Method for diffusion spot welding with solid phase assistance by efficient liquid phase of Al/Mg dissimilar metal

A dissimilar metal, high-efficiency liquid phase technology, applied in metal processing equipment, welding/welding/cutting items, welding equipment, etc., can solve problems such as low strength and difficulty in meeting actual needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

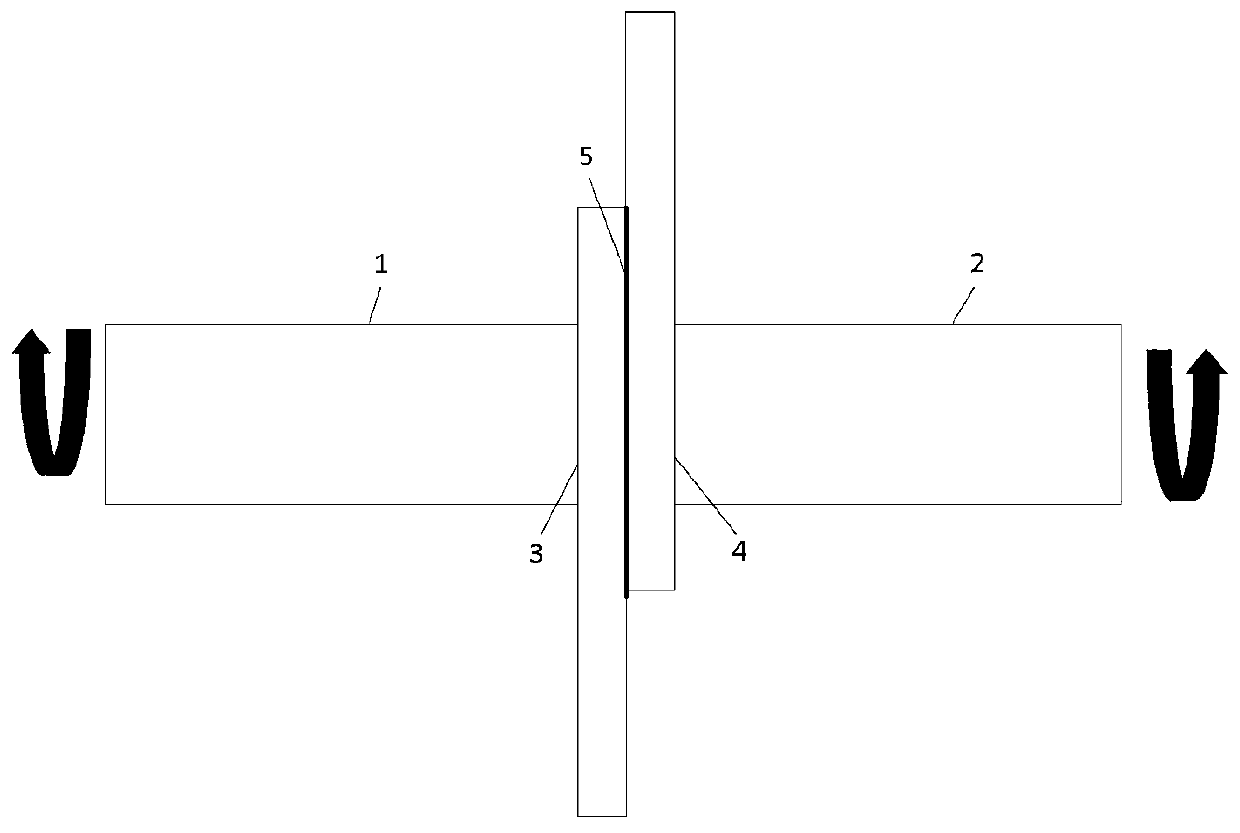

[0037] Schematic diagram of the diffusion spot welding process as figure 1 As shown, including the first friction head 1 and the second friction head 2 made of H13 steel, an aluminum plate 3 with a thickness of 2mm, a magnesium plate 4 with a thickness of 2mm, and a pure aluminum plate with a thickness of 0.1mm placed between the aluminum plate 3 and the magnesium plate 4 Sn metal foil 5; the first friction head 1 is in contact with the aluminum plate 3 and rotates at high speed, the second friction head 2 is in contact with the magnesium plate 4 and rotates at high speed, the rotation speed is 375r / min, the friction time is 9s, the metal foil 5 Melted into liquid metal; the first friction head 1 and the second friction head 2 squeeze and clamp each other to squeeze out the liquid metal, the relative extrusion amount is 0.8mm, and the holding time of extrusion and clamping is 18s; aluminum plate 3 and magnesium plate 4 Under the action of the clamping force of the first fricti...

Embodiment 2

[0039] Schematic diagram of the diffusion spot welding process as figure 1 As shown, it includes the first friction head 1 and the second friction head 2 made of nickel-based alloy, an aluminum plate 3 with a thickness of 2.5 mm, a magnesium plate 4 with a thickness of 2.5 mm, and a thickness of 0.15 mm between the aluminum plate 3 and the magnesium plate 4. mm Sn90-Zn10 metal foil 5; the first friction head 1 is in contact with the aluminum plate 3 and rotates at a high speed, the second friction head 2 is in contact with the magnesium plate 4 and rotates at a high speed, the rotation speed is 800r / min, and the friction time is 5s. The metal foil 5 is melted into liquid metal; the first friction head 1 and the second friction head 2 squeeze and clamp each other to squeeze out the liquid metal, the relative extrusion amount is 0.6mm, and the holding time of extrusion and clamping is 15s; the aluminum plate 3 The magnesium plate 4 is pressed together under the clamping force of...

Embodiment 3

[0041] Schematic diagram of the diffusion spot welding process as figure 1 As shown, it includes the first friction head 1 and the second friction head 2 made of H13 steel, an aluminum plate 3 with a thickness of 3.5mm, a magnesium plate 4 with a thickness of 3.5mm, and a thickness of 0.05mm placed between the aluminum plate 3 and the magnesium plate 4 Sn85-Zn15 metal foil 5; the first friction head 1 is in contact with the aluminum plate 3 and rotates at a high speed, the second friction head 2 is in contact with the magnesium plate 4 and rotates at a high speed, the rotation speed is 800r / min, and the friction time is 8s. The foil 5 is melted into liquid metal; the first friction head 1 and the second friction head 2 squeeze and clamp each other to squeeze out the liquid metal, the relative extrusion amount is 0.4mm, and the holding time of extrusion and clamping is 10s; the aluminum plate 3 and the The magnesium plate 4 is pressed together under the action of the clamping f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com