Cutting and separating device of fiber-reinforced composite material structure

A composite material and fiber-reinforced technology, which is applied to the docking device of space navigation vehicle, transportation and packaging, and space navigation equipment, etc. Design simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

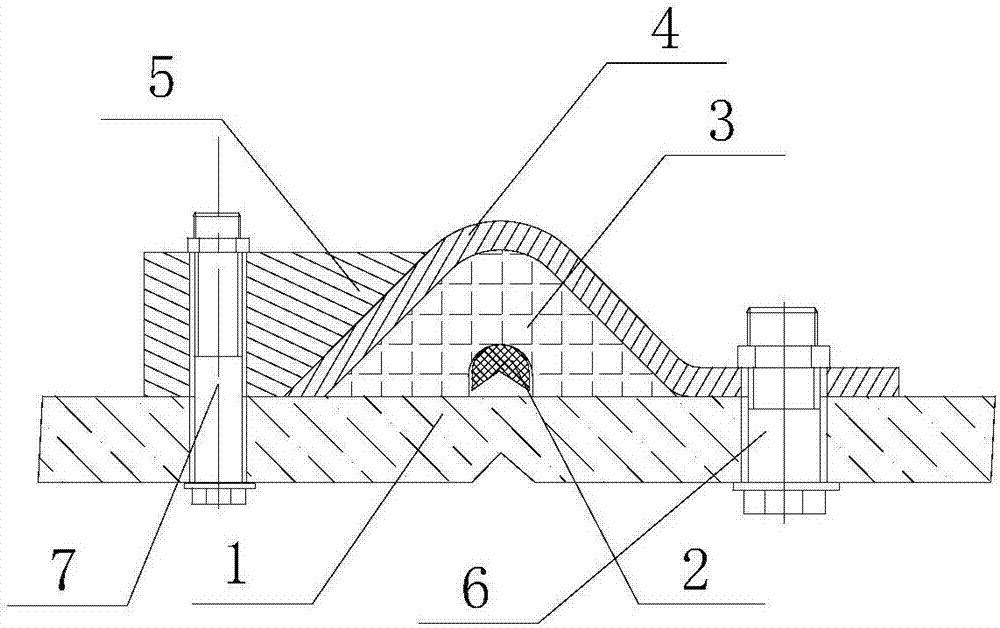

[0022] A cutting and separating device for a fiber-reinforced composite material structure, comprising a composite material plate 1; a gathering energy cutting cable 2; a buffer sheath 3; a protective cover 4; The bottom edge of the sheath 3 has a groove, the size of the groove matches the back size of the energy-concentrating cutting cable 2; the main part of the protective cover 4 is covered on the outer surface of the buffer sheath 3, and the mounting surface extending from one side is connected with the The cutting and separating part of the composite material plate 1 is fixed by the connecting bolt Ⅰ6; the working principle: the energy-concentrating cutting cable 2 is detonated to generate energy-concentrating jet and high-temperature and high-pressure gas, and the composite material plate 1 (ring) is cut and separated at the preset groove , to achi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com