Construction method of steel pipe support structure for foundation pit surrounded by ground connection wall

A technology of steel pipe support and construction method, which is applied in basic structure engineering, excavation, building construction, etc., can solve the problems of long construction period, high engineering cost, collapse of groove wall, etc., so as to increase the tensile and shear resistance and shorten the construction period. , make the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

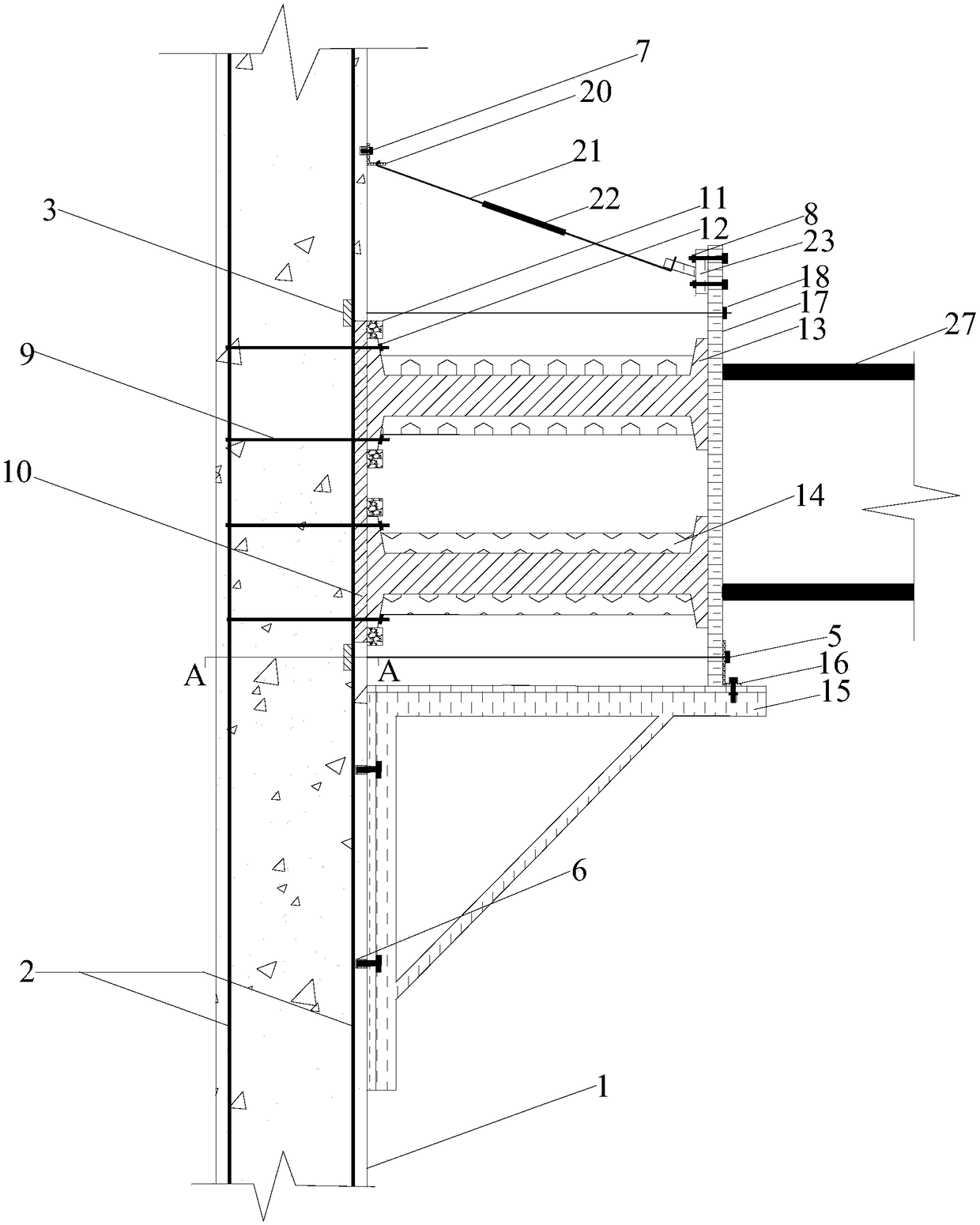

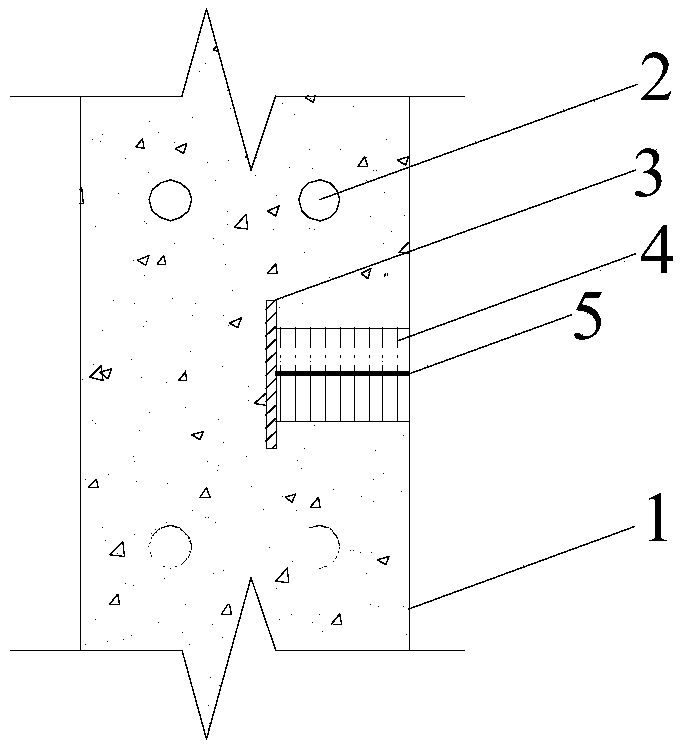

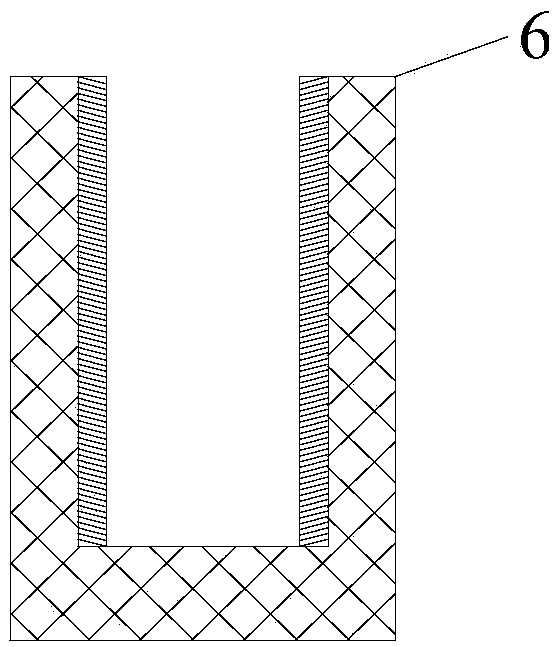

[0039] figure 1 It is a schematic diagram of the steel pipe support structure and construction method of the wall surrounding the foundation pit of the present invention, figure 2 yes figure 1 Sectional view along line A-A, image 3 is a schematic diagram of the embedded connection sleeve; Figure 4 is a schematic diagram of the bolt; Figure 5 is the schematic diagram of the nut; Figure 6 It is a schematic diagram of U-shaped fixing bars; Figure 7 is the schematic diagram of the embedded end plate; Figure 8 It is a schematic diagram of an L-shaped movable end plate; Figure 9 is a schematic diagram of the panel; Figure 10 is the schematic diagram of the anchorage; Figure 11 is the schematic diagram of the fixture; Figure 12 It is a schematic diagram of an L-shaped hanging board; Figure 13 is a schematic diagram of a movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com