Stepped chip breaking disk milling cutter

A step-shaped, disk milling cutter technology, applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc.

Inactive Publication Date: 2012-01-25

庞勇

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the knife rod is adjusted in place, the pressing screw can be used to lock the knife rod

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

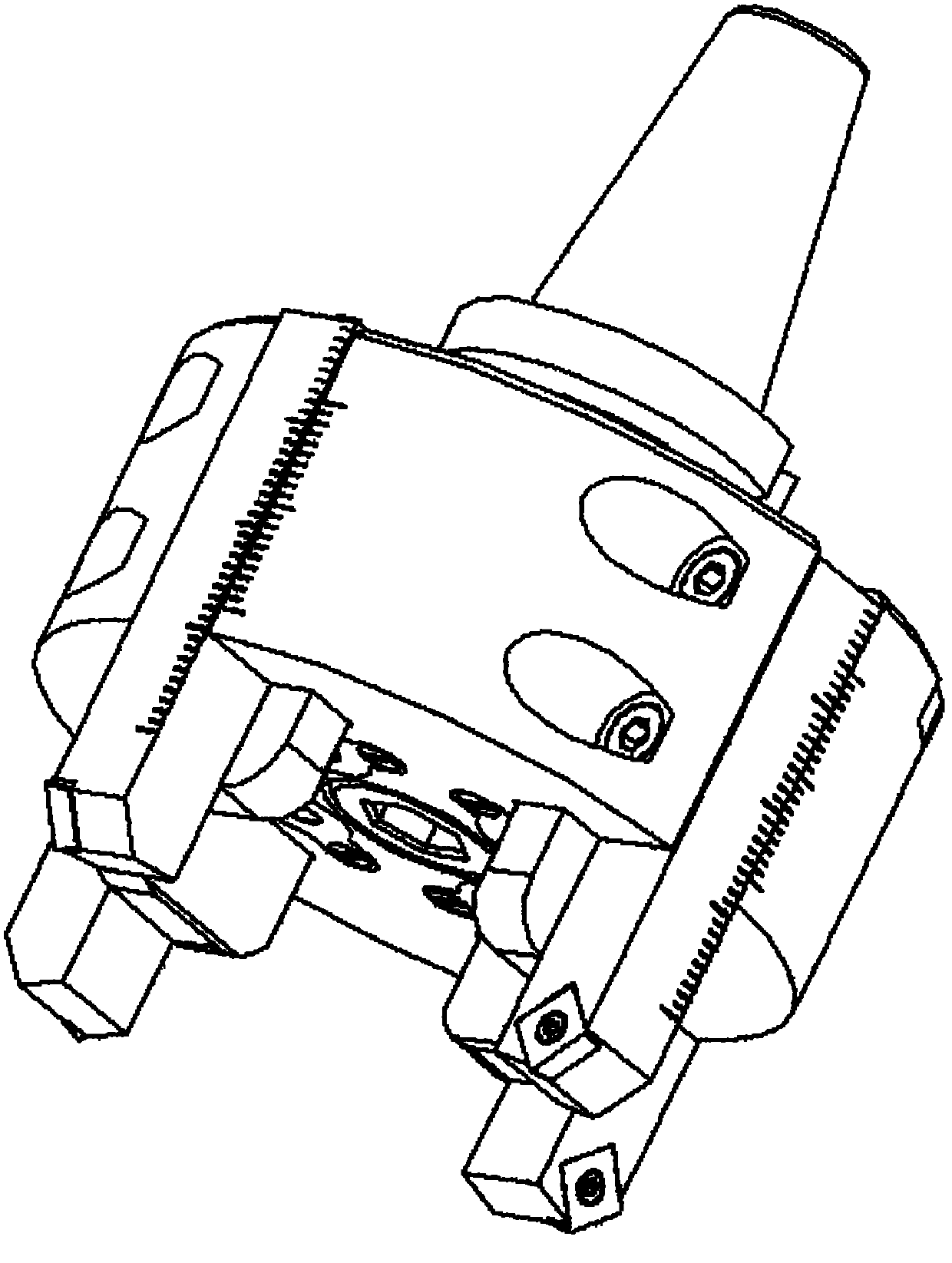

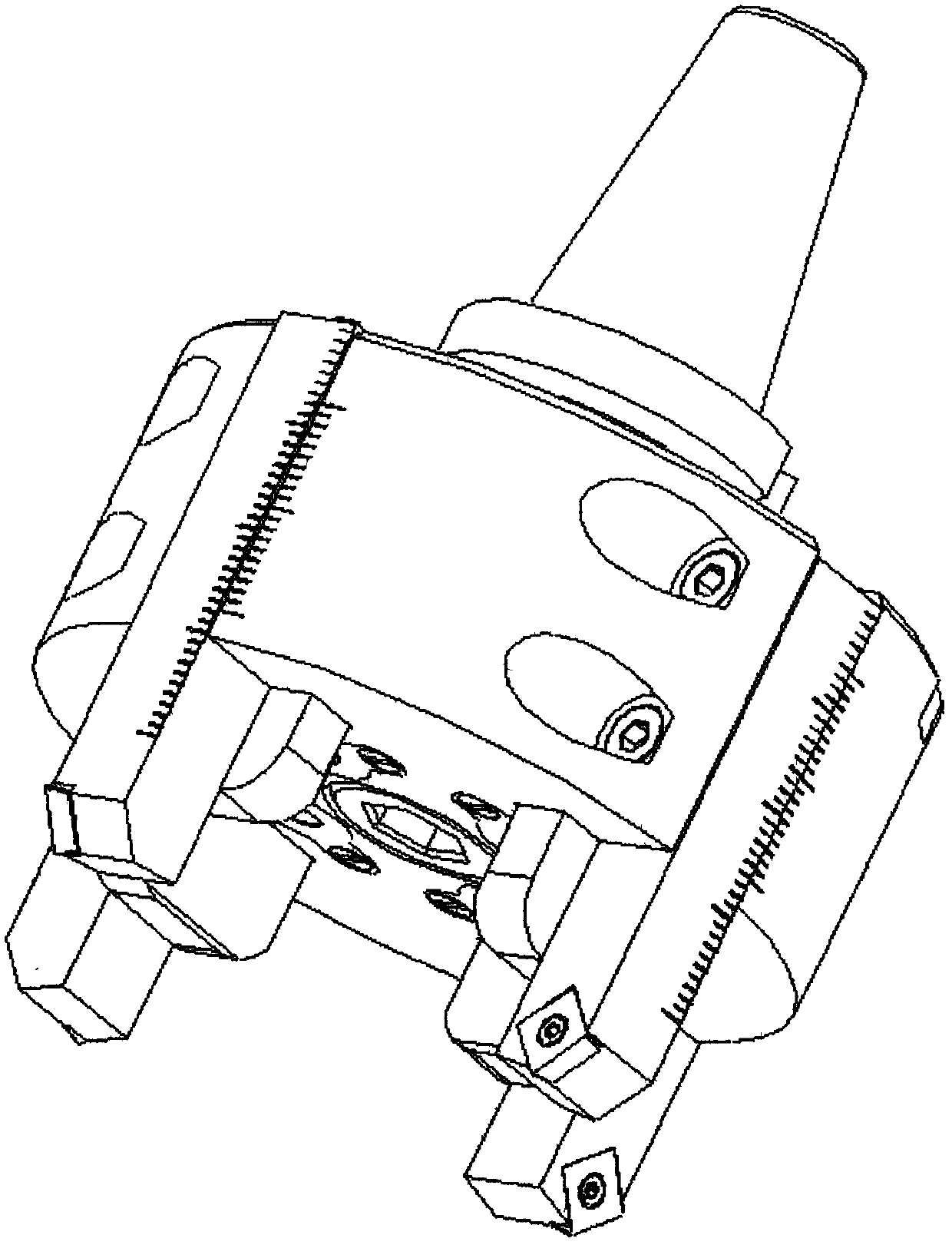

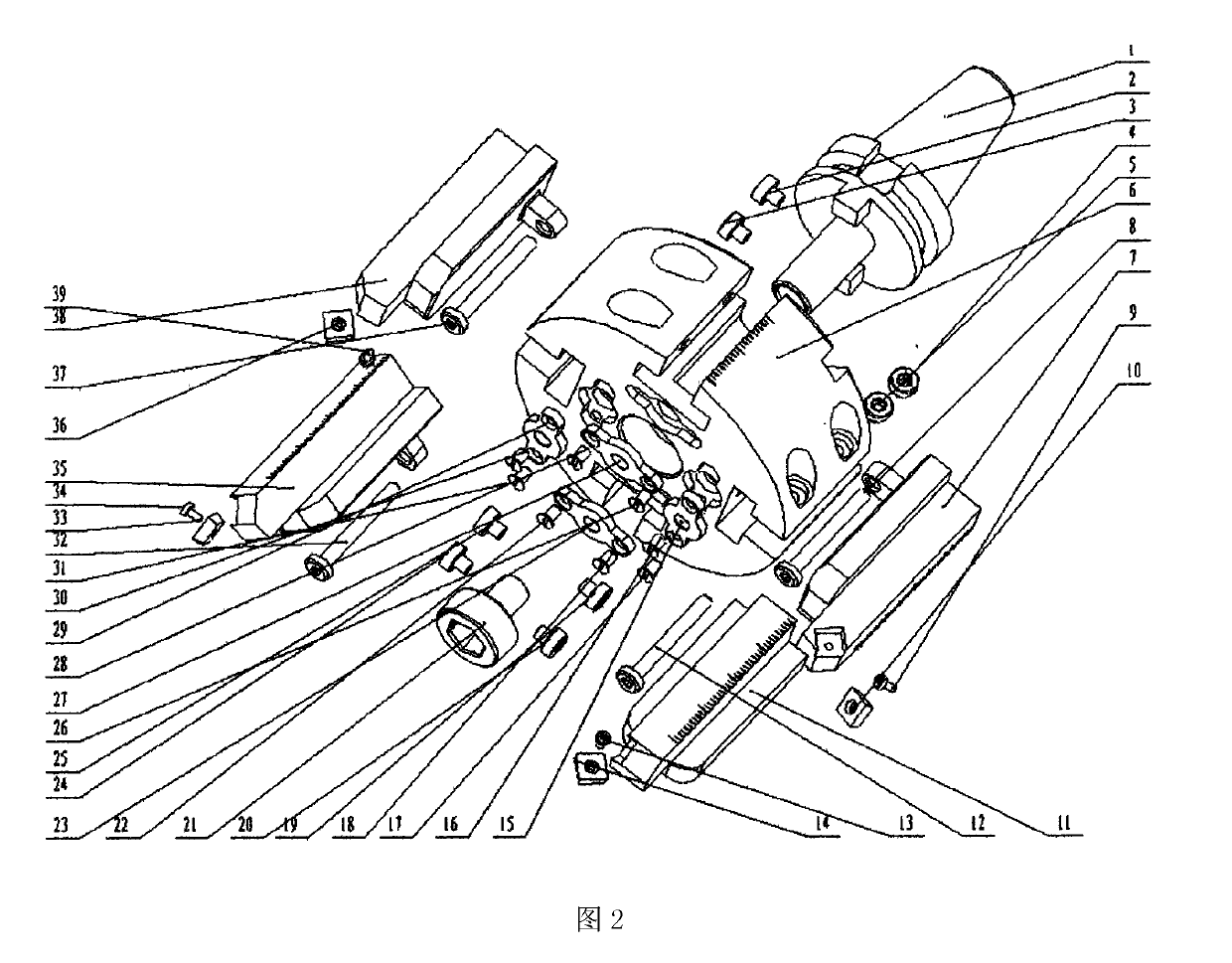

The invention relates to a milling cutter used on milling and boring machine tool equipment, in particular to a stepped chip breaking disk milling cutter. A cutter disk is respectively provided with four T-shaped grooves equipped with four cutter bars in a sliding way; the cutter bars are provided with thread holes and are connected with adjusting bolts through the cutter disk, and the adjusting bolts are screwed by a hexagonal wrench so that the cutter bar can be driven to move along the axis of the cutter disk; a specific position of the cutter rod relative to the cutter disk can be obtained conveniently through scales engraved on the cutter during the installation of the cutter bars, the four cutter bars are divided into two groups, a plane can be conveniently milled in two layers at the same time through adjusting the adjusting bolts; and the cutting layer thickness can be adjusted so as to realize the chip breaking cutting; when the milling cutter is in use, the milling force and milling power can be reduced, the cutting layer thickness of once cutting is increased, the cutting efficiency is improved, and the milling cutter is convenient to operate and has strong practicality.

Description

【Technical field】 The invention relates to a stepped chip dividing disk milling cutter used on machine tools. 【Background technique】 For some milling machine tools such as CNC milling machines and ordinary milling machines, the installation position of the clamp-type disc milling cutter blades used for milling planes is on the same radius of rotation and the same plane of rotation, and stepwise cutting adjustment cannot be performed. It has the characteristics of small cutting depth, step cutting, rough and finishing machining cannot be completed at one time, the cutting force and cutting power required for milling are relatively large, and it has the characteristics of unstable cutting and large impact force. 【Content of invention】 The invention proposes a disc milling cutter capable of step-shaped chip-splitting cutting. In order to solve the above-mentioned technical problems, the present invention proposes the following solutions. The stepped chip-distributing disc ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23C5/08B23C5/24

Inventor 庞勇

Owner 庞勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com