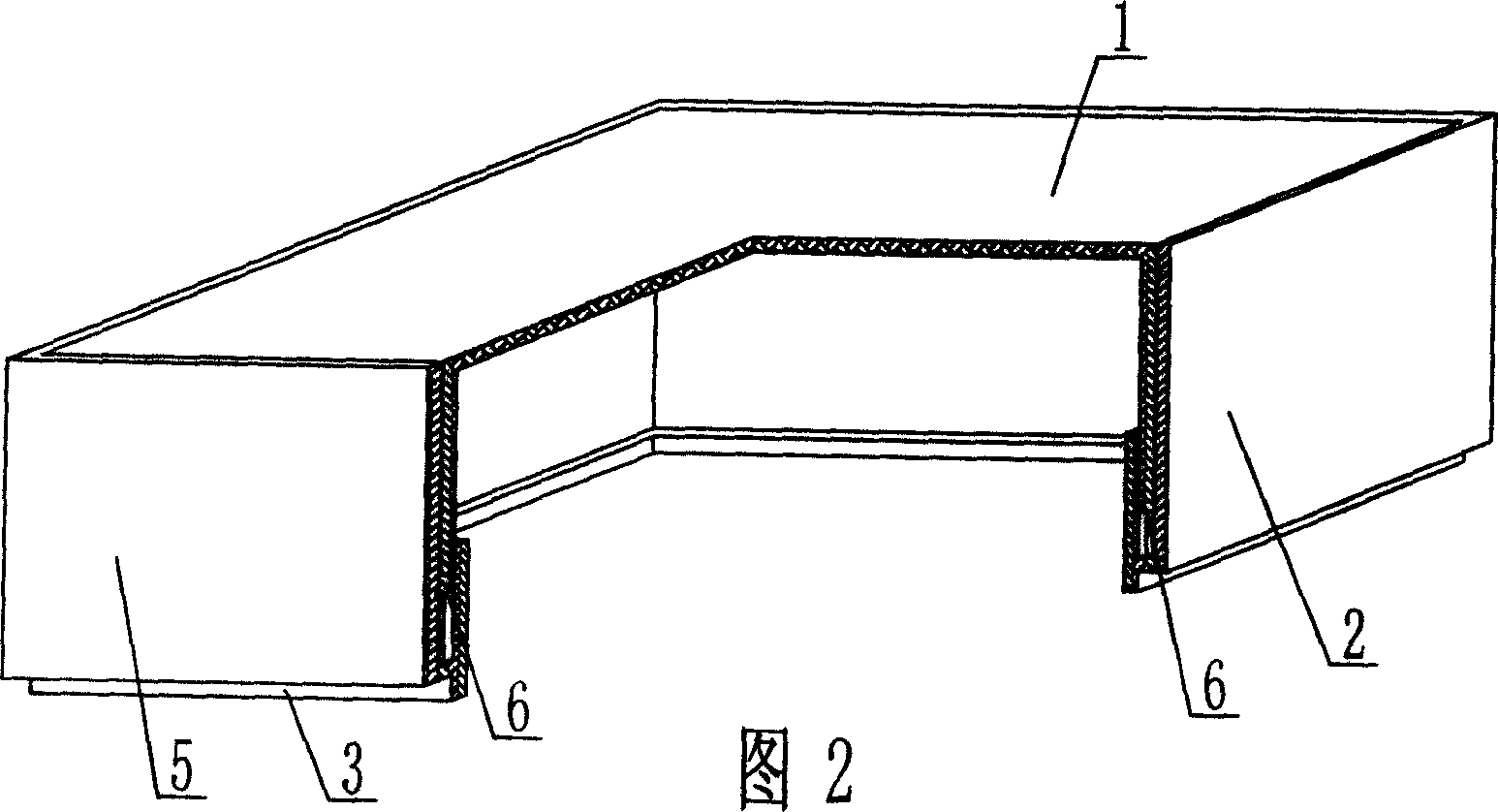

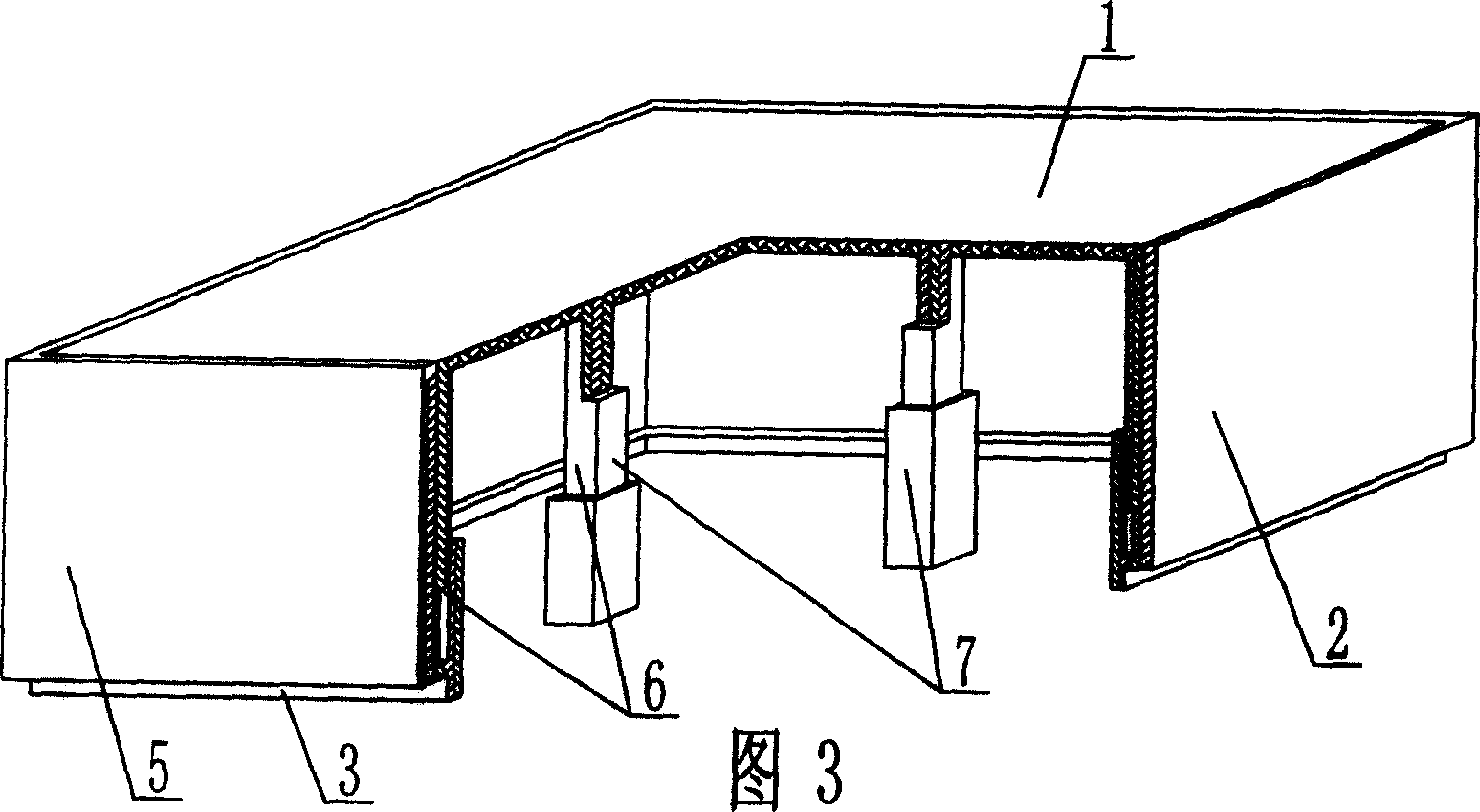

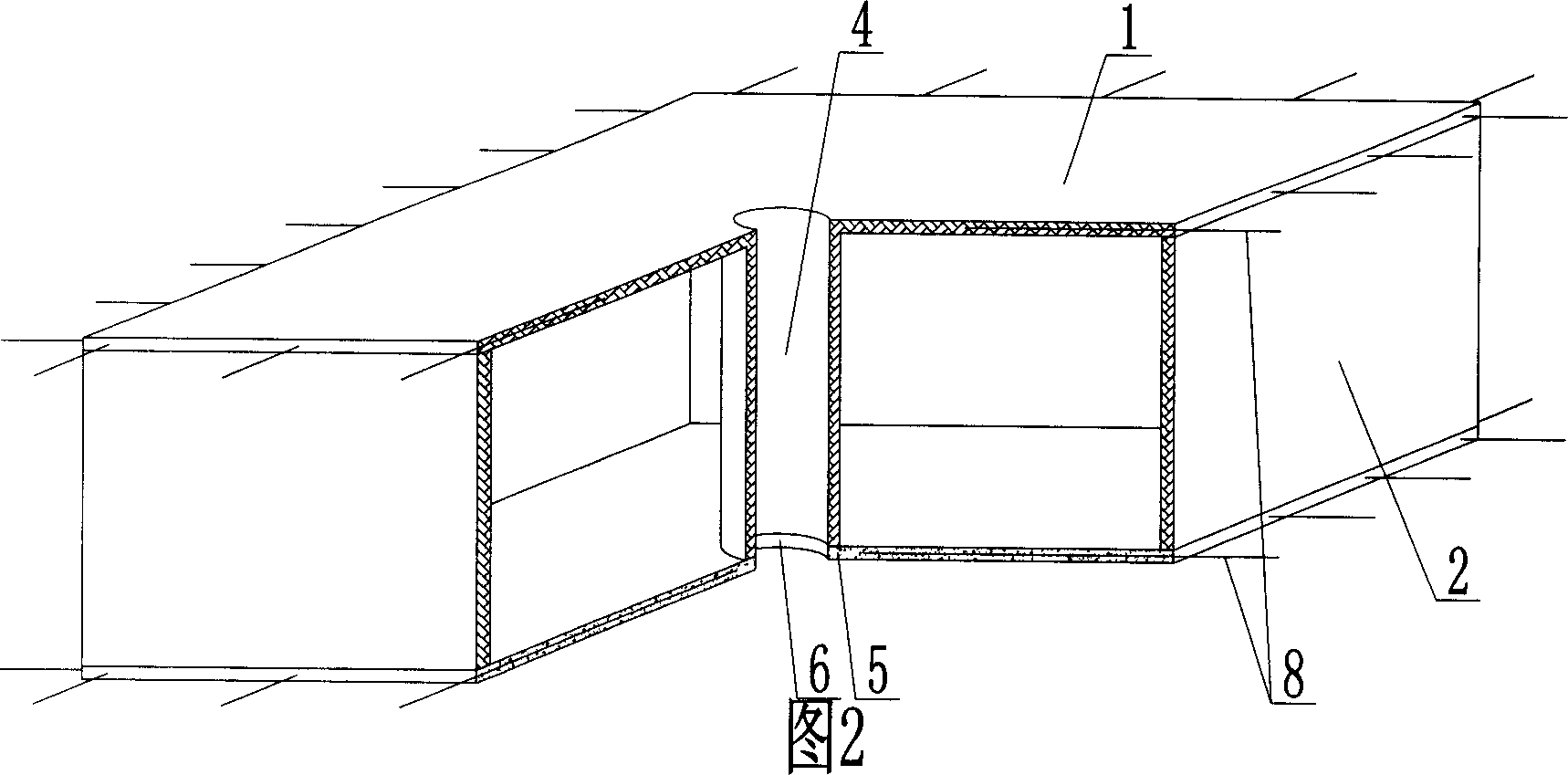

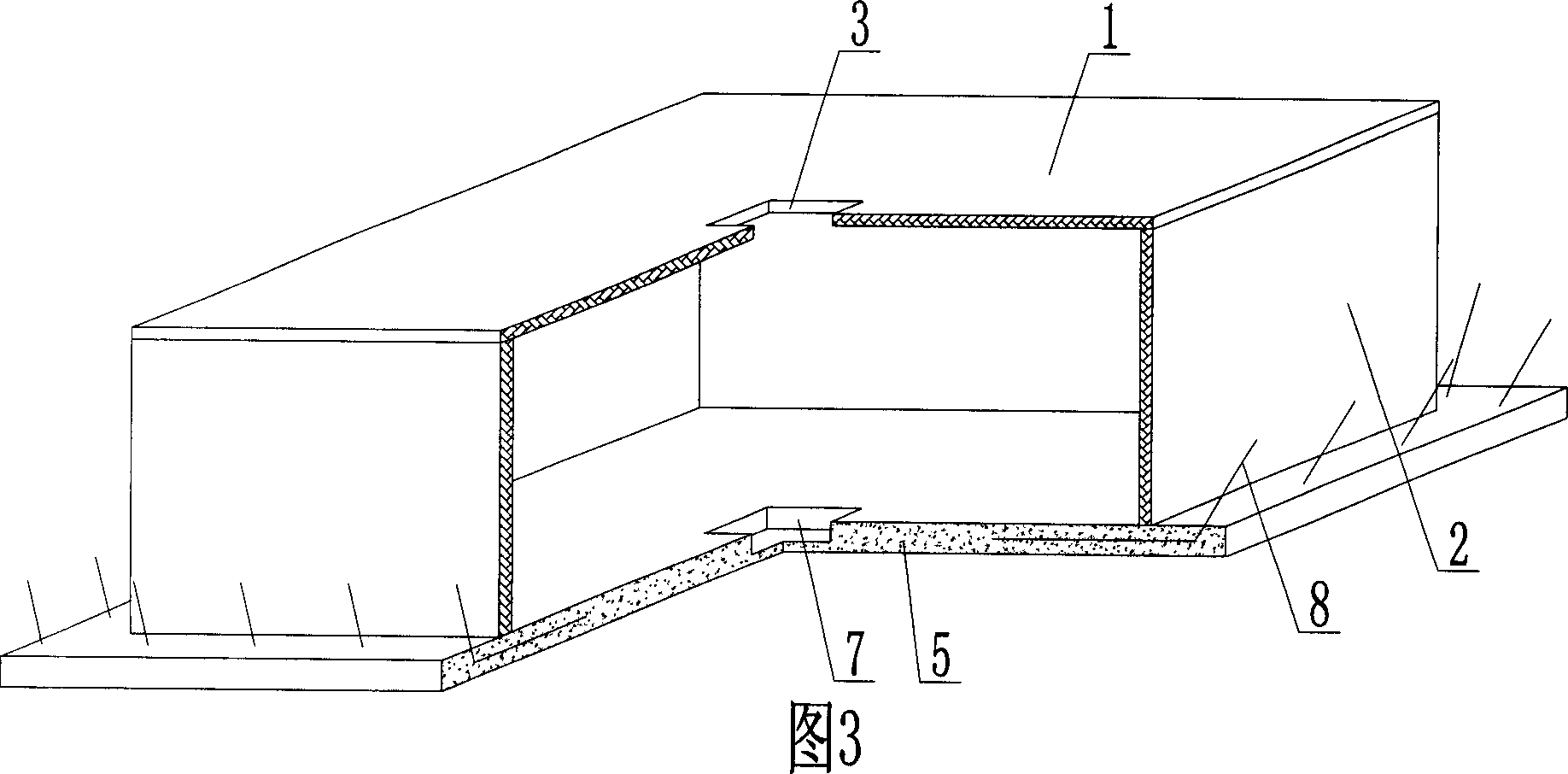

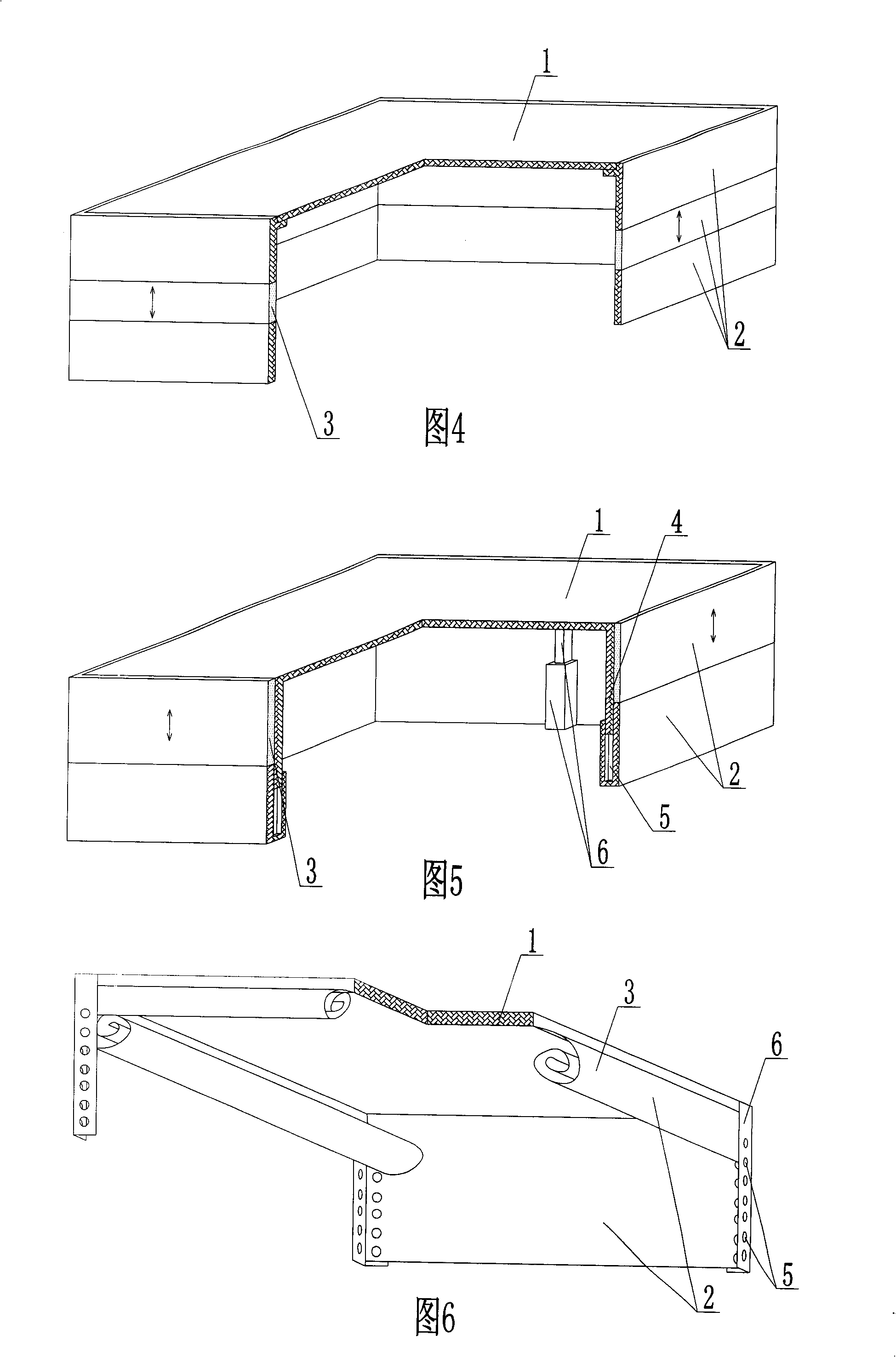

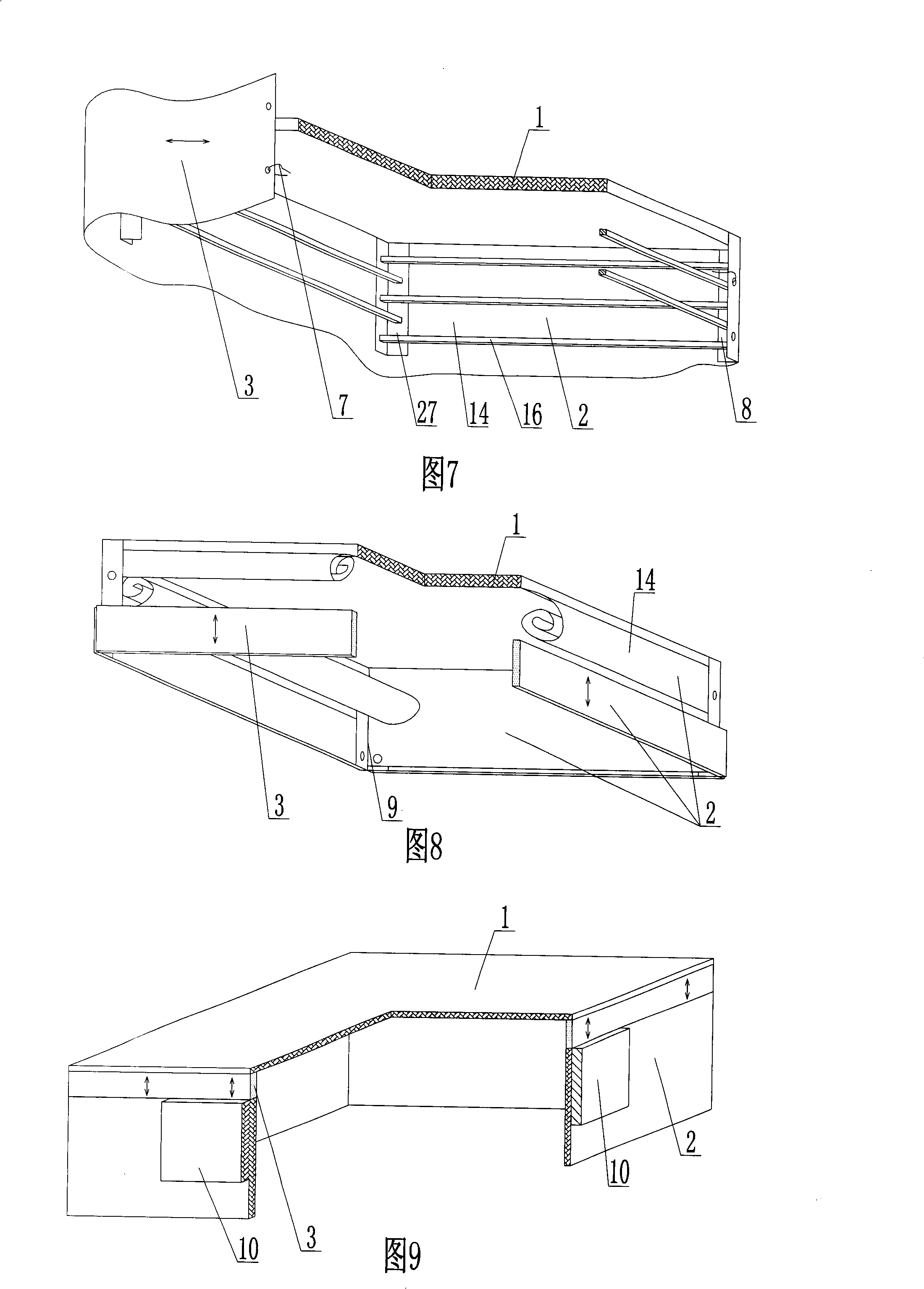

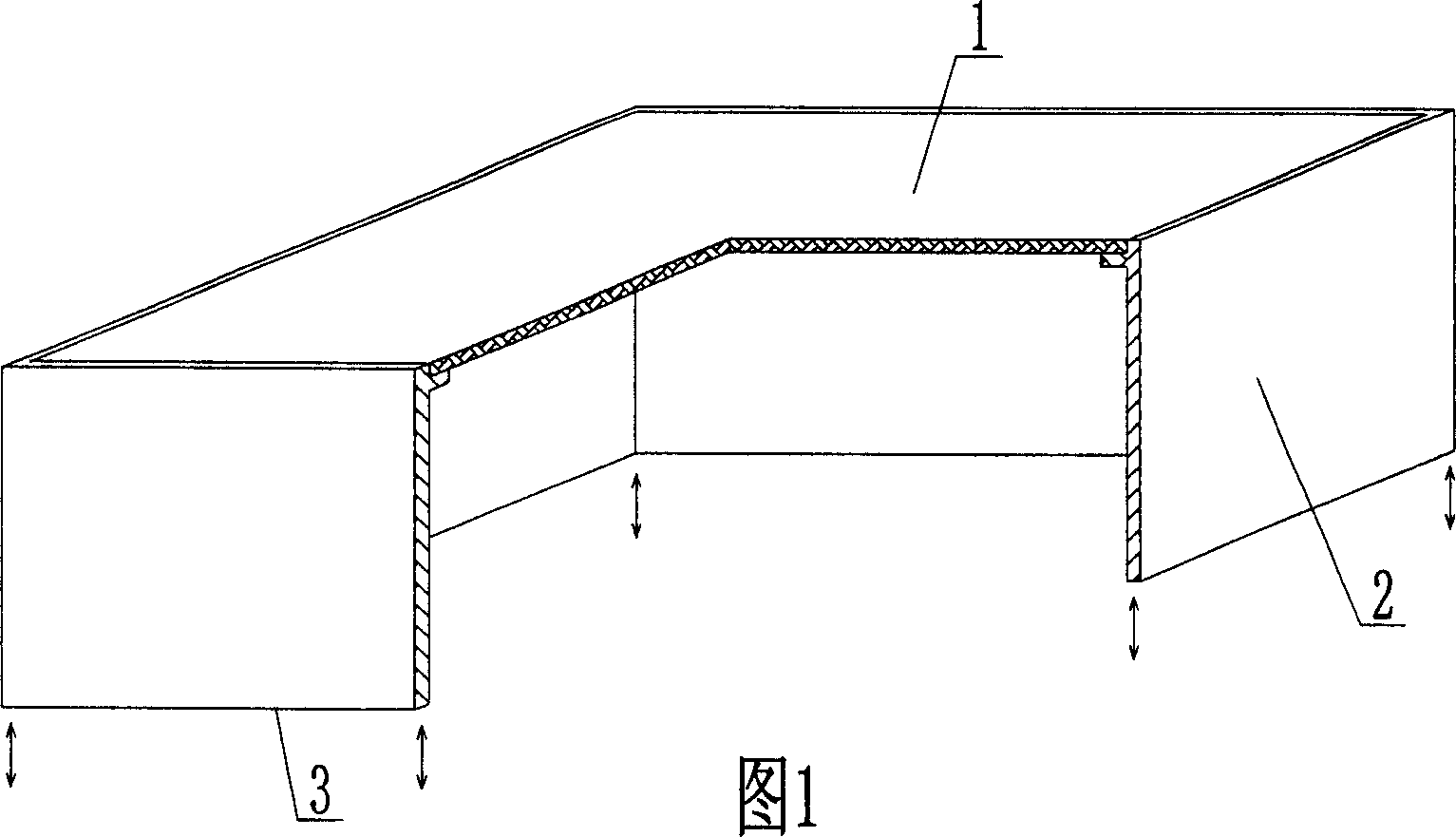

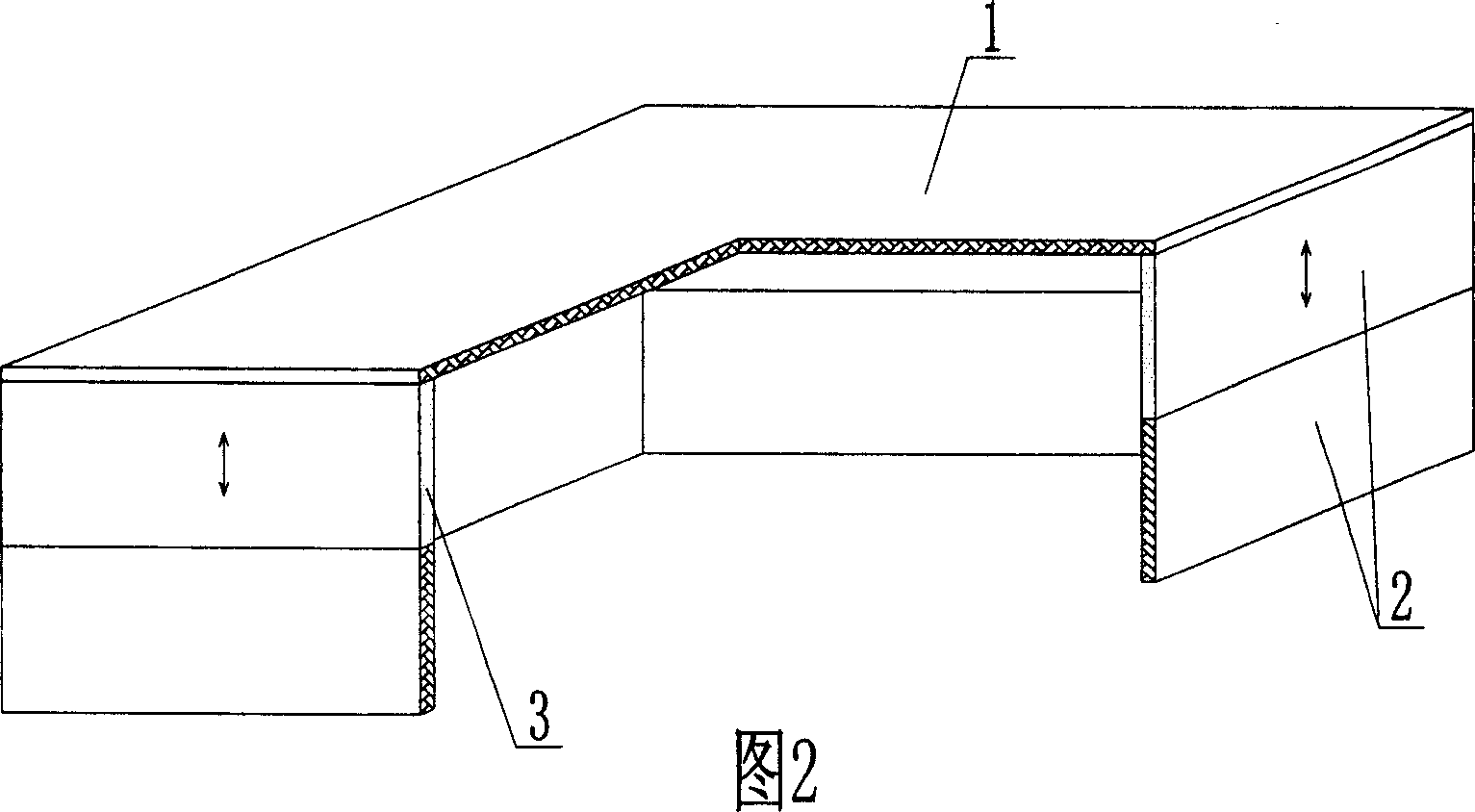

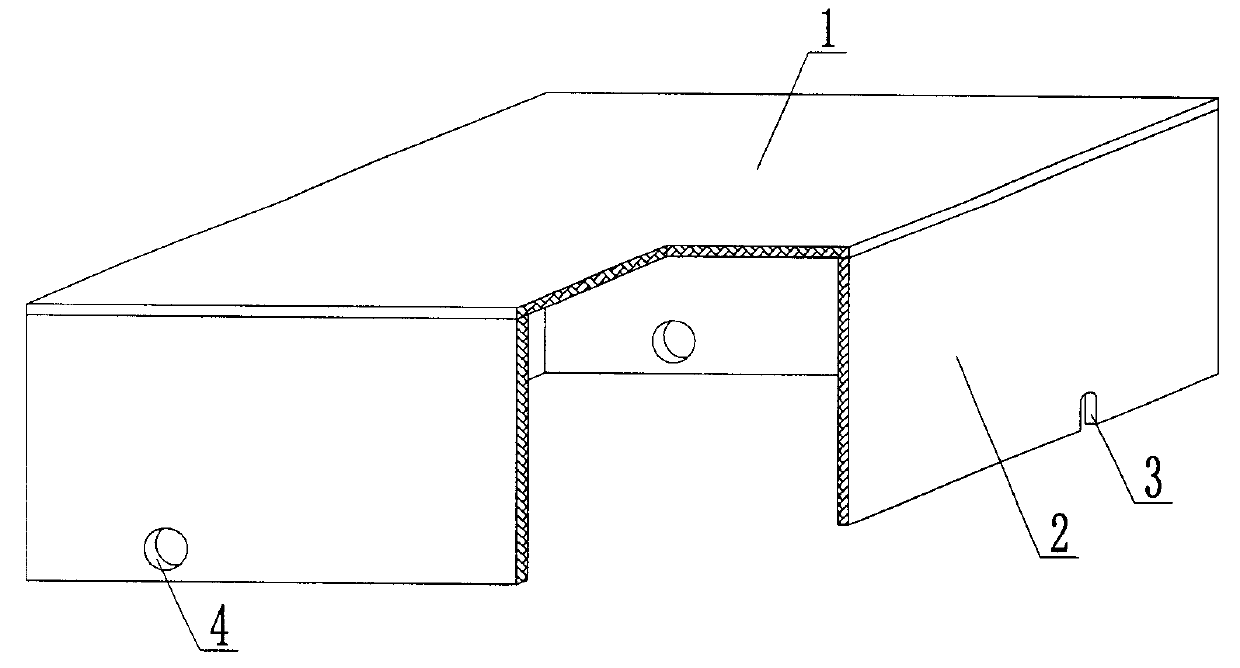

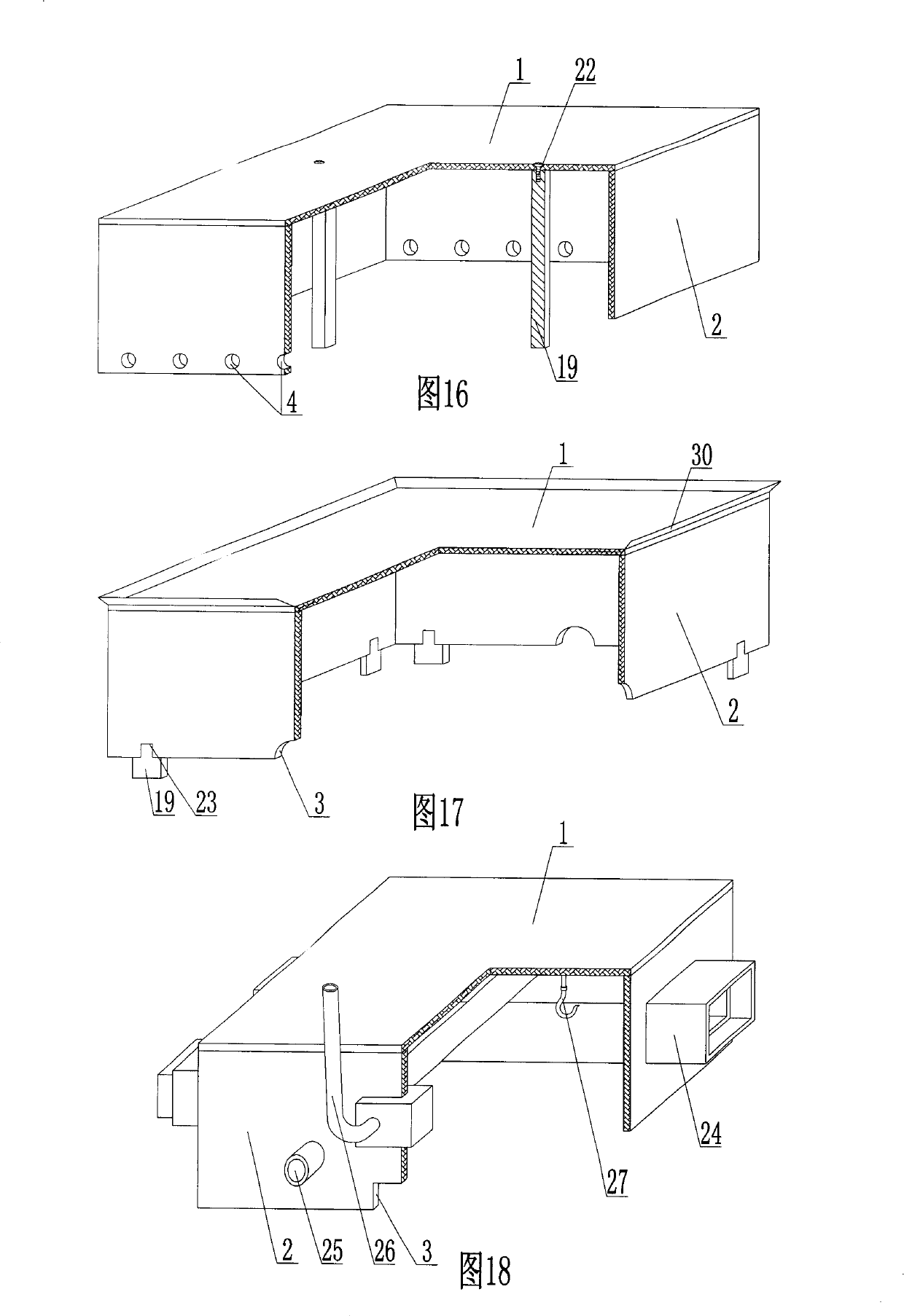

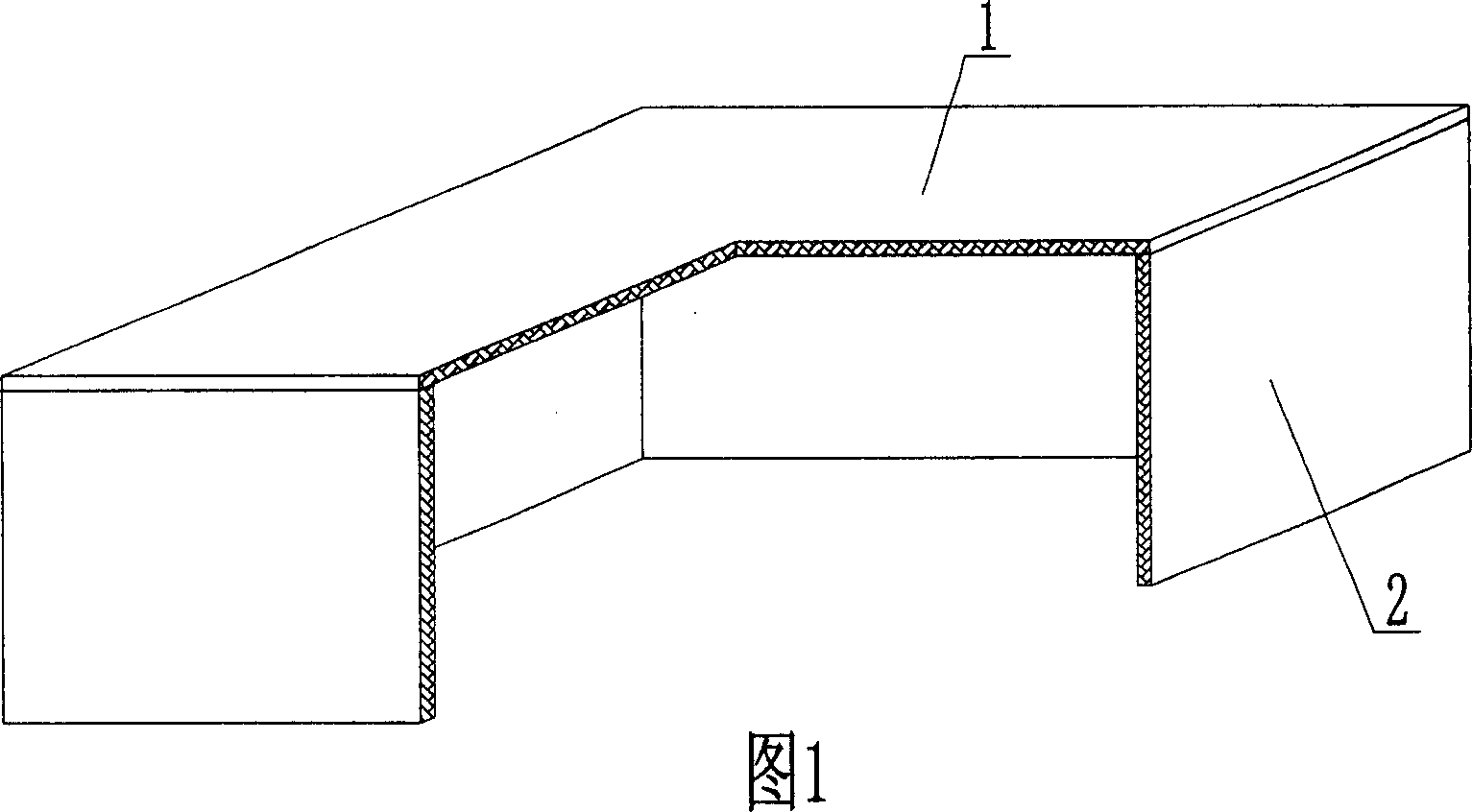

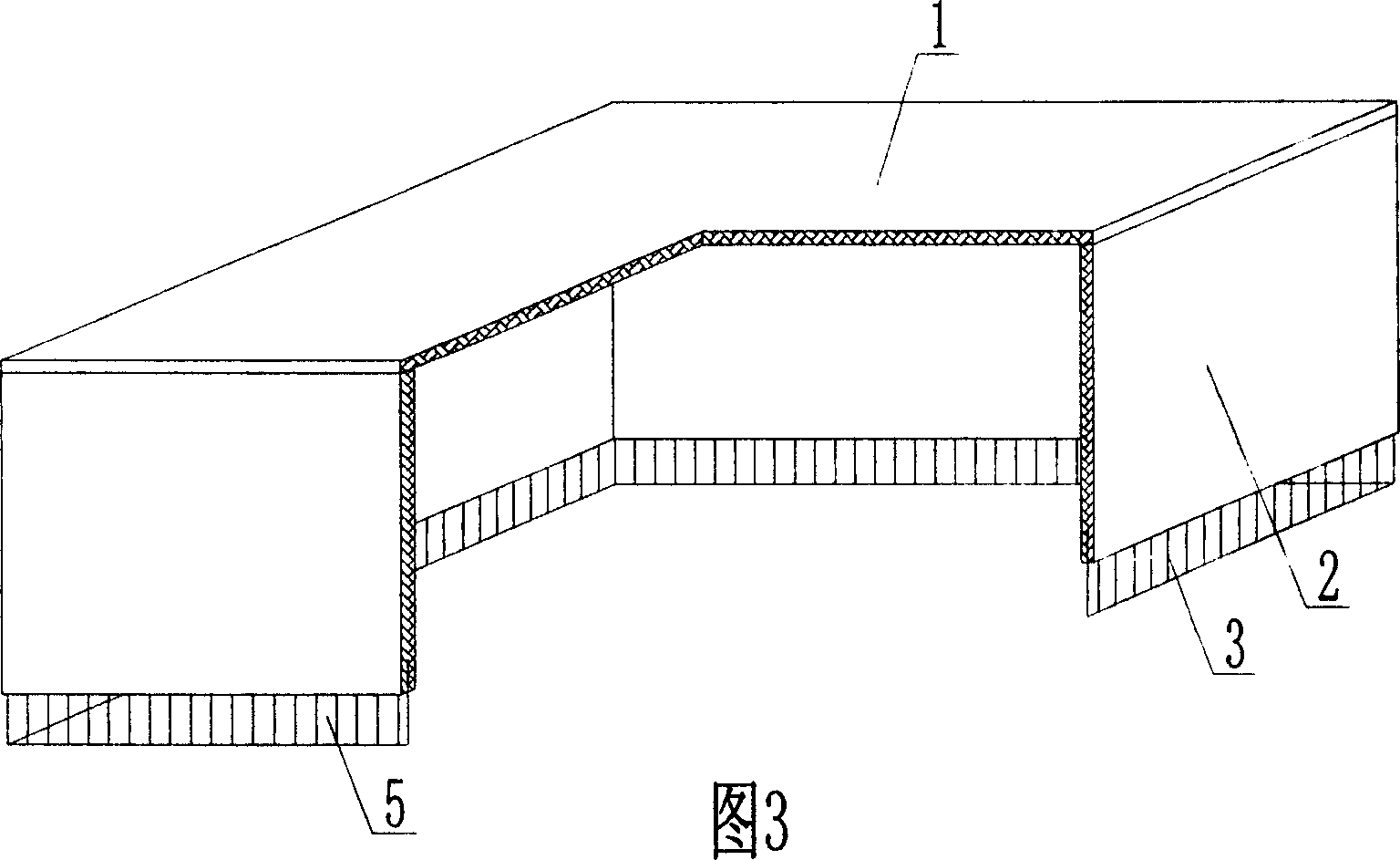

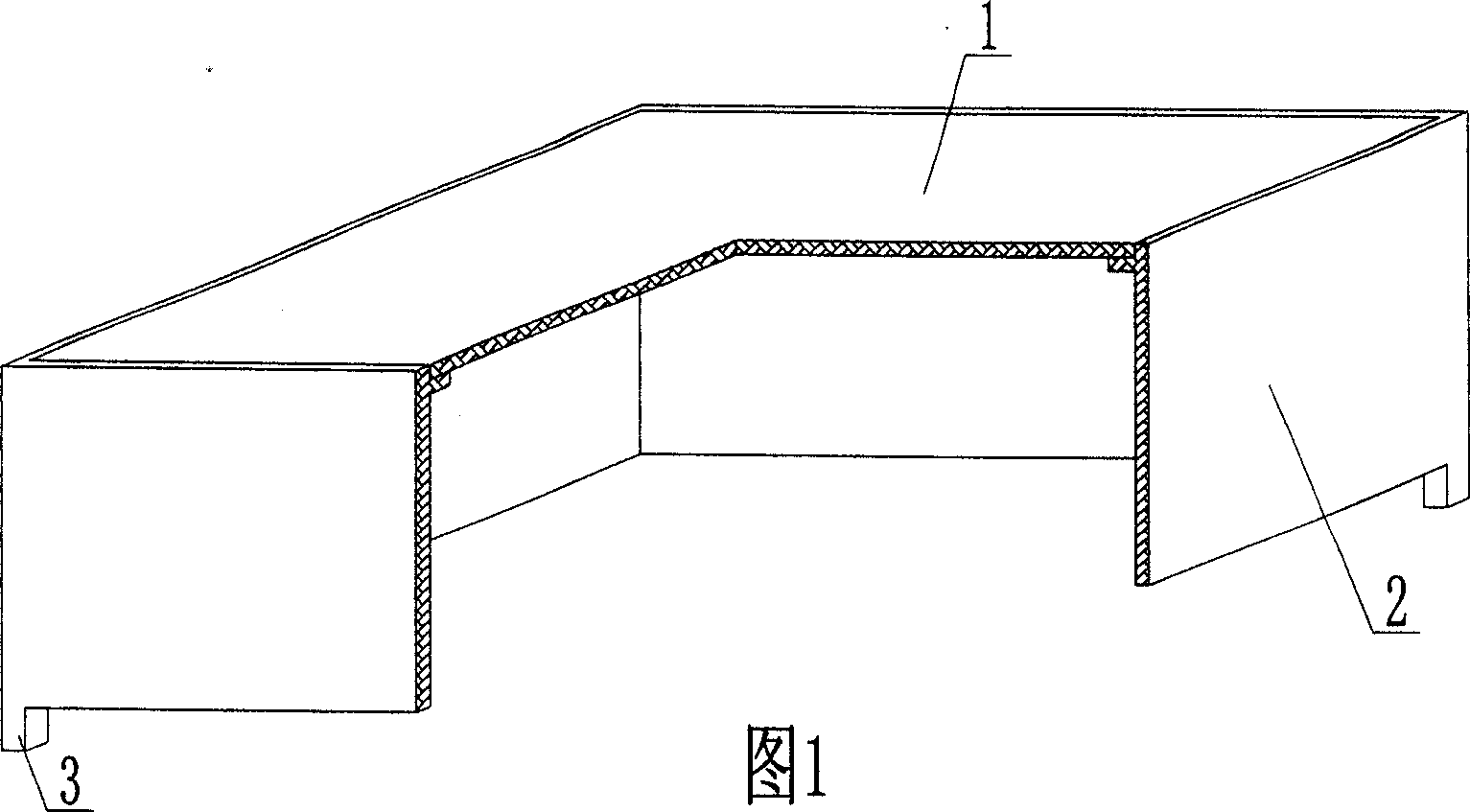

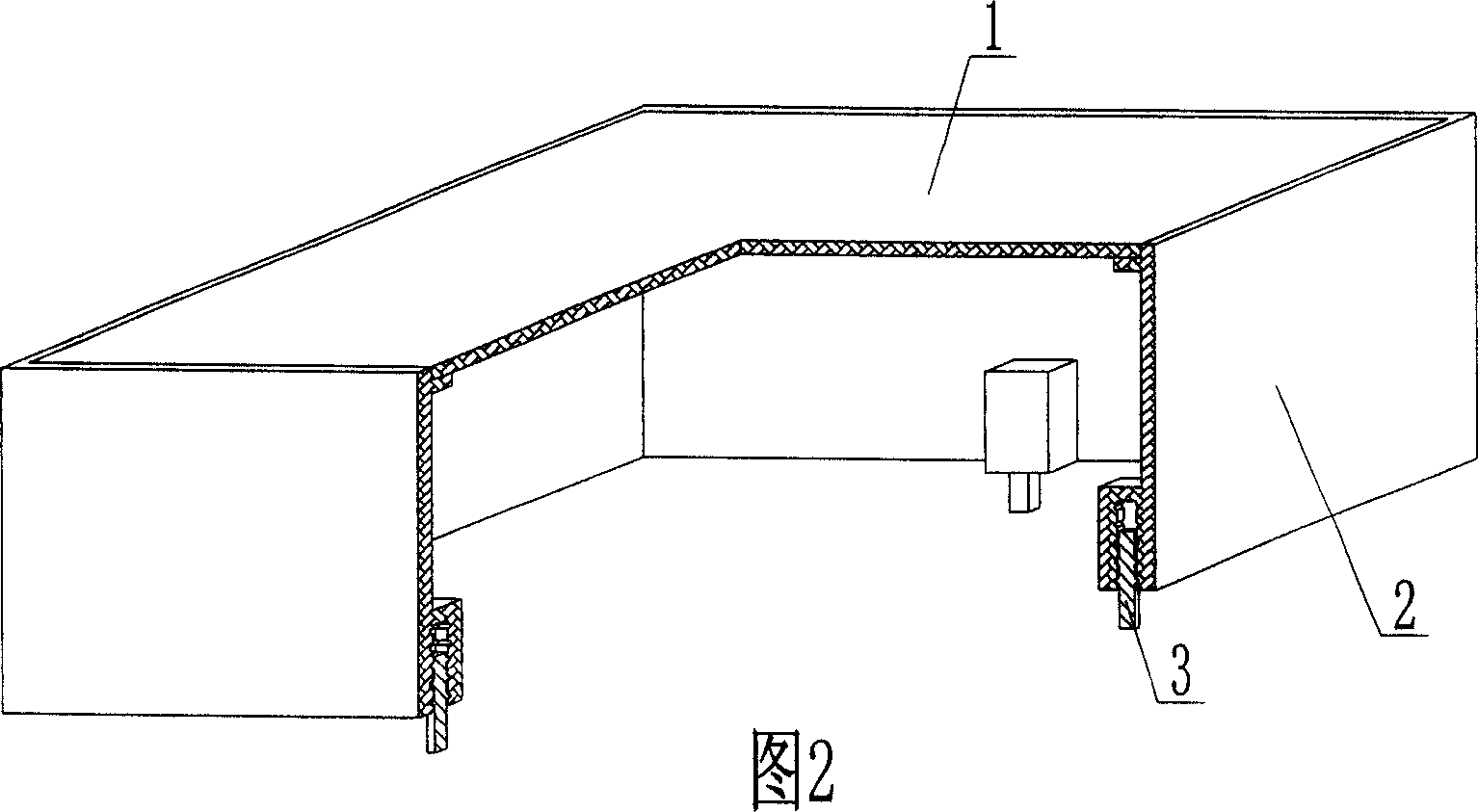

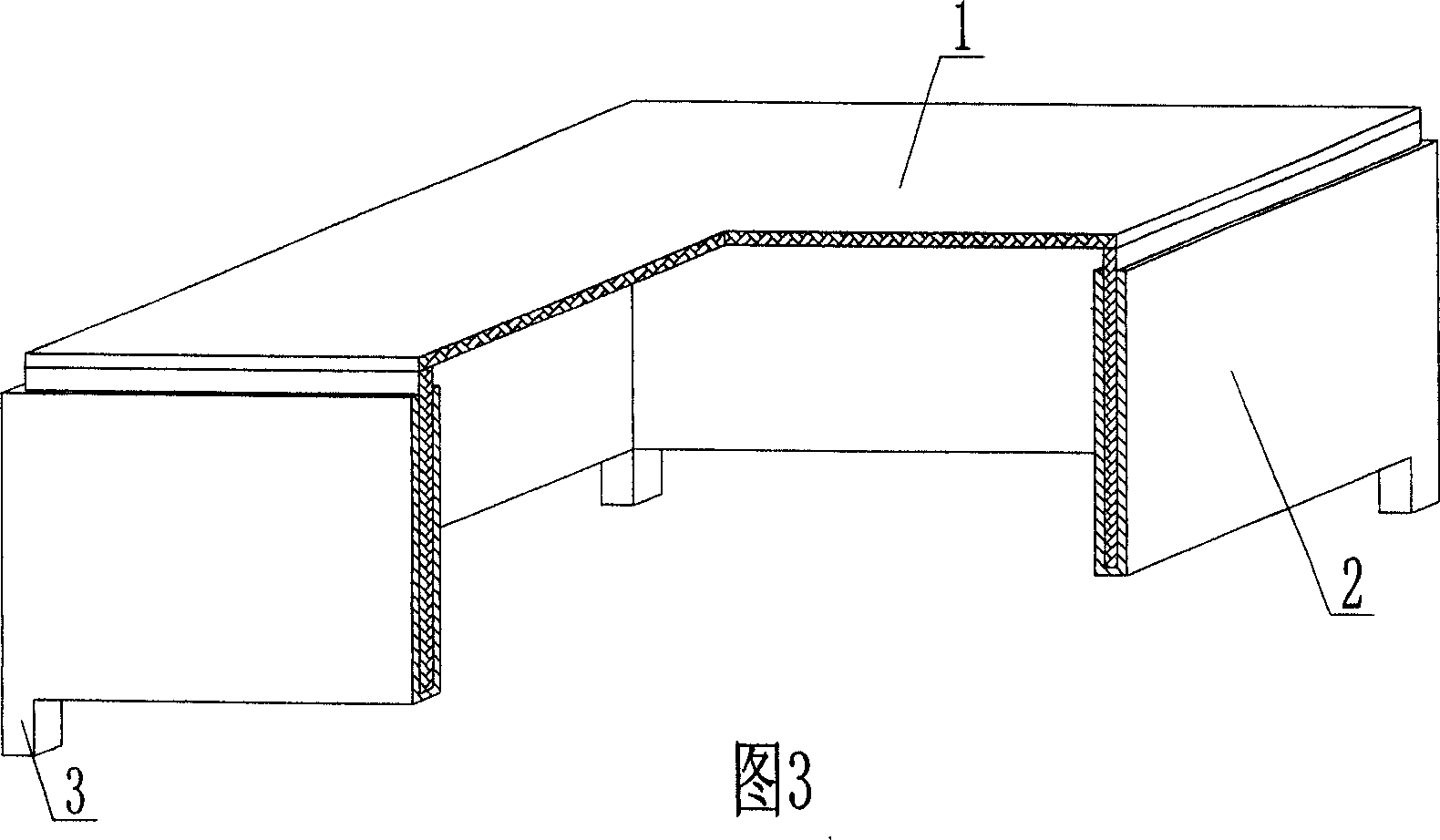

Disclosed is a hollow box for concrete structure, which comprises an upper box board (1) and peripheral formworks (2), the upper box board (1) and the peripheral formworks are split prefabricated members, characterized in that the upper box board (1) covers on the peripheral frameworks (2), the upper end or / and lower end of the peripheral framework (2) is an internal corner (3) or chamfering (4) or formwork (5). The invention can be applied to various building slabs, house roofings, walls, foundation bedplates and hollow bridges.

Owner:湖南邱则有专利战略策划有限公司

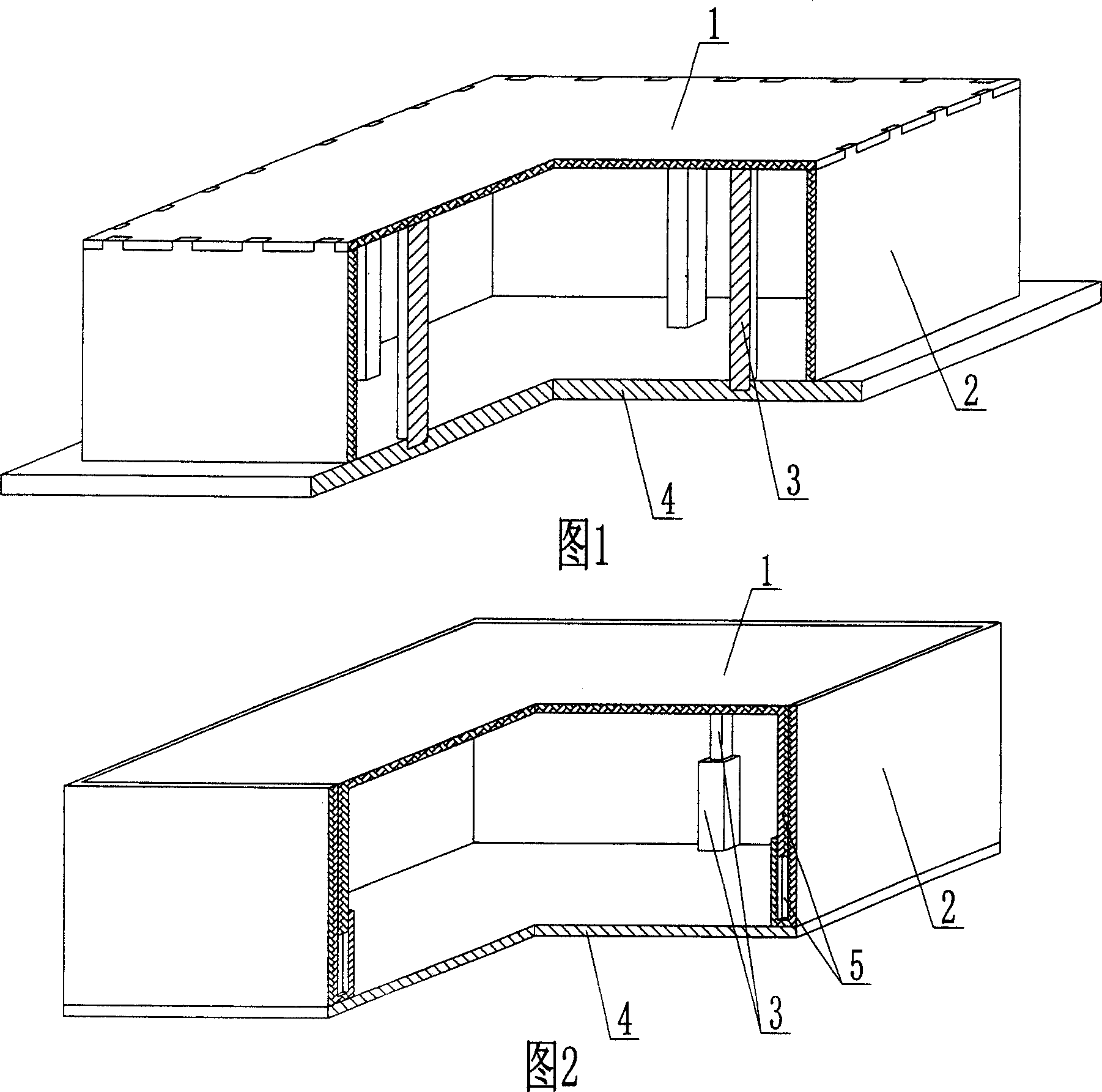

Opening box for concrete structure

Disclosed is a hollow box for concrete structure, which comprises an upper box board (1) and peripheral formworks (2), the upper box board (1) covers on the peripheral frameworks (2), the upper box board (1) and the peripheral formworks are split-and-paste prefabricated members, characterized in that the lower portion of the peripheral frameworks (2) is provided with at least a notch or hole (4). The invention can be applied to various building slabs, house roofings, walls, foundation bedplates and hollow bridges.

Owner:湖南邱则有专利战略策划有限公司

Opening box for concrete structure

Disclosed is a hollow box for concrete structure, which comprises an upper box board (1) and peripheral formworks (2), the upper box board (1) and the peripheral formworks are split-and-paste prefabricated members, characterized in that the upper box board (1) covers on the peripheral frameworks (2), the upper box board (1) is provided with a concrete casting upper hole (3) or / and a communicating tube hole (4). As a result, the hollow box can be equipped with other members easily. The invention can be applied to various building slabs, house roofings, walls, foundation bedplates and hollow bridges.

Owner:湖南邱则有专利战略策划有限公司

Sandwich member for concrete use

The sandwiched member for concrete includes one upper box board, one lower box board and one filling formwork between the upper box board and the lower box board, and features that in the peripheral of the upper box board, the lower box board and / or the filling formwork, there is at least one antiseepage and anti-cracking sheet to raise the binding strength of the interface between the in-situ cast and the pre-stressed reinforced concrete and raise the quality of the member. The present invention is suitable for in-situ cast or pre-stressed reinforced concrete hollow floor slab, roof, wall, foundation slab and hollow bridge, especially hollow flat floor slab.

Owner:湖南邱则有专利战略策划有限公司

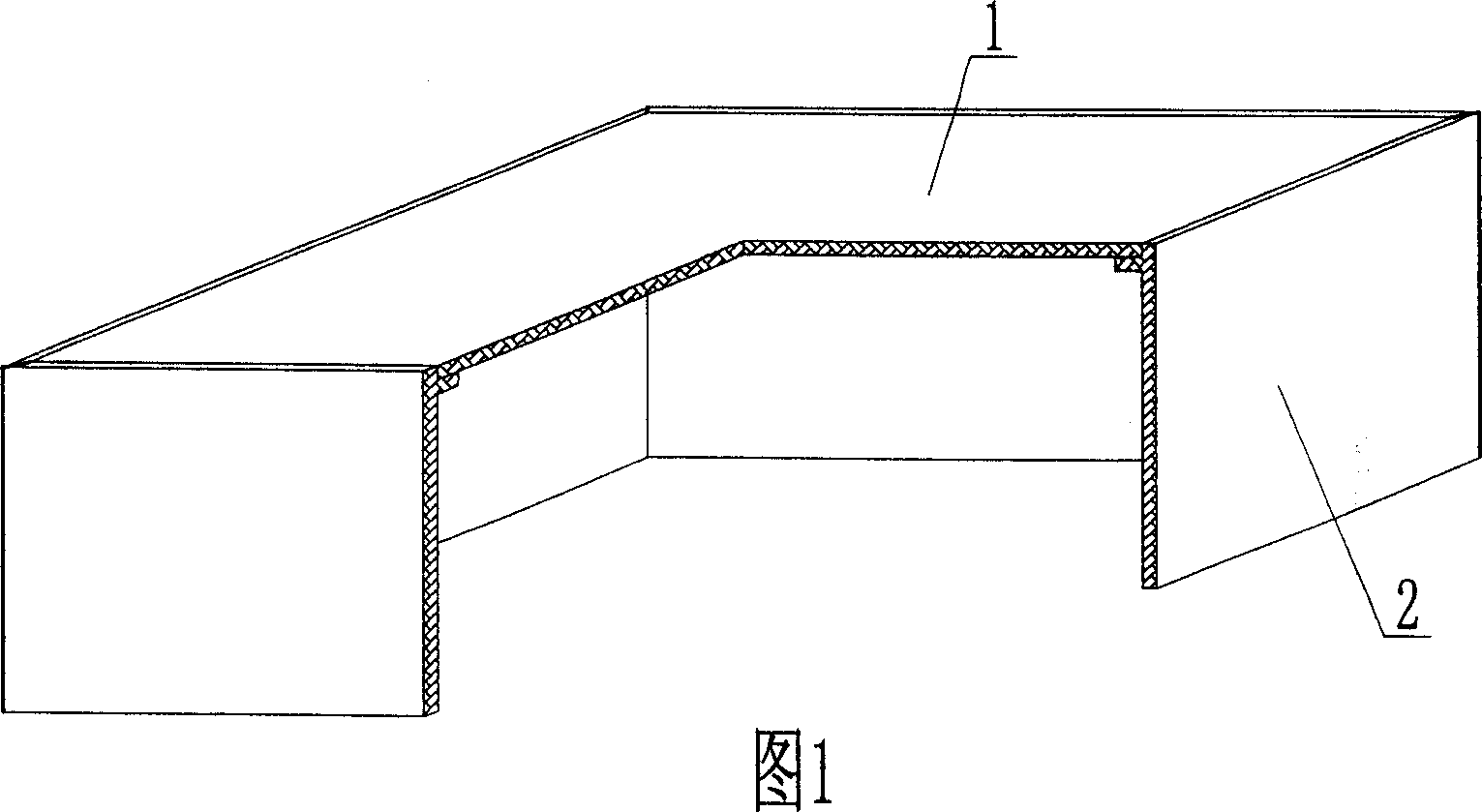

Opening box for concrete structure

Disclosed is a hollow box for concrete structure, which comprises an upper box board (1) and peripheral formworks (2), characterized in that the upper box board (1) and the peripheral formworks are split members, the upper box board covers on the peripheral frameworks, the upper box board and the peripheral formworks are split-and-paste prefabricated members. The invention can be applied to various cast-in-situ reinforced-bar concrete or prestressed reinforced-bar concrete hollow building roofings, house roofings, walls, foundation bedplates and hollow bridges, especially for hollow flat slabs.

Owner:湖南邱则有专利战略策划有限公司

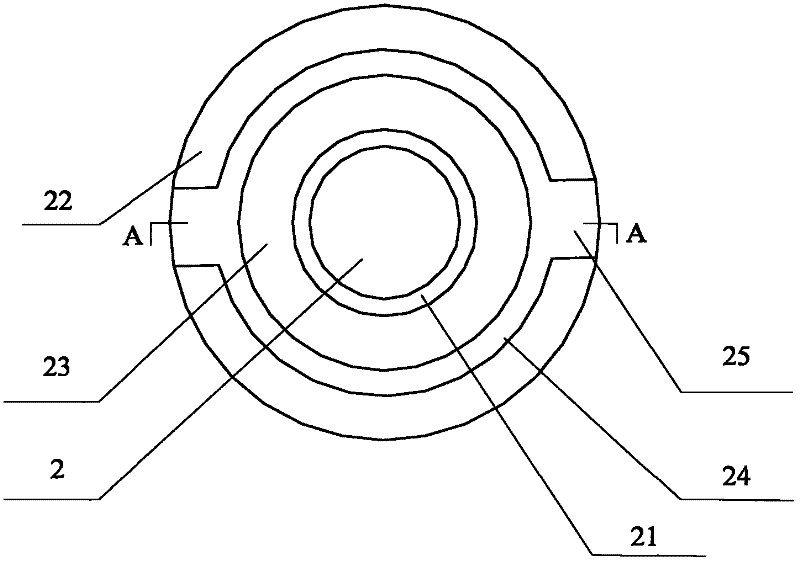

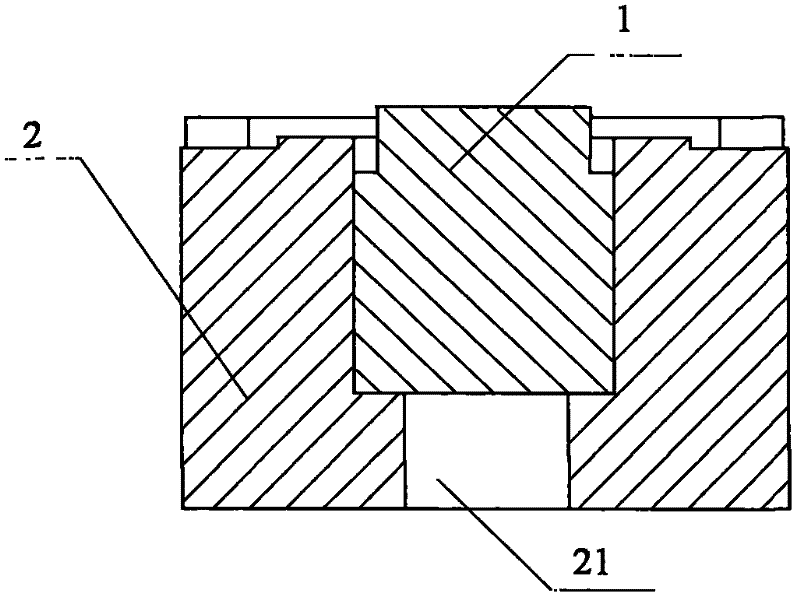

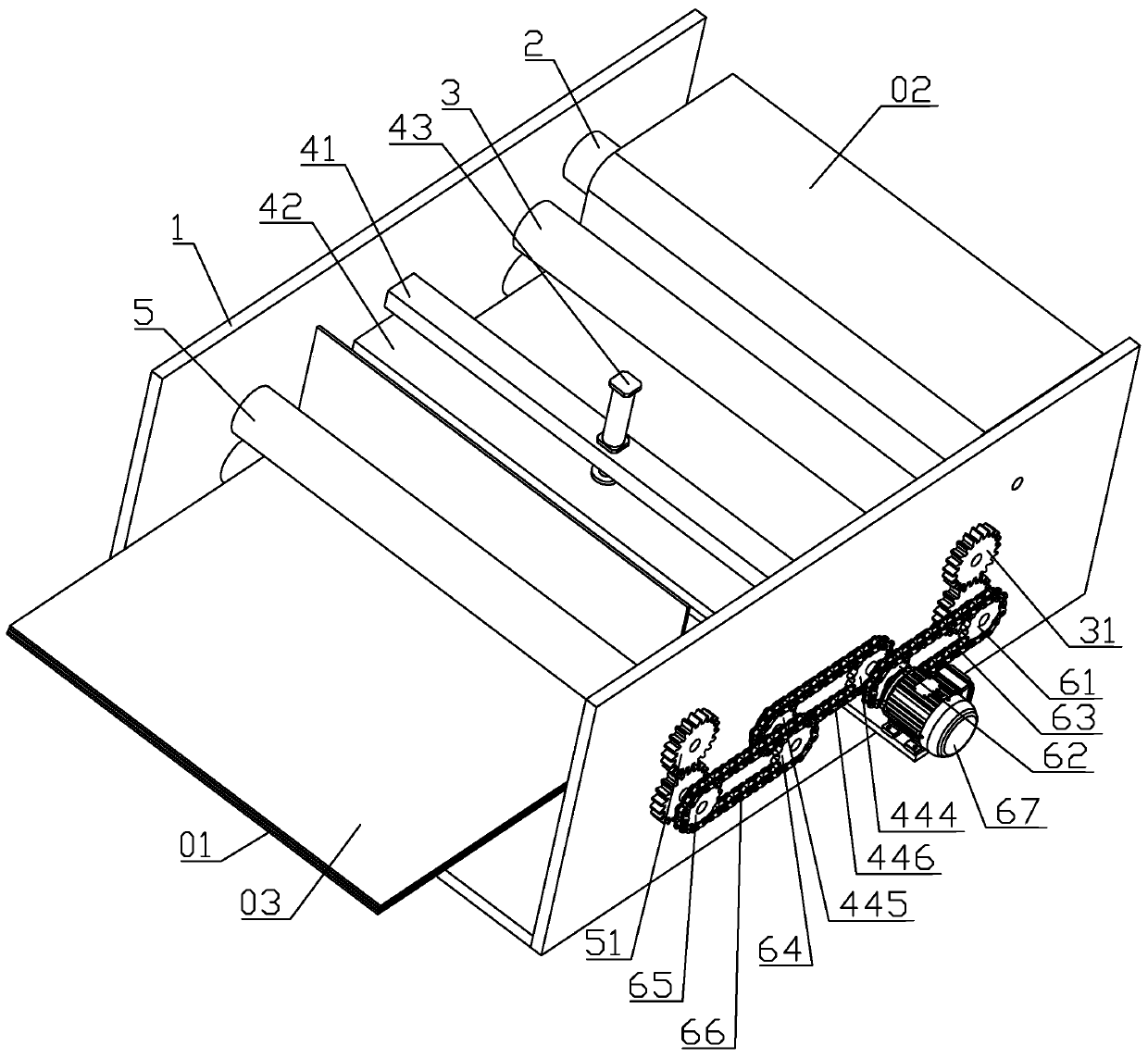

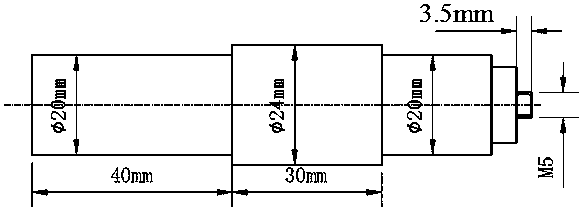

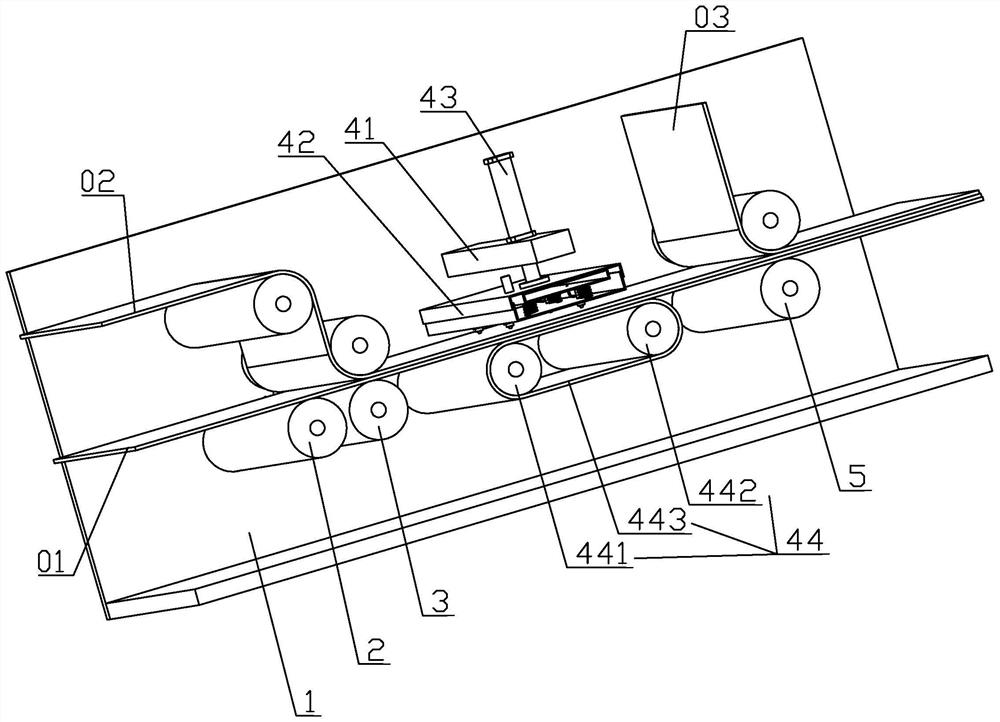

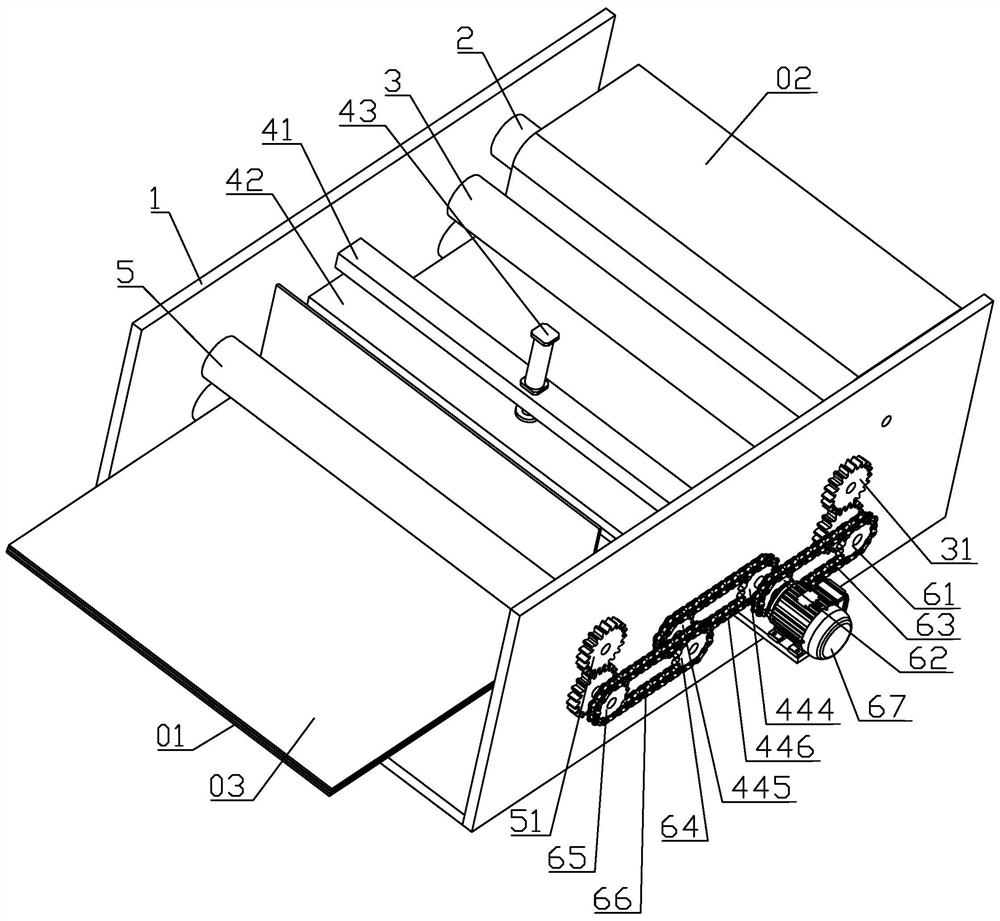

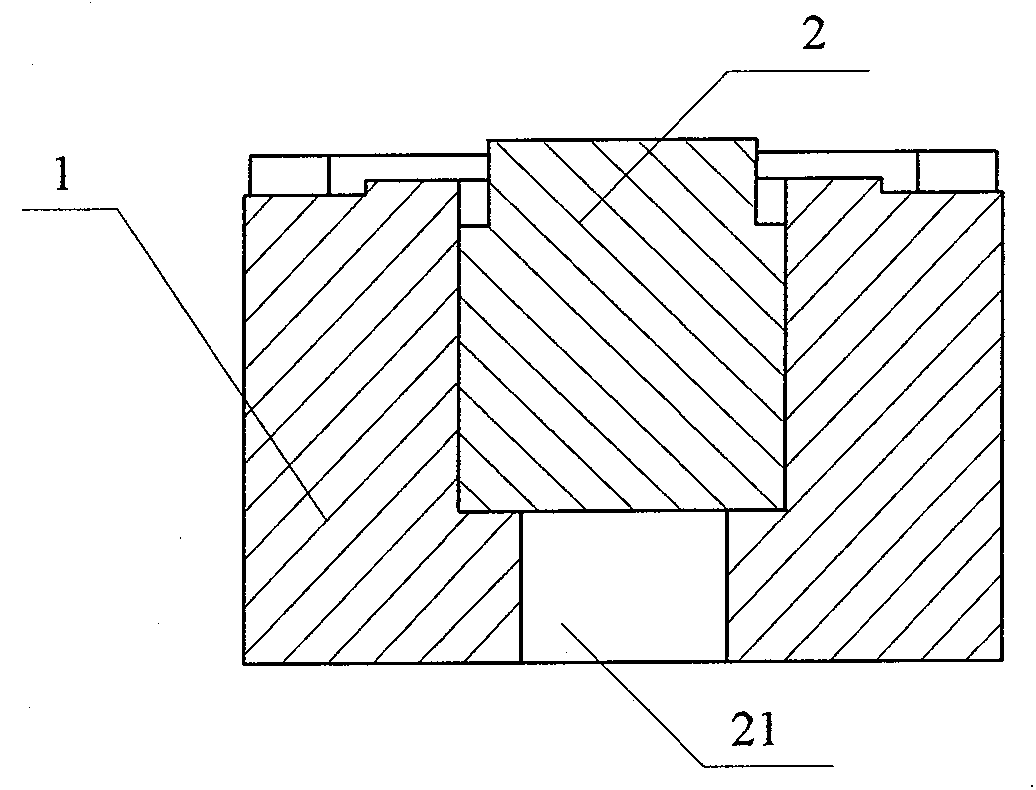

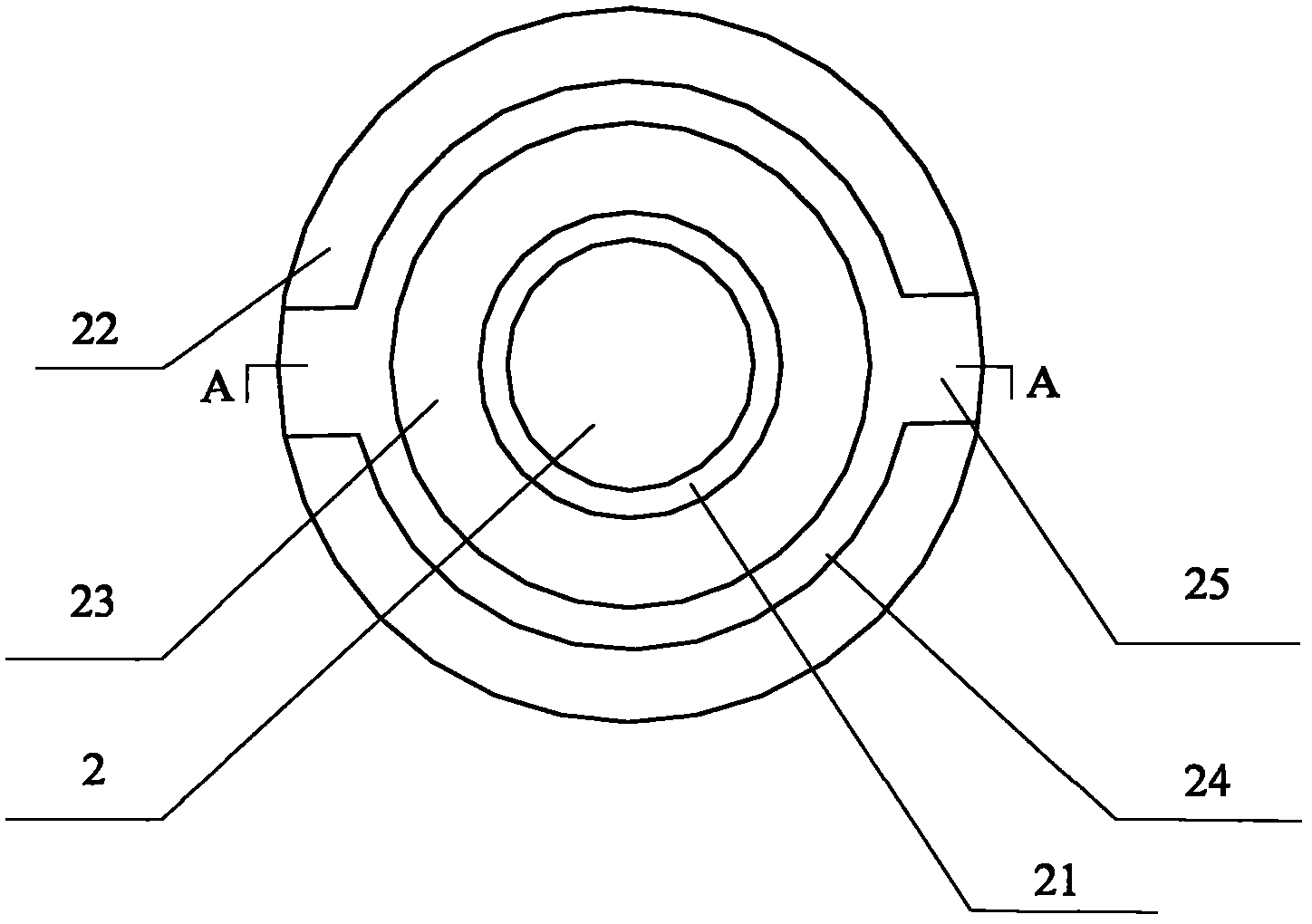

Device and method for carrying out thermocompression welding on enameled wires of pendulum components

ActiveCN102554448ASolve support positioning problemsPrecise positioningNon-electric welding apparatusSpecial designPass rate

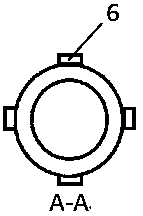

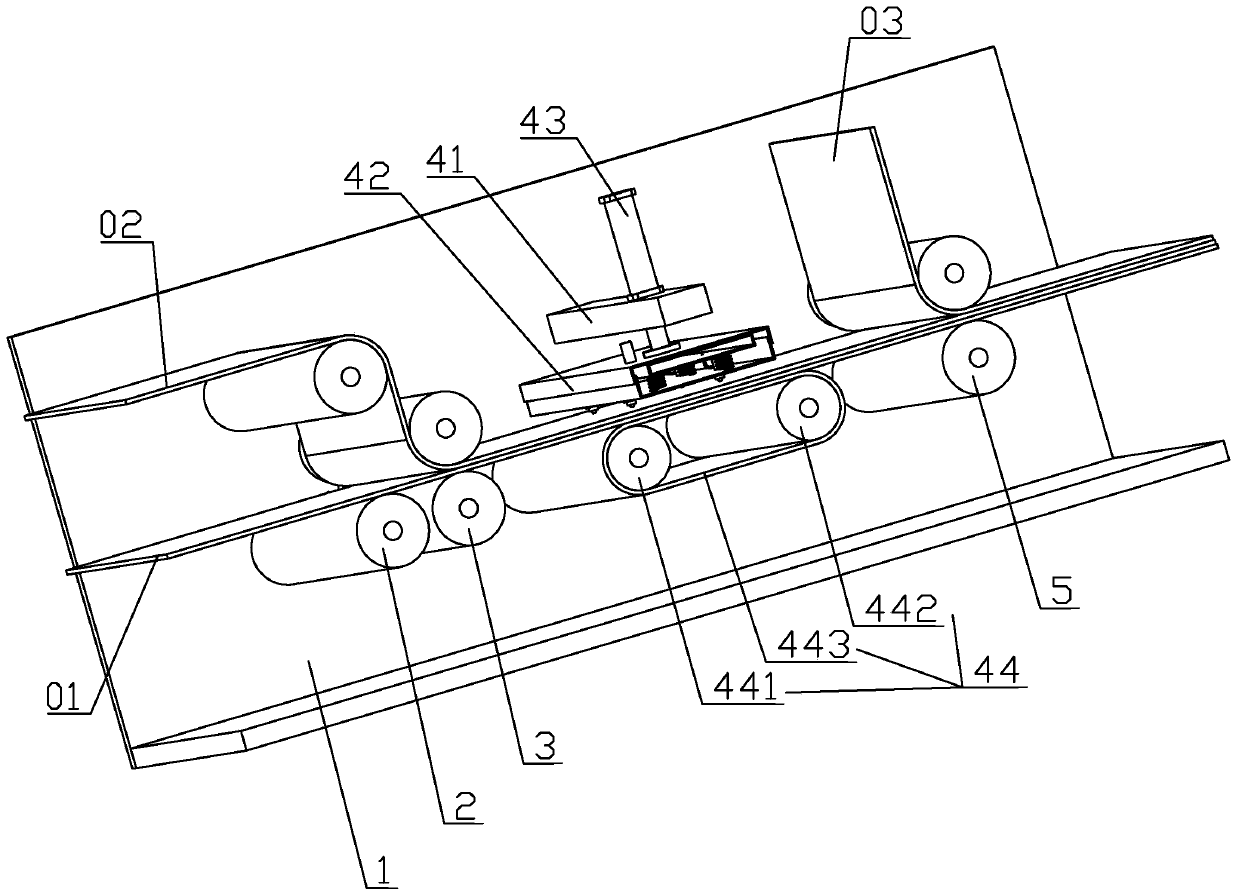

The invention provides a device and a method for carrying out thermocompression welding on enameled wires of pendulum components. The device comprises a base and a sliding shaft, wherein the base is cylindrical, a through stepped hole is formed in the central position of the base; the aperture of a big hole at the upper part of the stepped hole is a mounting hole for the sliding shaft; a ring-shaped boss is processed on the upper surface of the base, at the outer side of the stepped hole; a ring-shaped shallow slot is processed on the outer side of the ring-shaped boss; two arc-shaped non-closed surrounding structures symmetrically distributed are processed on the outer side of the ring-shaped shallow slot, and are separated by two shallow slots with different shapes. With the special design of the device, the supporting and positioning problems of a central pendulum of a pendulum plate and a moving coil of a torquer are solved, so that the reliable positioning on the pendulum plate is realized, the stability of welding is good, and the rate of finished products and the work efficiency are also greatly improved. For the welding method, a special welding technology is adopted, the welding quality is good, the welding parameters are stable and controllable, the consistency is good, the time for welding one pendulum component by adopting lead-tin welding is about 10 minutes, while the time for welding one pendulum by adopting the method is only about 4 minutes, the production efficiency is improved by 150%, and the product pass rate also reaches above 99.5%.

Owner:航天科工惯性技术有限公司

Method for diffusion spot welding with solid phase assistance by efficient liquid phase of Al/Mg dissimilar metal

PendingCN110587105AIncrease the effective bearing areaIncreased tensile and shear capacityWelding/soldering/cutting articlesNon-electric welding apparatusMetal foilLiquid metal

The invention relates to the technical field of welding of Al / Mg dissimilar materials and specifically relates to a method for diffusion spot welding with solid phase assistance by an efficient liquidphase of Al / Mg dissimilar metal. The method provided by the invention comprises the steps that an Al plate and an Mg plate are rubbed by a friction head to generate heat, a metal foil between the plates is melted by the heat, and an oxidation film on a contact face is cleaned by the molten metal obtained after melting; the liquid metal is then extruded out through extrusion of the friction head;and during maintenance of close adhesion between the Al plate and the Mg plate, atomic diffusion takes place on the cleaned contact face, so diffusion spot welding connection is formed. A welding connector obtained through utilization of the method provided by the invention is a solid diffusion welding head, and a key hole in a welding spot surface is eliminated, so an effective bearing area of the connector is significantly increased; resistance of the spot welding connector to tensile and shear is enhanced; and complicated mechanical equipment and subsequent processes of repair welding are omitted.

Owner:NANCHANG HANGKONG UNIVERSITY

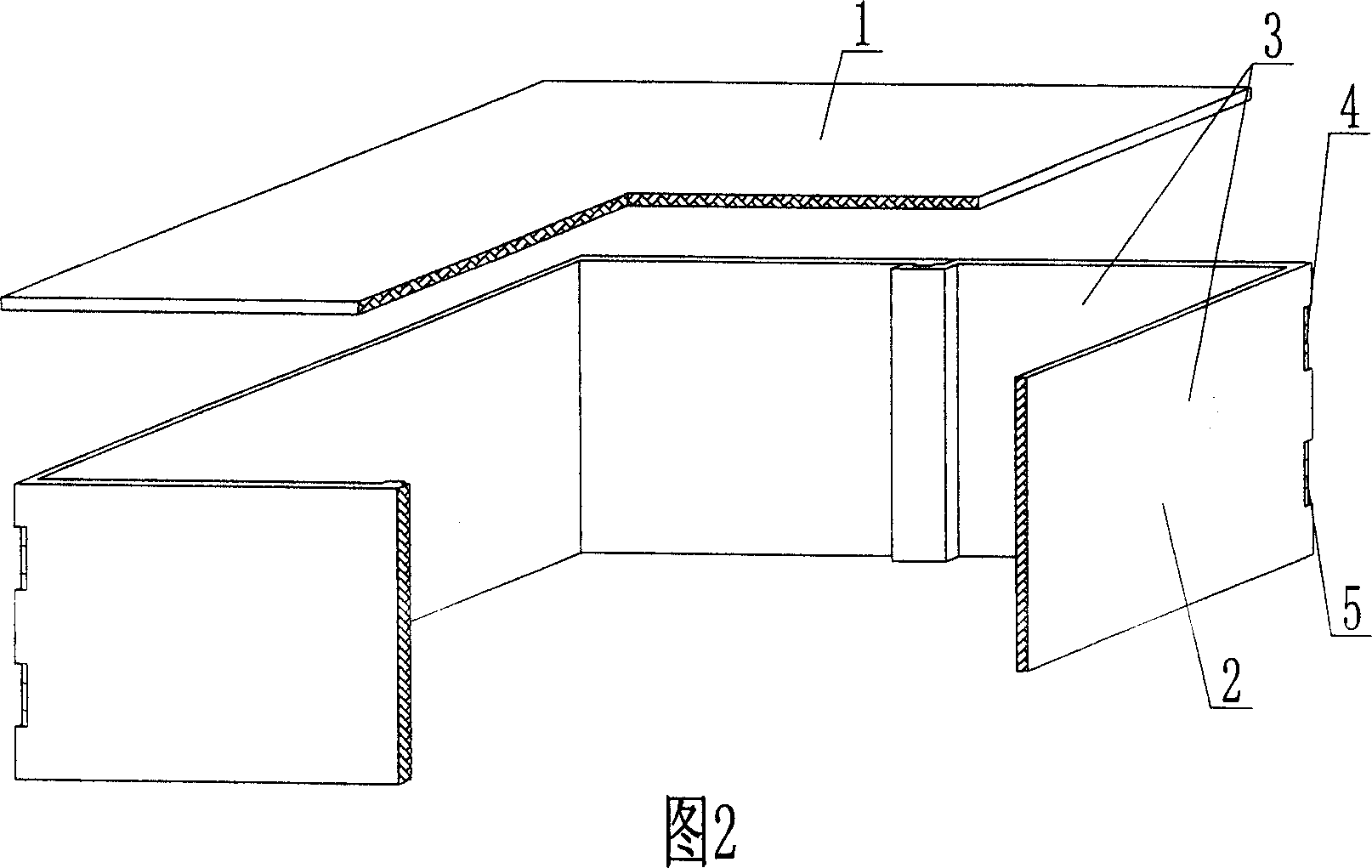

Opening box for concrete structure

Disclosed is a hollow box for concrete structure, which comprises an upper box board (1) and peripheral formworks (2), the upper box board (1) and the peripheral formworks are split-and-paste prefabricated members, characterized in that the upper box board (1) covers on the peripheral frameworks (2), the upper box board (1) is provided with a concrete casting upper hole (3) or / and a communicating tube hole (4). As a result, the hollow box can be equipped with other members easily. The invention can be applied to various building slabs, house roofings, walls, foundation bedplates and hollow bridges.

Owner:邱则有

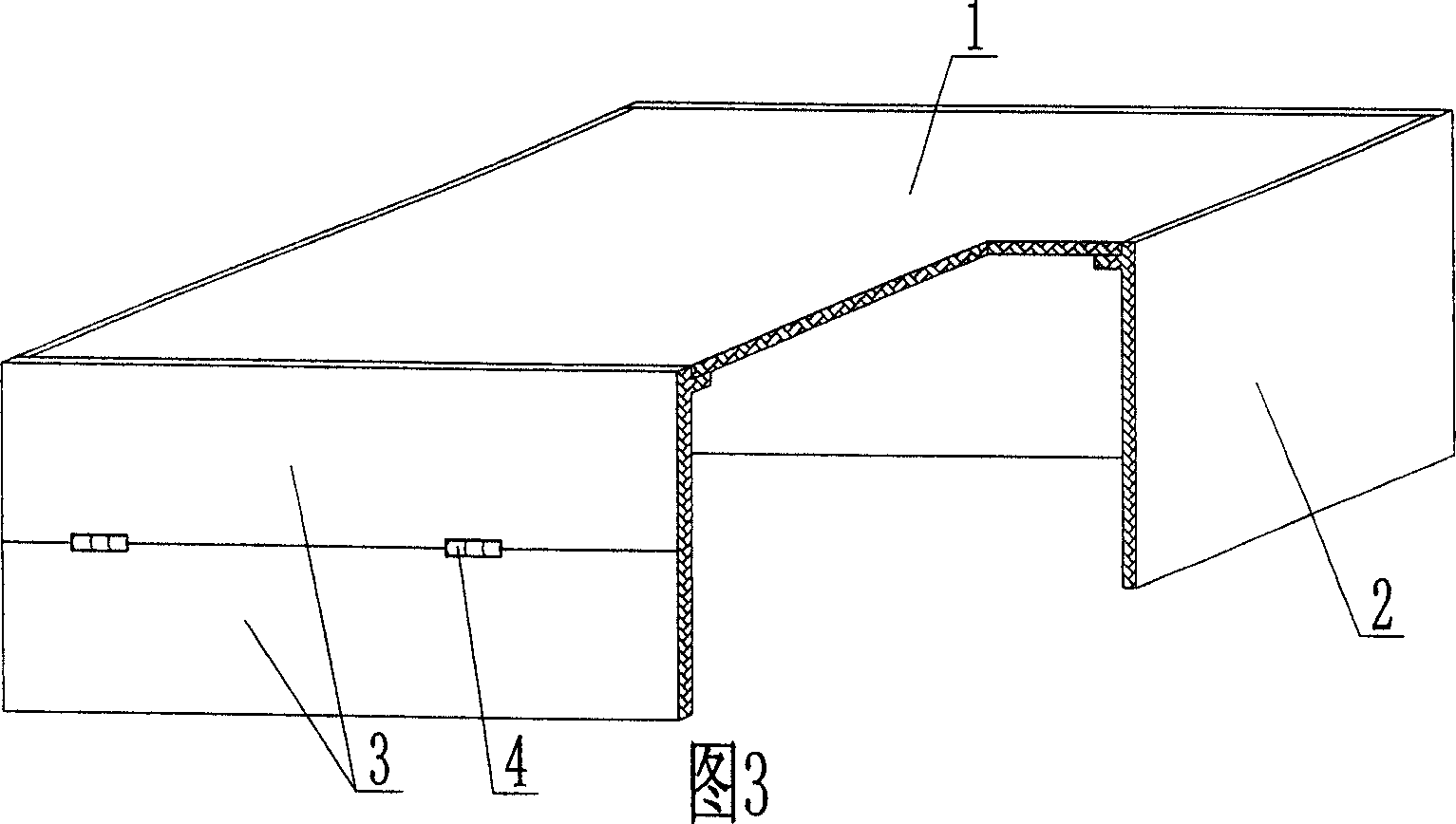

Opening box for concrete structure

Disclosed is a hollow box for concrete structure, which comprises an upper box board (1), peripheral formworks (2), the upper box board (1) and the peripheral formworks are separately prefabricated members, characterized in that the upper top box board (1) is supported onto a temporary bottom formwork (4) by a support member (3), the peripheral formworks (2) are suspended on the support member (3) or / and the upper box board (1). The invention can be applied to various cast-in-situ reinforced-bar concrete hollow building slabs, house roofings, walls, foundation bedplates and hollow bridges.

Owner:湖南邱则有专利战略策划有限公司

Carton and production process thereof

ActiveCN111002664AReduce thicknessReduce usageSynthetic resin layered productsLaminationPolymer sciencePunching

The invention relates to a carton production process, which comprises a film coating process, and the film coating process comprises the following steps: a1, preparing materials, namely preparing a corrugated board, a heat preservation film and an isolation film; a2, conducting film coating, specifically, the surface of the corrugated board is covered with the heat preservation film; a3, punching,specifically, glue containing grooves and glue injection holes are evenly formed in the composite corrugated board and the heat preservation film; a4, conducting glue injection, specifically, fixingglue is injected into the glue injection holes, so that the fixing glue is fixedly poured into the space between a second paperboard and the corrugated paperboard and overflows into the glue containing grooves; and a5, conducting secondary film coating, specifically, the isolation film and the surface, away from the second paperboard, of the heat preservation film are bonded and fixed, and the surface, attached to the heat preservation film, of the isolation film is bonded and fixed to the fixing glue in the glue containing grooves. According to the technology, in the step a5, the isolation film and the heat preservation film are bonded and fixed through the fixing glue in the glue containing grooves, so that the situation that the surface, close to the heat preservation film, of the isolation film is coated with the glue again is avoided, and the film coating process is simple in step and short in period.

Owner:上海绚丽包装彩印有限公司

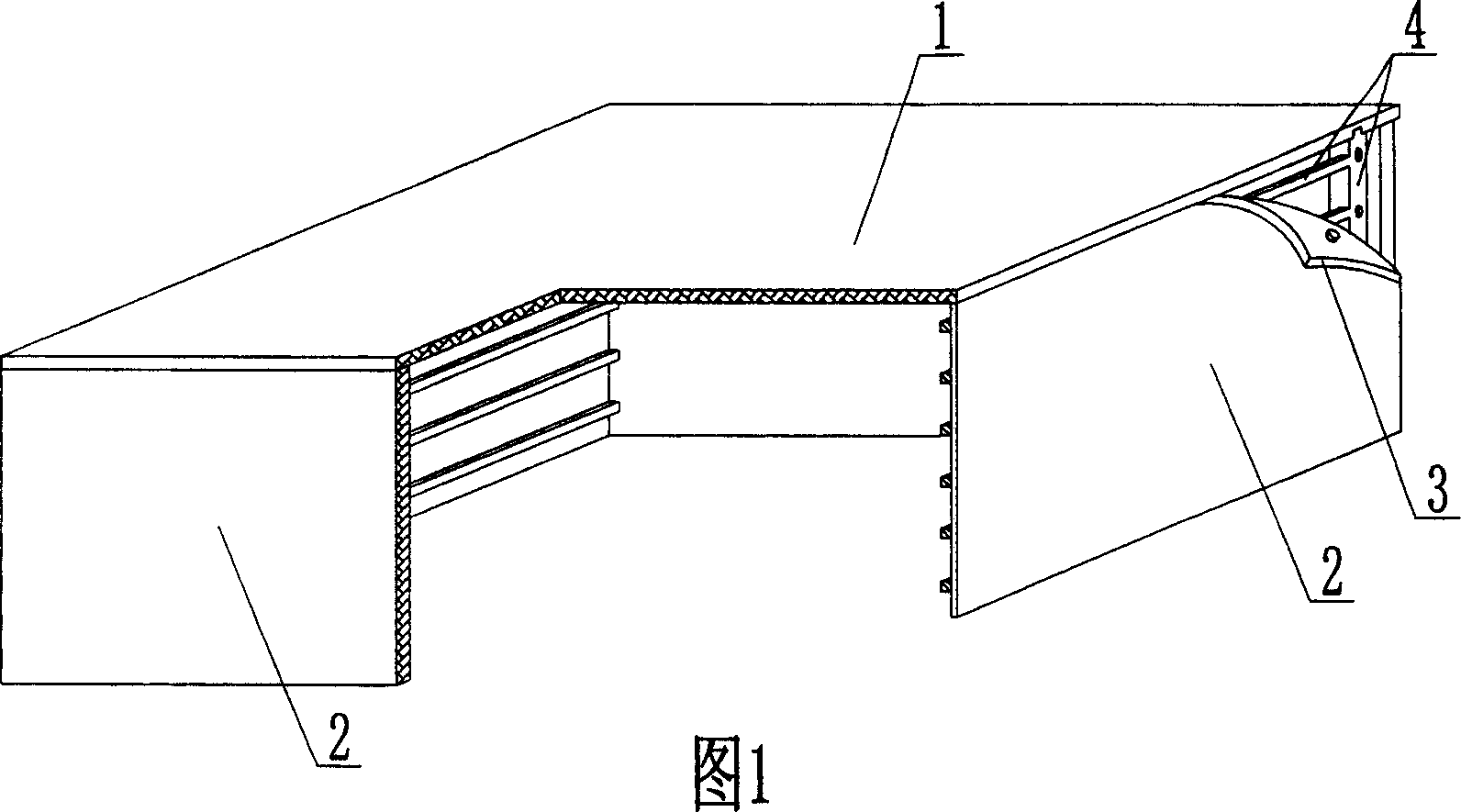

Sandwich member for concrete

The sandwiched member for concrete includes one upper box board, one lower box board and one filling formwork between the upper box board and the lower box board, and features that the filling formwork is formwork with telescopic formworks. The present invention is suitable for in-situ cast or pre-stressed reinforced concrete hollow floor slab, roof, wall, foundation slab and hollow bridge, especially hollow flat floor slab.

Owner:湖南邱则有专利战略策划有限公司

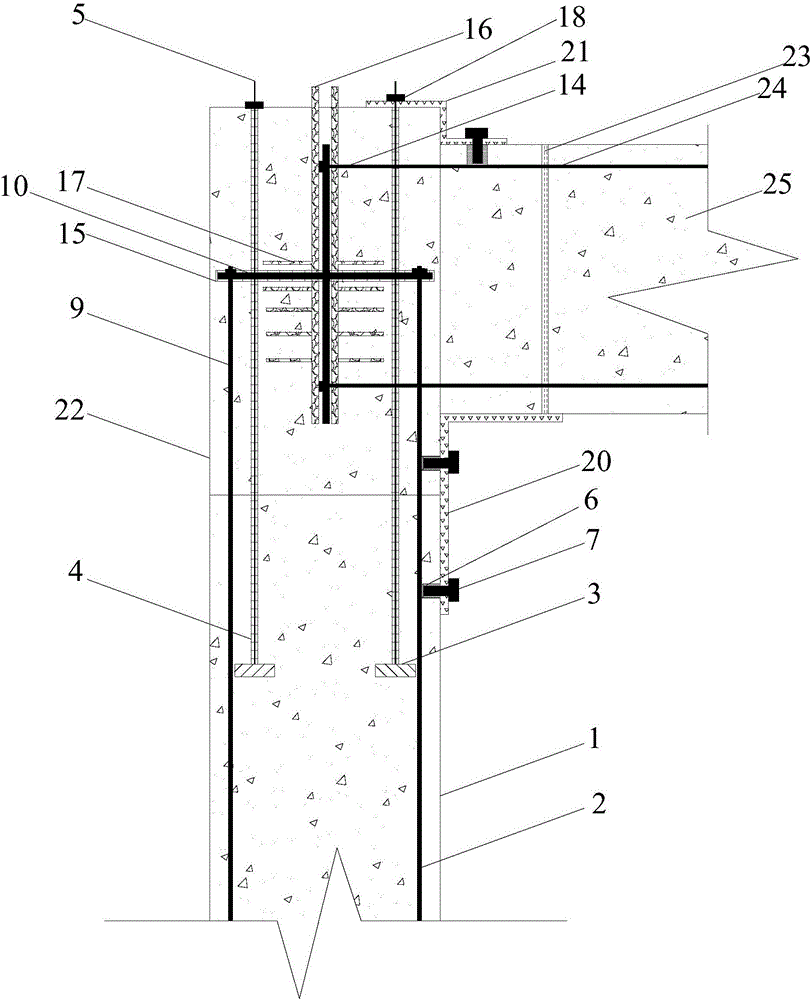

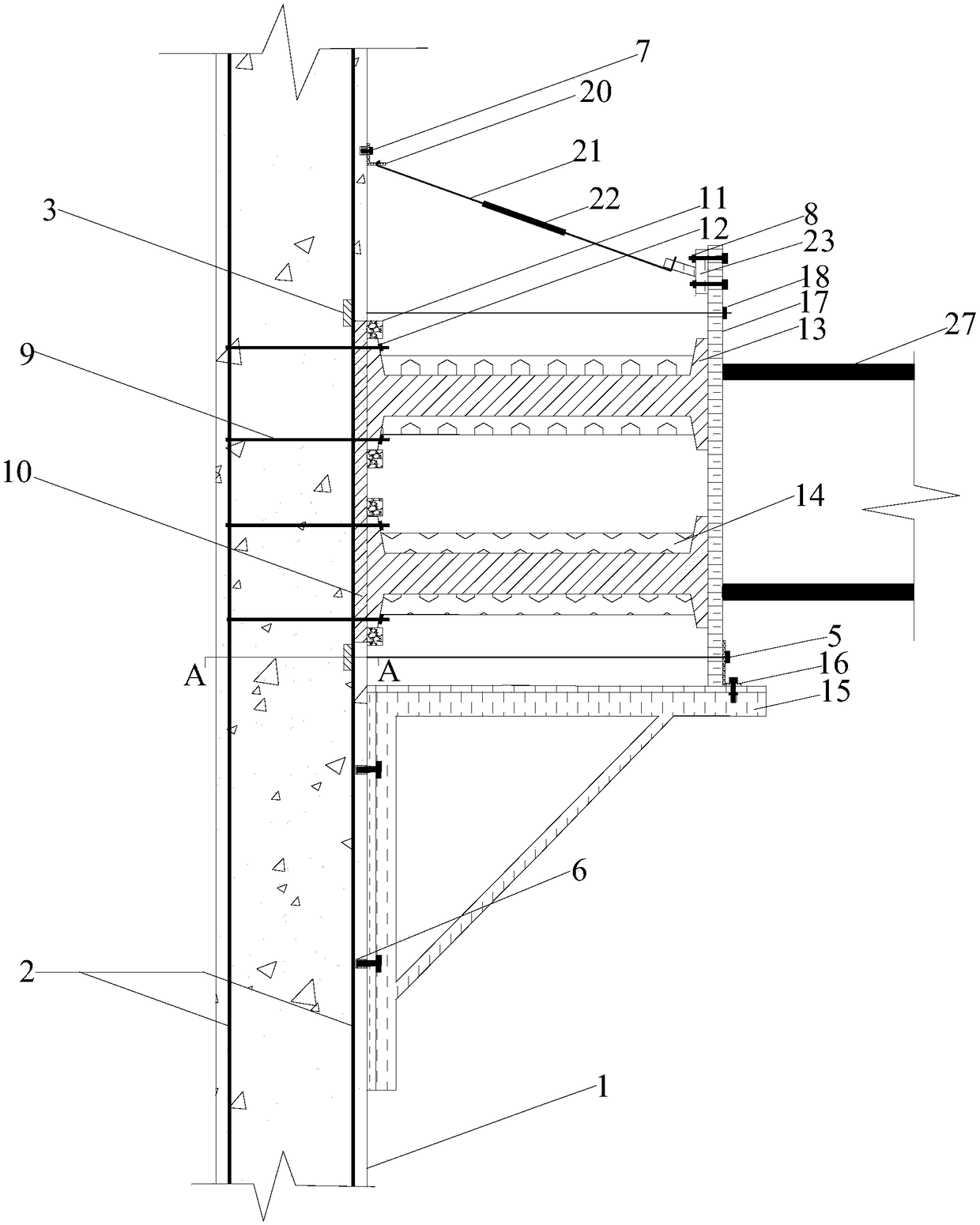

Construction method of reinforced concrete support structure of diaphgram wall retaining foundation pit

The invention discloses a construction method of a reinforced concrete support structure of a diaphgram wall retaining foundation pit. The reinforced concrete support structure of the diaphgram wall retaining foundation pit mainly comprises an underground diaphragm wall, a underground diaphragm wall main reinforcement, a pre-buried anchor cable fixing end, a anchor cable protecting tube, an anchor cable, a straight sleeve, a reserved connecting reinforcement with mantle fibers, a cross-shaped stiffened plate with holes, a horizontal connecting reinforcement with a thread, a fiber cloth isolating film, a vertical filling agent main pipe, a horizontal filling agent main pipe, a post-installed L-shaped lower supporting plate, a post-installed Z-shaped upper fixing plate, a pre-buried PVC pipe, a supporting main reinforcement and a reinforced concrete support. The construction method comprises the steps of trenching construction, reinforcement cage manufacturing, concrete pouring, part of a diaphgram wall chiseling off, crown beam and reinforcement concrete support pouring, demolition blasting and the like. The construction method of the reinforced concrete support structure of the diaphgram wall retaining foundation pit has the advantages that shear resisting strength is high, connection is convenient and quick, and steel can be recycled and reused; and the purposes of shortening the construction period and reducing construction cost are achieved.

Owner:SHANGHAI GEOLOGICAL CONSTR

Opening box for concrete structure

Disclosed is a hollow box for concrete structure, which comprises an upper box board (1) and peripheral formworks (2), characterized in that the peripheral formworks (2) are partly or completely deformable formworks (3) through compressing deformation or / and stretch deformation. The invention can be applied to various cast-in-situ reinforced-bar concrete or prestressed reinforced-bar concrete hollow building roofings, house roofings, walls, foundation bedplates and hollow bridges, especially for hollow flat slabs.

Owner:湖南邱则有专利战略策划有限公司

Opening box for concrete structure

Disclosed is a hollow box for concrete structure, which comprises an upper box board (1) and peripheral formworks (2), characterized in that the peripheral formworks (2) are partly or completely deformable formworks (3) through compressing deformation or / and stretch deformation. The invention can be applied to various cast-in-situ reinforced-bar concrete or prestressed reinforced-bar concrete hollow building roofings, house roofings, walls, foundation bedplates and hollow bridges, especially for hollow flat slabs.

Owner:湖南邱则有专利战略策划有限公司

A method for simultaneous friction stir spot welding-brazing-diffusion welding of aluminum and magnesium dissimilar materials

ActiveCN105834608BIncrease the effective bearing areaIncreased tensile and shear capacitySoldering apparatusWelding/soldering/cutting articlesSpot weldingAtomic diffusion

A method for synchronously realizing friction stir spot welding-brazing-diffusion welding of aluminum and magnesium dissimilar materials. Both sides of the blank are respectively in contact with the aluminum plate and the magnesium plate. Friction stir spot welding is performed on the fixed overlapping structure. During the welding process, on the one hand, the friction stir spot welding of the aluminum plate and the magnesium plate is realized through the action of the stirring pin on the stirring head and the plate below; Under the action of heat generated by shaft shoulder friction and forging pressure, the temperature in the area close to the stirring pin is high, the brazing sheet melts, and a brazed connection is formed between the aluminum plate and the magnesium plate; Under the action of heat, atomic diffusion occurs between aluminum plate / solder sheet and magnesium plate / solder sheet to form diffusion welding. The invention can form brazing and diffusion welding joints at the same time of friction stirring spot welding, increase the effective bearing area of solder joints, and improve the tensile shear force of the joints.

Owner:NANCHANG HANGKONG UNIVERSITY

Opening box for concrete structure

Disclosed is a hollow box for concrete structure, which comprises an upper box board (1) and peripheral formworks (2), the upper box board (1) covers on the peripheral frameworks (2), the upper box board (1) and the peripheral formworks are split-and-paste prefabricated members, characterized in that the lower portion of the peripheral frameworks (2) is provided with at least a notch or hole (4).The invention can be applied to various building slabs, house roofings, walls, foundation bedplates and hollow bridges.

Owner:湖南邱则有专利战略策划有限公司

Opening box for concrete structure

Disclosed is a hollow box for concrete structure, which comprises an upper box board (1) and peripheral formworks (2), characterized in that the upper box board (1) and the peripheral formworks are split-and-paste prefabricated members, the upper box board (1) covers on the peripheral frameworks (2). The invention can be applied to various cast-in-situ reinforced-bar concrete or prestressed reinforced-bar concrete hollow building roofings, house roofings, walls, foundation bedplates and hollow bridges, especially for hollow flat slabs.

Owner:邱则有

Opening box for concrete structure

Disclosed is a hollow box for concrete structure, which comprises an upper box board (1) and peripheral formworks (2), characterized in that the lower end framework of at least one side of the peripheral framework (2) is a framework with holes for passing grouts. The invention can be applied to various cast-in-situ reinforced-bar concrete or prestressed reinforced-bar concrete hollow building roofings, house roofings, walls, foundation bedplates and hollow bridges.

Owner:湖南邱则有专利战略策划有限公司

Opening box for concrete structure

Disclosed is a hollow box for concrete structure, which comprises an upper box board (1) and peripheral formworks (2), characterized in that the hollow box is provided with an overhead member (3) for dangling the lower end of the peripheral framework (2). The invention can be applied to various cast-in-situ reinforced-bar concrete or prestressed reinforced-bar concrete hollow building roofings, house roofings, walls, foundation bedplates and hollow bridges, especially for hollow flat slabs.

Owner:湖南邱则有专利战略策划有限公司

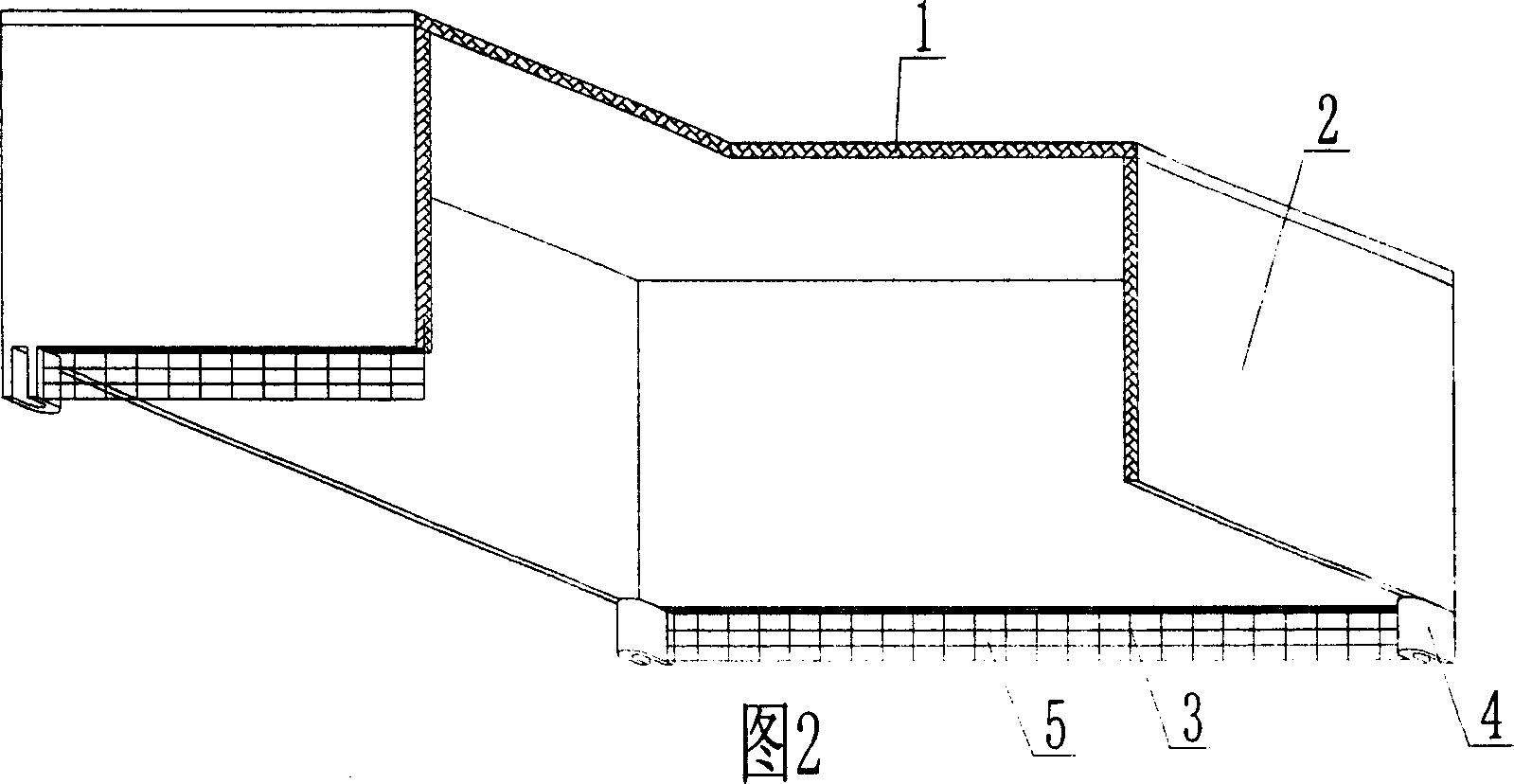

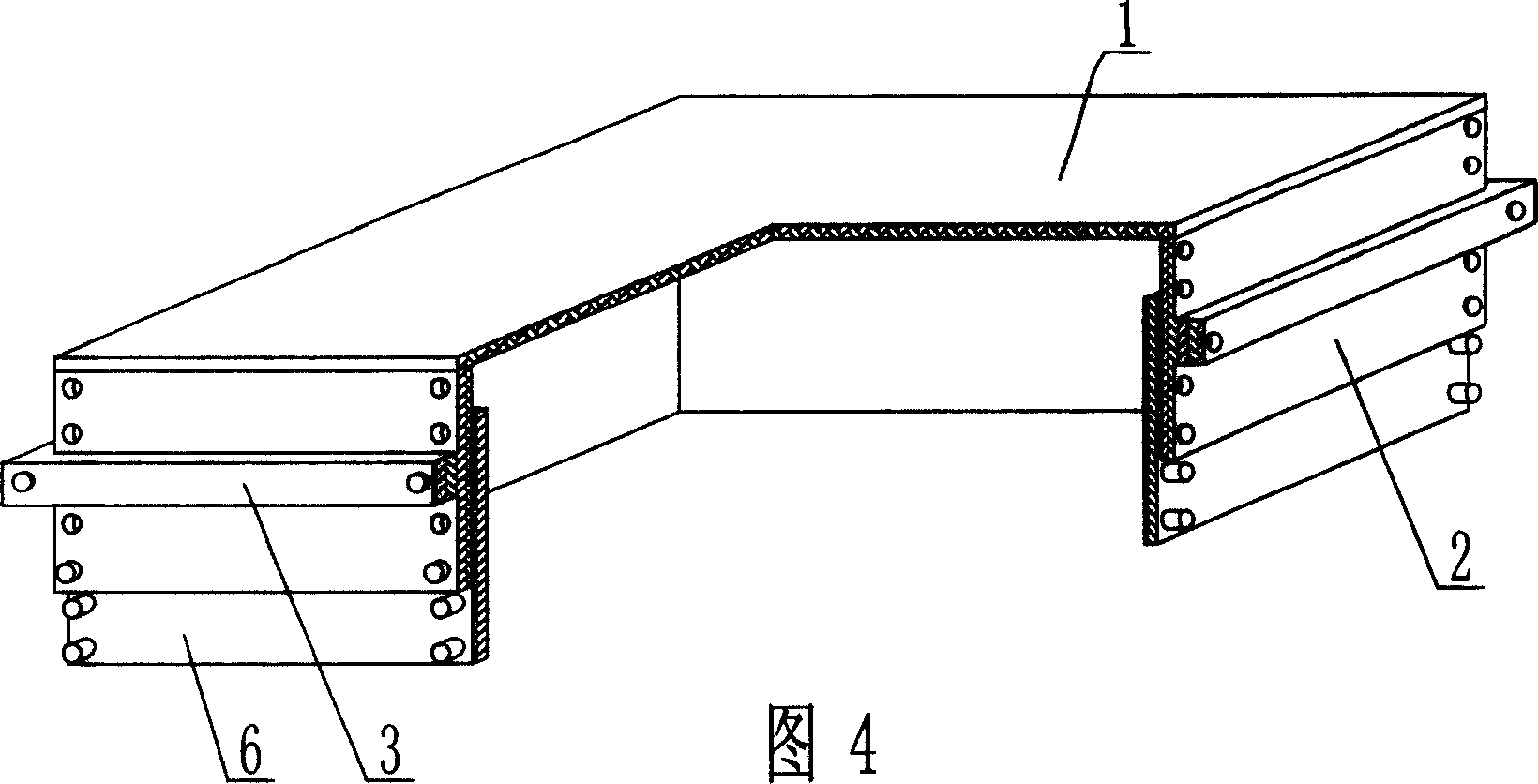

Aluminum formwork structure

ActiveCN113107189AImprove the forceImprove structural strengthForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringStructural engineering

Owner:山东华铝模板有限公司 +1

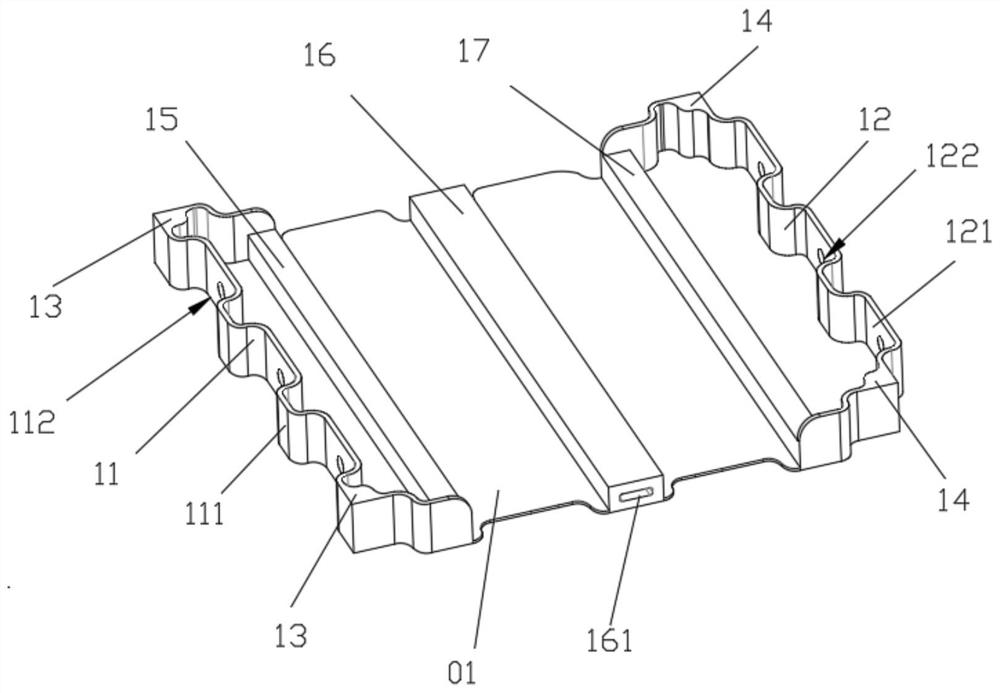

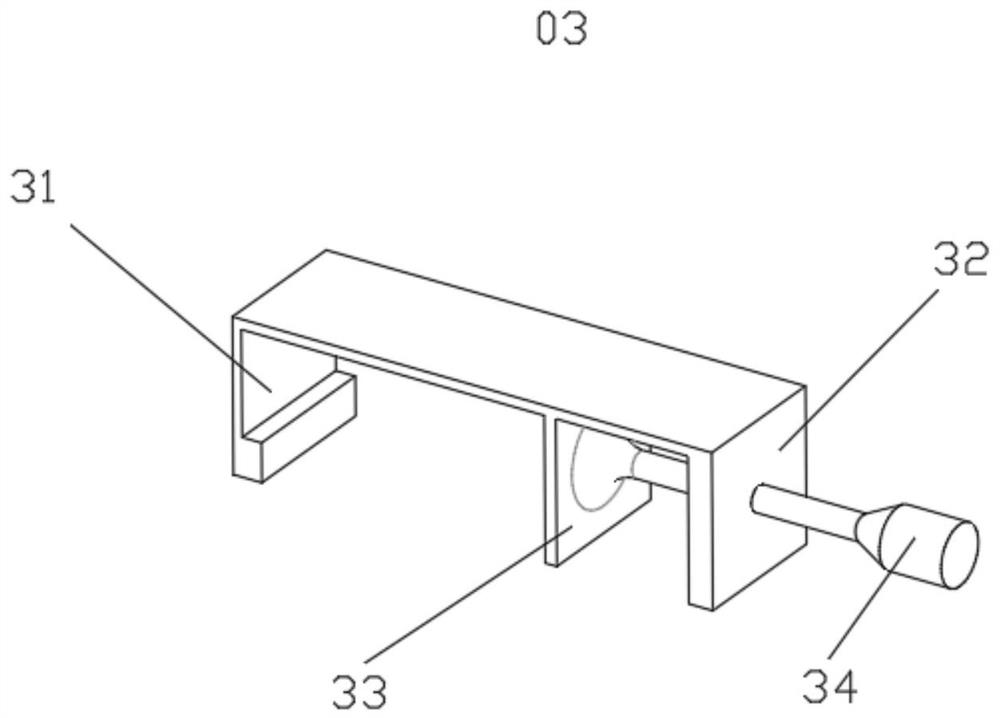

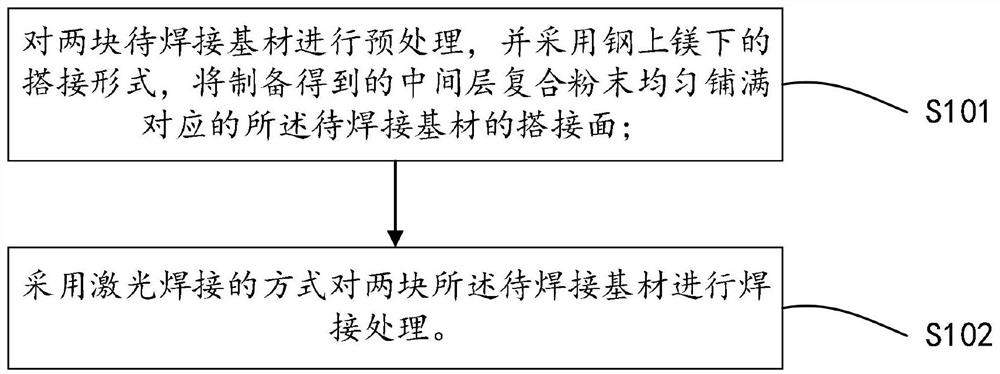

Preparation and welding method of intermediate layer composite powder for magnesium alloy steel laser welding

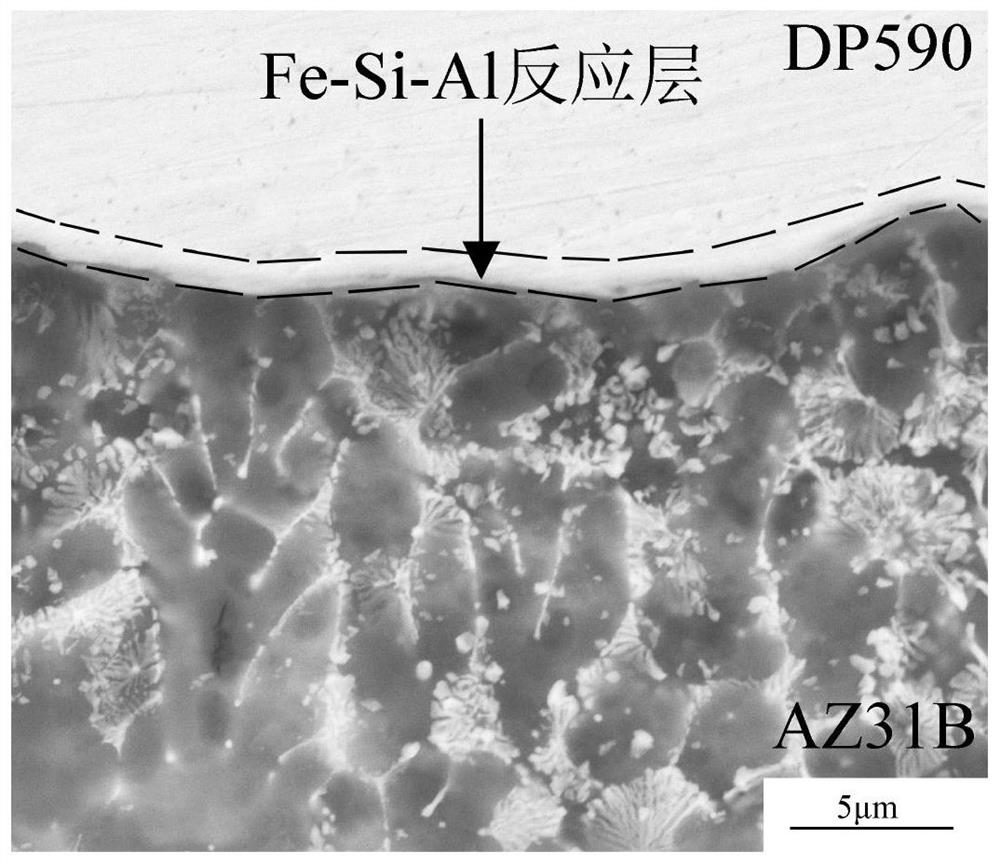

ActiveCN113146039AIncreased tensile and shear capacityStable generationWelding/cutting media/materialsSoldering mediaCu elementLap joint

The invention discloses a preparation and welding method of intermediate layer composite powder for magnesium alloy steel laser welding. Dual-phase steel and magnesium alloy are in a lap joint form of upper steel and lower magnesium, an intermediate layer adopts Cu powder and Si powder with the purity being 99.9%, and laser welding is carried out on the intermediate layer composite powder prepared by uniformly mixing the Cu powder and the Si powder according to different mass ratios. The method has the technical effects that the Cu element improves the stability of the welding process, reduces the generation of welding defects and promotes the uniform and stable generation of a Fe-Al layer at an Mg / Fe interface in a welding seam, and addition of the Si element can convert a Fe-Al phase with relatively high brittleness in a Fe-Al reaction layer into a Fe-Si-Al phase with relatively low brittleness, so that the tensile shear force of a magnesium alloy / steel welding joint is improved.

Owner:NANCHANG UNIV

A kind of carton and its production process

ActiveCN111002664BReduce thicknessReduce usageSynthetic resin layered productsLaminationCardboardPolymer science

The invention relates to a production process of a carton, which includes a film covering process, and the film covering process includes the following steps: A1. Prepare materials, prepare corrugated cardboard, thermal insulation film and isolation film; A2. Cover film, cover the surface of the corrugated cardboard with the thermal insulation film ; A3. Punching holes, evenly opening out glue grooves and glue injection holes on the composite corrugated cardboard and insulation film; A4. and overflow into the glue tank; A5. Secondary lamination, paste and fix the surface of the isolation film and the insulation film away from the second cardboard, and the surface of the isolation film attached to the insulation film is bonded with the fixed glue in the glue tank fixed. In step A5 of this process, the isolation film and the heat preservation film are bonded and fixed by the fixed glue in the glue tank, thereby avoiding the recoating of glue on the surface of the isolation film close to the heat preservation film. The steps of the film coating process are simple and the cycle is short.

Owner:上海绚丽包装彩印有限公司

Construction method of steel pipe support structure for foundation pit surrounded by ground connection wall

ActiveCN106869135BIncreased tensile and shear capacityImprove securityExcavationsBuilding material handlingSlurry wallBatten

The invention discloses a construction method for an underground diaphragm wall containment foundation pit steel pipe supporting structure. The underground diaphragm wall containment foundation pit steel pipe supporting structure mainly comprises an underground diaphragm wall, underground continuous wall main ribs, embedded anchor cable fixing ends, anchor cables, anchor cable protection pipes, embedded connecting sleeves, U-shaped fixing ribs, an embedded end plate, positioning steel plates, joint steel, ribbed rib plates, a supporting bracket, a batten plate, a pull rod with a hook and a steel support. The construction method mainly includes the steps of grooving construction, reinforcement cage manufacturing, concrete pouring, chiseling of a part of the underground diaphragm wall, joint connecting and the like. A connecting joint of the construction method has the beneficial effects that the shear strength is high, connecting is convenient and fast, and structural steel can be recycled and reused; and the construction method achieves the purposes that the construction period is shortened, and the construction cost is reduced.

Owner:SHANGHAI GEOLOGICAL CONSTR

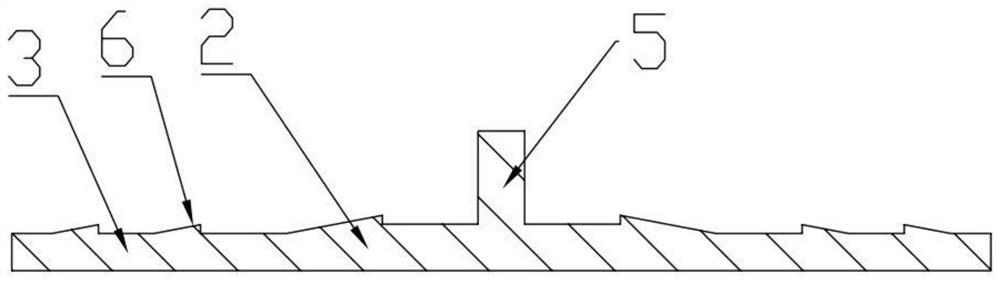

Connecting structure of socket self-sealing pipe in rigid-flexible interference fit

PendingCN113007472ANo risk of installation leakageIncreased tensile and shear capacityHose connectionsInterference fitPipe fitting

The invention relates to the technical field of pipeline construction, and provides a connecting structure of a socket self-sealing pipe in rigid-flexible interference fit. The connecting structure comprises a flexible pipe fitting and a rigid connecting pipe, wherein socket heads are arranged at the two ends of the connecting pipe; a socket opening is formed in the inner side of one end or the inner sides of the two ends of the pipe fitting; the outer diameter of each socket head is in interference fit with the inner diameter of the socket opening; and the pipe fitting and the connecting pipe are connected by inserting the socket heads into the socket opening. According to the connecting structure, interference fit self-sealing is adopted, so that the risk of installation leakage is avoided; retaining teeth are arranged on the socket heads, so that the tensile strength of the pipe fitting after being connected with the connecting pipe is improved; a baffle is arranged in the middle of the connecting pipe, so that the socket heads and the socket opening are matched in place, the baffle directly abuts against the end part of the pipe fitting, and pipe jacking construction is facilitated; and the problem that a rigid material joint is prone to cracking during jacking deviation correction is solved, the problem that the stress at the socket opening of the flexible pipe fitting is poor is solved, and the problem of corrosion prevention of the inner wall of the connecting pipe is solved.

Owner:佛山市三鑫市政工程有限公司

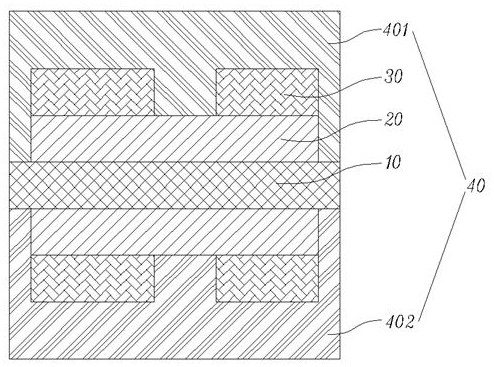

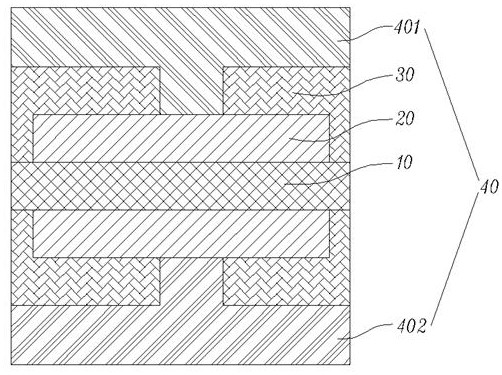

An omni-directional shielded antenna structure and antenna

ActiveCN110970729BAvoid signalingImprove structural toughnessMagnetic/electric field screeningCross-talk/noise/interference reductionSputteringElectromagnetic shielding

The invention discloses an antenna structure with omnidirectional shielding, which includes a circuit board for the antenna, and the circuit board includes an insulating layer, circuit layers arranged on both sides of the insulating layer, and covering films respectively arranged on the surface of each circuit layer , also includes a shielding film, the shielding film is divided into an upper shielding film and a lower shielding film, the upper shielding film is attached to the surface of the covering film on one side, and the lower shielding film is attached to the surface of the covering film on the other side; wherein, the The shielding film comprises a protective layer, an insulating layer, a metal shielding layer and a conductive layer, the insulating layer is arranged on the surface of the protective layer, the metal shielding layer is arranged on the surface of the insulating layer, the conductive layer is arranged on the surface of the metal shielding layer, the The insulating layer is made of vinyl, and the metal shielding layer includes a first metal shielding layer formed by sputtering and a second metal shielding layer formed by electroplating. The omnidirectional shielding antenna structure provided by the invention has good electromagnetic shielding performance and stable structure.

Owner:SHENZHEN KNQ SCI & TECH CO LTD

Opening box for concrete structure

Disclosed is a hollow box for concrete structure, which comprises an upper box board (1) and peripheral formworks (2), the upper box board (1) and the peripheral formworks are split-and-paste prefabricated members, characterized in that the upper box board (1) covers on the peripheral frameworks (2), the peripheral frameworks are provided with transverse ring shaped projected ribs (3). The invention can be applied to various cast-in-situ reinforced-bar concrete or prestressed reinforced-bar concrete hollow building roofings, house roofings, walls, foundation bedplates and hollow bridges.

Owner:湖南邱则有专利战略策划有限公司

Device and method for carrying out thermocompression welding on enameled wires of pendulum components

ActiveCN102554448BSolve support positioning problemsPrecise positioningAcceleration measurement using interia forcesNon-electric welding apparatusSpecial designPass rate

The invention provides a device and a method for carrying out thermocompression welding on enameled wires of pendulum components. The device comprises a base and a sliding shaft, wherein the base is cylindrical, a through stepped hole is formed in the central position of the base; the aperture of a big hole at the upper part of the stepped hole is a mounting hole for the sliding shaft; a ring-shaped boss is processed on the upper surface of the base, at the outer side of the stepped hole; a ring-shaped shallow slot is processed on the outer side of the ring-shaped boss; two arc-shaped non-closed surrounding structures symmetrically distributed are processed on the outer side of the ring-shaped shallow slot, and are separated by two shallow slots with different shapes. With the special design of the device, the supporting and positioning problems of a central pendulum of a pendulum plate and a moving coil of a torquer are solved, so that the reliable positioning on the pendulum plate is realized, the stability of welding is good, and the rate of finished products and the work efficiency are also greatly improved. For the welding method, a special welding technology is adopted, the welding quality is good, the welding parameters are stable and controllable, the consistency is good, the time for welding one pendulum component by adopting lead-tin welding is about 10 minutes, while the time for welding one pendulum by adopting the method is only about 4 minutes, the production efficiency is improved by 150%, and the product pass rate also reaches above 99.5%.

Owner:航天科工惯性技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com