Device for longitudinally cutting cigarettes

A cigarette, vertical technology, applied in the field of tobacco production equipment, can solve the problems of broken tobacco, cut tobacco, etc., and achieve the effects of reducing impact, saving time, and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

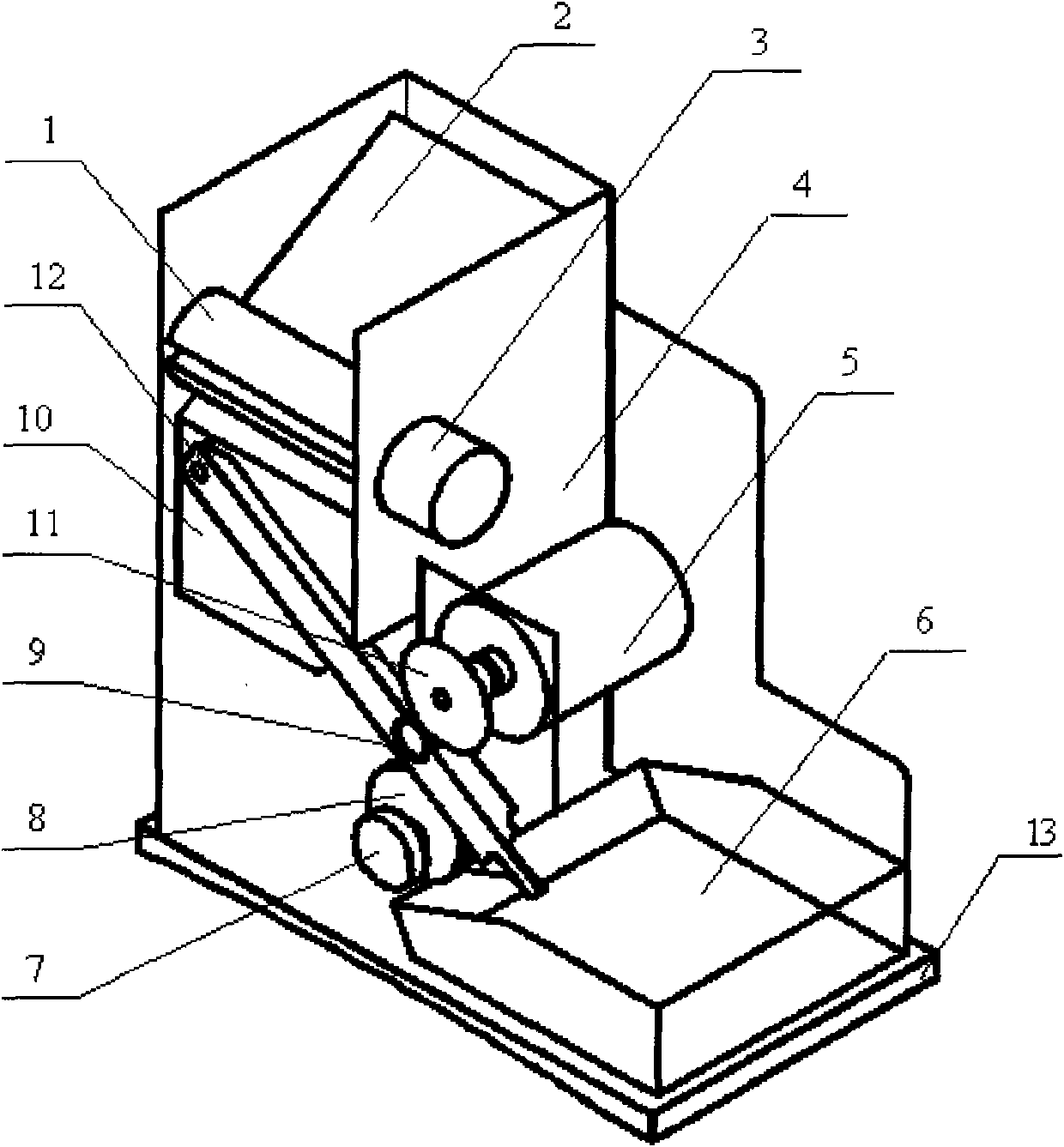

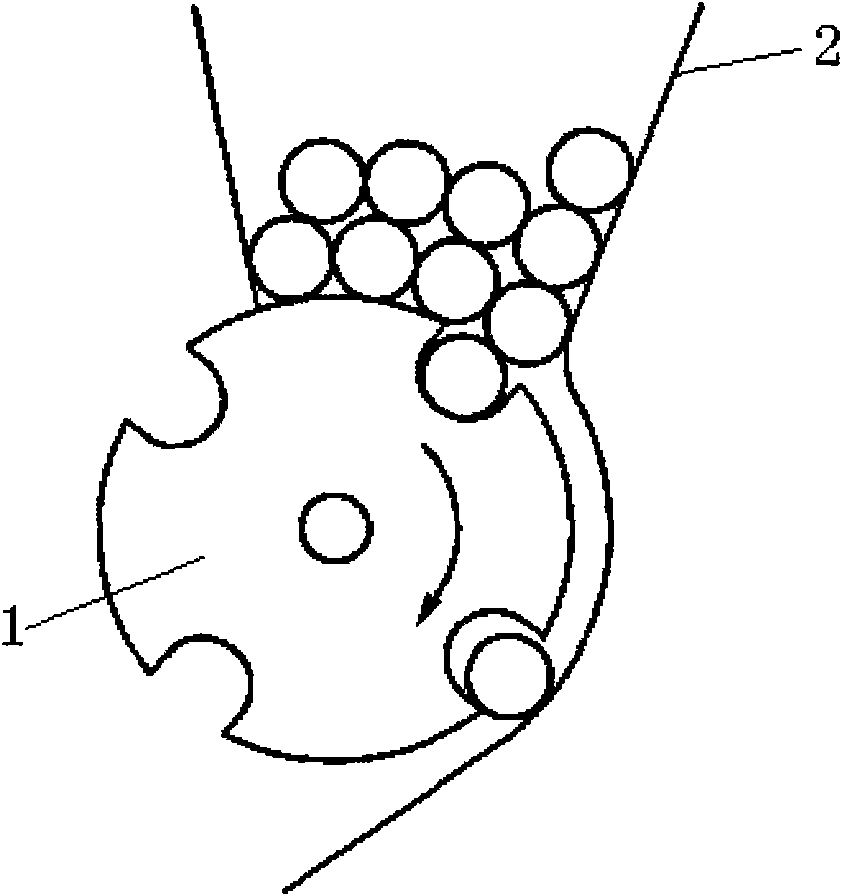

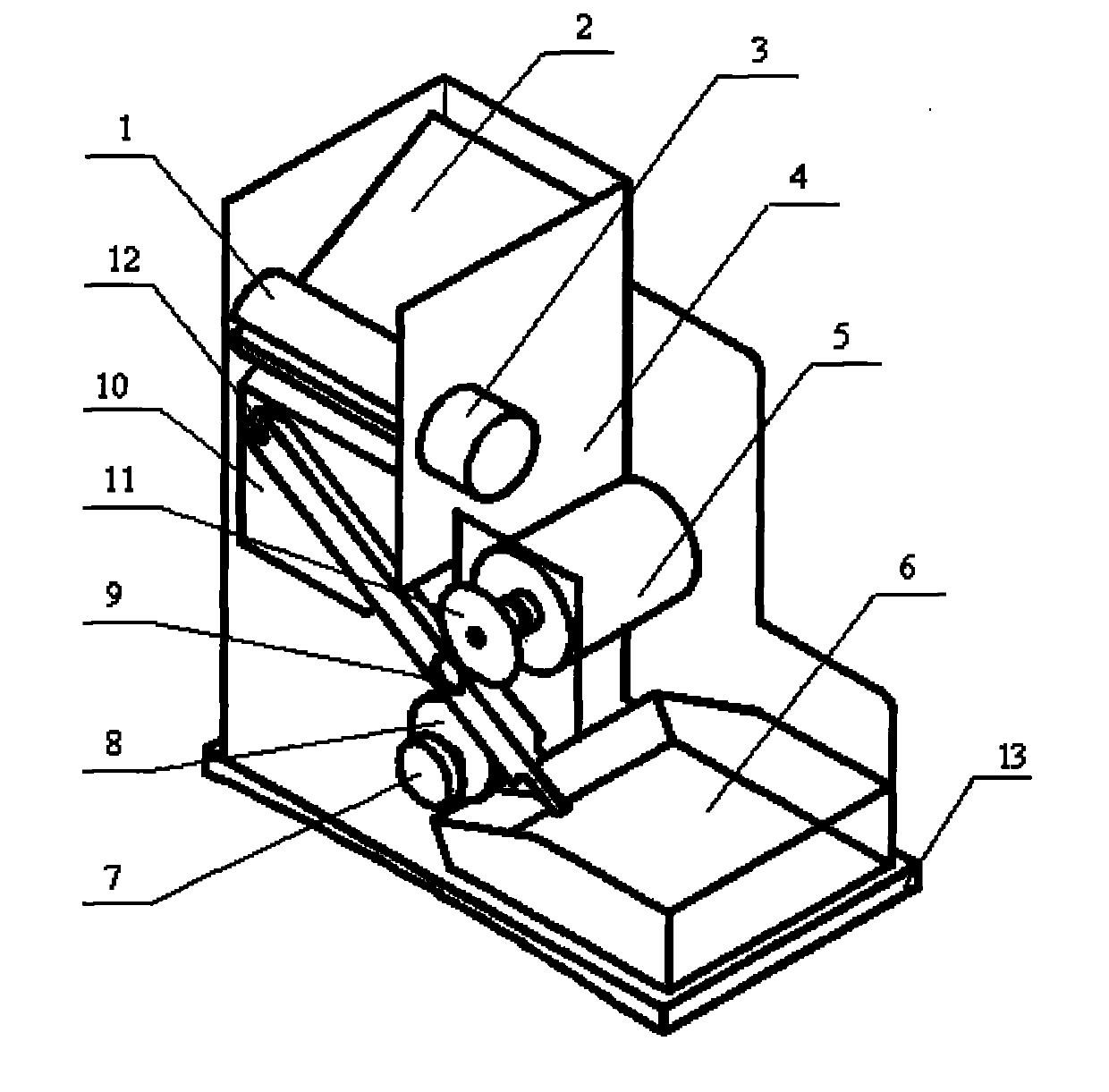

[0021] Such as figure 1 shown. The cigarette longitudinal cutting device includes a base 13, on which there is a cigarette collection box 6, on the base 13 there is a side plate standing on one side of the cigarette collection box 6, and there is a front panel and a rear panel opposite to the front panel. The fuselage 4 formed by the panel, the middle plate connecting the front panel and the rear panel, the fuselage 4 is connected on the base 13 through the middle plate, a funnel-shaped cigarette storehouse 2 is installed on the top of the middle plate of the fuselage 4, and the rear panel A sampling motor 3 is installed, and the rotating shaft of the sampling motor 3 is connected with a sampling roller 1. The sampling motor 3 drives the sampling roller 1 to rotate. Sampling groove in the direction, there is a vertical baffle plate 10 sandwiched between the front panel and the rear panel under the sampling roller 1, and there is an inclined slideway 12, the slideway 12 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com