Preparation and welding method of intermediate layer composite powder for magnesium alloy steel laser welding

A technology of laser welding and composite powder, which is applied in the direction of laser welding equipment, welding equipment, welding equipment, etc., can solve the problem of low tensile and shear force of welding joints, improve tensile and shear force, promote uniform and stable generation, reduce The effect of welding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

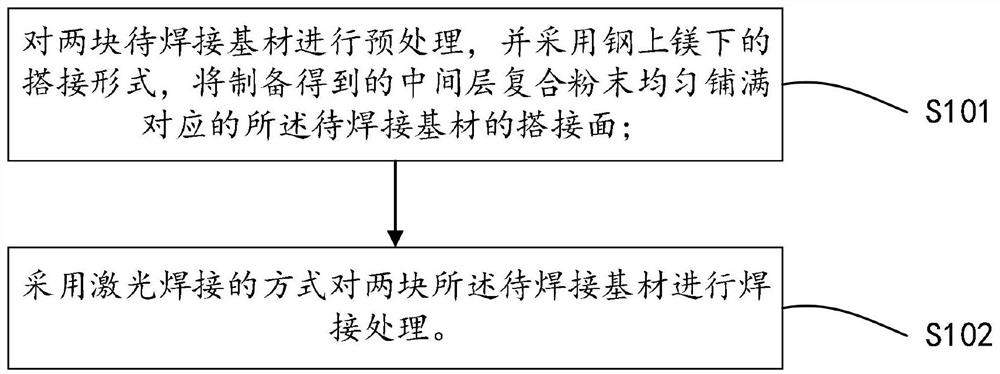

[0023] The invention provides a method for preparing a middle layer composite powder for laser welding of magnesium alloy steel, which is suitable for the welding method of the middle layer composite powder for laser welding of magnesium alloy steel, including:

[0024] Based on the set mass ratio, the interlayer composite powder is made by using pure Cu powder and pure Si powder with a purity of 99.9%, wherein the mass ratio of Cu is 80%-98%, and Si is 2%-20%.

[0025] In this embodiment, based on the set mass ratio, pure Cu powder with a purity of 99.9% and pure Si powder are used to make the interlayer composite powder, wherein the mass ratio is 80%-98% for Cu and 2% for Si -20%, the thickness is 50-300μm.

[0026] The present invention will be further illustrated by the following examples

Embodiment 1

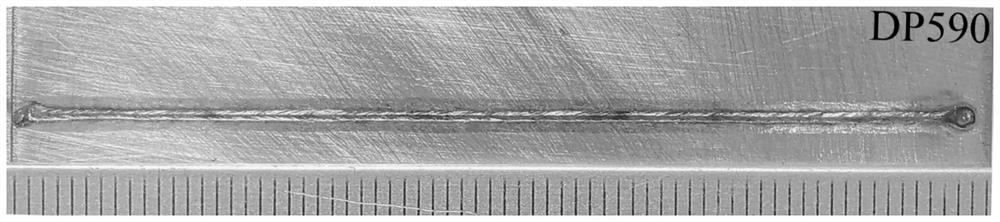

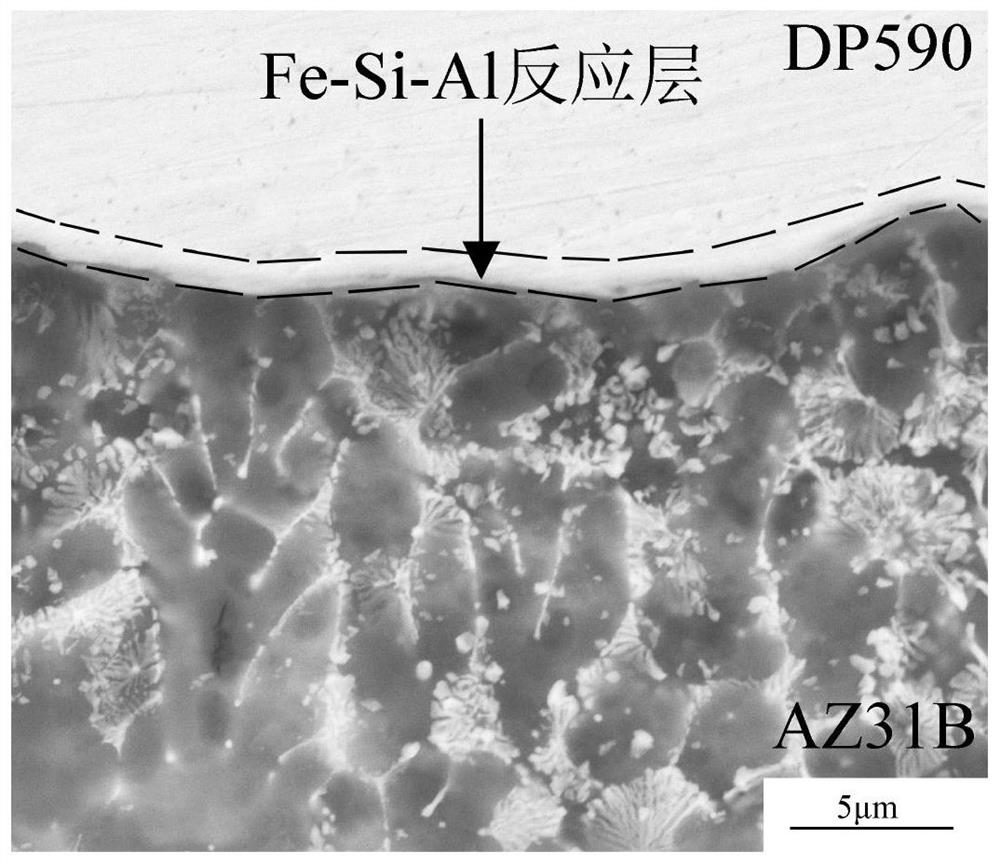

[0028] The base material is 105mm×45mm×0.8mm DP590 galvanized dual-phase steel and 105mm×45mm×1mm AZ31B magnesium alloy, the middle layer is made of pure Cu powder with a purity of 99.9% and pure Si powder with a mass ratio of 95% Cu-5%Si composite powder with a thickness of 130μm. The base metal is polished with sandpaper, washed with acetone and dried, and then fixed in the form of "steel on magnesium and bottom" lap joint, with a lap length of 20mm. Laser laser process parameters are laser power of 800W, welding speed of 0.05m / s, defocus of 0mm, protective gas of 99.99% argon, side blowing, and gas flow rate of 22L / min. The laser head deviates 5° along the direction of vertical laser travel. Such as figure 2 and image 3 As shown, the tensile shear force tested by a universal tensile machine is 81.9N / mm.

Embodiment 2

[0030] The base material is DP590 galvanized dual-phase steel of 105mm×45mm×0.8mm and AZ31B magnesium alloy of 105mm×45mm×1mm, and the middle layer is made of pure Cu powder with a purity of 99.9% and pure Si powder with a mass ratio of 92% Cu-8%Si composite powder with a thickness of 130μm. The base metal is polished with sandpaper, washed with acetone and dried, and then fixed in the form of "steel on magnesium and bottom" lap joint, with a lap length of 20mm. Laser laser process parameters are laser power of 800W, welding speed of 0.05m / s, defocus of 0mm, protective gas of 99.99% argon, side blowing, and gas flow rate of 22L / min. The laser head deviates 5° along the direction of vertical laser travel. The tensile shear force tested by a universal tensile machine was 76.6N / mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com