Novel grouting anchoring rod with steel sleeve rod

A grouting bolt, a new technology, applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of grouting material bolt failure, etc., to increase the tensile and shear resistance, improve the strength, and ensure the stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

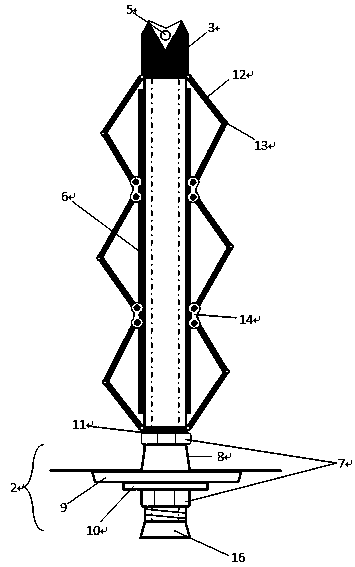

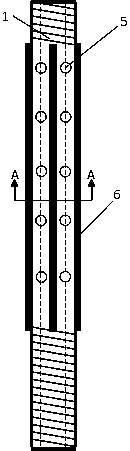

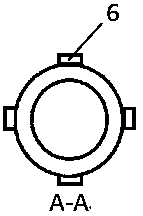

[0024] as attached Figure 1-3 As shown, a new type of grouting anchor rod with a steel sleeve rod includes a rod body 1, an anchor end 2 and an anchor head 3 located at both ends of the rod body, and a rod sleeve device 4 outside the rod body. It is characterized in that: The guide rail 6 is evenly distributed around the rod body 1; the rod sleeve device 4 is a multi-segment cage-like structure, which is set on the outside of the rod body. The rod sleeve device includes a node and a cage body. Each section of the cage body adopts a two-stage hinged structure. When the new grouting anchor rod is loaded into the borehole and tightened and compressed with the anchor head, the cage body is compressed axially and expanded radially to contact and support the wall of the borehole. Both ends of the rod body 1 are threaded for fixing the anchor head 3 and reinforcing the anchor segment 2 . The anchoring section 2 includes a nut 7 , a grout stopper 8 , a backing plate 9 and a gasket 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com