Force-bearing disk squeezing and expanding machine

A technology of extruding and expanding machine and bearing plate, which is applied in the direction of fluid pressure actuating device, sheet pile wall, building, etc. Effective bearing area, avoid the increase of manufacturing cost, and improve the effect of bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to specific examples.

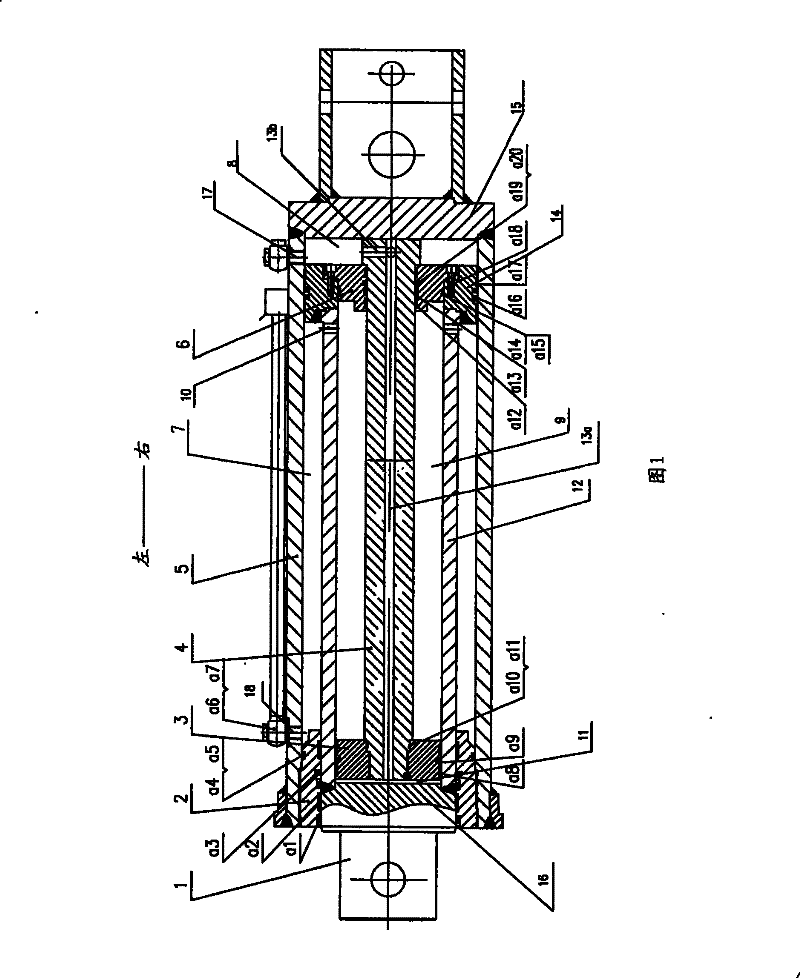

[0025] Such as figure 1 as shown, figure 1 It is a longitudinal sectional view of the booster oil cylinder in the bearing disc extruder of the present invention. The booster oil cylinder comprises a cylindrical cylinder body 5, the cylinder body 5 has two ends opposite to each other in the axial direction, one end is closed by the cylinder head 15 by being welded into one with the cylinder head 5, and the other end is provided with a large body fixed therewith. The guide sleeve 2 and the outer surface of the large guide sleeve 2 and the inner surface of the cylinder body 5 are provided with an O-ring retaining ring a4 and an O-ring sealing ring a5.

[0026] A large piston rod 1 that is substantially coaxial with the cylinder body 5 is provided. The large piston rod 1 includes a large piston rod main body 12 and a connecting portion 16. The large piston rod main body 12 is cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com