Welding connection method for aluminum alloy pipelines of different diameters

A welding connection, aluminum alloy technology, applied in the direction of welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of reduced mechanical properties, large expansion coefficient, harmful performance, etc., to increase the effective bearing area, improve welding strength, Operation implements simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

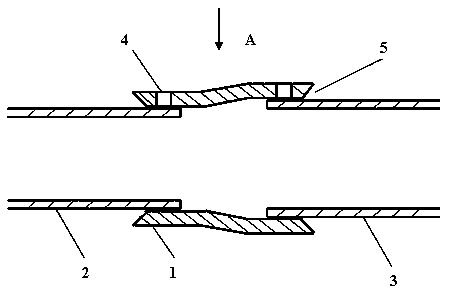

[0041] In this embodiment, the base materials are the aluminum alloy tube 2024 of φ208×4mm and the aluminum alloy tube 2024 of φ226×4mm, and the following steps are performed:

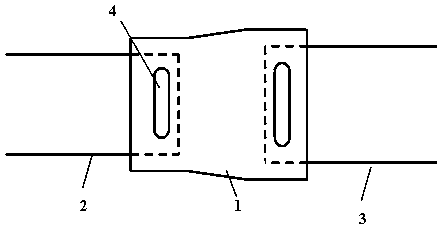

[0042] (1) According to the size of the two aluminum alloy pipes, machined aluminum alloy pipe joints with diameters at both ends matching the diameters of the two aluminum alloy pipes. On both sides of the pipe joints, three equally spaced grooves are opened in the circumferential direction. Through hole, the slot center line of the slot-shaped through hole is perpendicular to the axis of the pipe joint, and the distance between two adjacent slot-shaped through holes is not less than the hole length of each groove-shaped through hole; The inner surface of the two ends of the machine has a groove of 60°;

[0043] (2) First use acetone to remove all oil stains on the pipe joints and aluminum alloy pipe end surfaces, groove-shaped through-hole hole walls, groove-shaped through-holes and the joint surface of t...

Embodiment 2

[0064] In this embodiment, the base materials are the aluminum alloy tube 2024 of φ208×4mm and the aluminum alloy tube 2024 of φ226×4mm, and the following steps are performed:

[0065] (1) According to the size of the two aluminum alloy pipes, machined aluminum alloy pipe joints with diameters at both ends matching the diameters of the two aluminum alloy pipes, and 4 equidistant grooves are respectively opened in the circumferential direction on both sides of the pipe joints Through hole, the slot center line of the slot-shaped through hole is perpendicular to the axis of the pipe joint, and the distance between two adjacent slot-shaped through holes is not less than the hole length of each groove-shaped through hole; The inner surface of the two ends of the machine has a groove of 50°;

[0066] (2) First use acetone to remove all oil stains on the pipe joints and aluminum alloy pipe end surfaces, groove-shaped through-hole hole walls, groove-shaped through-holes and the joint surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com