Grouting filling method in irregular mined-out area

A goaf and grouting technology, applied in the fields of backfill, mining equipment, earthwork drilling, etc., can solve the problems of inability to eliminate the sudden subsidence of the coal pillar surface, difficult to ensure the effect of reducing subsidence, and high treatment costs, and to eliminate the surface Sudden subsidence, reduced wind oxidation, low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0033] see Figure 1 to Figure 6 As shown, according to an embodiment of the present invention, a method of grouting filling in a goaf is provided, comprising the following steps:

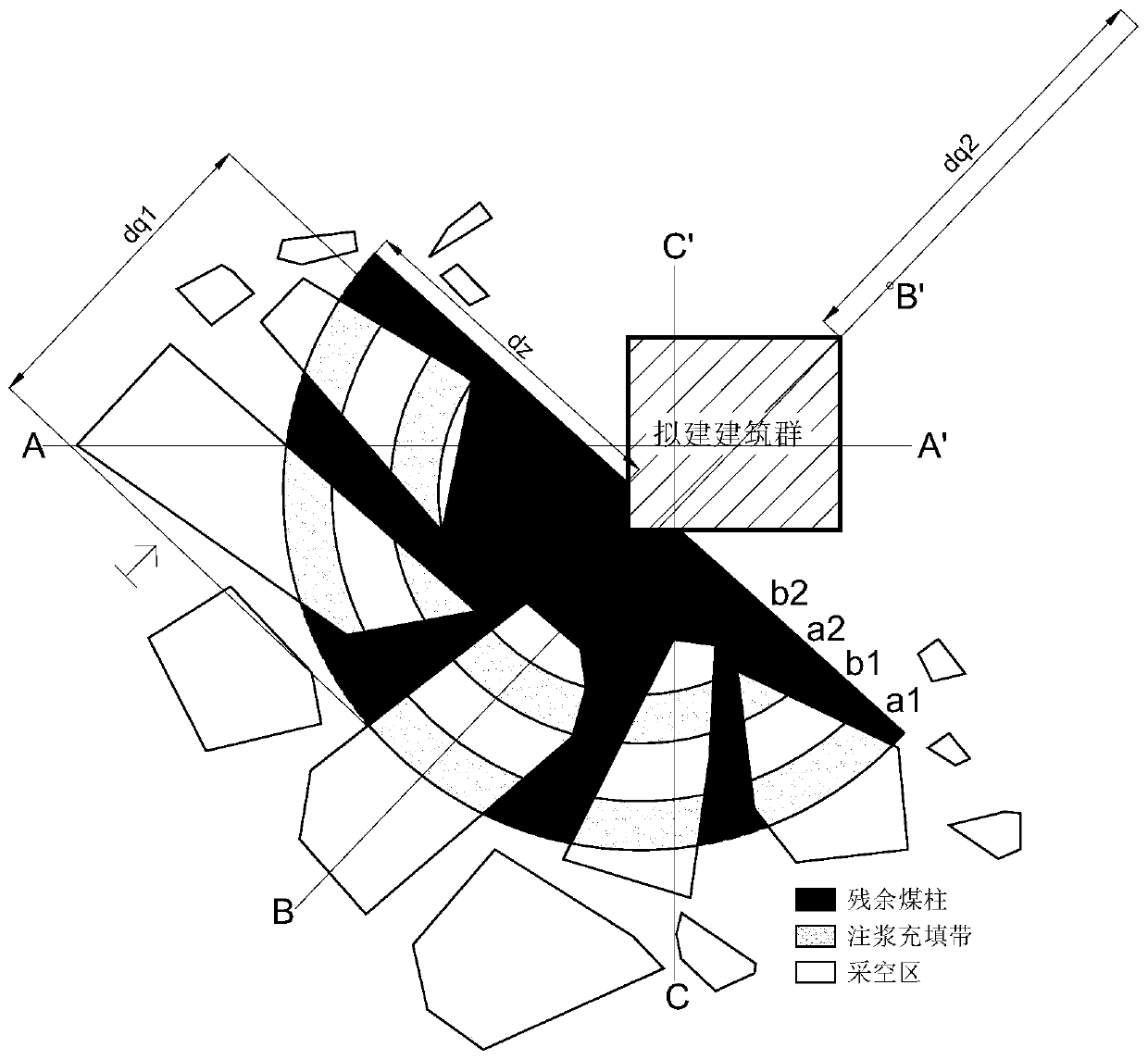

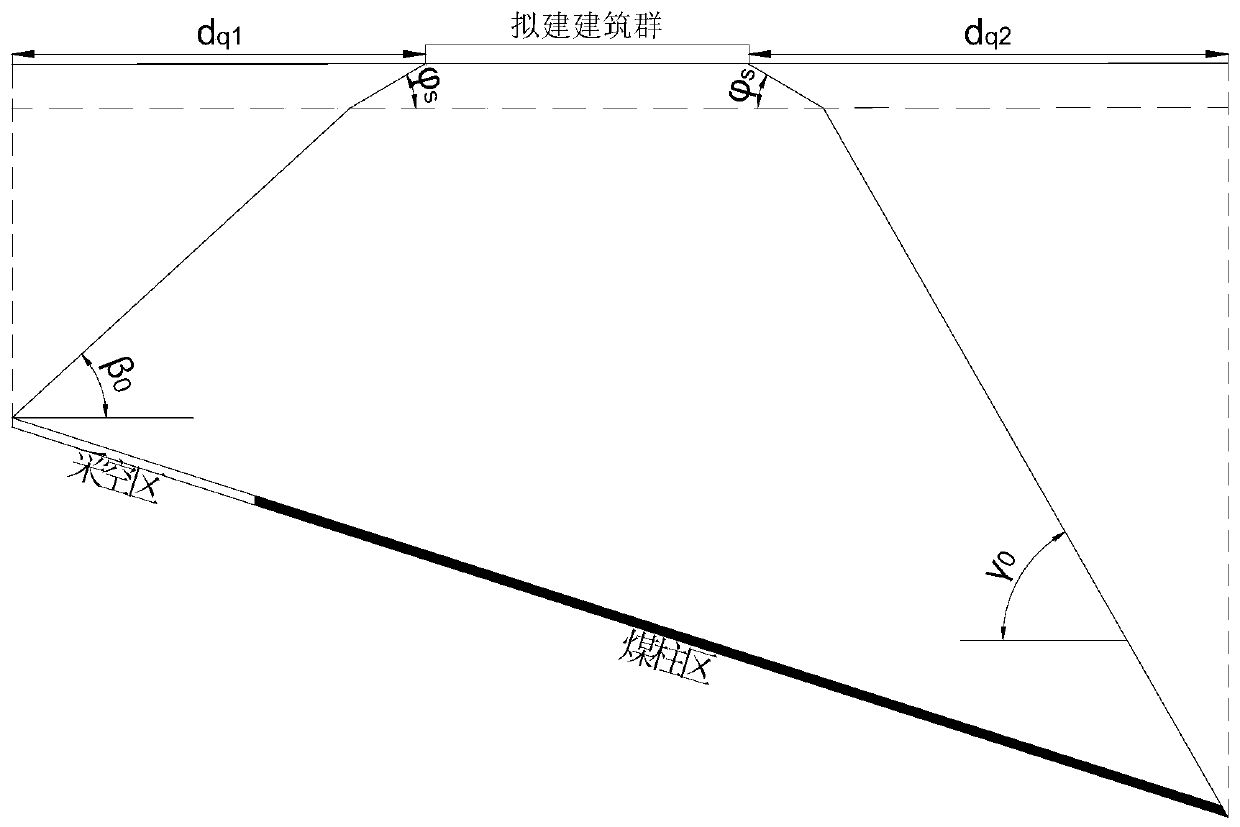

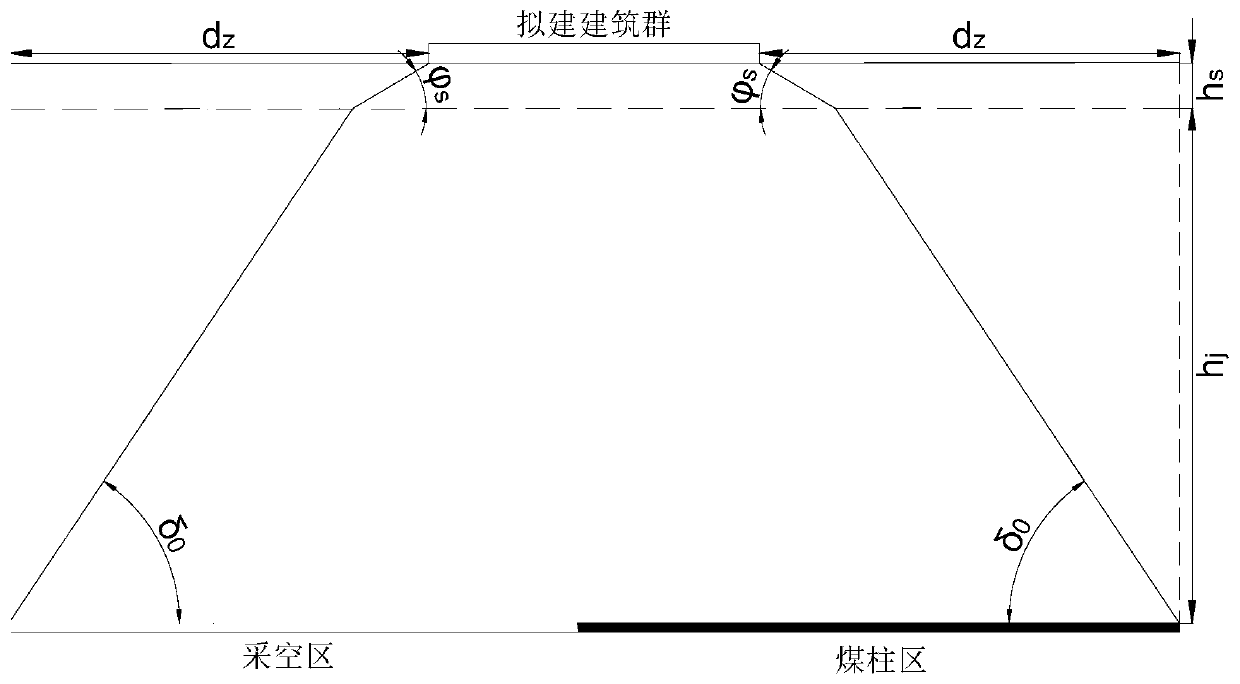

[0034] Step 1: Take the building group to be built as the protected object, and delineate the governance scope of the goaf according to the boundary angle.

[0035] Step 2: Arrange a plurality of grouting filling belts at intervals within the treatment range, the said grouting filling belts are annular or arc-shaped; the ring center or arc center of said grouting filling belts are based on the buildings to be built as a reference point.

[0036] Step 3: Grouting is performed at the position of the grouting filling zone through the grouting equipment, and the filling body formed by the grouting forms a str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com