Patents

Literature

39results about How to "Increase the effective bearing area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

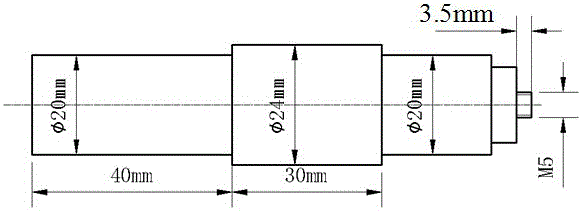

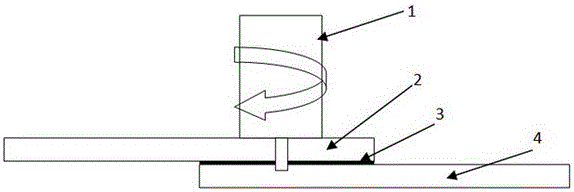

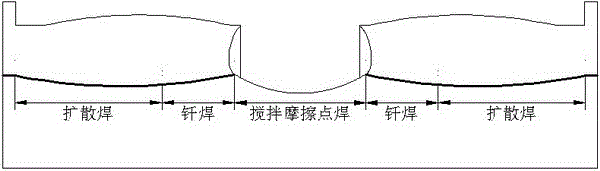

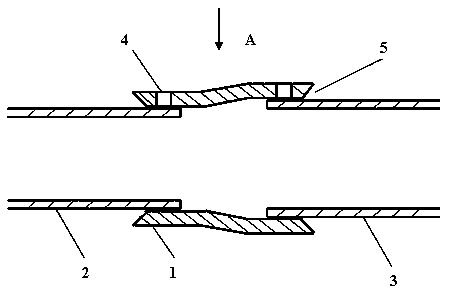

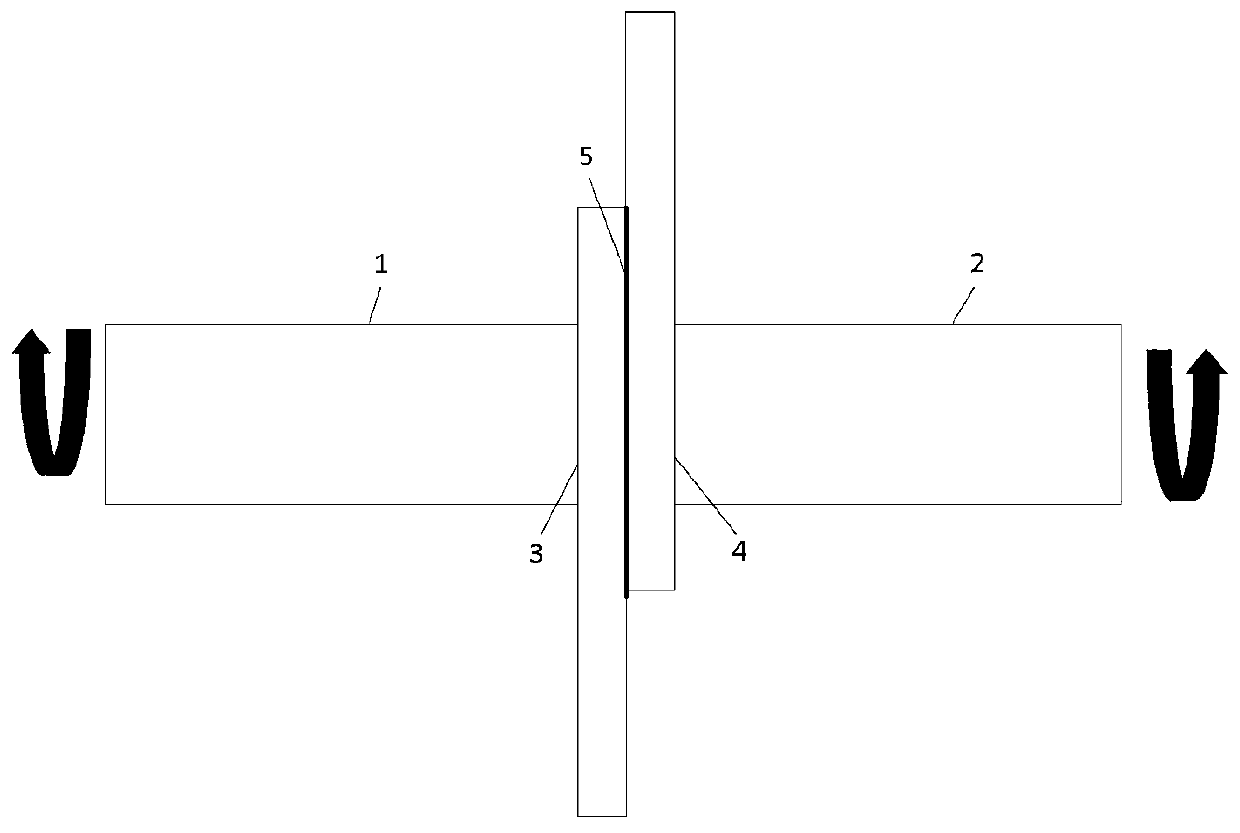

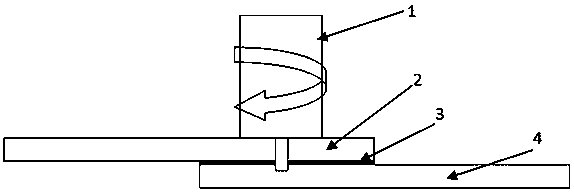

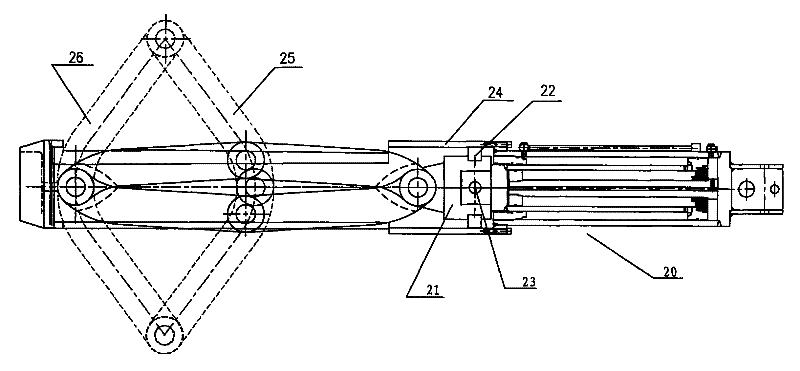

Method for synchronously implementing friction stir spot welding, soldering and diffusion welding of aluminum and magnesium dissimilar materials

ActiveCN105834608AIncrease the effective bearing areaIncreased tensile and shear capacitySoldering apparatusWelding/soldering/cutting articlesMagnesiumAluminium

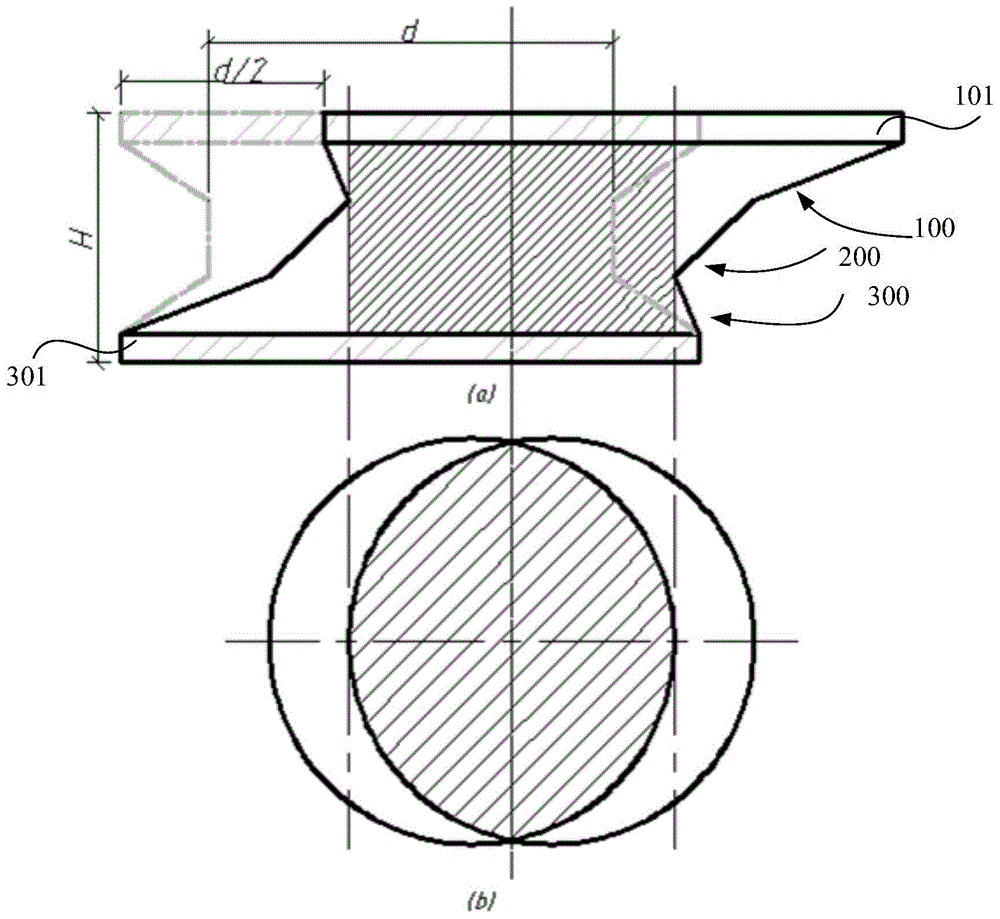

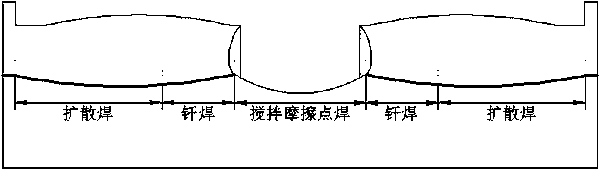

The invention discloses a method for synchronously implementing friction stir spot welding, soldering and diffusion welding of aluminum and magnesium dissimilar materials. The operation process includes the following steps of fixing a clean aluminum plate to a clean magnesium plate in an overlap joint mode, adding a solder piece between the two plates with both sides of the solder piece in contact with the aluminum plate and the magnesium plate, and implementing friction stir spot welding on the fixed overlap joint structure. In the welding process, on the one hand, the friction stir spot welding of the aluminum plate and the magnesium plate is realized through the action of a stirring pin on a stirring head with the plates below; on the other hand, under the action of friction heat of a shaft shoulder of the stirring head and forging force, the surrounding area near the stirring pin is high in temperature, the solder piece is melted, and soldering connection is formed between the aluminum plate and the magnesium plate; while in the area far away from the stirring pin, atomic diffusion occurs between the aluminum plate and the solder piece as well as between the magnesium plate and the solder piece under the action of heat of stirring friction, so that diffusion welding is formed. The method can form soldering and diffusion welding connectors at the same time of friction stir spot welding, increase the effective bearing area of welding spots and improve the anti-tensioning shear force of the connectors.

Owner:NANCHANG HANGKONG UNIVERSITY

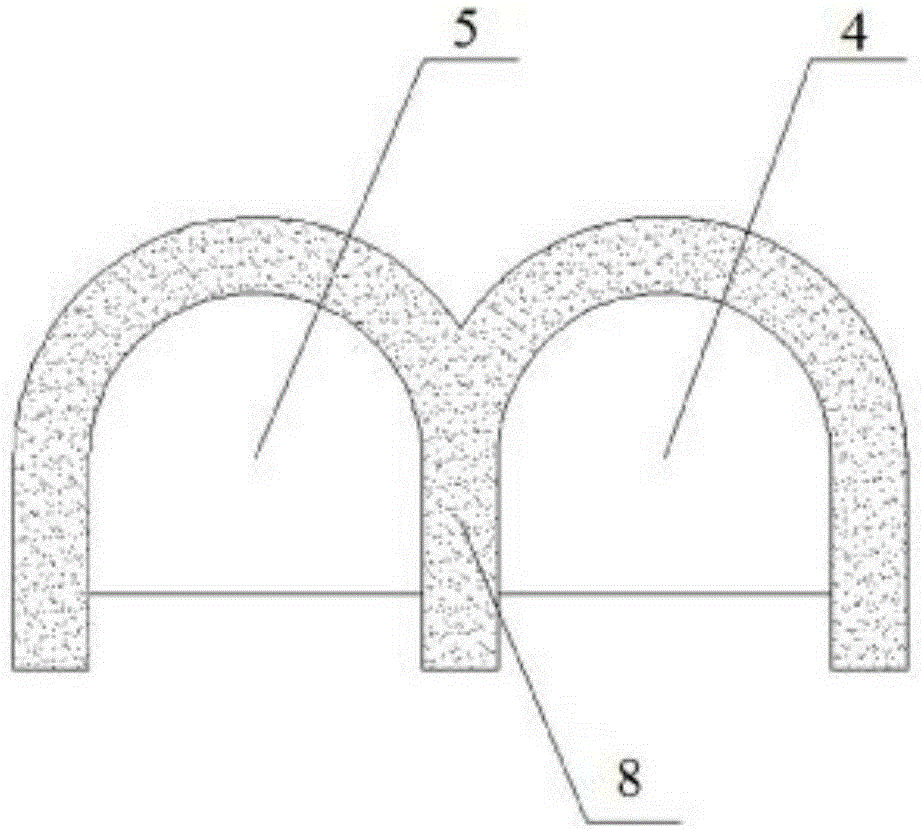

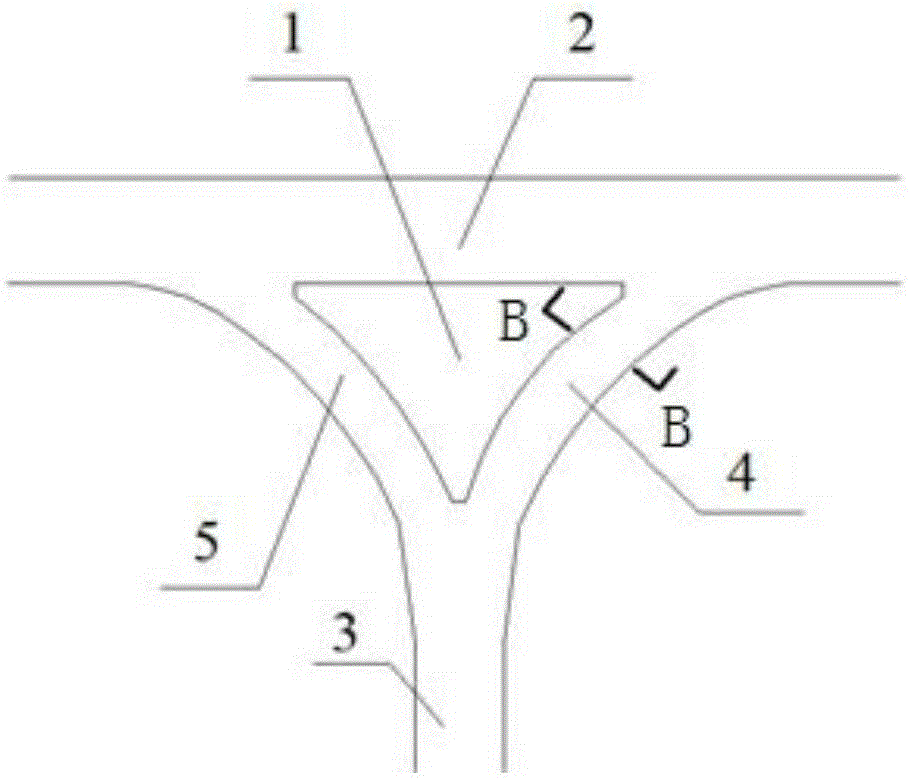

Enlarging repair and reinforcement method of roadways at crossing

InactiveCN105156114ANo reduction in effective load-carrying areaIncrease the effective bearing areaUnderground chambersMaterial fill-upEngineeringHigh stress

The invention discloses an enlarging repair and reinforcement method of roadways at a crossing. The method includes the steps of 1, selecting the roadways at the crossing, requiring enlarging repair and reinforcement, and referring the roadways on left and right sides of the crossing as a left crossheading and a right crossheading; 2, detecting growth condition of surrounding rock fissures of the right crossheading, and performing grouting reinforcement; 3, enlarging the right crossheading to form an enlarged right crossheading (10); 4, closing the left crossheading; and 5, excavating a new left crossheading (12) on one side of the left crossheading. The problems that when the roadways at the crossing are under the effect of factors such as mining induction and high stress, surrounding rock deformation is large and repair and reinforcement are difficult can be effectively solved. Effective bearing area of a coal (rock) pillar in a repaired triangular area is not decreased but increased, unit stress of the coal (rock) pillar is reduced, and overall stability of the coal (rock) pillar is improved. During repairing, the left and right crossheadings are carried out in order, and normal production of a mine is guaranteed.

Owner:CHINA UNIV OF MINING & TECH

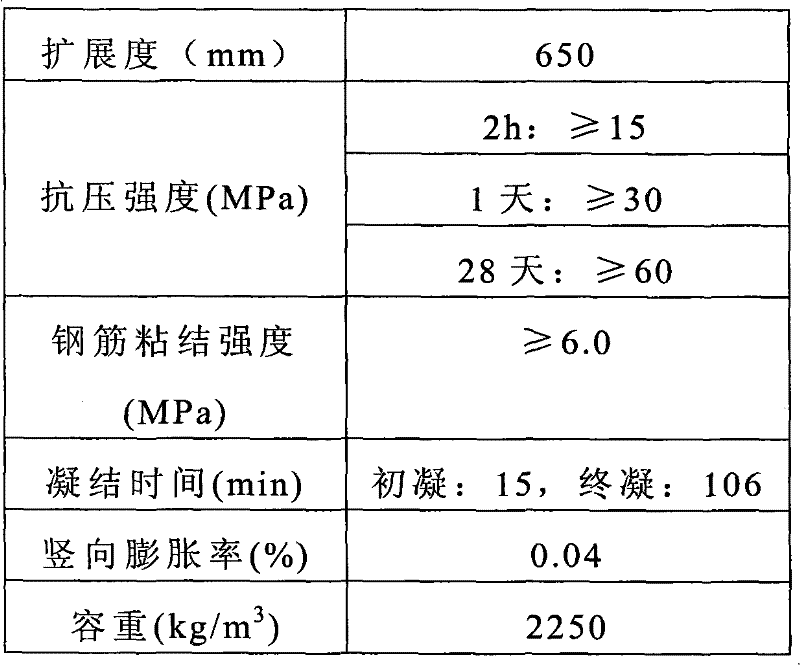

Early-strength grouting material for installation of overweight and oversized equipment and its construction method

InactiveCN102295443AIncrease the effective bearing areaImprove mechanical propertiesBuilding material handlingDefoamerGrout

An early-strength grouting material for overweight and oversized equipment installation is characterized in that the raw materials are composed of cement, fly ash, expansion agent, coagulation regulator, retarder, water reducer, yellow sand, defoamer and pebbles, and its The ratio is calculated in parts by mass: cement: 1.00~1.05, fly ash: 0.18~0.22, expansion agent: 0.1~0.12, coagulation regulator: 0.13~0.16, retarder: 0.003~0.005, water reducer: 0.003~0.005, yellow sand: 1.09~1.29, defoamer: 0.004~0.006, pebble: 1.1~1.3. The early-strength grouting material for installation of super-heavy and super-large equipment and the construction method thereof have the advantages of super-early strength, fast setting speed, high mechanical performance, shortened construction period, and reduced engineering cost.

Owner:中冶检测认证(上海)有限公司

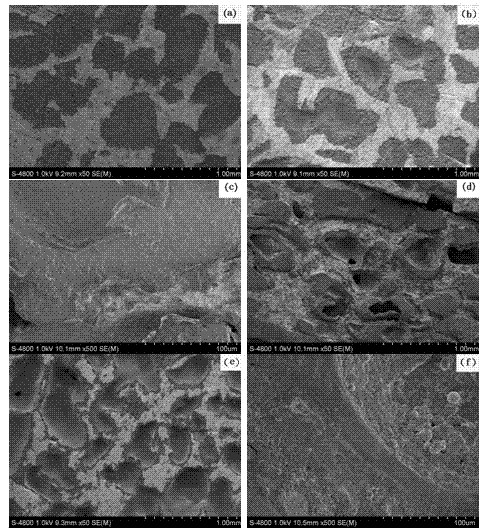

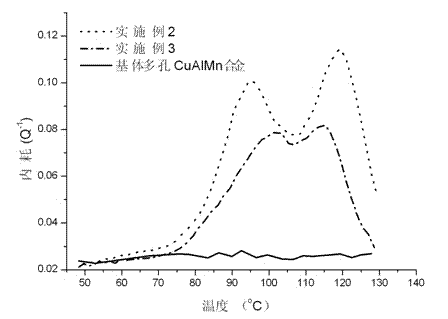

Preparation method for porous copper-based shape memory alloy-based damping composite material

The invention discloses a preparation method for a porous copper-based shape memory alloy-based damping composite material and relates to preparation of damping materials. The method comprises the following steps of: performing thermal circulation and ultrasonic cleaning on a quenching-state porous CuAlMn shape memory alloy sample to remove stains adhered to the outer surface of the sample and the inner surfaces of pores; immersing the sample in a polystyrene-2-methyltetrahydrofuran solution, and performing ultrasonic oscillation until the polystyrene-2-methyltetrahydrofuran solution is fully permeated into the pores of the porous CuAlMn shape memory alloy sample, which are communicated in a three-dimensional way; and finally drying until the 2-methyltetrahydrofuran solvent is volatilized completely to prepare a porous copper-based shape memory alloy-based damping composite material finished product, wherein polystyrene layers are deposited in the pores of the porous CuAlMn shape memory alloy. The finished product is high and controllable in damping property, and overcomes the defect that the stress concentration or microcracks are easily generated on edges of pore walls under the external load in the conventional CuAlMn shape memory alloy.

Owner:HEBEI UNIV OF TECH

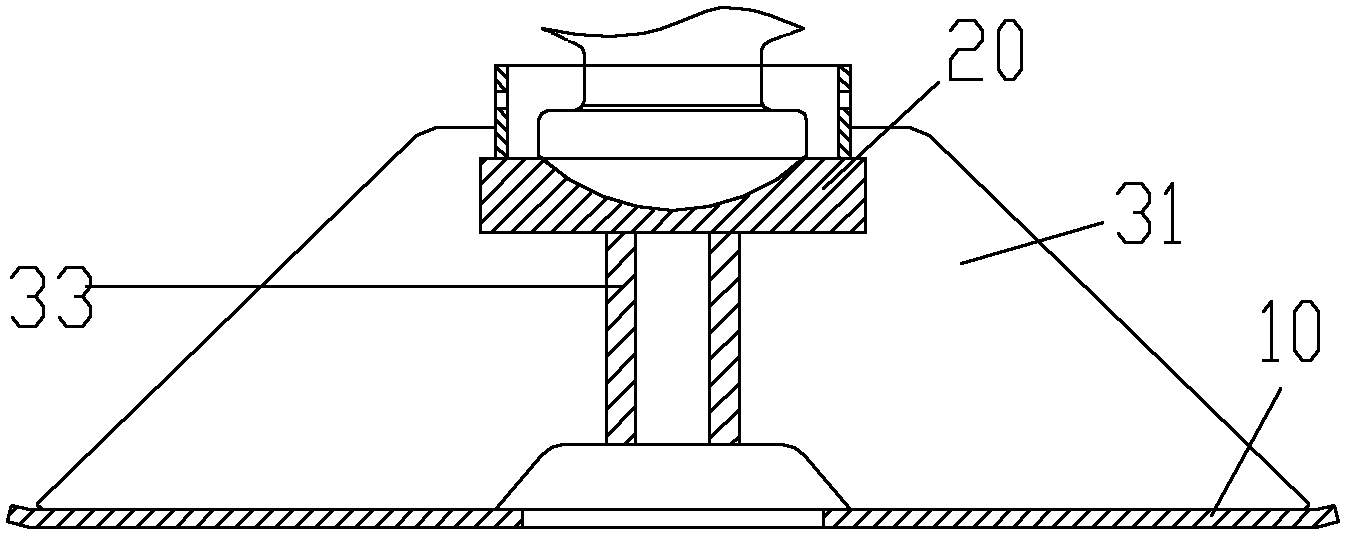

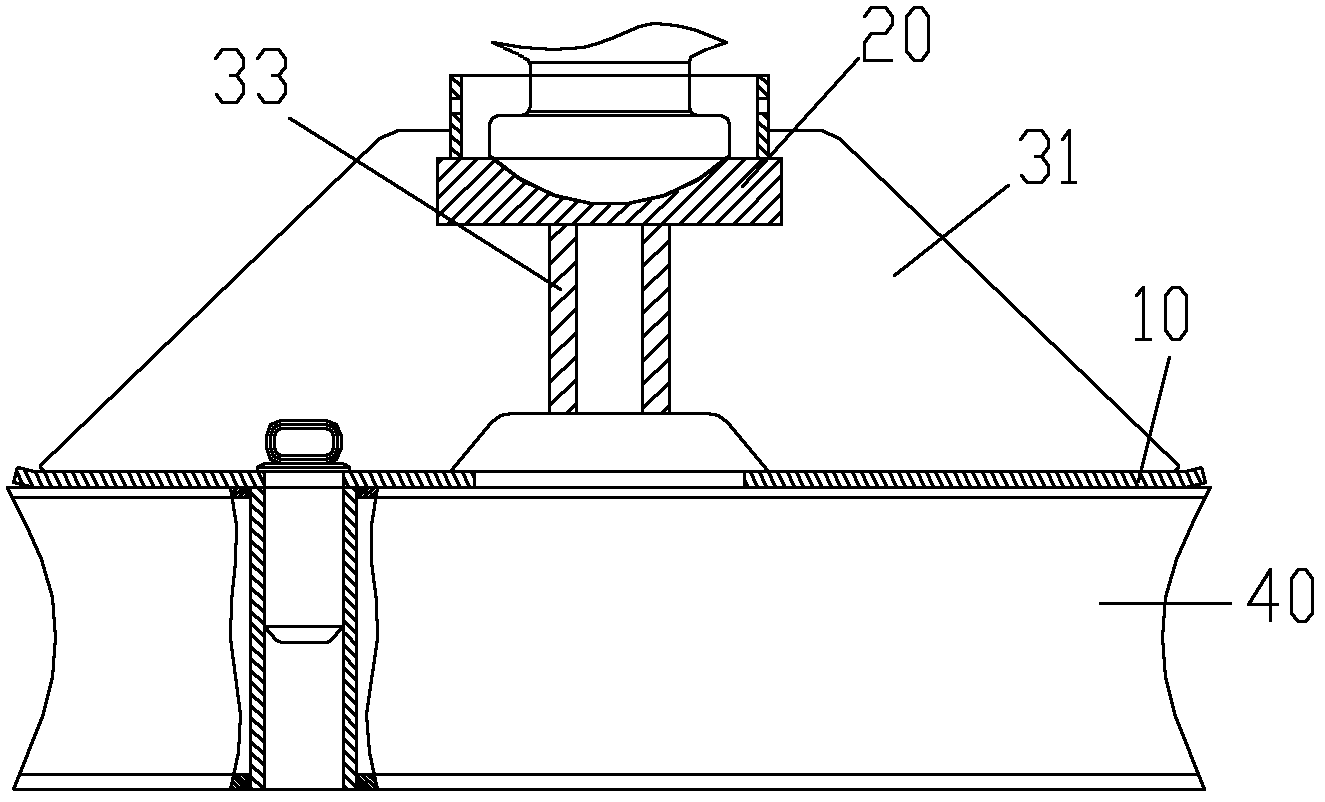

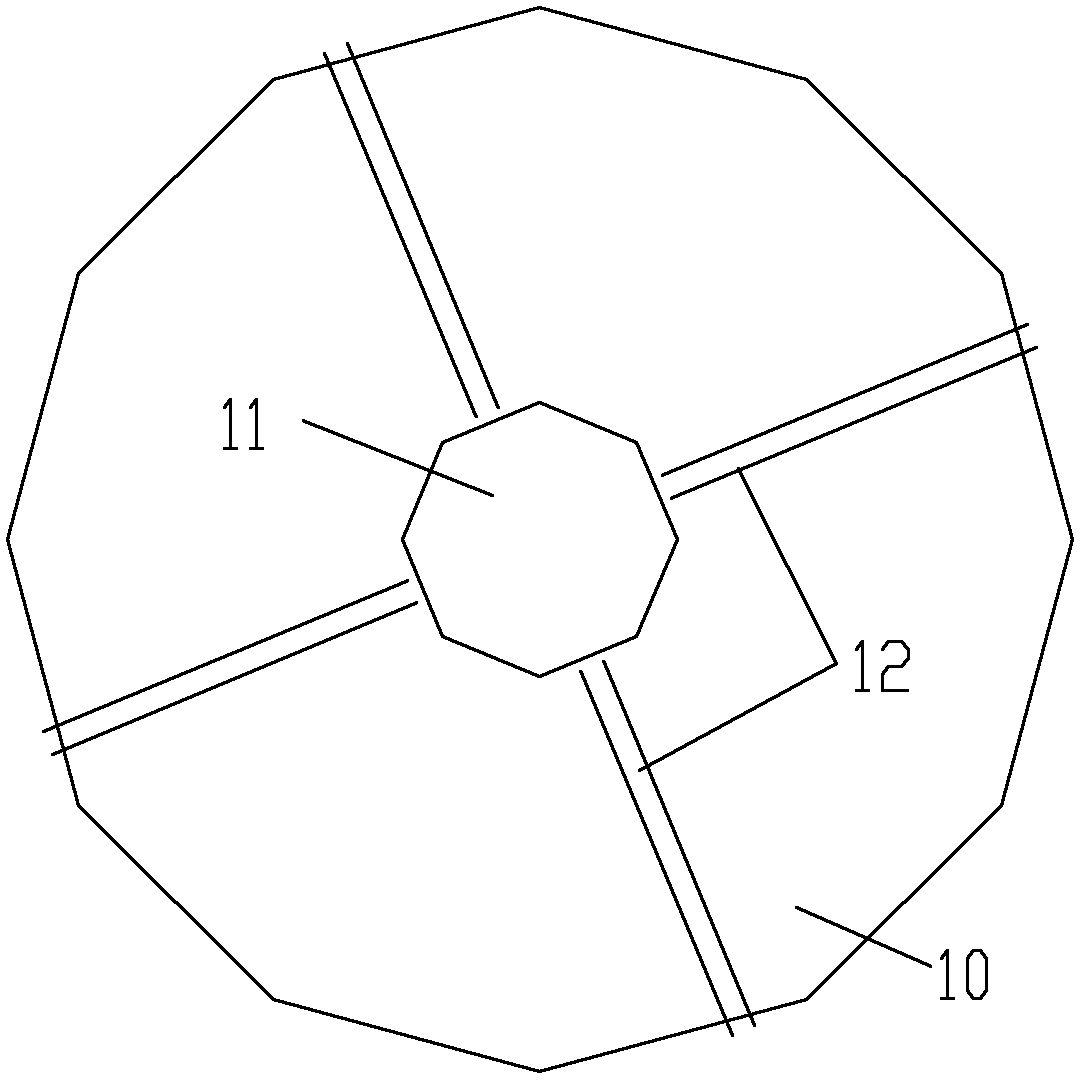

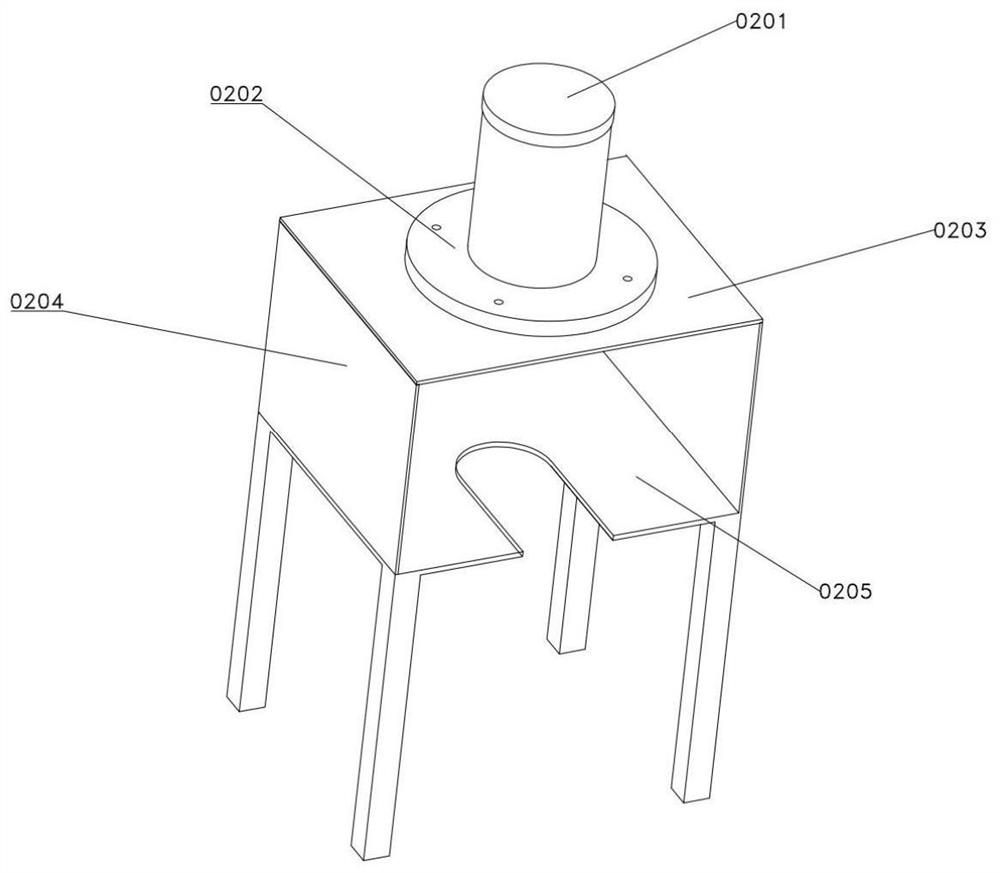

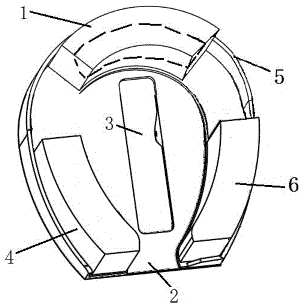

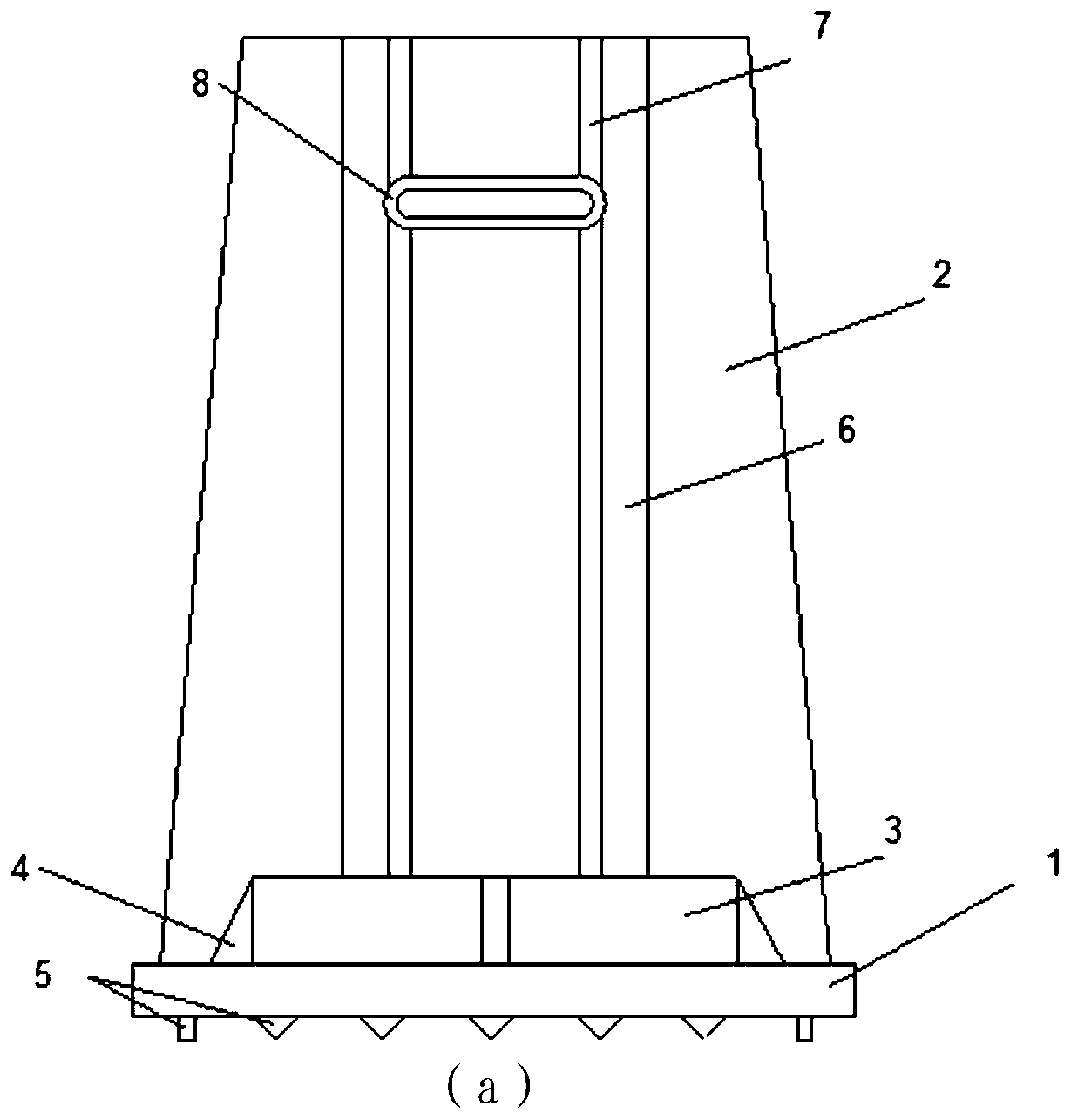

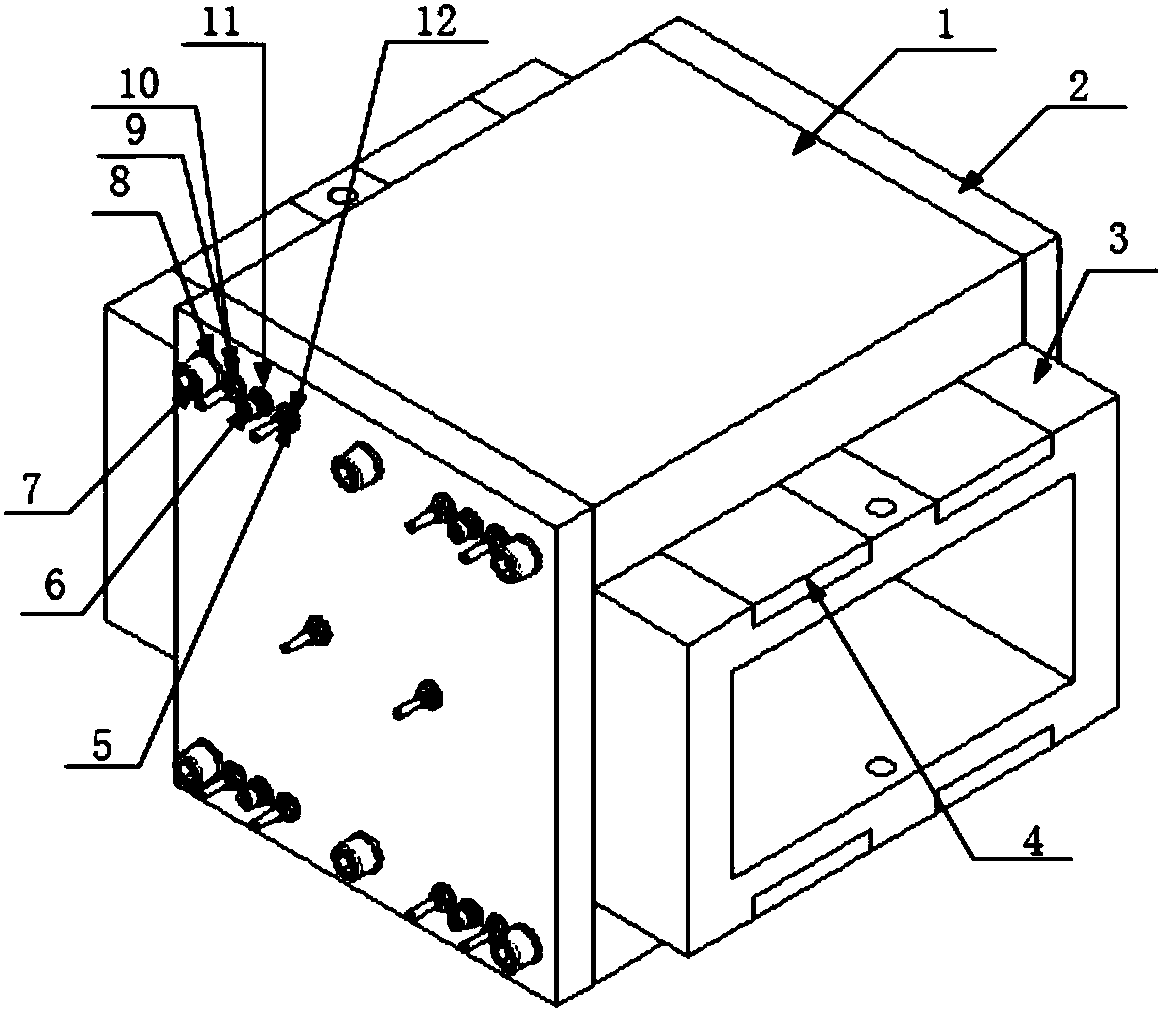

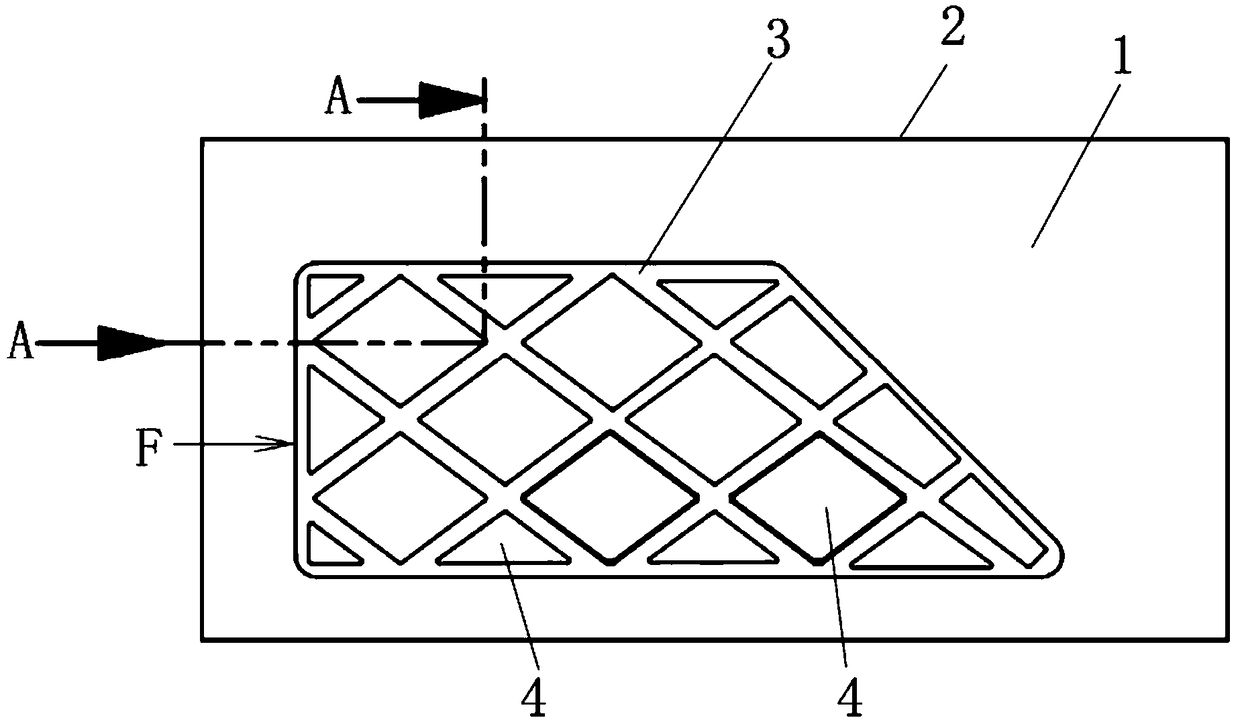

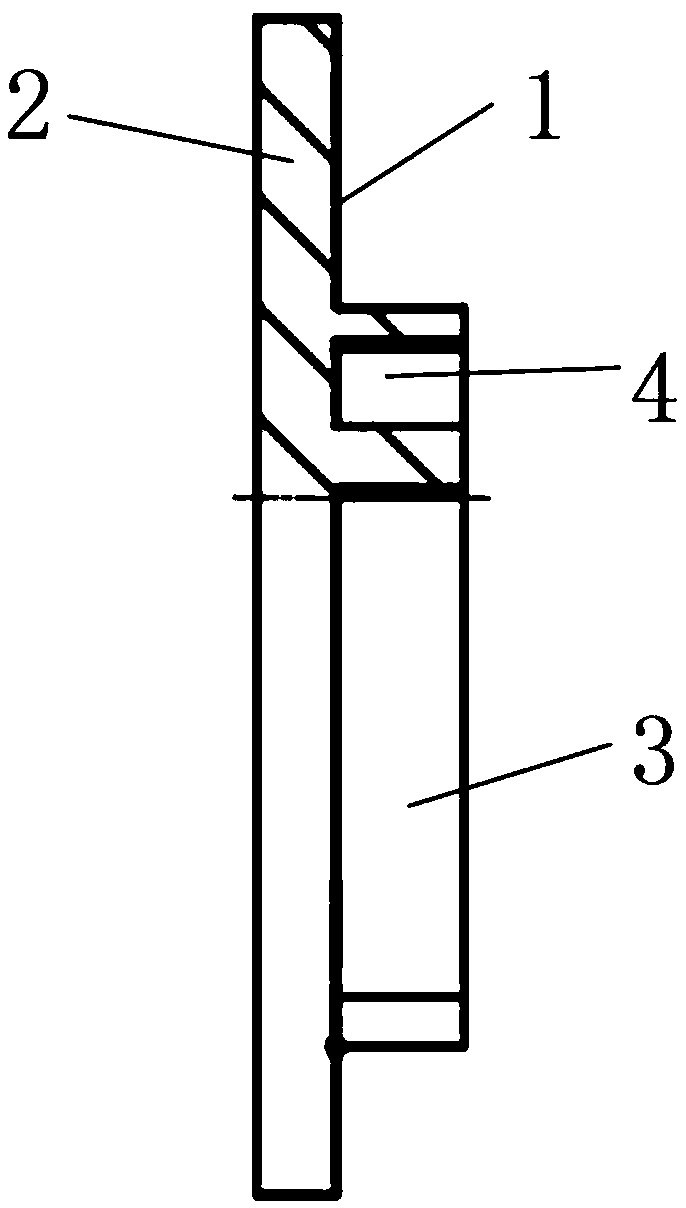

Support leg disc, support device and engineering vehicle

ActiveCN102491201AIncrease the effective bearing areaEvenly distributed profitsVehicle fittings for liftingCranesGyroscopic momentVertical load

The invention discloses a support leg disc, which comprises a bottom plate (10), a ball head concave seat (20) and a support plate, wherein the center of the bottom plate (10) is provided with a center hole (11), the lower side edge of the support plate is fixedly arranged on the bottom plate (10) in the radial direction, and the ball head concave seat (20) is fixedly arranged on the upper side edge of the support plate. Through the technical scheme, the center hole is arranged in the bottom plate of the support leg disc, so a born vertical load is transmitted to the bottom plate in an inclined way. Through the structure, the effective carrying area is enlarged, in addition, the profit distribution is uniform, and simultaneously, the gyroscopic moment transmitting capability is improved.

Owner:ZOOMLION HEAVY IND CO LTD

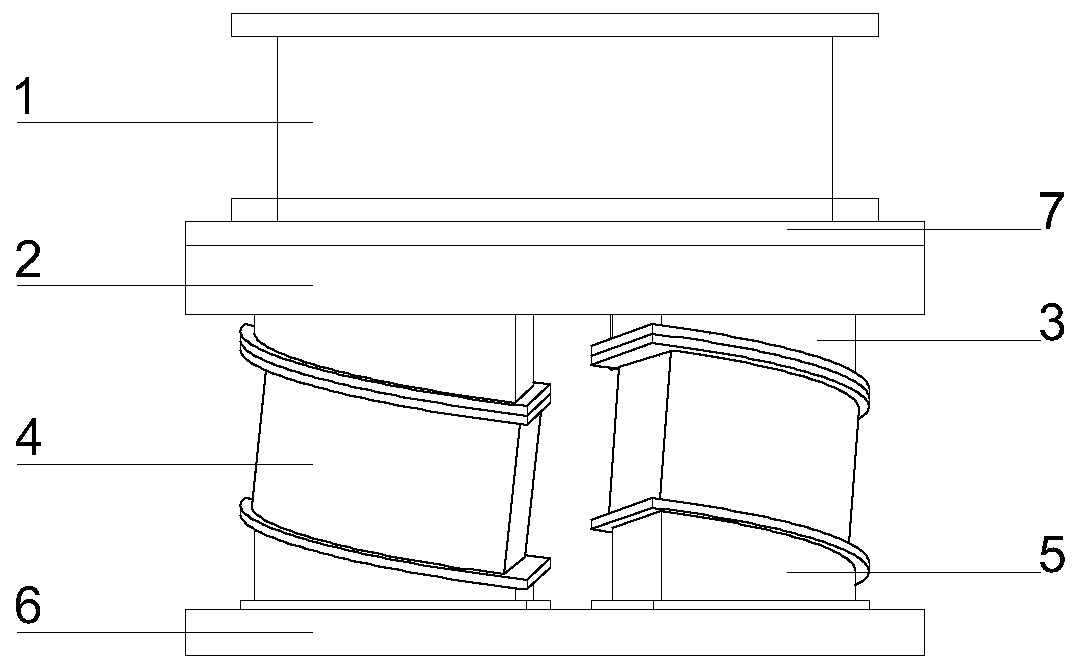

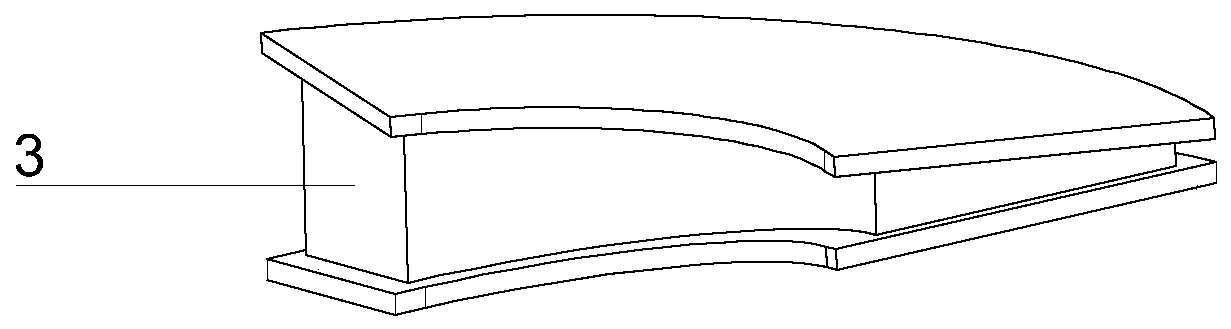

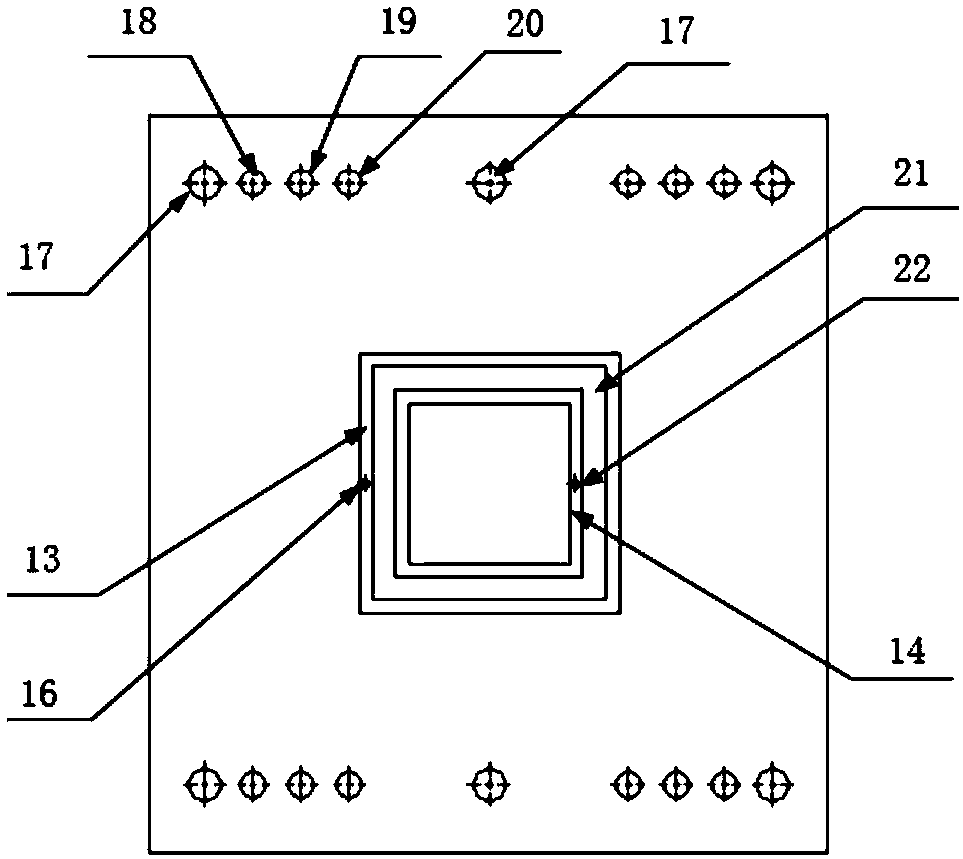

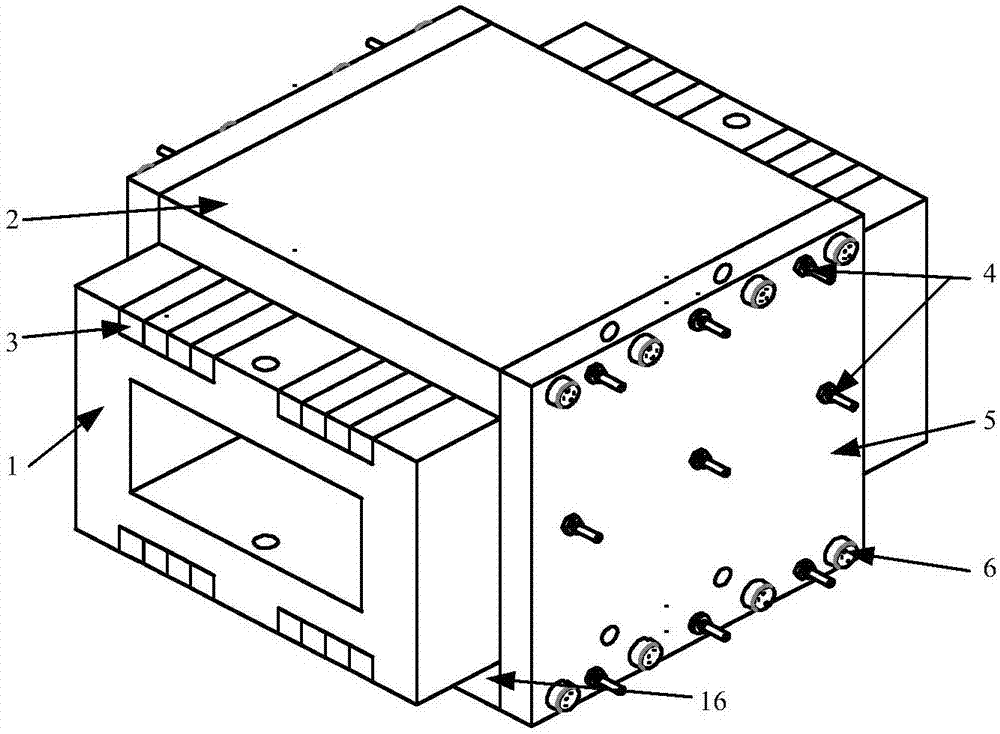

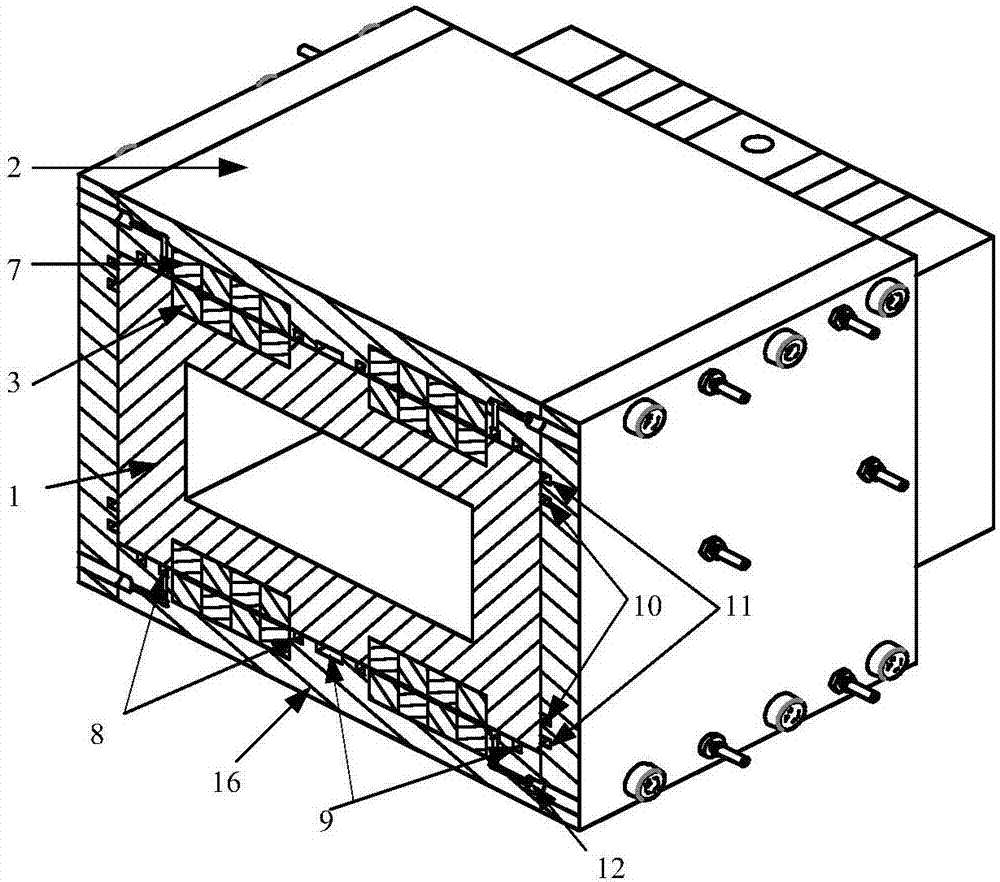

Special-shaped three-dimensional earthquake isolation supporting base

ActiveCN110029736ARealize the purpose of three-dimensional shock absorption/vibrationApplicable earthquakeNon-rotating vibration suppressionBridge structural detailsHorizontal and verticalSelf weight

The invention discloses a special-shaped three-dimensional earthquake isolation supporting base. The special-shaped three-dimensional earthquake isolation supporting base is arranged between an upper-part structure and a lower-part structure which need earthquake isolation, and comprises a bottom board, at least two special-shaped supporting base bodies, upper-part connecting corner blocks, lower-part connecting corner blocks, a horizontal supporting base and a sliding face board; the bottom board is connected with a lower-part structure; the special-shaped supporting base bodies are composedof first elastic blocks clamped by upper sealing boards and lower sealing boards in parallel with one another; the upper-part connecting corner blocks and the lower-part connecting corner blocks are provided with horizontal bottom surfaces and oblique top surfaces, and when the upper-part connecting corner blocks are arranged invertedly and the lower-part connecting corner blocks are overlaid withthe upper-part connecting corner blocks, the bottom surfaces are parallel; the horizontal supporting base is composed of a second elastic block clamped by an upper board and a lower board; after theupper-part connecting corner blocks are arranged invertedly and sequentially connected with the special-shaped supporting base bodies and the lower-part connecting corner blocks, the upper-part connecting corner blocks are fixedly supported on the bottom board in a central symmetrically distributed mode, and the sliding face board is fixed to the bottom surfaces of the upper-part connecting cornerblocks; and the horizontal supporting base is supported on the sliding face board in a mode capable of rotating round a central symmetric line, the contact surface of the horizontal supporting base and the sliding face plate adopts a friction material, and the upper board of the horizontal supporting base is connected with an upper-part structure. The special-shaped three-dimensional earthquake isolation supporting base can be synchronously isolate horizontal and vertical earthquake, and can be used for vertical earthquake isolation of buildings with comparatively large self-weight.

Owner:SHANGHAI UNIV +1

Manufacturing process for high-strength double-layer oil storage tank

The invention discloses a manufacturing process for a high-strength double-layer oil storage tank. The process comprises the steps of preparing of an inner tank body and two seal heads, splicing, preparing of a middle layer and preparing of an outer-layer tank body and tank mouth hole accessories; and an inner-layer tank body and the two seal heads are manufactured through dies, and are spliced toform the inner tank body, and then the steps of preparing of the middle layer, preparing and bonding of reinforcing ribs and preparing of the outer-layer tank body and the tank mouth hole accessoriesare carried out to obtain the double-layer oil storage tank. The oil storage tank is made of high-strength glass fiber reinforced plastic, and a glass fiber material is arranged between an outer structure layer and an inner structure layer of a tank body wall. According to the process, an anti-impact plate is arranged on the inner surface of a tank body, so that the inner wall of the storage tankis not prone to damage; the plurality of reinforcing ribs are arranged in the oil storage tank body, so that the pressure-bearing capacity of the tank body is greatly improved, and the storage tank is not prone to deformation when being used for a long time after being buried; the seal heads of the tank body adopt two split seal head body structures, so that the pressure bearing capacity of the oil tank is further improved, the evaporation loss of an oil liquid can be effectively reduced, and the leakage of the oil liquid is prevented; and according to the high-strength double-layer oil storage tank, the sealing effect is good, the service life is long, and the safety is higher.

Owner:JIANGYIN YUFEI NEW CONTAINER

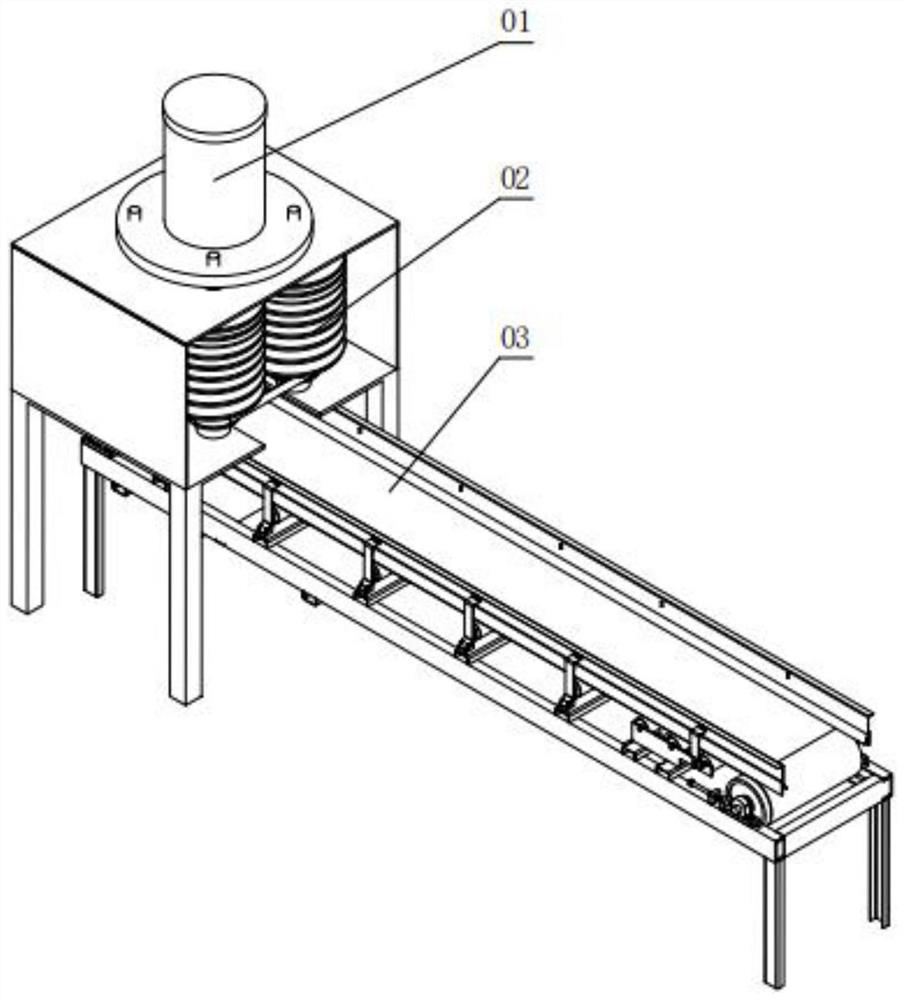

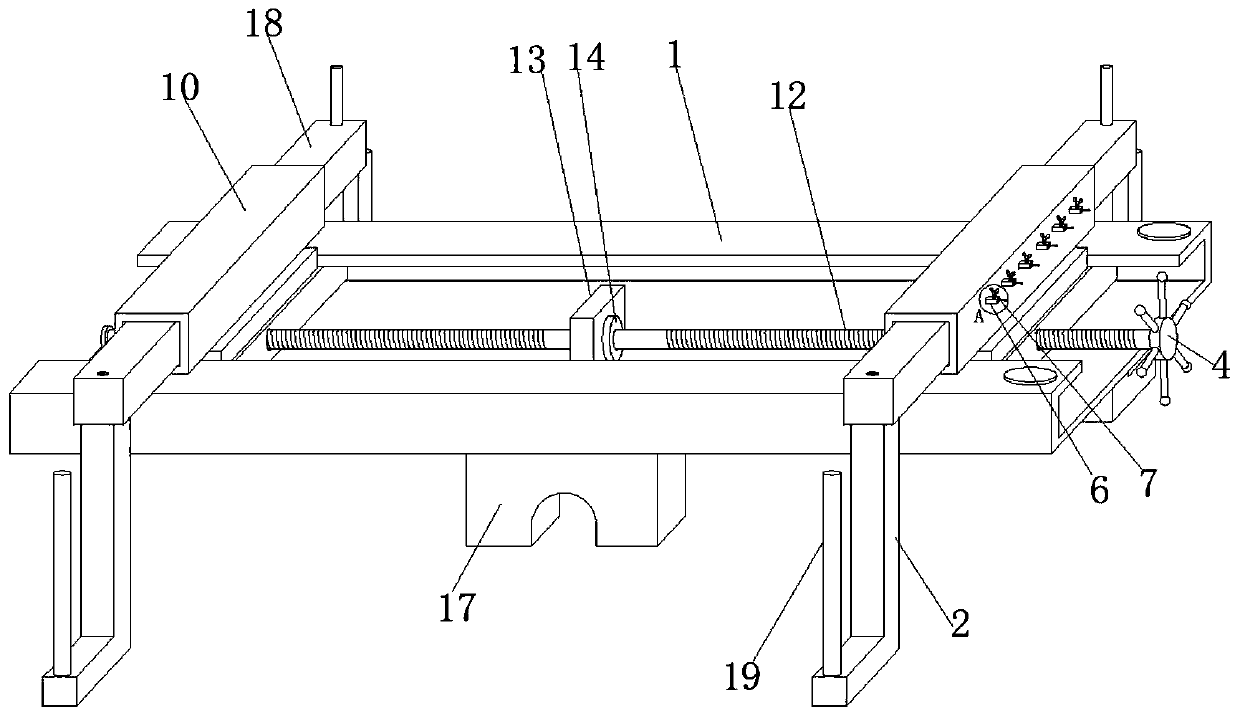

Flowerpot separating device and method suitable for stacking of plastic flowerpots in various shapes

ActiveCN114014024AEasy to produceStable separationConveyorsPlastic recyclingStructural engineeringMechanical engineering

The invention discloses a flowerpot separating device and method suitable for stacking of plastic flowerpots in various shapes. The flowerpot separating device comprises a positioning and bearing mechanism, a flowerpot separating mechanism and a single flowerpot conveying mechanism. The positioning and bearing mechanism is used for limiting the flowerpot to only move in the vertical direction; the flowerpot separating mechanism separates the stacked flowerpots into single flowerpots and the single flowerpots fall to the single flowerpot conveying mechanism; the flowerpot separating mechanism comprises four double-line variable-pitch screws; each of the double-line variable-pitch screws is provided with two spiral lines of which the screw pitches are gradually increased from top to bottom, and the space between the smaller sides of the two spiral lines is kept unchanged in the axial direction of the double-line variable-pitch screw; the difference between the phase angles of every two adjacent double-line variable-pitch screws is 90 degrees, and the phase angles of the four double-line variable-pitch screws are not equal. Two adjacent flowerpots can be gradually and slowly separated, and it is guaranteed that the flowerpots fall in a stable posture and are arranged on the conveying belt at the same interval.

Owner:ZHEJIANG SCI-TECH UNIV

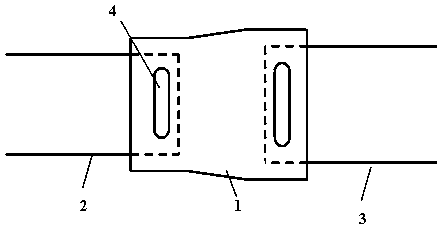

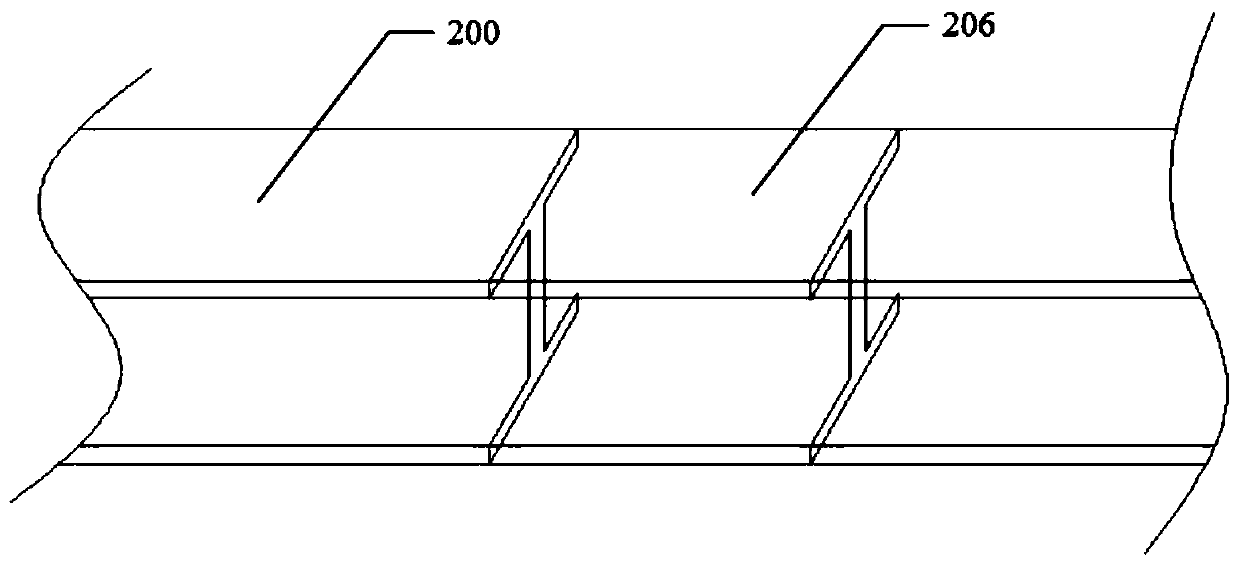

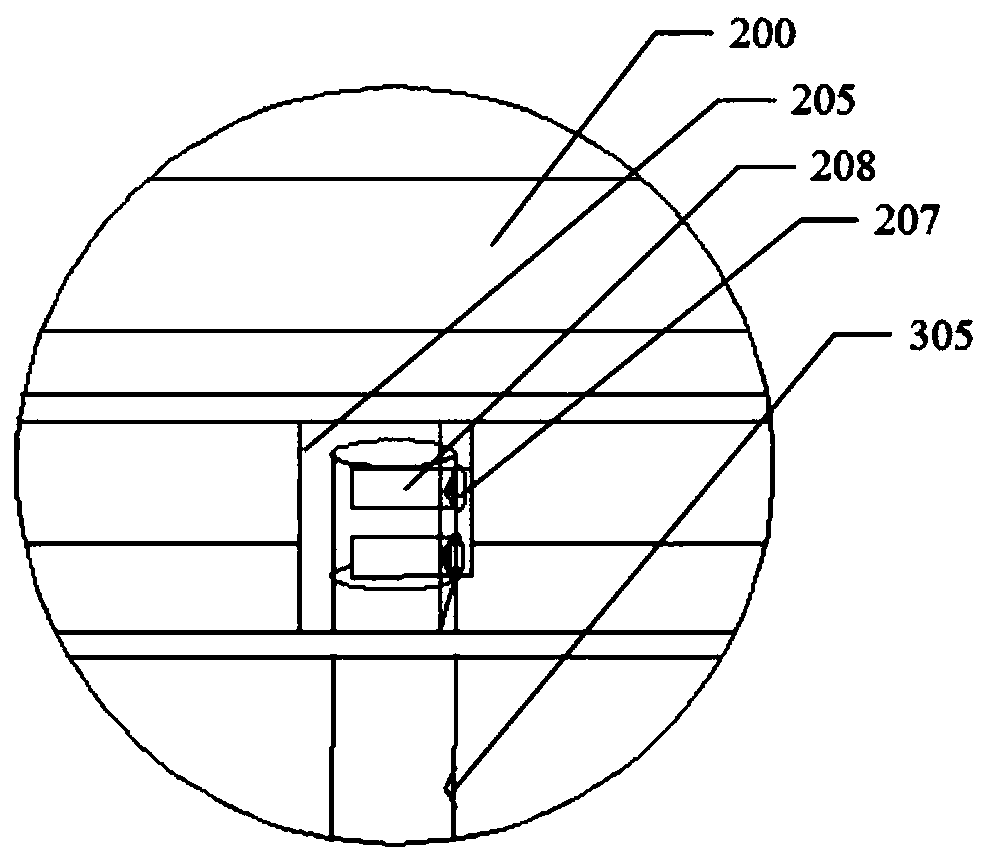

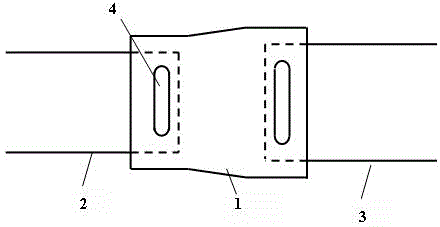

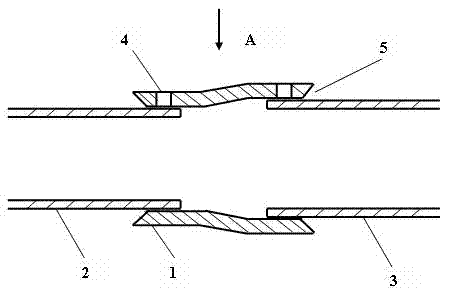

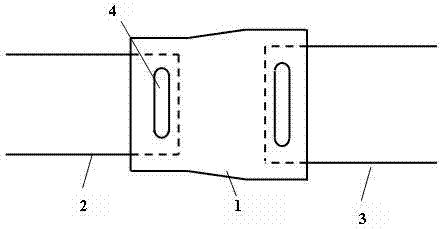

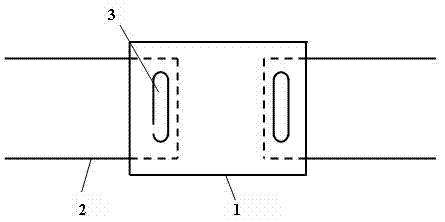

Welding connection method for aluminum alloy pipelines of different diameters

ActiveCN103464915AIncrease the effective bearing areaImprove welding strengthWelding apparatusStructural engineeringAluminium alloy

The invention discloses a welding connection method for aluminum alloy pipelines of different diameters. The method comprises the steps that an aluminum alloy pipeline connector with the diameter slightly larger than that of an alloy pipeline is machined according to the diameter of the alloy pipeline , a plurality of trough type through holes are formed in the two sides of the pipeline connector in the circumferential direction, the center line of each trough type through hole is perpendicular to the axis of the pipeline, the distance between every two adjacent trough type through hole is no smaller than the length of each trough type through hole, and 50-60-degree beveled edges are machined on the inner surface of the two ends of the pipeline connector, welding is conducted on the ends and the trough type through holes, then partial heat treatment is conducted on the pipeline connector, and anticorrosive paint is prepared to paint the pipeline connector at last. The welding connection method for the aluminum alloy pipelines of the different diameters can be used for connecting the aluminum alloy pipelines of the different diameters, and is easy to operate and implement, and easy to industrially popularize.

Owner:东和管道科技(江苏)有限公司

High-temperature inorganic ink based on low-melting-point glass powder and preparation method thereof

The invention discloses a high-temperature inorganic ink based on low-melting-point glass powder, and belongs to the technical field of ink. The inorganic ink comprises the following raw materials inparts by weight: 40-60 parts of low-melting-point glass powder, 15-20 parts of an inorganic pigment, 25-35 parts of water-based high-viscosity resin and 12-15 parts of zirconium oxide. The invention further discloses a preparation method of the high-temperature inorganic ink based on the low-melting-point glass powder. The preparation method comprises the following steps: step 1, adding low-melting-point glass powder, water-based high-viscosity resin and zirconium oxide into a container according to the formula, uniformly stirring to form a mixture, and controlling the temperature to be 50-70DEG C; and step 2, adding an inorganic pigment into the mixture obtained in the step 1, and continuously stirring for 30-50 minutes to obtain the high-temperature inorganic ink. According to the method, the high-temperature inorganic ink is prepared from the low-melting-point glass powder, in the application process, on the premise that certain hardness is maintained, the rigidity is reduced, thetoughness is enhanced, and the impact resistance and the tear resistance are improved at the same time.

Owner:湖南衡义材料科技有限公司

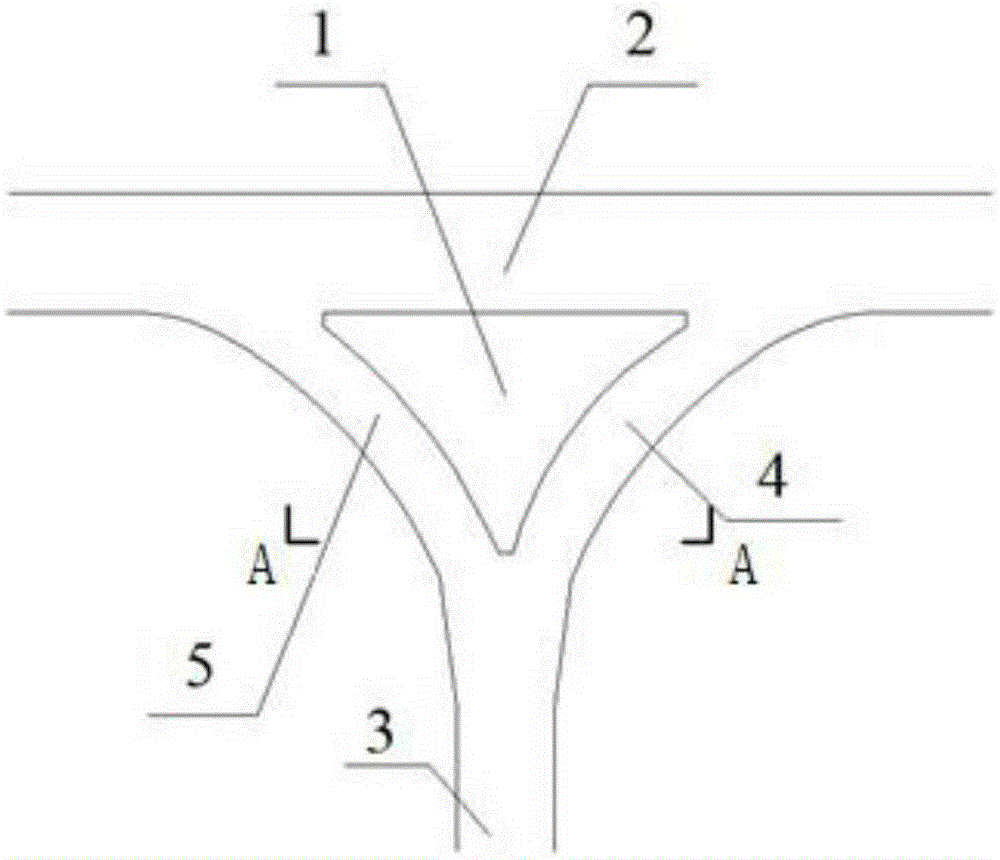

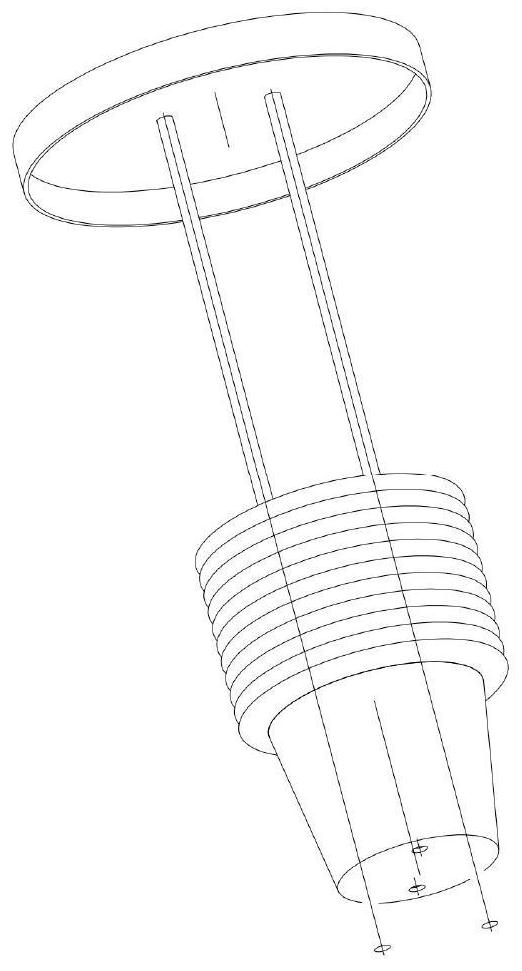

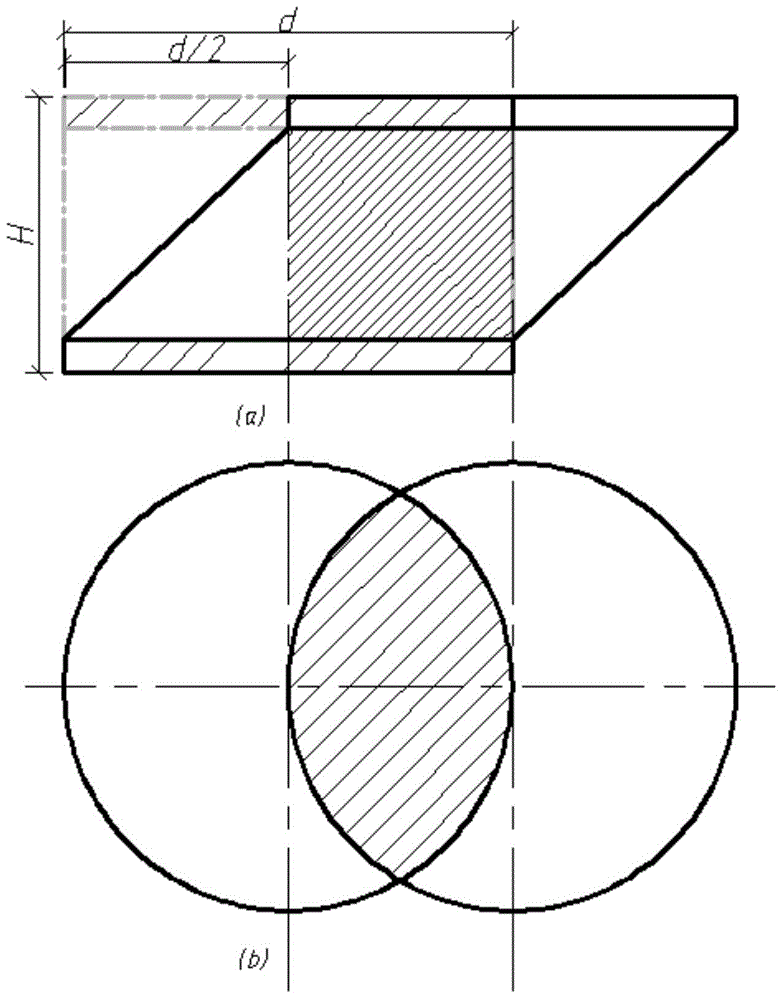

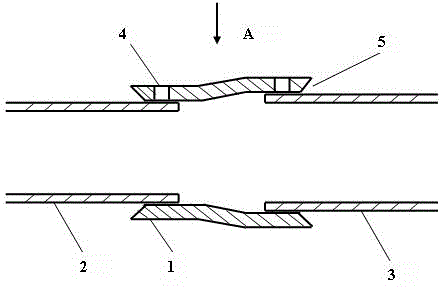

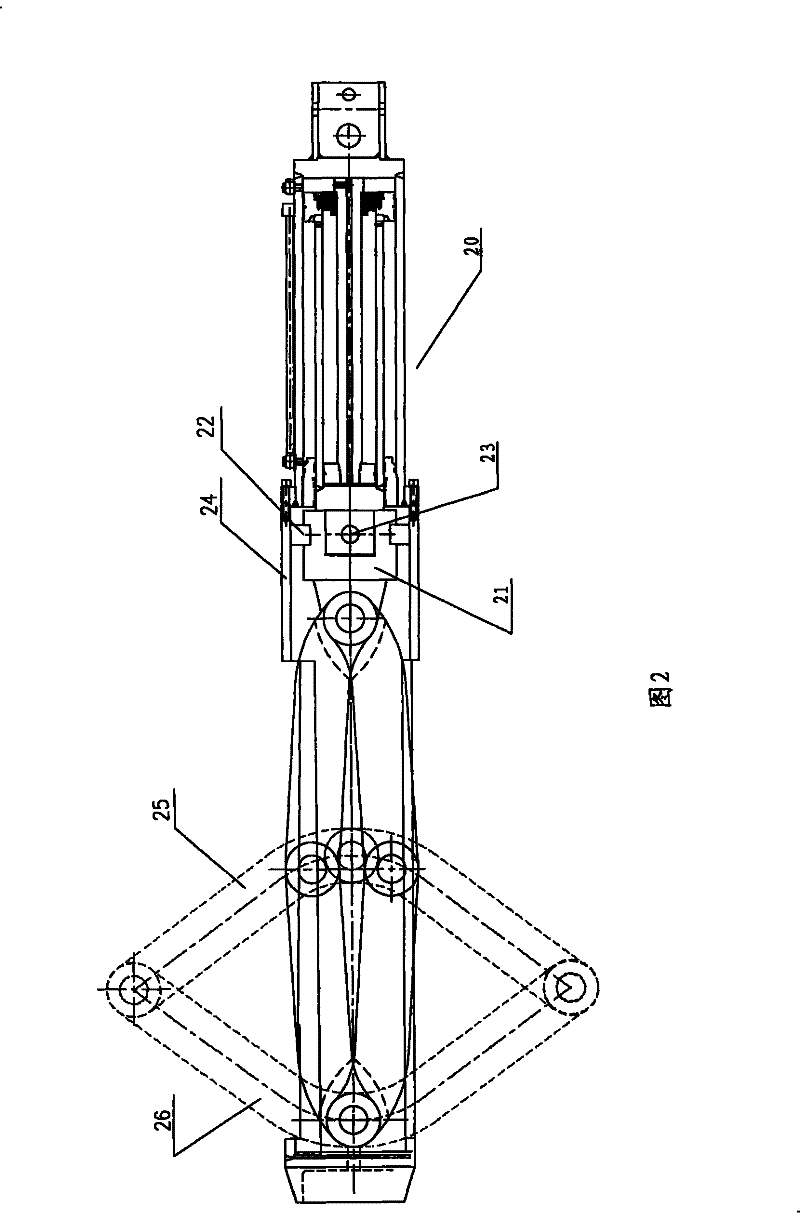

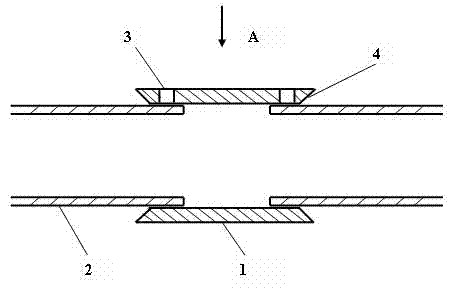

Method for diffusion spot welding with solid phase assistance by efficient liquid phase of Al/Mg dissimilar metal

PendingCN110587105AIncrease the effective bearing areaIncreased tensile and shear capacityWelding/soldering/cutting articlesNon-electric welding apparatusMetal foilLiquid metal

The invention relates to the technical field of welding of Al / Mg dissimilar materials and specifically relates to a method for diffusion spot welding with solid phase assistance by an efficient liquidphase of Al / Mg dissimilar metal. The method provided by the invention comprises the steps that an Al plate and an Mg plate are rubbed by a friction head to generate heat, a metal foil between the plates is melted by the heat, and an oxidation film on a contact face is cleaned by the molten metal obtained after melting; the liquid metal is then extruded out through extrusion of the friction head;and during maintenance of close adhesion between the Al plate and the Mg plate, atomic diffusion takes place on the cleaned contact face, so diffusion spot welding connection is formed. A welding connector obtained through utilization of the method provided by the invention is a solid diffusion welding head, and a key hole in a welding spot surface is eliminated, so an effective bearing area of the connector is significantly increased; resistance of the spot welding connector to tensile and shear is enhanced; and complicated mechanical equipment and subsequent processes of repair welding are omitted.

Owner:NANCHANG HANGKONG UNIVERSITY

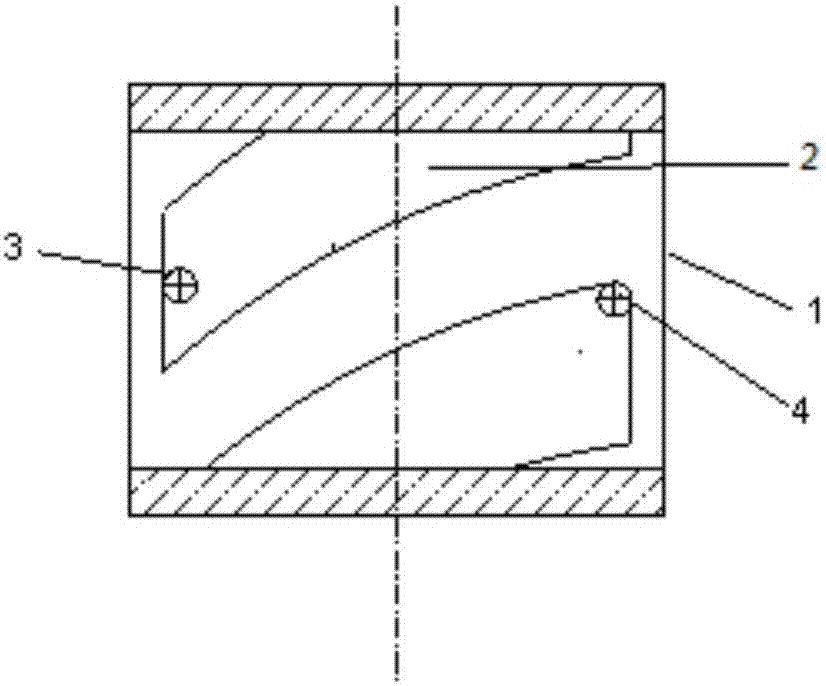

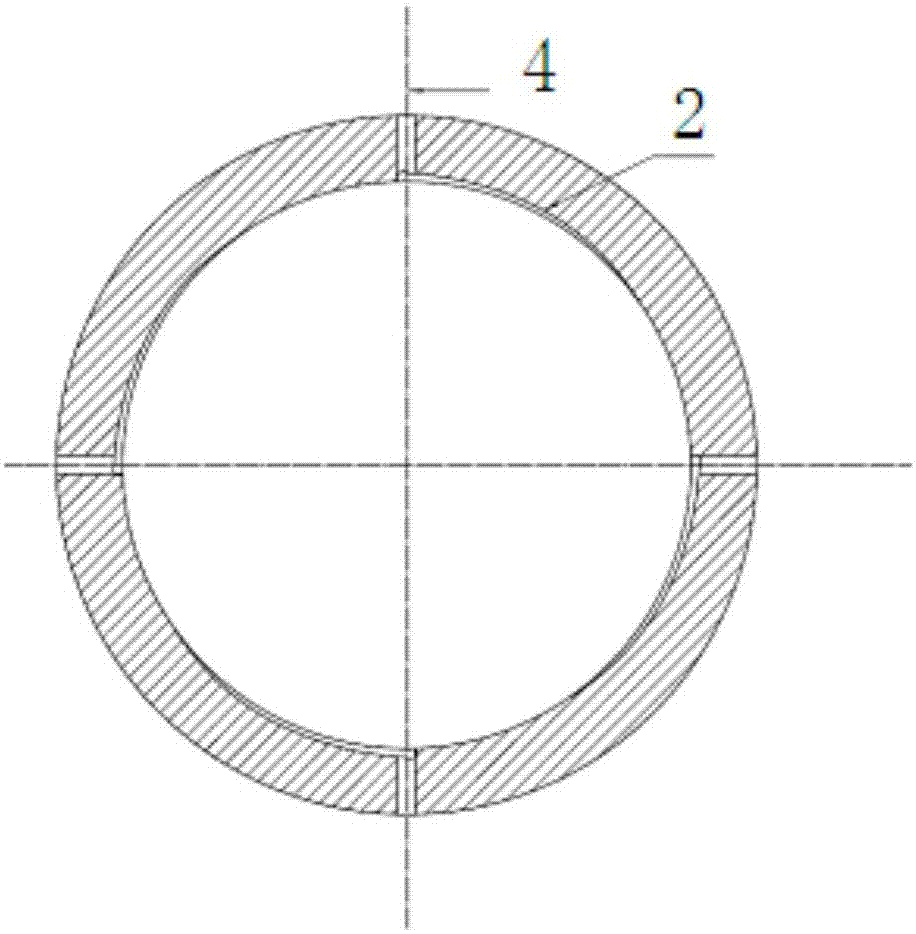

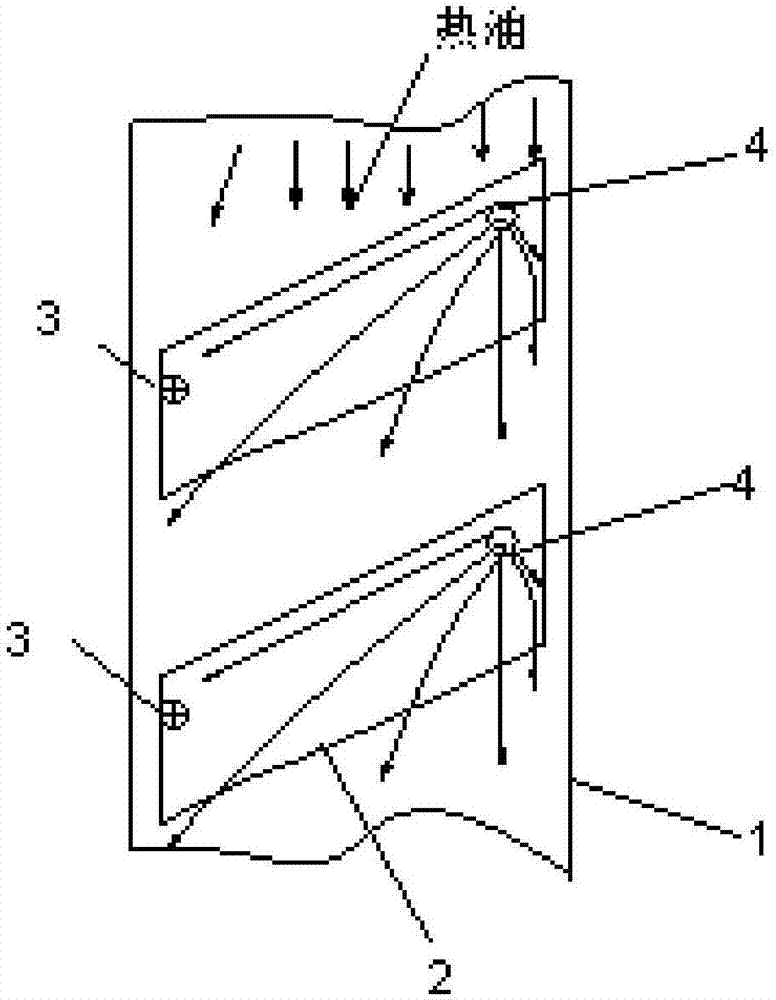

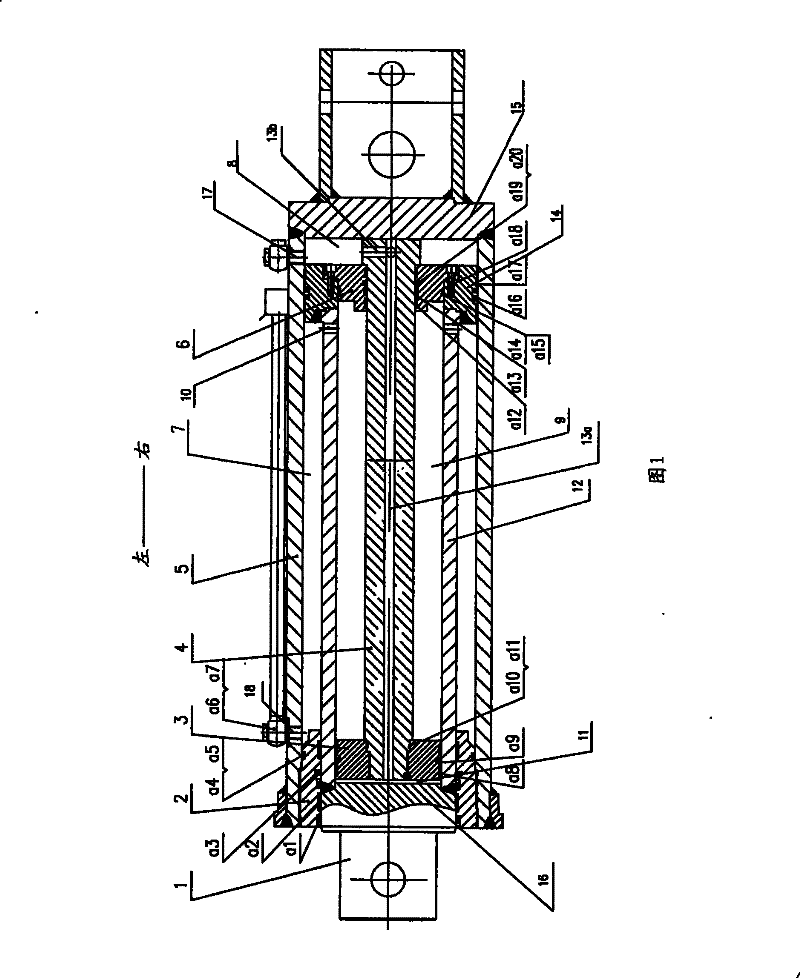

Archimedes spiral curved surface dynamic-pressure sliding bearing and application thereof

ActiveCN107387548AReduce feverReduce temperature riseShaftsHydro energy generationOil canSlider bearing

The invention discloses an Archimedes spiral curved surface dynamic-pressure sliding bearing and application thereof. The sliding bearing includes a bearing body, and at least one Archimedes spiral curved surface is arranged on the inner wall of the bearing body in the peripheral direction, and used for forming a bearing lubricating oil cavity; the maximum cutting-in depth portion of the top of the Archimedes spiral curved surface is provided with an oil inlet, and the maximum cutting-in depth portion, close to the end face of the bearing body, of the bottom of the Archimedes spiral curved surface is provided with an oil outlet. According to the Archimedes spiral curved surface dynamic-pressure sliding bearing and the application thereof, an existing sliding bearing structure is referred to, and in combination with the practical application background, a novel oil cavity structure which is the oil cavity formed by the Archimedes spiral curved surface is provided; therefore, the circulation of lubricating oil can be effectively speeded up, the heating of the bearing can be reduced, and the temperature rise of the bearing can be reduced; meanwhile, the bearing has a large effective load area and is suitable for high-speed heavy-load occasions.

Owner:SHANDONG UNIV

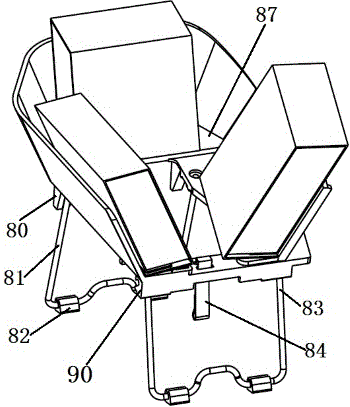

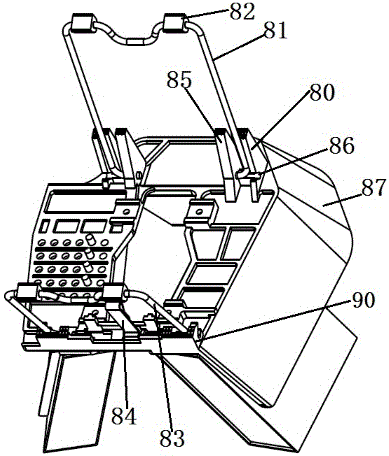

Headrest system for resting and sleeping and resting mode

Disclosed is a headrest system for resting and sleeping. Soft and elastic substances such as sponge are arranged in a headrest. The headrest system is characterized by comprising a forehead pillow and a base, the forehead of a head contacts with the forehead pillow when the headrest system is in use, face pillows are arranged below two sides of the forehead pillow, and the headrest and the face pillows are arranged on the base.

Owner:陈健全

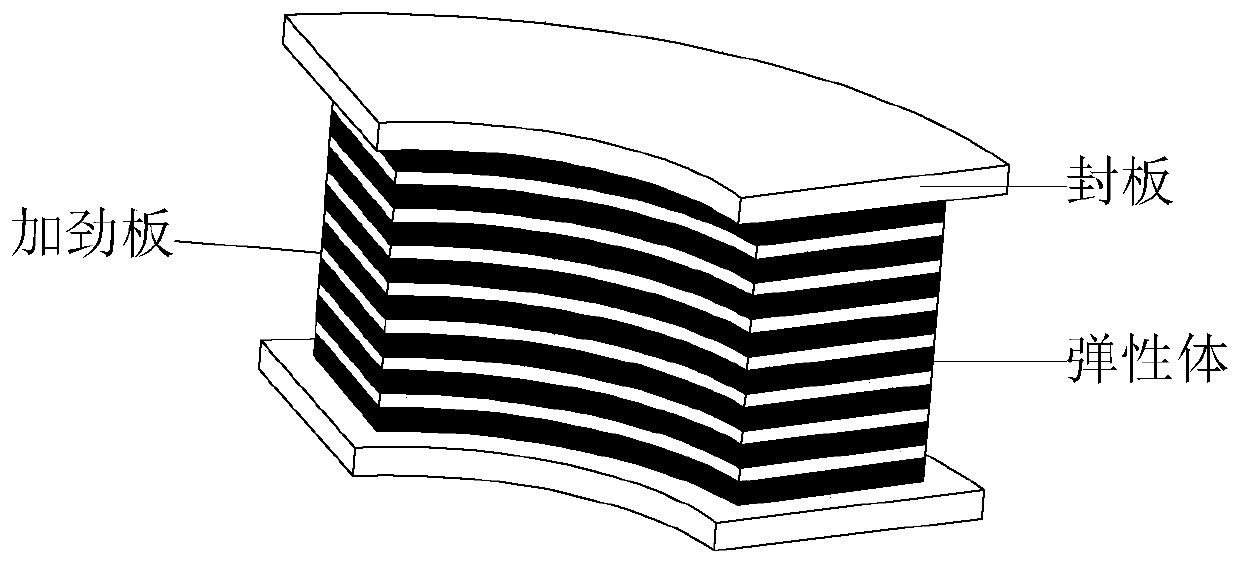

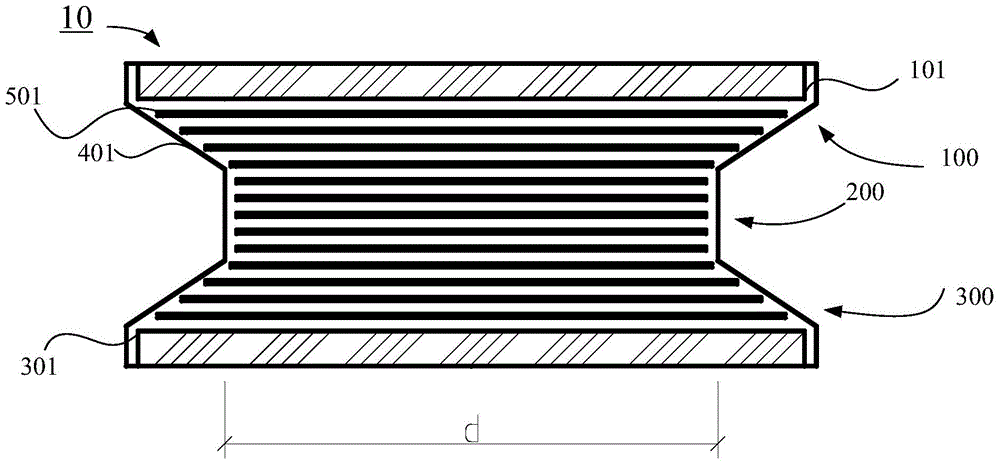

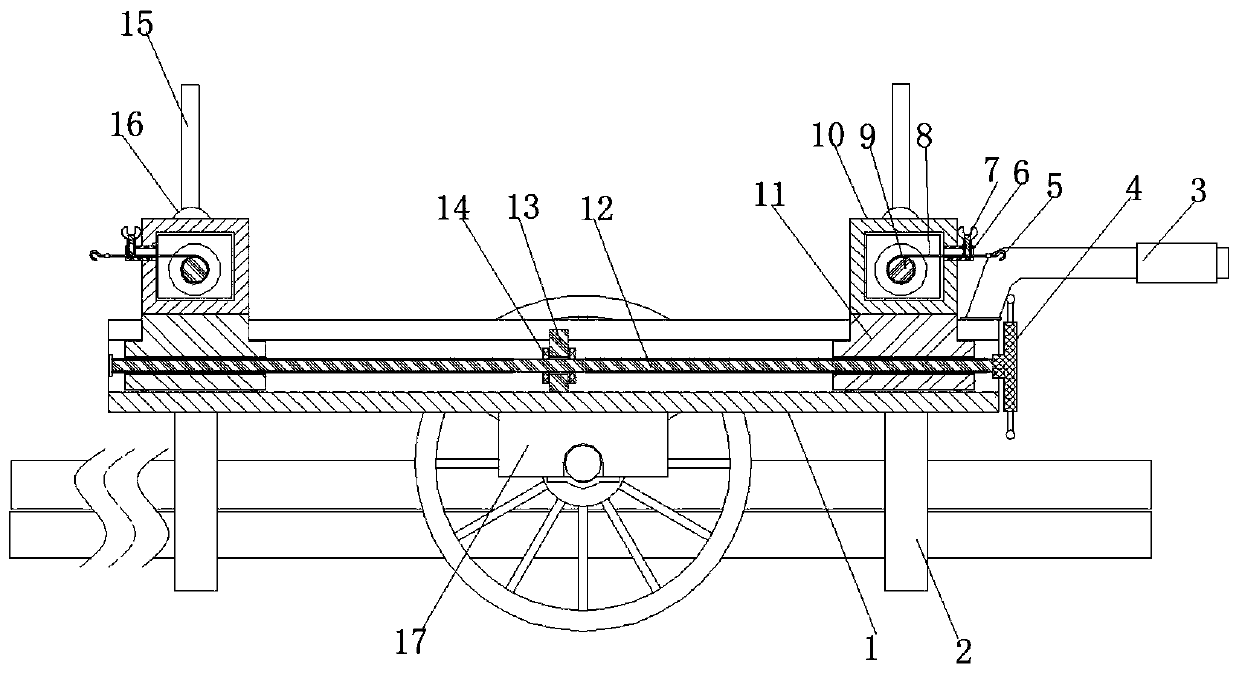

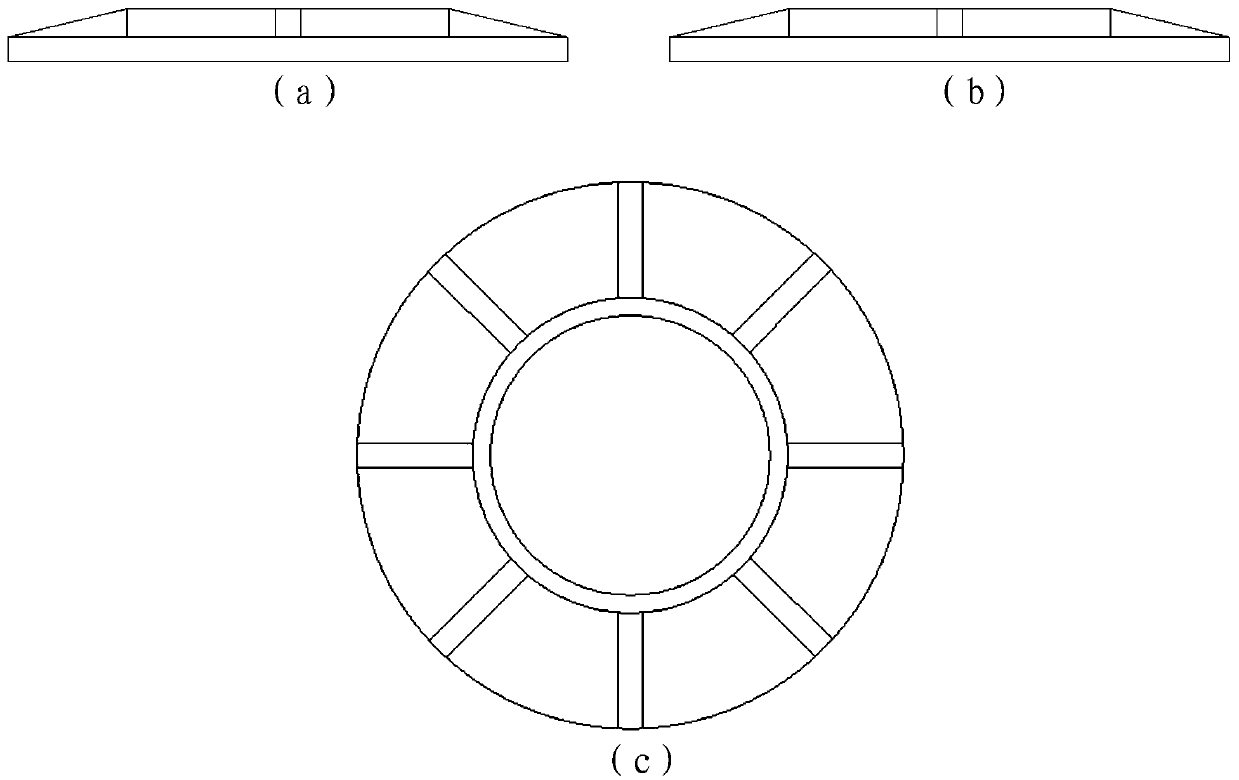

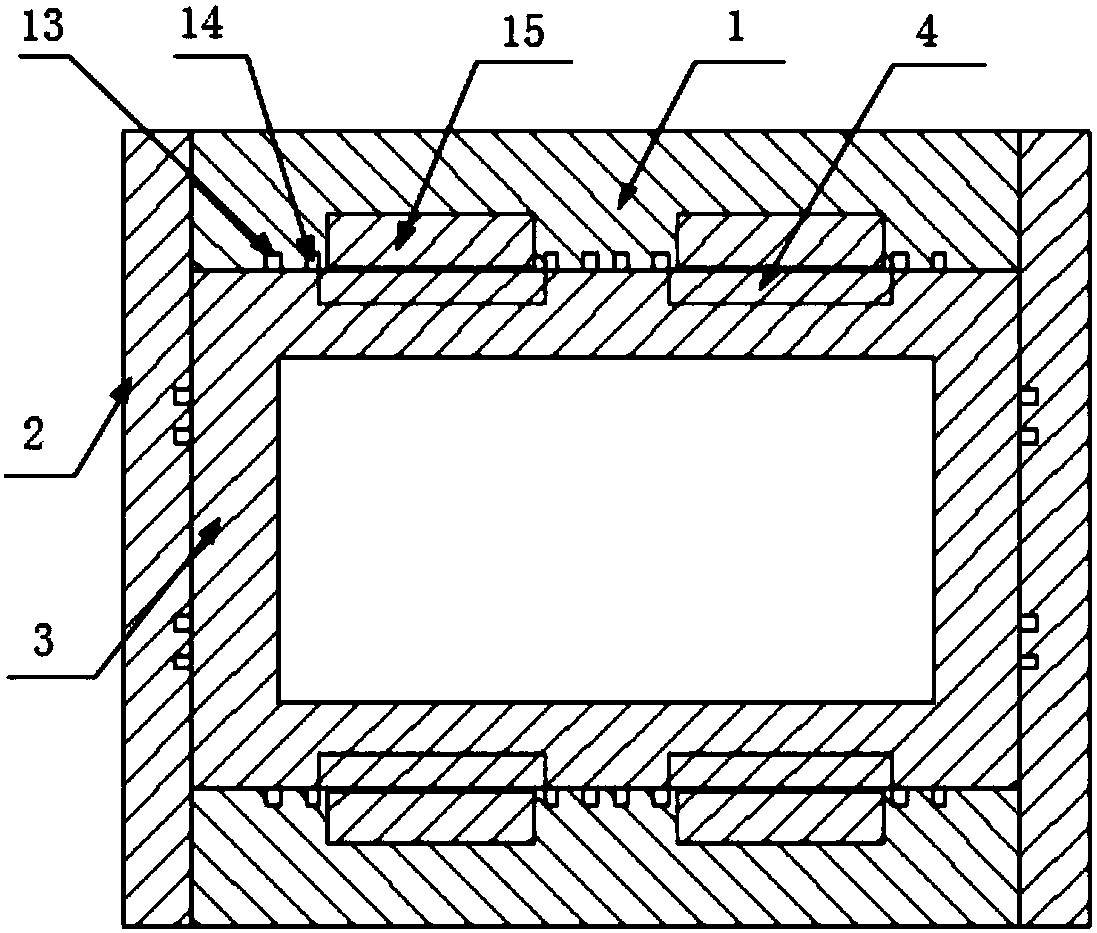

Irregular shape shock insulation support having high bearing capacity

ActiveCN104878839AIncrease the effective bearing areaReduce concentrated stressShock proofingShearing deformationAbnormal shaped

The invention discloses an irregular shape shock insulation support having a high bearing capacity. The irregular shape shock insulation support consists of the alternately overlapped portions of an upper sealing plate, a lower sealing plate, an elastomer and a reinforcing plate. With respect to other shock insulation supports having rectangular vertical cross sections, when the irregular shape shock insulation support is in a horizontal ultimate deformation state, the effective bearing area of the shock insulation support under an ultimate shearing deformation state is increased by means of haunching on the top and at the bottom of the support, and the concentrated stress of the reinforcing plate is reduced, thereby greatly increasing the vertical bearing capacity of the shock insulation support; meanwhile, the upper sealing plate and the lower sealing plate are in the same size, accordingly providing convenience to the installation and the construction, and being able to meet the requirements of buildings and equipment to the shock insulation support having the high bearing capacity.

Owner:GUANGZHOU UNIVERSITY

Fire-fighting pipeline transportation device

InactiveCN111483498APiled upIncrease the effective bearing areaHand carts with one axisHand cart accessoriesPipeline transportPipe

The invention belongs to the technical field of fire-fighting pipelines, and particularly relates to a fire-fighting pipeline transportation device, and aims at the problems in the prior art at leasttwo persons are still needed to lift heavy pipelines when the existing transport trolley is loaded and unloaded, and danger is easily caused due to hand disengaging. The following scheme is put forward: the fire-fighting pipeline transportation device comprises a trolley base is of C-shaped steel structure with upward opening. T-shaped sliding blocks are slidably connected to the positions, closeto the two ends, of the bottom of the groove of the trolley base, screw holes which are coaxially distributed and opposite in thread direction are formed in the positions, close to the middle, of theopposite sides of the two T-shaped sliding blocks respectively, and the same double-end stud is screwed into the two screw holes. When the device is in use, only one end of the pipe needs to be placedin the first supporting rod when the pipe body needs to be loaded and unloaded, then the other end of the pipe is clamped in the other supporting rod, and the distance between the two supporting rodscan be adjusted by rotating the shifting wheel before transportation so that the device is suitable for pipes with different lengths.

Owner:陶建平

Mining L type steel column shoe

The invention discloses a mining L type steel column shoe. The mining L type steel column shoe comprises a bottom steel plate, a side steel plate and a reinforcing rib steel plate; the bottom steel plate is provided with a cylindrical groove; a monomer hydraulic support column is put in the cylindrical groove to realize a shoe putting-on supporting form, and forms a whole support pressure-resistance buffering structure with the L type steel column shoe; channel steel extending in the vertical direction of the side steel plate is arranged in the middle position of the side steel plate for inserting in an II type steel beam and forming overall connection with the L type steel column shoe; and when a top plate is used for pressing, the pressure of the top plate is buffered by using redundantdisplacement in the connected place of the II type steel beam and the channel steel. The mining L type steel column shoe can be matched with a supporting module to effectively improve the surroundingrock deformation resistance of a gob-side entry retaining overall supporting structure, to reduce the gob-side entry retaining roadway rebuilding cost, to prolong the gob-side entry retaining servicelife, to prevent massive failure of gob-side entry retaining by a no-roadway side dense monomer supporting mode and to guarantee the gob-side entry retaining top plate management safety and reliability.

Owner:LIAONING TECHNICAL UNIVERSITY

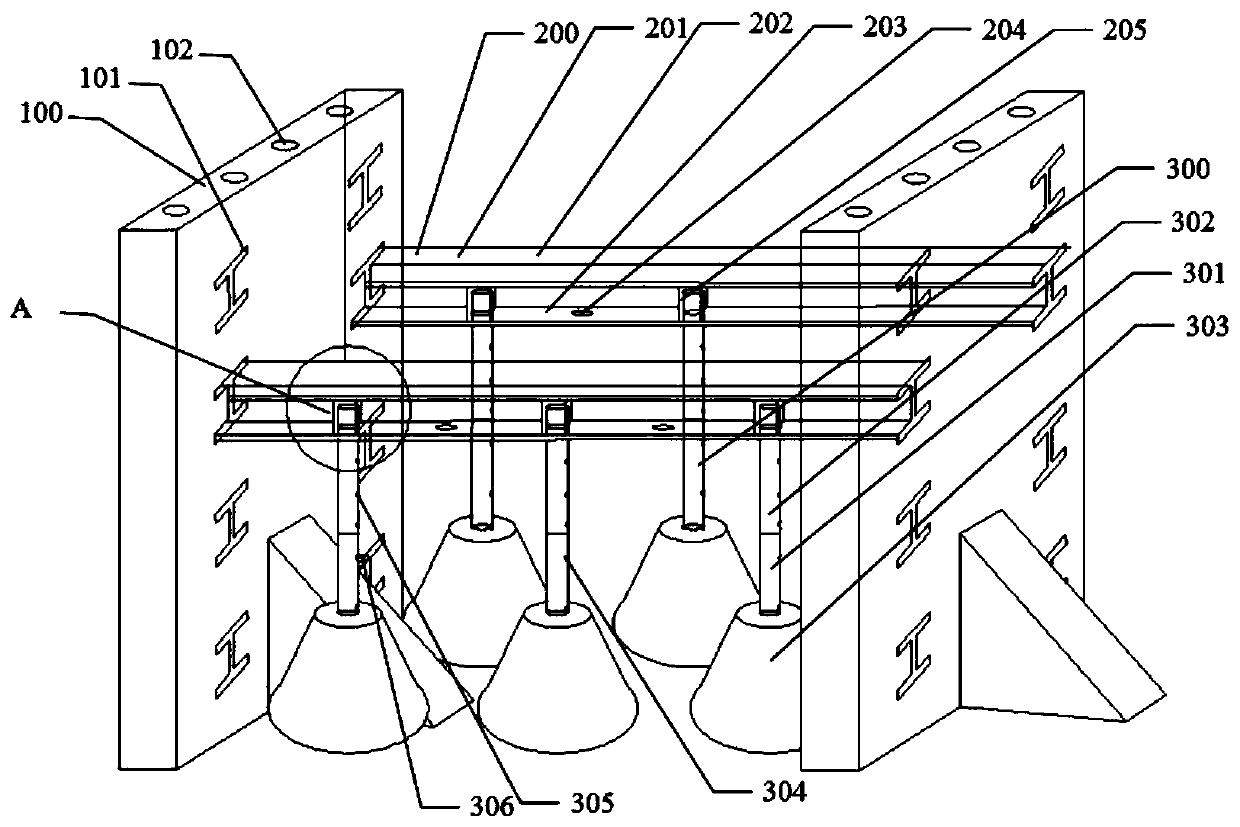

A magnetic fluid double suspension support rail system

ActiveCN106271684BReasonable structureLimit separationLarge fixed membersEngineeringProcessing accuracy

The invention discloses a magnetic fluid dual-suspension guide rail system. A liquid static-pressure and electromagnetic suspension bearing system consists of a static guide rail, static-pressure guide plates, an electromagnet, a permanent magnet, wherein the static-pressure guide plates are of a closed structure and are arranged at the periphery of the static guide rail; a rectangular-ambulatory-plane oil cavity is distributed in the static-pressure guide plate in a vertical direction; a middle entity part of the oil cavity is hollowed and is provided with a groove in which the electromagnet is arranged; the static-pressure guide plates on two sides are of a planar structure; an oil way and an electromagnet cable joint are uniformly distributed on the side static-pressure guide plates; the permanent magnet is distributed in the static guide rail, and the position and direction of the permanent magnet are matched with those of the electromagnet. According to the magnetic fluid dual-suspension guide rail system, oil films are formed between the static-pressure guide plates and the static guide rail, so that the two guide rails are separated, coarse adjustment on the guide rail rigidity is realized, the electromagnet is electrified to generate electromagnetic suspension bearing, and thus fine adjustment on the guide rail rigidity is realized. Compared with the prior art, the magnetic fluid dual-suspension guide rail system has the advantages that the bearing capacity and static rigidity of the guide rail system is increased, and the processing accuracy and the stability are improved.

Owner:YANSHAN UNIV

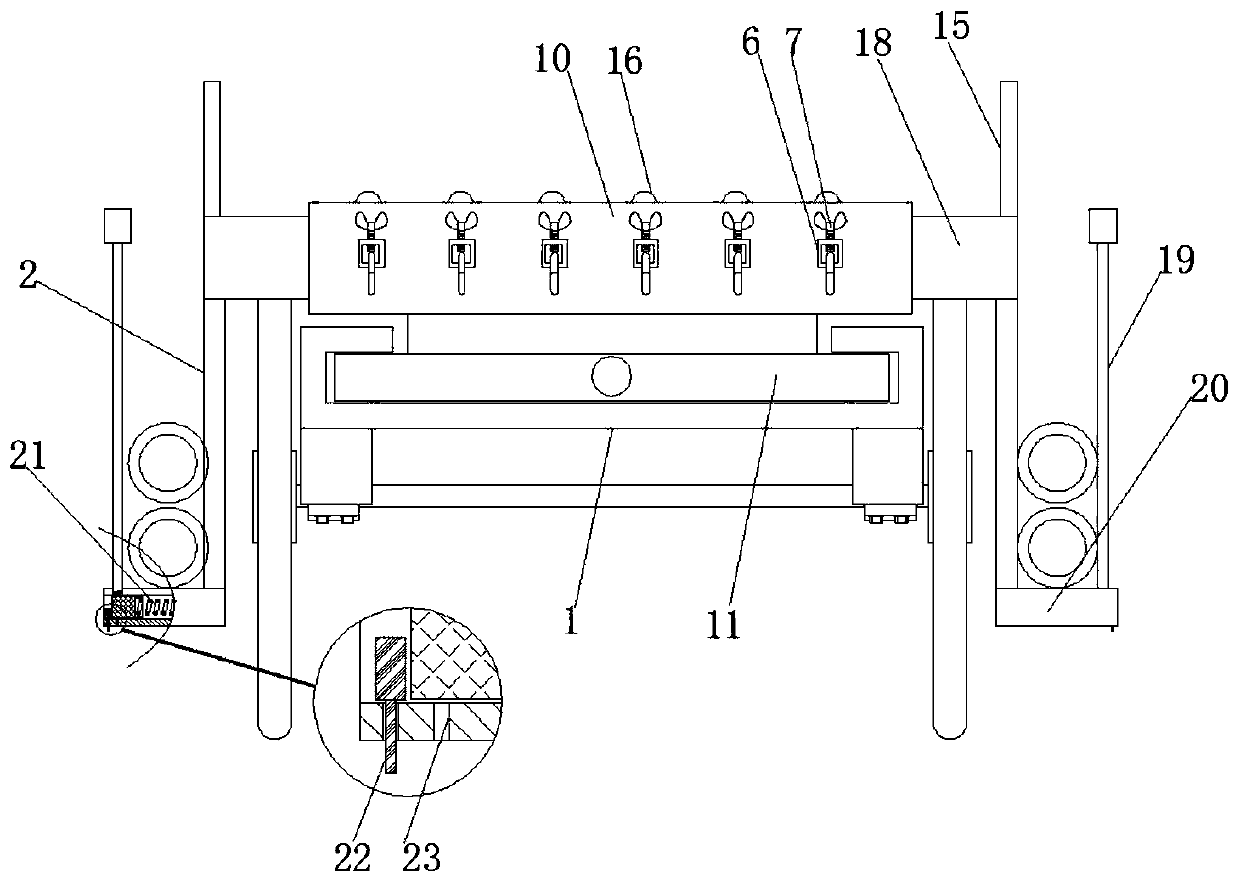

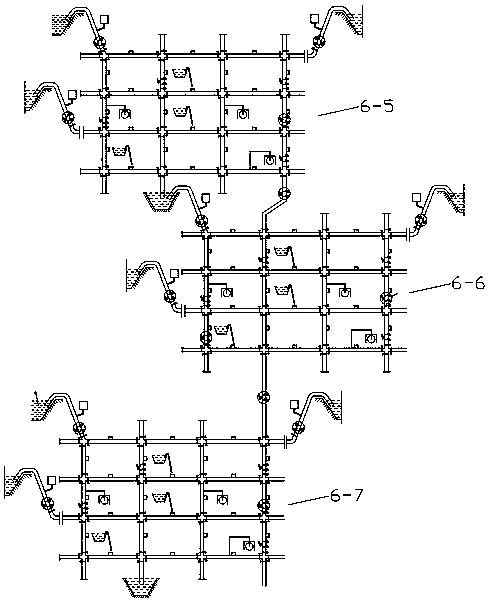

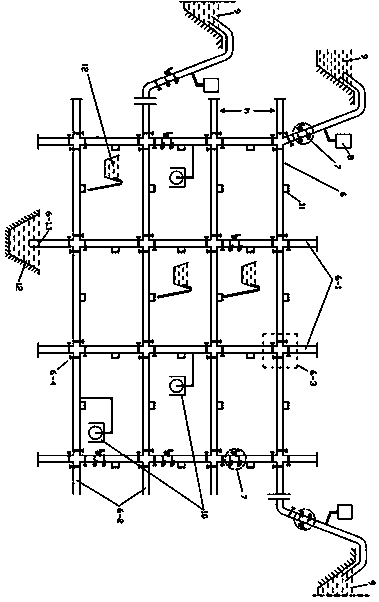

High formwork

ActiveCN107268998BIncrease the effective bearing areaReduce weightAuxillary members of forms/shuttering/falseworksButt jointBearing capacity

The invention discloses a high-supported formwork. The high-supported formwork comprises vertical plates, a horizontal rod and casing pipes, wherein the vertical plates are rectangular plates, a plurality of first fixing holes are uniformly distributed in the two faces of the vertical plates, first through holes extending in the longitudinal direction of the vertical plates are formed inside the vertical plates, the horizontal rod is horizontally arranged between the vertical plates in the mode of being perpendicular to the vertical plates, side wings are arranged on the two edges of the horizontal rod, the side wings, the side wings include upper side wings and lower side wings which are parallel to the upper side wings and are arranged below the upper side wings, second fixing holes are formed in the lower side wings, and U-shaped supporting pieces are arranged between the second fixing holes and the upper side wings; butt-joint pipes are arranged at the two ends of the horizontal rod and matched with the first fixing holes; the casing pipes are perpendicularly arranged at the lower end of the horizontal rod and located between the vertical plates; the casing pipes include an outer casing pipe and an inner casing pipe attached to the inner wall of the outer casing pipe, and a supporting block is arranged at the lower end of the outer casing pipe; a first positioning hole is formed in the outer casing pipe, and a plurality of second positioning holes matched with the first positioning hole are formed in the inner casing pipe. The high-supported formwork is good in stability, high in bearing capacity and high in safety.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

A method for simultaneous friction stir spot welding-brazing-diffusion welding of aluminum and magnesium dissimilar materials

ActiveCN105834608BIncrease the effective bearing areaIncreased tensile and shear capacitySoldering apparatusWelding/soldering/cutting articlesSpot weldingAtomic diffusion

A method for synchronously realizing friction stir spot welding-brazing-diffusion welding of aluminum and magnesium dissimilar materials. Both sides of the blank are respectively in contact with the aluminum plate and the magnesium plate. Friction stir spot welding is performed on the fixed overlapping structure. During the welding process, on the one hand, the friction stir spot welding of the aluminum plate and the magnesium plate is realized through the action of the stirring pin on the stirring head and the plate below; Under the action of heat generated by shaft shoulder friction and forging pressure, the temperature in the area close to the stirring pin is high, the brazing sheet melts, and a brazed connection is formed between the aluminum plate and the magnesium plate; Under the action of heat, atomic diffusion occurs between aluminum plate / solder sheet and magnesium plate / solder sheet to form diffusion welding. The invention can form brazing and diffusion welding joints at the same time of friction stirring spot welding, increase the effective bearing area of solder joints, and improve the tensile shear force of the joints.

Owner:NANCHANG HANGKONG UNIVERSITY

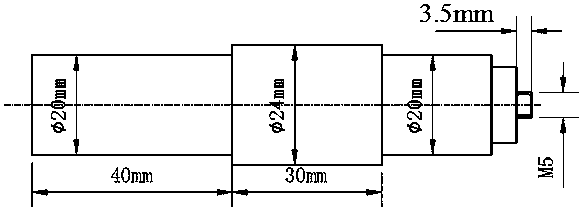

A non-equal-diameter welded butt joint aluminum alloy pipe

ActiveCN103521898BIncrease the effective bearing areaImprove welding strengthArc welding apparatusAnti-corrosive paintsPipeHeat treated

The invention relates to a non-equal-diameter welded butt joint aluminum alloy pipe. According to the diameter of the aluminum alloy pipe, an aluminum alloy pipe joint with a diameter slightly larger than the diameter of the pipe is processed. hole, the center line of the grooved through hole is perpendicular to the axis of the pipe joint, and the distance between two adjacent grooved through holes is not less than the hole length of each grooved through hole; A 50-60° bevel is processed on the inner surface of both ends; then the above-mentioned ends and grooved through holes are welded respectively, and then the pipe joint is subjected to local heat treatment, and finally an anti-corrosion coating is prepared and applied to the pipe joint. The invention has simple operation and implementation, and is easy to be popularized in industry.

Owner:广西中强铝业科技有限公司

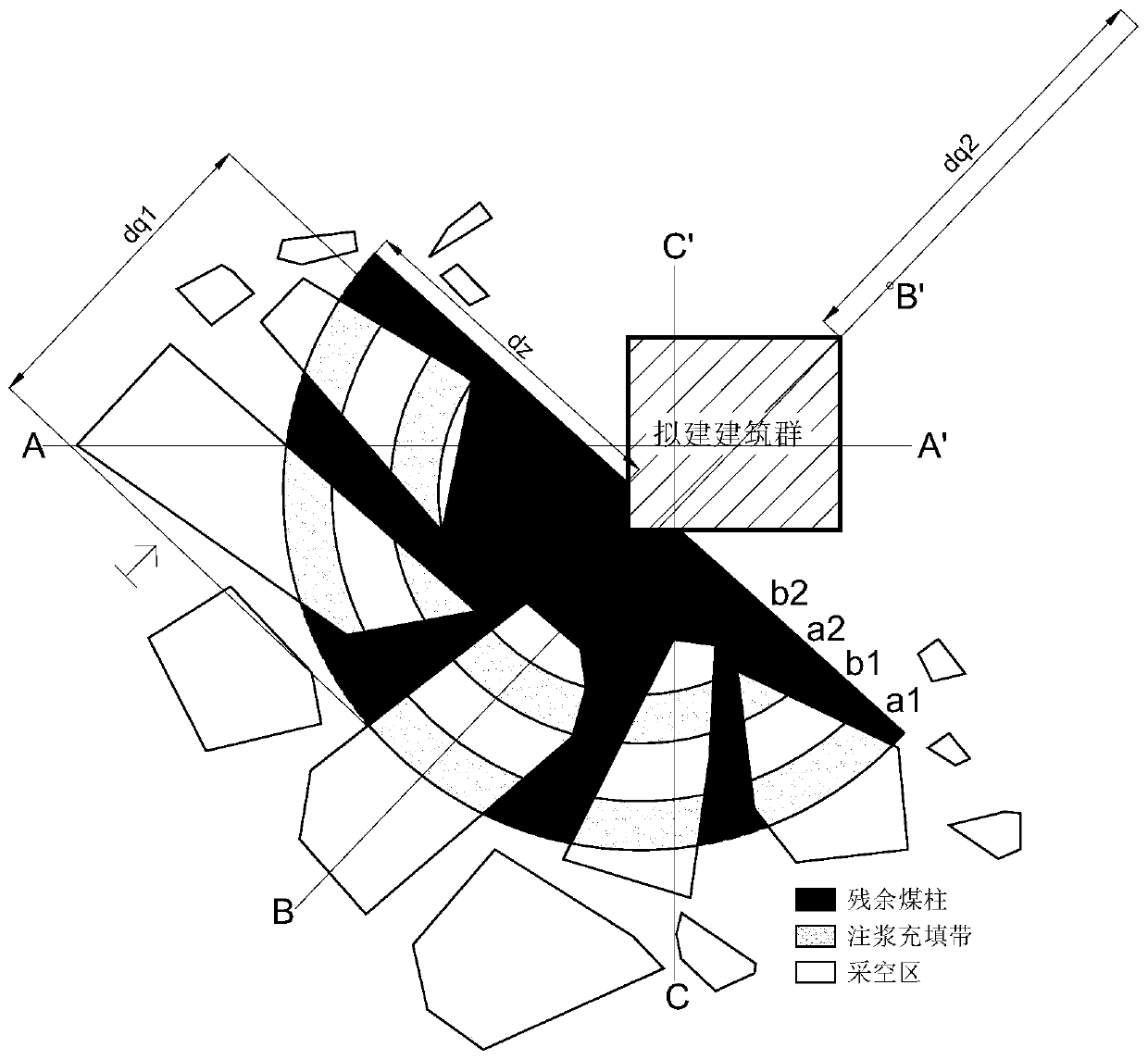

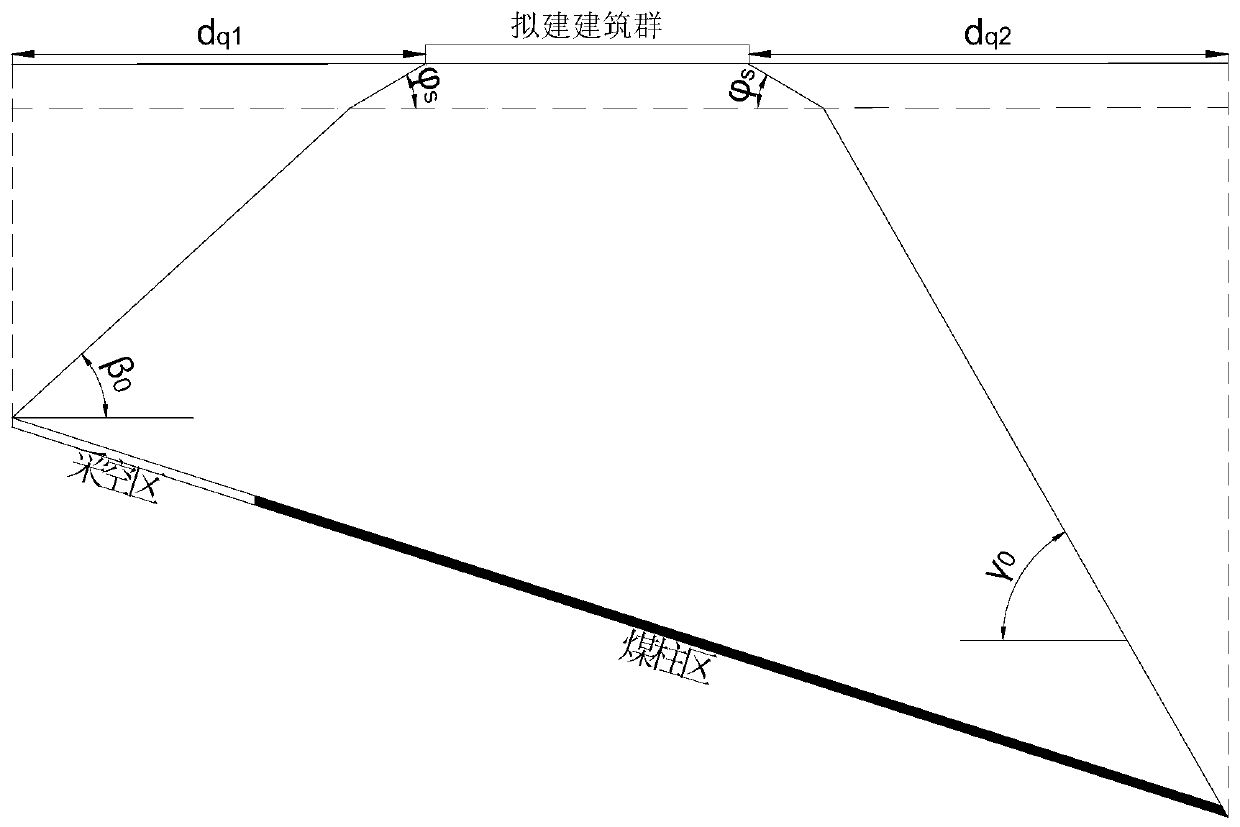

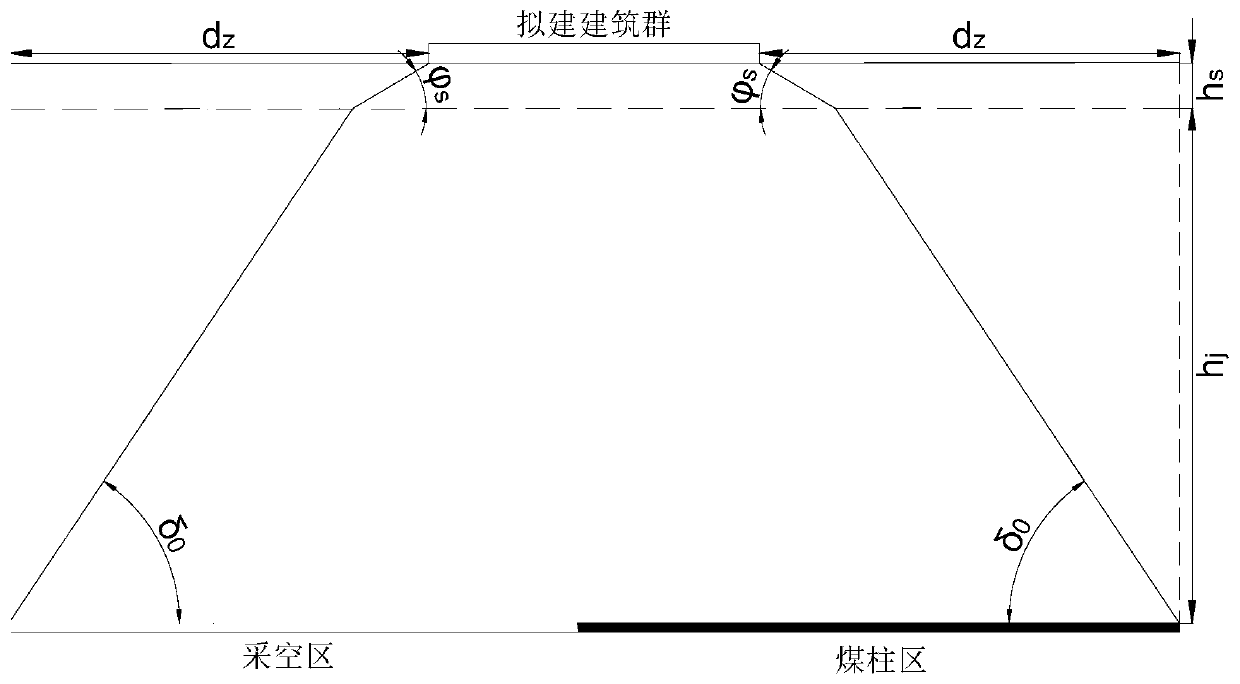

Grouting filling method in irregular mined-out area

ActiveCN109899109BIncrease the effective bearing areaImprove integrityMaterial fill-upArchitectural engineeringStructural engineering

The invention discloses a grouting and filling method in an irregular mined-out area. The grouting and filling method in the irregular mined-out area comprises the steps that firstly, a to-be-built building group is taken as a protected object, and the governance range of the mined-out area is determined according to boundary angles; secondly, a plurality of grouting and filling belts are arrangedin the governance range at intervals, and the grouting and filling belts are in annular or arc shapes; and thirdly, grouting is conducted on the positions of the grouting and filling belts through grouting devices, and the filling body formed by grouting and coal columns in the mined-out area commonly form a structural support. According to the grouting and filling method in the irregular mined-out area, the problems that in the prior art, in terms of the grouting and filling method in the irregular mined-out area, the governance cost is high, the potential danger that the coal column is instable and the ground sinks suddenly, and the sinking-reducing effect is difficult to ensure are effectively solved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

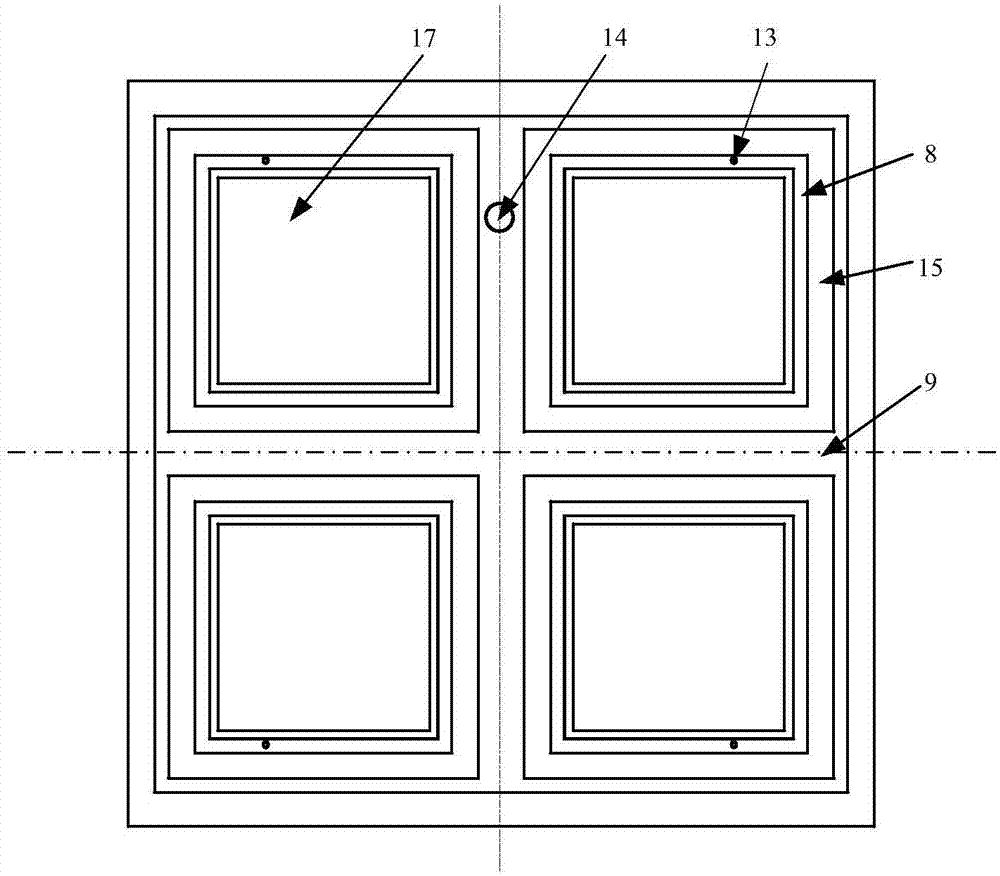

Hydrostatic-permanent magnet dual-suspension bearing guide rail system

InactiveCN107398739AReasonable structureImprove carrying capacityLarge fixed membersChinese charactersMagnetic poles

A static pressure-permanent magnetic double suspension support guide rail system is composed of two sets of support systems: a permanent magnetic suspension system and a hydrostatic pressure system. The four bar-shaped grooves on the top and bottom of the existing guide rail are equipped with permanent magnet strips that are installed side by side and have opposite magnetic pole directions of the two adjacent permanent magnet strips. There are four identical rectangular oil inlet chambers on the inner side of the upper and lower static pressure guide plates, and a connected Tianzi-shaped oil return chamber A is arranged around the four oil inlet chambers. Grooves are arranged in the middle entities of the four oil inlet chambers, and permanent magnet strips are arranged in parallel in each groove. These permanent magnet strips are all opposite to the permanent magnet strips on the guide rail grooves and have the same magnetic poles. The static pressure guide plates on both sides are provided with a rectangular oil inlet chamber and a Japanese-shaped oil return chamber, and the oil pipe joints and fastening screws are all arranged on the static pressure guide plates on both sides. The invention can increase the bearing capacity and static rigidity of the guide rail system, and improve the machining accuracy and stability of workpieces.

Owner:YANSHAN UNIV

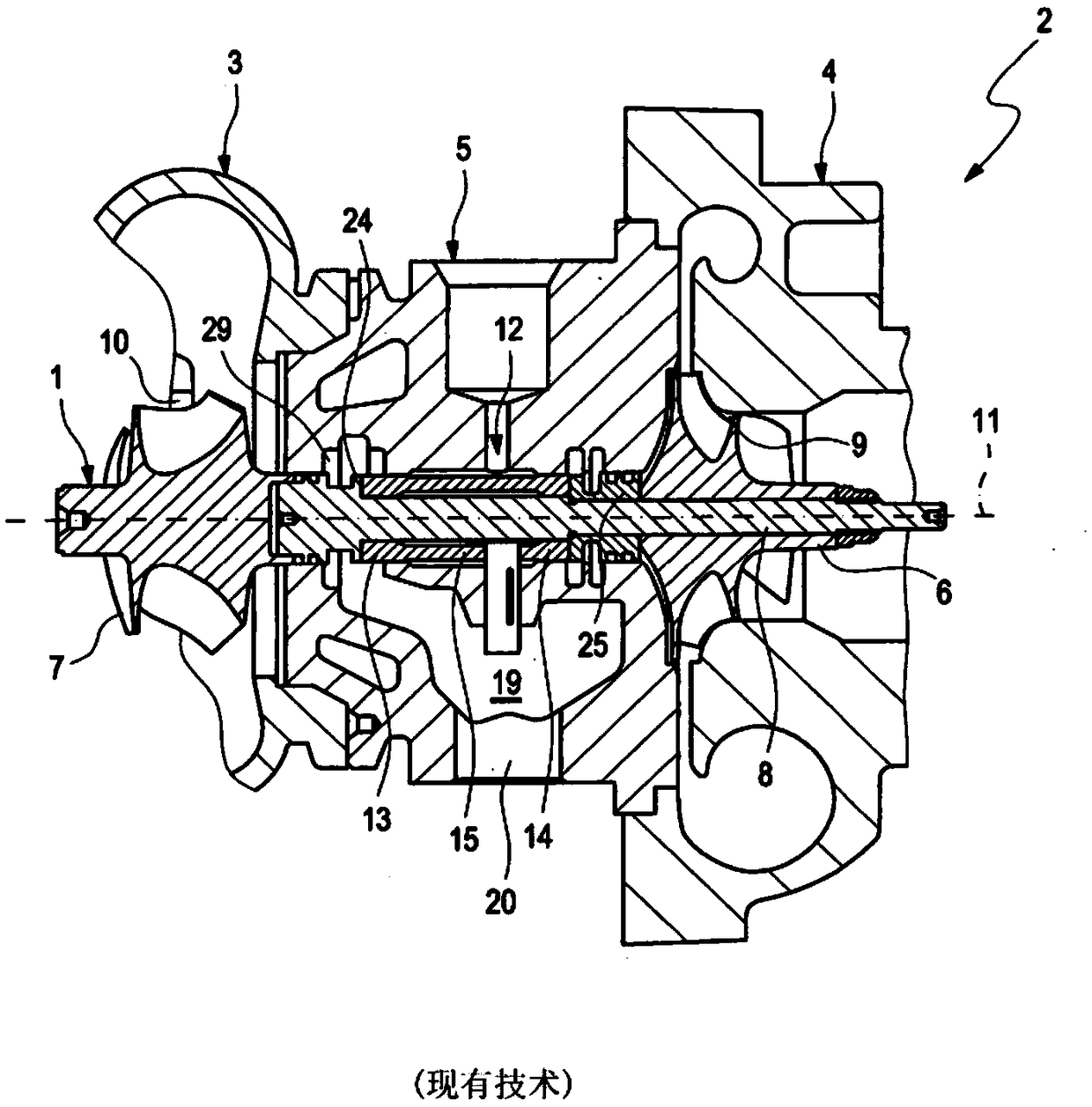

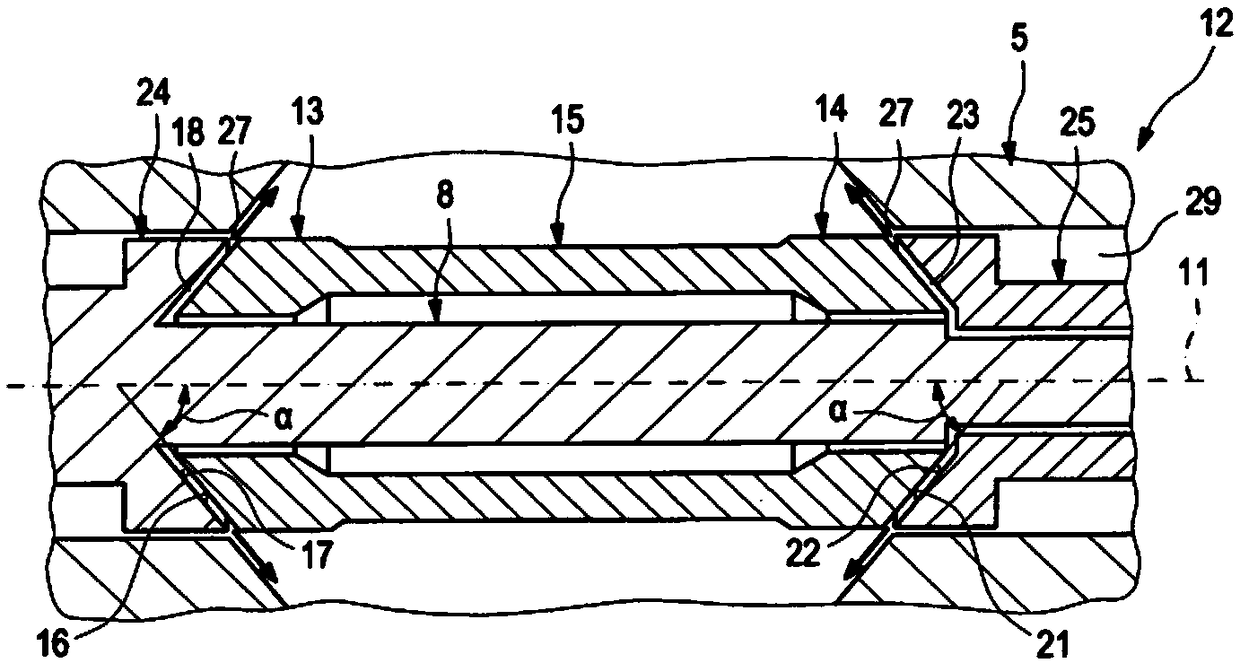

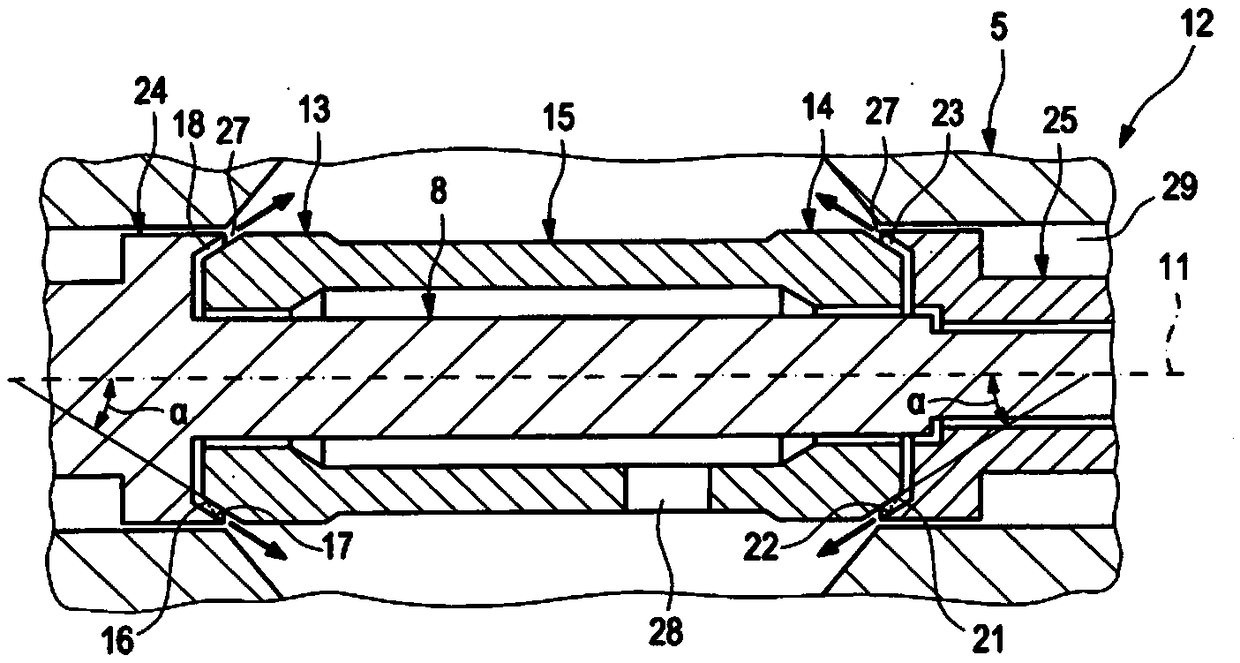

Bearing device for an exhaust gas turbocharger, and exhaust gas turbocharger

The invention relates to a bearing device for an exhaust gas turbocharger, having a first radial bearing (13) and a second radial bearing (14), wherein the radial bearings (13, 14) are configured forradially mounting a shaft (8) of the exhaust gas turbocharger (2) with a rotational axis (11), and wherein a first outflow gap (18) and a second outflow gap (23), respectively, are configured betweenthe first radial bearing (13) and a first supporting wall (17) of the exhaust gas turbocharger (2) for axially supporting the first radial bearing (13), which first supporting wall (17) extends radially and is configured so as to face a turbine wheel (7) of the exhaust gas turbocharger (2), and between the second radial bearing (14) and a second supporting wall (22) of the exhaust gas turbocharger(2) for axially supporting the second radial bearing (14), which second supporting wall (22) extends radially and is configured so as to face a compressor impeller (6) of the exhaust gas turbocharger(2). According to the invention, for axial and simultaneous radial bearing and / or for supporting the radial bearing, the first outflow gap (18) and / or the second outflow gap (23) are / is configured soas to be inclined or curved with respect to the rotational axis (11) at least partially with the configuration of an angle (alpha) which is greater than or less than 90 DEG.

Owner:IHI CHARGING SYST INT +1

Bearing structure, mechanical part and construction device

PendingCN109210363AIncrease the effective bearing areaReduce the bearing stress of the sectionConstructions elementsEngineeringWeld seam

The invention discloses a bearing structure, a mechanical part and a construction device, and relates to the technical field of bearing. The bearing structure comprises a basic member, a bearing partand recess cavities, the basic member includes a first surface, the bearing part includes second and third surfaces arranged opposite to each other, the bearing part is connected to the basic member via surface-surface connection between the second and first surfaces, and the multiple recess cavities extending towards the first surface are arranged in at least part of the third surface at interval. Compared with a present weld seam, the surface-surface connection area can be increased substantially, a bearing force is higher, and under the same load condition, the maximal stress peak of the bearing structure is lower, the possibility of risk is lower, and the bearing structure is safer; and the recess cavities are arranged so that the bearing force can be diffused and distributed to wallsof the recess cavities, the load force is easier to bear, the safety of the bearing structure is improved, the weight of the bearing part can be reduced, and the cost is reduced.

Owner:ZOOMLION HEAVY IND CO LTD

Power generation network system composed of siphon network

InactiveCN109441699AEfficient use ofEfficient conversionHydro energy generationSafety/regulatory devicesTerrainSiphon

The invention relates to a power generation network system composed of a siphon network. The power generation network system aims to solve the defects, caused by dam construction of hydropower stations, of large investment, long construction period and low utilization rate of water resources in the prior art. The power generation network system comprises water sources at different altitudes, siphon water diversion power generation devices, water reservoirs at different altitudes, connector bolts, easy-to-build easy-to-control siphon pumps, water transportation pipe networks and siphon water transfer valves. The easy-to-build easy-to-control siphon pumps suck and deliver water in the water sources at different altitudes to the water transportation pipe networks by using the siphon principle, and the siphon water diversion power generation devices can be driven to generate power by using the terrain differences of the water transportation pipe networks. The power generation network system composed of the siphon network has the beneficial effects that the high-efficiency utilization of the water resources and the high-efficiency conversion of potential energy are realized, one pipe network has a plurality of functions such as flood control, irrigation and power generation, the power generation network system is not affected by dry seasons and wet seasons, and the potential energyconversion effect is good.

Owner:SHENZHEN PUFANG ENVIRONMENTAL PROTECTION DEV

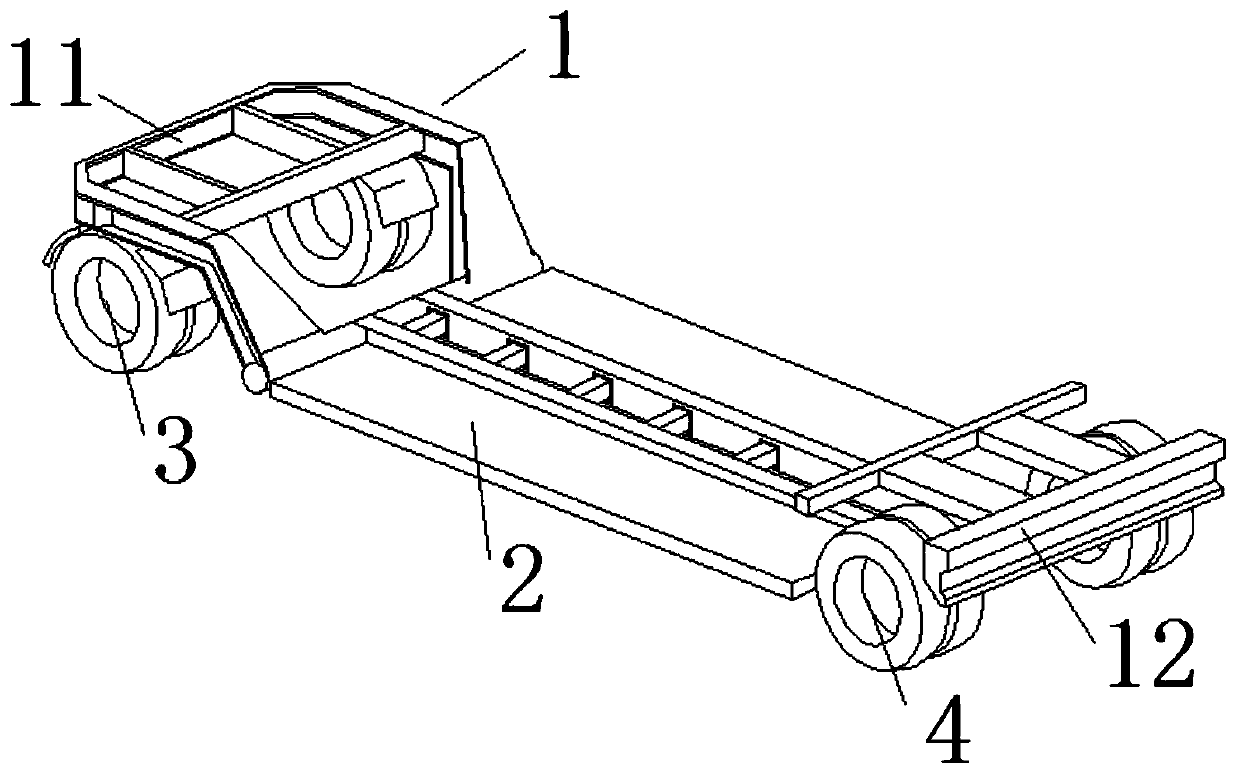

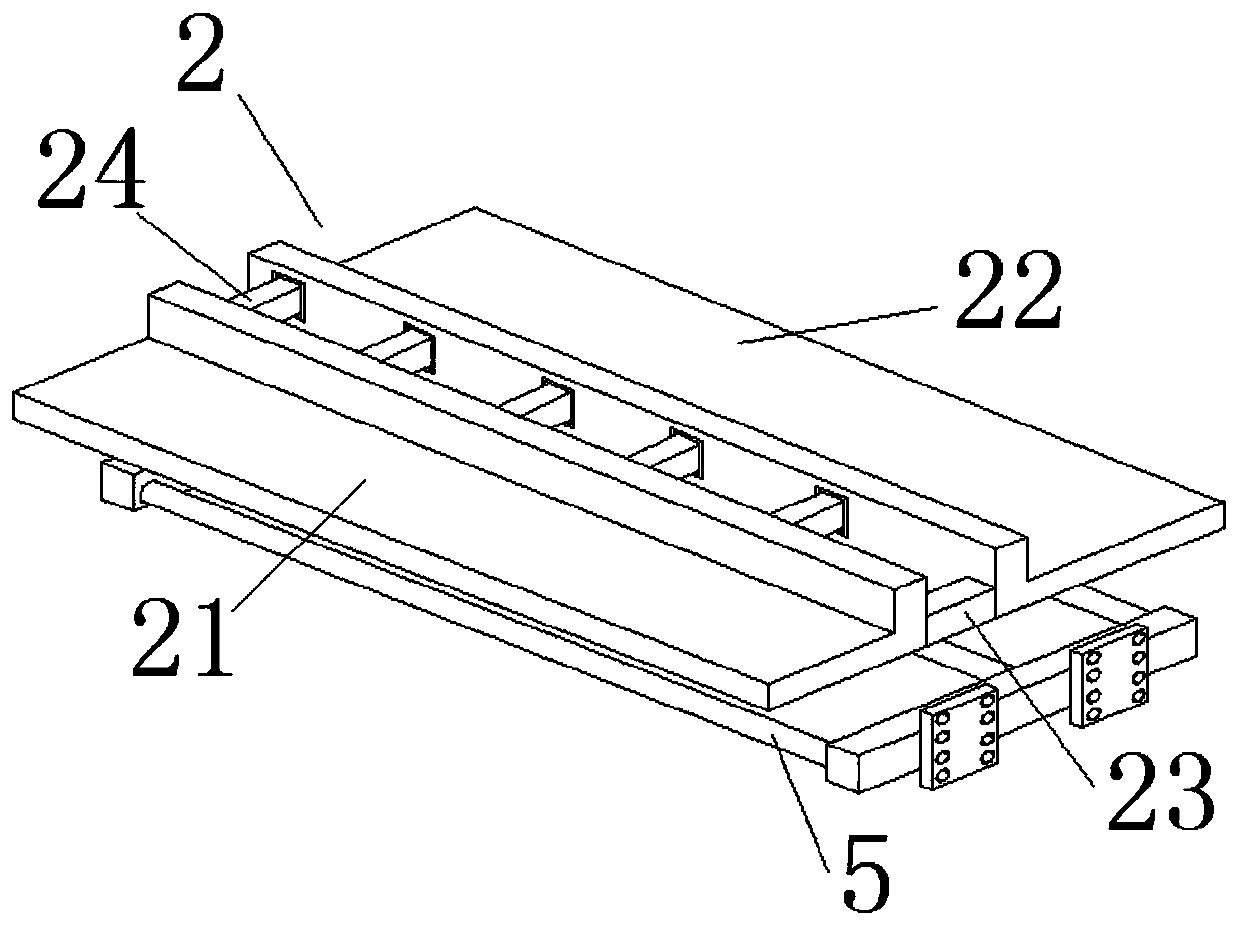

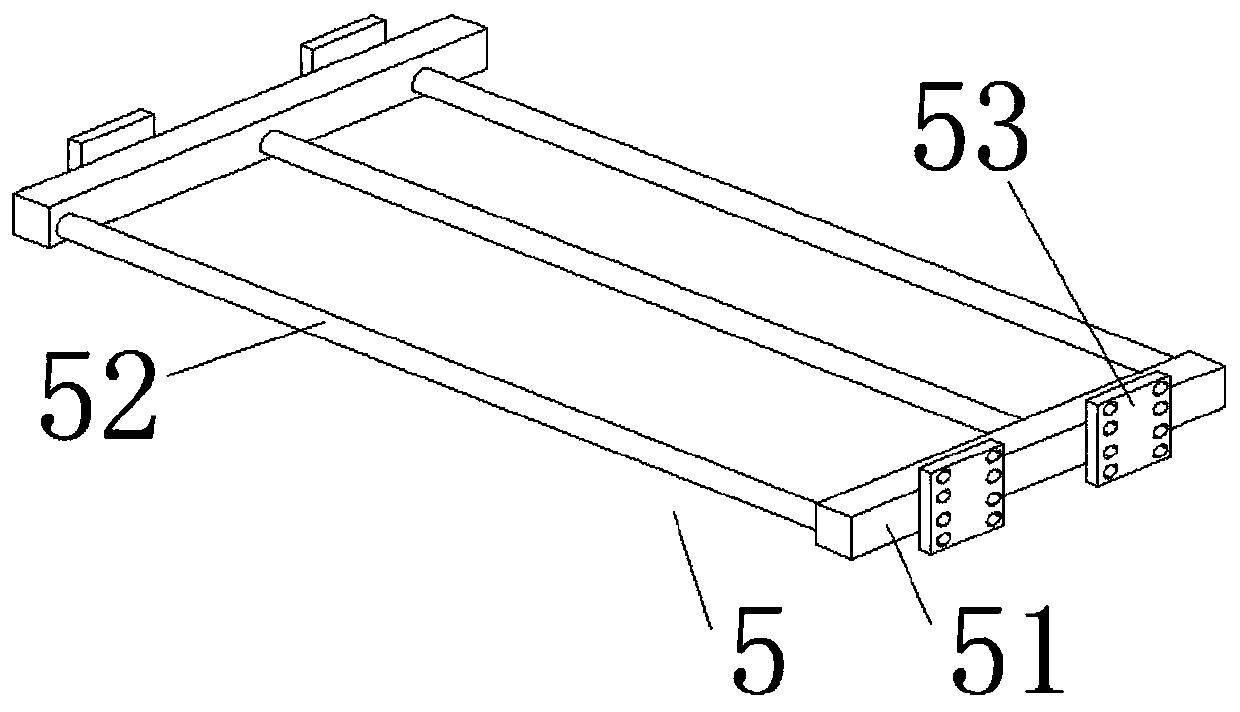

a tractor trailer

The invention discloses a towing vehicle. The towing vehicle comprises a main frame and a loading plate, wherein the main frame comprises a front vehicle frame and a rear vehicle frame; the loading plate is arranged between the front vehicle frame and the rear vehicle frame; a fixing rack is arranged under the loading plate; two ends of the fixing rack are respectively fixed on the front vehicle frame and the rear vehicle frame; the loading plate comprises a left plate body and a right plate body; and sliding rails are respectively arranged at the front end and the rear end of the left plate body and the right plate body. The towing vehicle is simple in structure and convenient to use. The loading surface of the towing vehicle can be regulated, and the loading capacity can be changed; andbesides, the regulating process is simple, rapid and easy to operate, and change can be quickly made on a spot, so that regulating operation is convenient and quick. The towing vehicle is high in practicality and convenient to popularize.

Owner:安徽富林农业机械装备有限公司

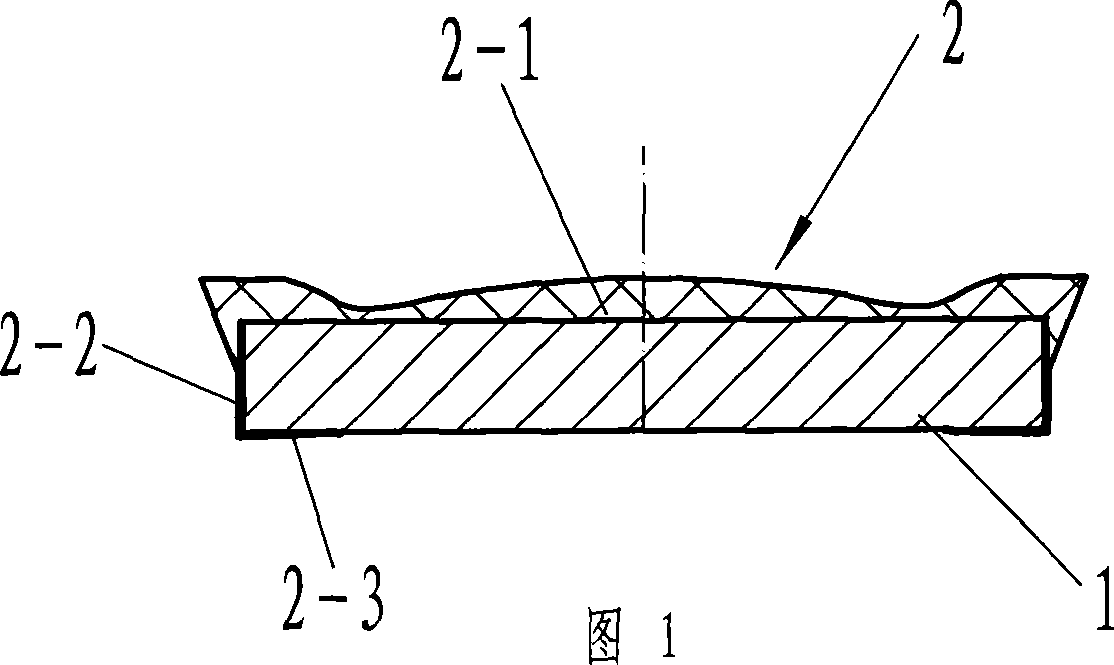

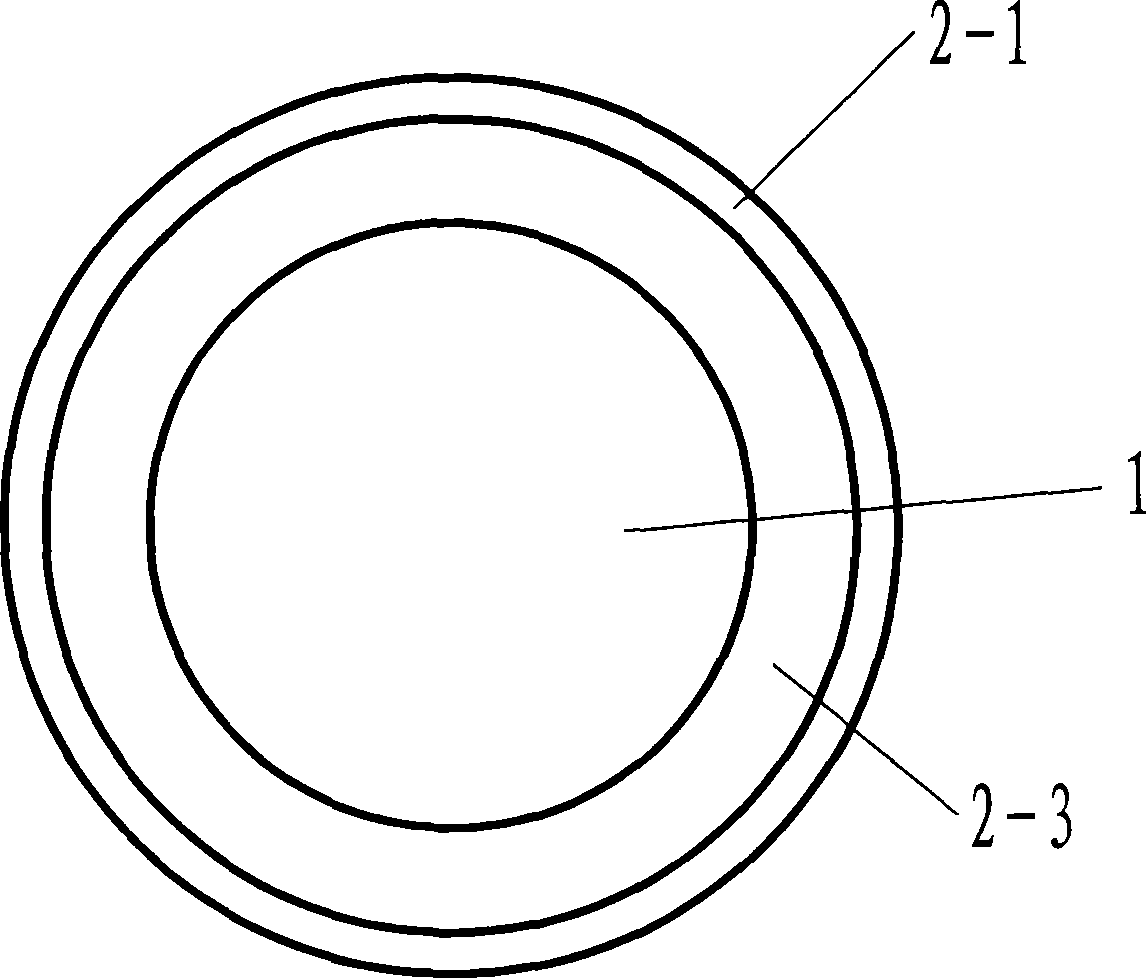

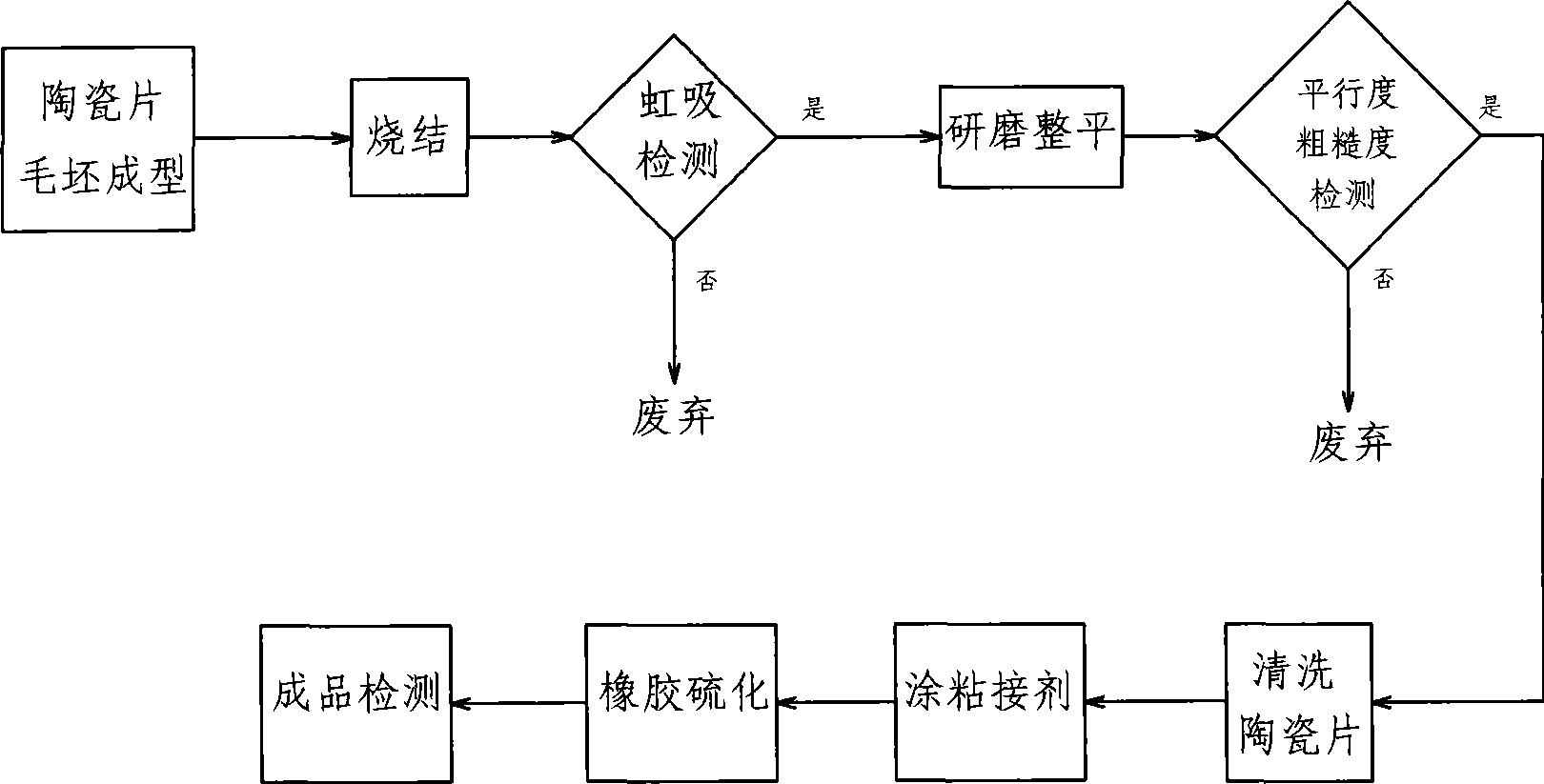

Gun perforation block cap of oil well perforator and producing method thereof

InactiveCN101435325AImprove pressure resistanceSmall particlesAdhesive processesFluid removalVulcanizationMetallic materials

The invention relates to a ceramic perforation blanking cover of an oil well perforator and a production method thereof. The improvement of the invention is that a metal wafer in the existing perforation blanking cover is replaced with a ceramic part by utilizing the characteristics of ceramic of good bursting performance, easy frangibility, high hardness and the like so that the perforation blanking cover bursts into a large number of fragments in a perforation, the particles of the ceramic fragments are small, the hardness is high, and the capacity of penetrating rock strata and the penetrating area are greatly improved so as to lead the perforation effect to be greatly improved. The production method is characterized in that the grinding procedures of ceramic wafers are increased so that the ceramic wafers are ground to be level in the process and the effective pressure bearing area in vulcanization is enlarged, meanwhile, certain roughness of the surface is ensured in grinding so that the ceramic wafers are not crushed and can be stuck fixedly in the subsequent rubber vulcanization hot moulding process. Therefore, the problem that the blanking cover is easy to be crushed in vulcanization moulding process is solved, the yield is greatly improved and metal material is replaced with ceramic material.

Owner:冯锋

Force-bearing disk squeezing and expanding machine

InactiveCN101130977BIncrease the bearing areaLarge thrustFluid-pressure actuatorsBulkheads/pilesHydraulic cylinderSystem pressure

The present invention provides one kind of bearing disc extruding and expanding machine comprising one support, one forming mechanism and one hydraulic cylinder. The forming mechanism includes two sets of arched pressing arms set axially symmetrically hinged to the support and driven by the hydraulic cylinder, and each of the arched pressing arm set consists of one pair of branch arms. The hydraulic cylinder includes one cylinder, one first piston assembly reciprocating axially inside the cylinder and one second piston assembly reciprocating relatively to the first piston assembly, with the second piston assembly possessing one piston rod penetrating the piston of the first piston assembly. The bearing disc extruding and expanding machine has forming mechanism with obviously raised extruding and expanding capacity.

Owner:韩顺和 +1

Welding connection method for aluminum alloy pipelines of different diameters

ActiveCN103464915BIncrease the effective bearing areaImprove welding strengthWelding apparatusHeat treatingAluminium alloy

The invention relates to a welding connection method for aluminum alloy pipes with different diameters. According to the diameter of the aluminum alloy pipes, an aluminum alloy pipe joint with a diameter slightly larger than the diameter of the pipe is processed, and several grooves are respectively opened along the circumferential direction on both sides of the pipe joint. hole, the center line of the grooved through hole is perpendicular to the axis of the pipe joint, and the distance between two adjacent grooved through holes is not less than the hole length of each grooved through hole; A 50-60° bevel is processed on the inner surface of both ends; then the above-mentioned ends and grooved through holes are welded respectively, and then the pipe joint is subjected to local heat treatment, and finally an anti-corrosion coating is prepared and applied to the pipe joint. The invention can be used to connect aluminum alloy pipes of different diameters in any size, and has simple operation and implementation, and is easy to be popularized in industry.

Owner:东和管道科技(江苏)有限公司

Welding connection method of aluminum-alloy pipelines of same diameter

ActiveCN103464914BIncrease the effective bearing areaImprove welding strengthWelding apparatusEngineeringStructural engineering

The invention relates to a welding connection method for aluminum alloy pipes with the same diameter. According to the diameter of the aluminum alloy pipe, a section of aluminum alloy pipe with a diameter slightly larger than the diameter of the pipe to be connected is selected or processed as a pipe joint. A number of groove-shaped through holes are respectively opened along the circumferential direction on both sides. The center line of the groove-shaped through-hole is perpendicular to the axis of the pipe joint, and the distance between two adjacent groove-shaped through-holes is not less than the hole of each groove-shaped through-hole length; then process a 50-60° bevel on the inner surface of the two ends of the pipe joint; then weld the above-mentioned ends and grooved through holes respectively, and then perform local heat treatment on the pipe joint, and finally prepare an anti-corrosion coating at the pipe joint. The invention has simple operation and implementation, and is easy to be popularized in industry.

Owner:南通百业工具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com