A kind of carton and its production process

A production process and carton technology, applied in the direction of paper/cardboard layered products, layered products, synthetic resin layered products, etc. Tensile and shear resistance, enhanced connection, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

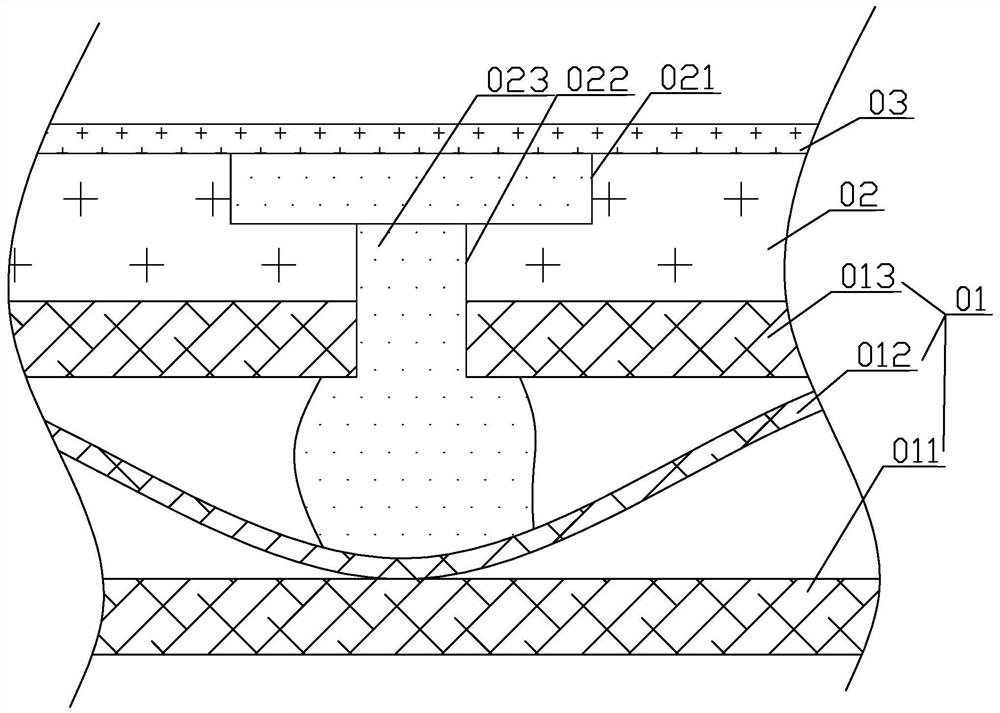

[0032] refer to figure 1 , is a kind of carton disclosed by the present invention, comprising a carton body, the carton body is a cardboard shape, which is cut and folded into an existing box structure for storing and transporting articles, and the carton body is sequentially arranged from the outside to the inside of the carton Corrugated cardboard 01, insulation film 02 and isolation film 03. The corrugated cardboard 01 is provided with a first cardboard 011, a corrugated layer 012 and a second cardboard 013 in sequence from the outside of the carton to the inside of the carton. The first cardboard 011 and the second cardboard 013 are both made of pulp. The cross section of the corrugated layer 012 is S-shaped. The corrugated layer 012 is made of pulp, and it is arranged between the first cardboard 011 and the second cardboard 013 and is pasted and fixed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com