Aluminum formwork structure

A technology of aluminum formwork and formwork, which is applied to formwork/formwork/work frame, connection parts of formwork/formwork/work frame, building structure, etc., can solve the problem of unsatisfactory effect, increase installation time and reduce construction efficiency and other problems, to achieve the effect of improving stress, improving structural strength, and increasing shear and tensile capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

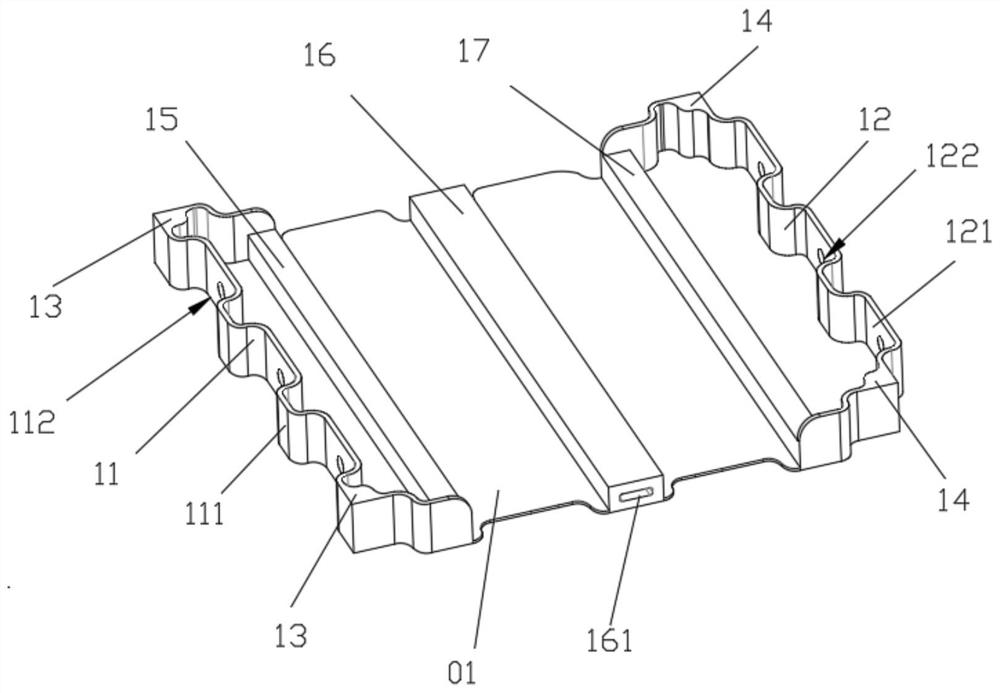

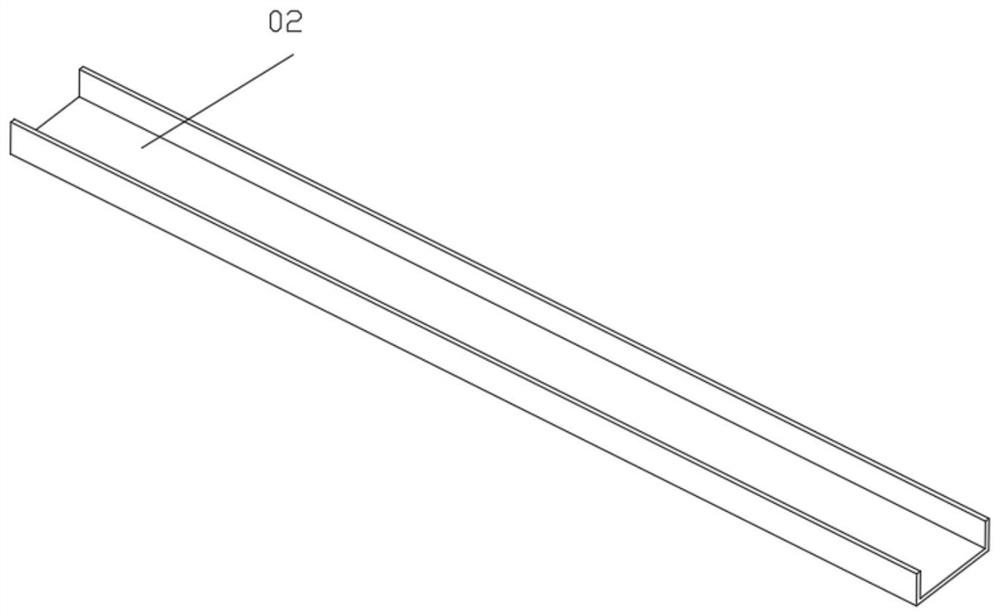

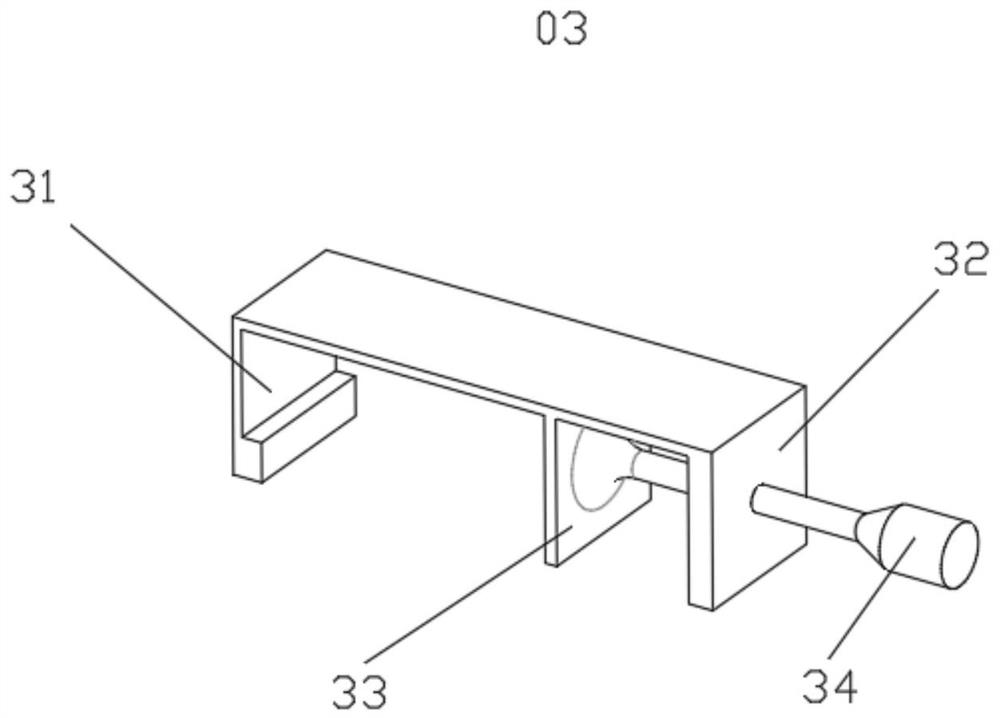

[0028] like Figure 1 ~ Figure 3 As shown, an aluminum formwork structure includes a formwork surface 01, a first side plate 11, a second side plate 12, a first reinforcement strip 15, a second reinforcement strip 16, a third reinforcement strip 17, a fixing fixture 03 and a fixing groove Steel 02. Formwork surface 01 forms a seal to the pouring space after splicing multiple aluminum formwork structures, and completes the shaping of the pouring surface.

[0029] Wherein, the first side plate 11 and the second side plate 12 are oppositely arranged on two sides of the template surface 01 . The first side plate 11 and the second side plate 12 are spliced and connected in the transverse direction X when the aluminum formwork is spliced. Therefore, the shape and size of the first side plate 11 are adapted to the shape and size of the second side plate 12 .

[0030] It is worth noting that since the template surface 01 will produce stress deformation when it is squeezed by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com