Preparation method for porous copper-based shape memory alloy-based damping composite material

A technology of damping composite material and memory alloy, which is applied in the field of damping material manufacturing, can solve problems such as deteriorating the mechanical properties of materials, and achieve the effect of good contact and improved contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

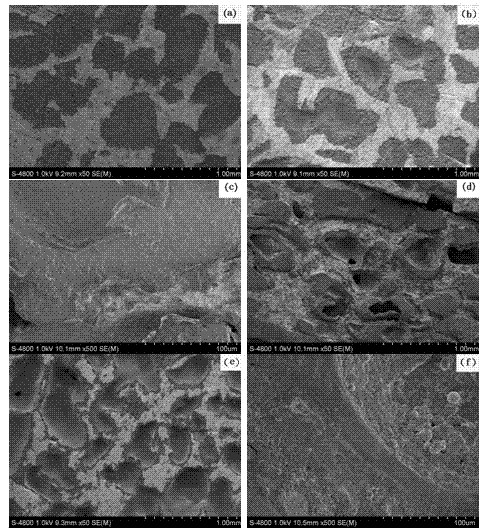

[0029] The first step, pretreatment of porous CuAlMn shape memory alloy samples

[0030] Firstly, under the protection of high-purity argon, the quenched porous CuAlMn shape memory alloy sample was thermally cycled 5 times in the temperature range from room temperature to 350 °C, then placed in an ultrasonic cleaner, cleaned with deionized water for 20 minutes, and then washed with anhydrous Wash with ethanol for 20 minutes until the stains adhered to the outer surface of the porous CuAlMn shape memory alloy sample and the inner surface of the hole are removed;

[0031] The second step, the preparation of polystyrene-2-methyltetrahydrofuran solution

[0032]First, polystyrene: 2-methyltetrahydrofuran=1:4 according to the mass ratio, get the required amount of 2-methyltetrahydrofuran solvent, weigh the polystyrene of the proportioning amount at the same time, then put the weighed polystyrene Mix ethylene and 2-methyltetrahydrofuran solvent, and stir with a magnetic stirrer for...

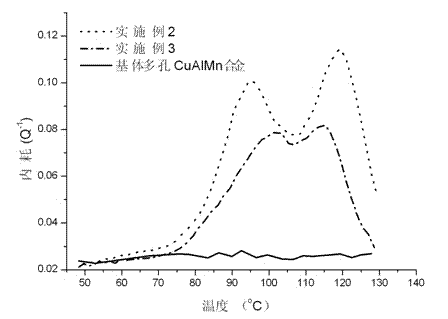

Embodiment 2

[0038] The first step, pretreatment of porous CuAlMn shape memory alloy samples

[0039] First, under the protection of high-purity argon, the quenched porous CuAlMn shape memory alloy sample was thermally cycled 5 times in the temperature range from room temperature to 350 °C, then placed in an ultrasonic cleaner, cleaned with deionized water for 25 minutes, and then washed with anhydrous Wash with ethanol for 25 minutes until the stains adhered to the outer surface of the porous CuAlMn shape memory alloy sample and the inner surface of the hole are removed;

[0040] The second step, the preparation of polystyrene-2-methyltetrahydrofuran solution

[0041] First, polystyrene: 2-methyltetrahydrofuran=1:5 according to the mass ratio, take the required amount of 2-methyltetrahydrofuran solvent, weigh the polystyrene of the proportioning amount at the same time, then put the weighed polystyrene Mix ethylene and 2-methyltetrahydrofuran solvent, and stir with a magnetic stirrer for...

Embodiment 3

[0049] The first step, pretreatment of porous CuAlMn shape memory alloy samples

[0050] First, under the protection of high-purity argon, the quenched porous CuAlMn shape memory alloy sample was thermally cycled 6 times in the temperature range from room temperature to 350 °C, then placed in an ultrasonic cleaner, cleaned with deionized water for 25 minutes, and then washed with anhydrous Wash with ethanol for 25 minutes until the stains adhered to the outer surface of the porous CuAlMn shape memory alloy sample and the inner surface of the hole are removed;

[0051] The second step, the preparation of polystyrene-2-methyltetrahydrofuran solution

[0052] First, polystyrene: 2-methyltetrahydrofuran=1:6 according to the mass ratio, get the required amount of 2-methyltetrahydrofuran solvent, weigh the polystyrene of the proportioning amount at the same time, then put the weighed polystyrene Mix ethylene and 2-methyltetrahydrofuran solvent, and stir with a magnetic stirrer for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com