Early-strength grouting material for installation of overweight and oversized equipment and its construction method

A technology for equipment installation and grouting materials, which is applied in the field of early-strength grouting materials to achieve the effects of fast setting speed, high mechanical performance and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

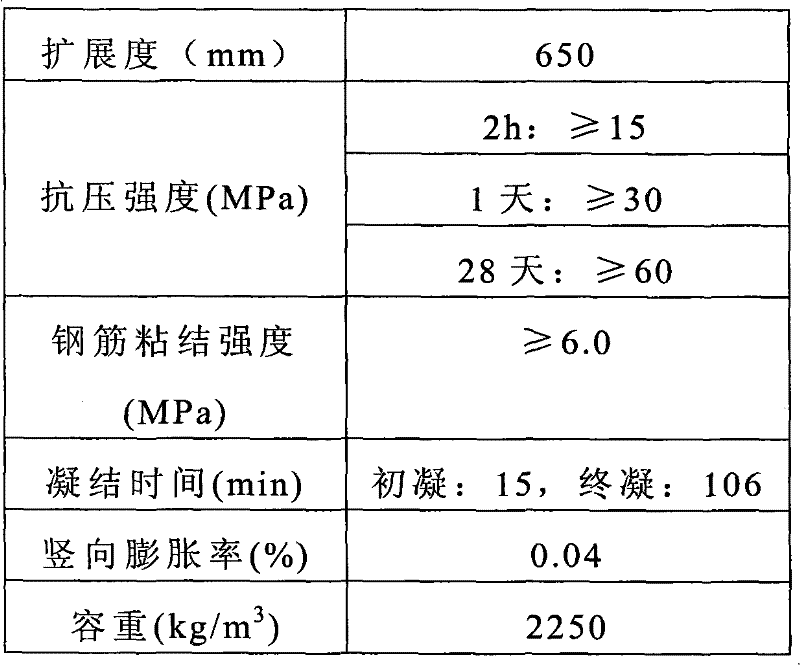

Image

Examples

Embodiment 1

[0034] Adopt the early-strength grouting material that overweight, oversized equipment installation of the present invention is used, its proportioning is counted as in parts by mass:

[0035] Cement: 1.00

[0036] Fly ash: 0.21

[0037] Expansion agent: 0.1

[0038] Coagulant regulator: 0.15

[0039] Retarder: 0.004

[0040] Water reducer: 0.004

[0041] Yellow sand: 1.19

[0042] Defoamer: 0.004

[0043] Pebbles: 1.1.

[0044] Among them: the cement is P042.5R, the fly ash is low-calcium grade II ash, the expansion agent is calcium sulfoaluminate, the coagulation regulator is gypsum, the retarder is sodium gluconate, and the water reducer is acrylic acid graft copolymerization The yellow sand has a particle size of 0.315-5mm, the medium-coarse sand with a fineness modulus Mx of 2.3-3.7, the pebbles have a particle size of 5-10mm, and the defoaming agent is silicon dioxide.

[0045] A construction method of an early-strength grouting material for overweight and oversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com