Connecting structure of socket self-sealing pipe in rigid-flexible interference fit

A technology of interference fit and connection structure, which is applied in the direction of hose connection device, pipe/pipe joint/pipe fitting, mechanical equipment, etc. The effect of improving tensile and shear resistance, long service life and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

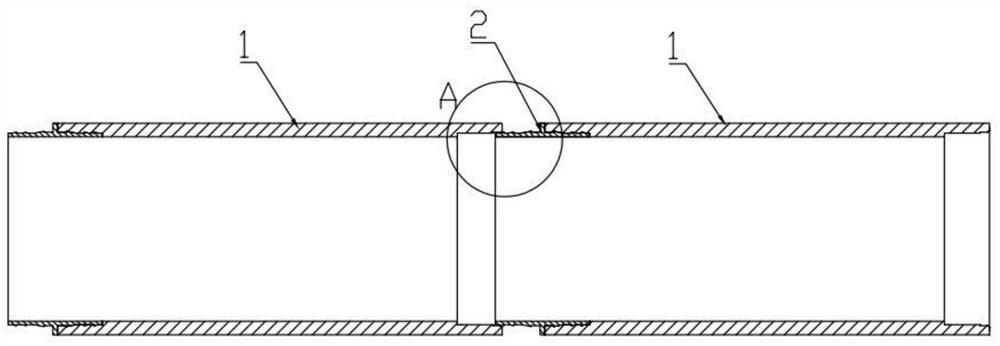

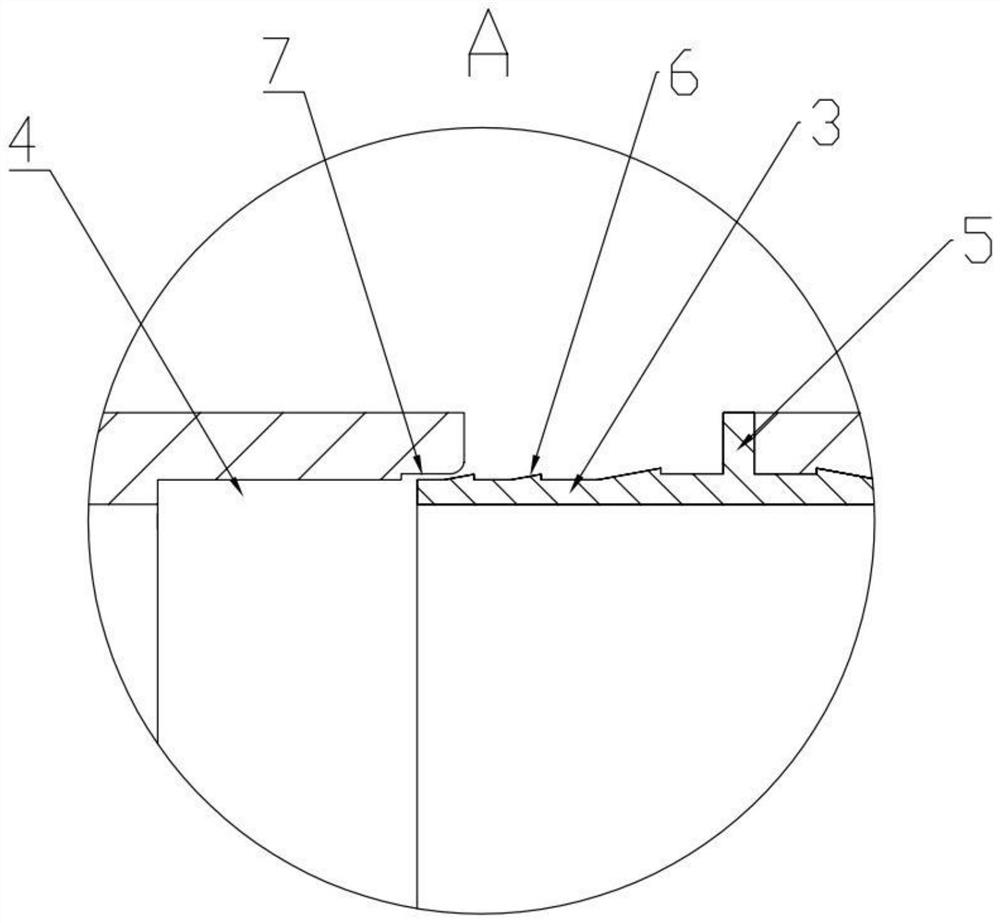

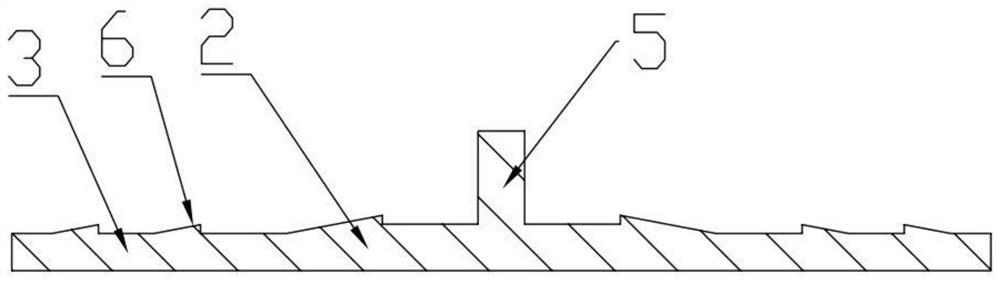

[0035] Embodiment 1: refer to Figure 1 to Figure 3 , this embodiment provides a rigid-flexible interference fit socket self-sealing pipe connection structure, including a plurality of flexible pipe fittings 1, and also includes a plurality of rigid connecting pipes 2, the two ends of the connecting pipe 2 are provided with bearings Plug 3, the inner side of both ends of the pipe fitting 1 is provided with a socket 4, the outer diameter of the socket plug 3 and the inner diameter of the socket 4 are interference fit, and the pipe fitting 1 and the connecting pipe 2 pass through the The socket plug 3 is inserted into the socket 4 to realize the connection. The flexibility and rigidity mentioned here are relative, that is, the pipe fitting 1 is easier to deform than the connecting pipe 2. It is preferably more than 10 times of that, and the plastic deformation of the pipe fitting 1 itself is used to achieve the sealing effect.

[0036] Specifically, a raised annular baffle 5 is...

Embodiment 2

[0044] Embodiment 2: Refer again Figure 4, with respect to embodiment 1, its difference lies in: present embodiment is that fine stone concrete pipe 8 is docked with flexible pipe fitting 1, and the two ends of fine stone concrete pipe 8 are fixedly provided with adapter 2, same as embodiment, in The connecting pipe 2 is connected to the pipe fitting 1, and the inner wall of the fine stone concrete pipe 8 can be sprayed with resin for corrosion protection.

Embodiment 3

[0045] Embodiment 3: Compared with Embodiment 2, the difference is that the fine stone concrete pipe 8 is replaced with a resin material pipe, and the rest are the same as Embodiment 2.

[0046] It can be known from Embodiment 2 and Embodiment 3 that the present invention can be extended to other material pipes fixedly connected with the connecting pipe 2 , and the end of the connecting pipe 2 can be connected with the plastic pipe fitting 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com