A magnetic fluid double suspension support rail system

A technology of rail system and support system, which is applied in the field of machine tool rails to achieve the effects of improving poor machining accuracy, increasing effective bearing area and increasing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

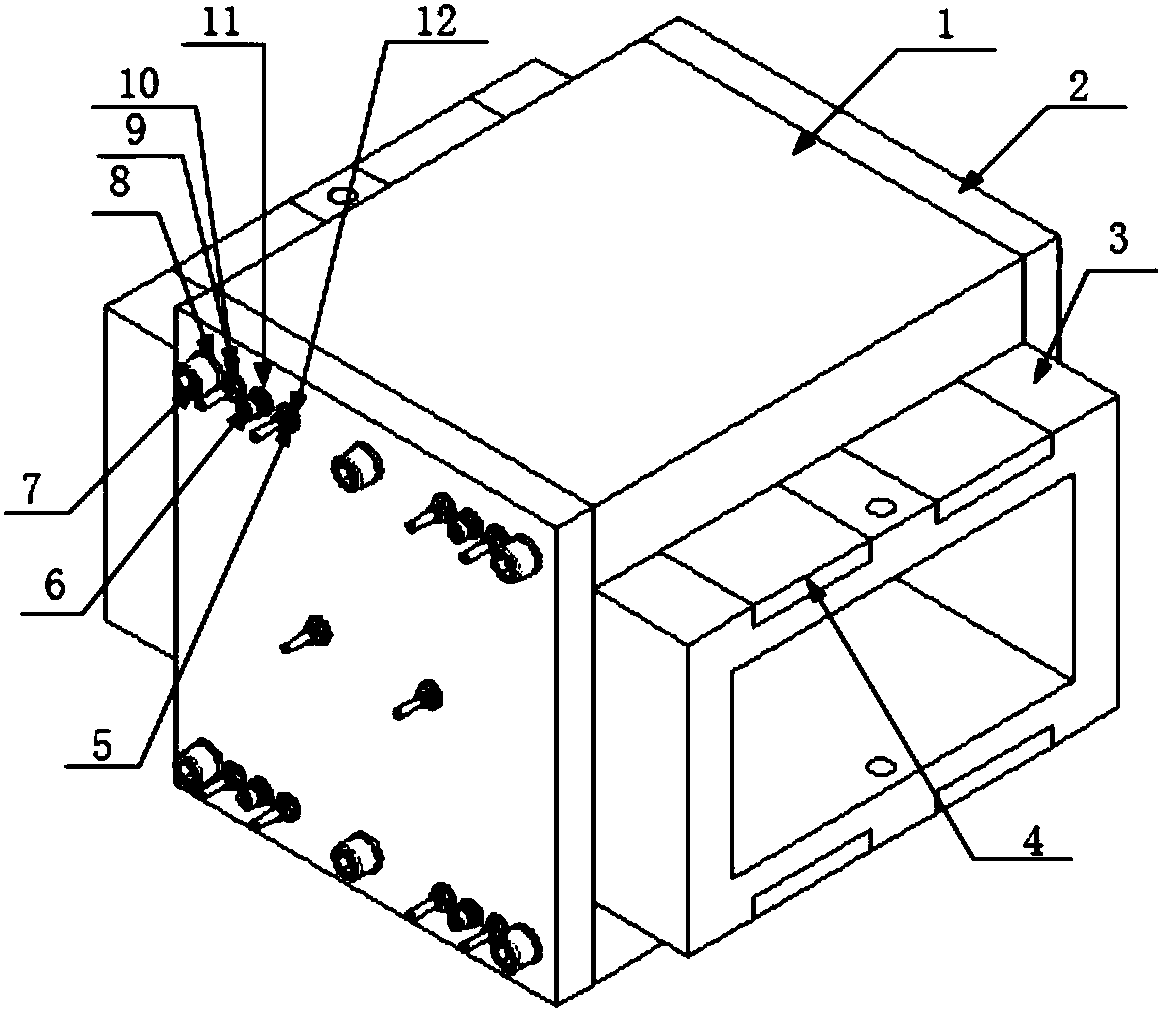

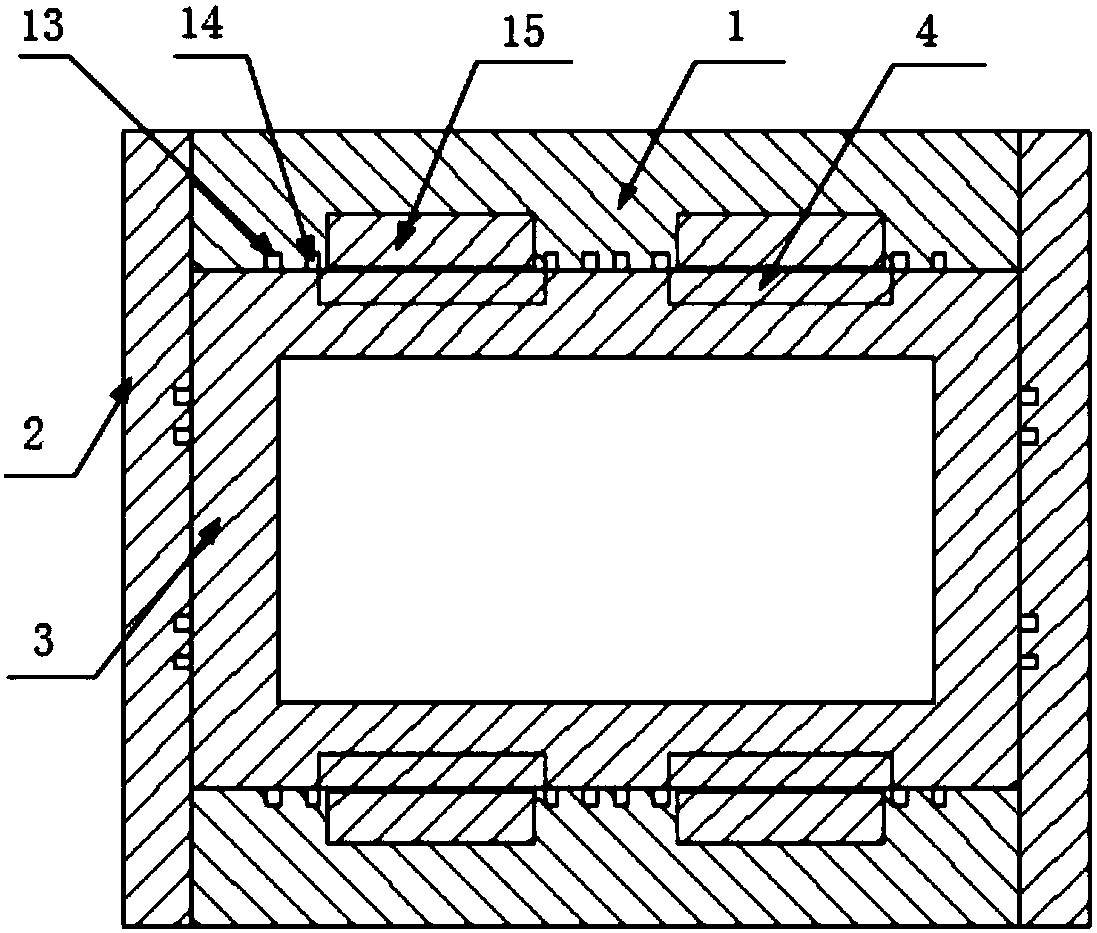

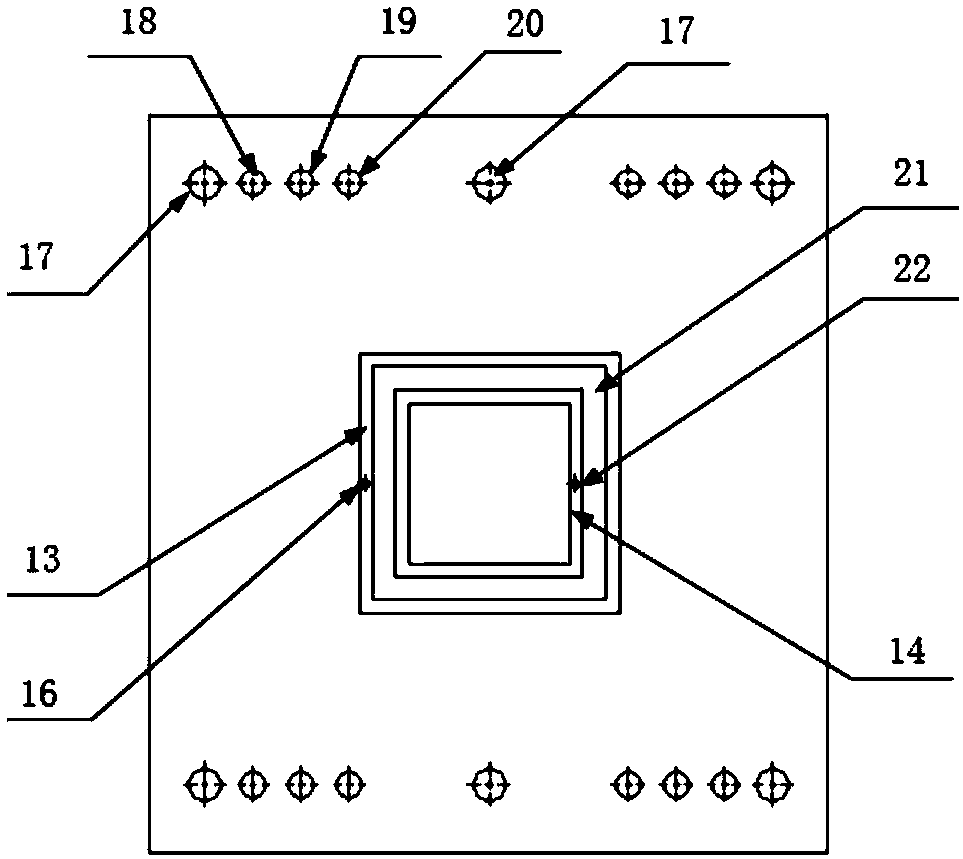

[0024] Such as Figure 1-7 As shown, a magnetic fluid double-suspension support guide rail system according to the embodiment of the present invention, the hydrostatic support part includes: upper and lower static pressure guide plates 1, side static pressure guide plates 2, static guide rails 3, oil inlet hose joints 5, Fixing screw 7, oil return line connector 9. The hydraulic oil pipeline joints of the inlet and outlet of the back-shaped oil chambers in the upper and lower static pressure guide plates are completely sealed with sealing rings to reduce leakage. The hydraulic oil hose joints are fixed on the left and right static pressure guide plates. The supply pressure of the hydrostatic guide plate is about 3MPa. The width of the oil groove is 8mm, the depth is 5mm, the width of the oil sealing edge is 15mm, the size of the back-shaped oil cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com