Food production equipment for automatically cutting chestnuts

An automatic chestnut technology, applied in food science, shelling, pod removal, etc., can solve problems such as low efficiency, easy cutting, and difficulty in ensuring a smooth cut, so as to reduce time cost, reduce fatigue, and facilitate collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] A device for automatically cutting chestnuts in food production, such as figure 1 , Figure 6 , Figure 10 As shown, include bracket one 1, bracket two 101, pad 102, servo motor 2, first pulley 201, second pulley 202, first rotating shaft 3, third pulley 301, fourth pulley 302, The first flat belt 303, the second rotating shaft 304, the fifth pulley 305, the claw 306, the second flat belt 307, the cutting device and the fixing device, the upper left part of the support one 1 is connected with the support two 101, on the support one 1 Side left part is connected with spacer 102, and spacer 102 is positioned at support two 101 right sides, and support one 1 bottom side left front part is connected with servomotor 2, and the output shaft of servomotor 2 is connected with first pulley 201, servomotor 2 The output shaft of the second pulley 202 is connected with the second pulley 202 above the first pulley 201. The upper left side of the support one 1 is connected with the...

Embodiment 2

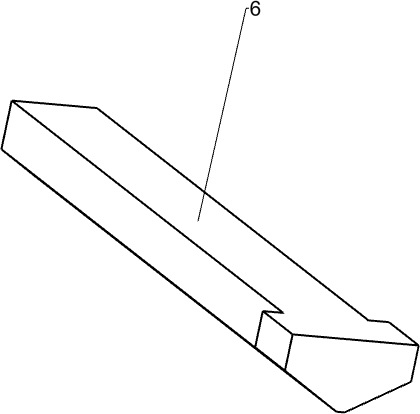

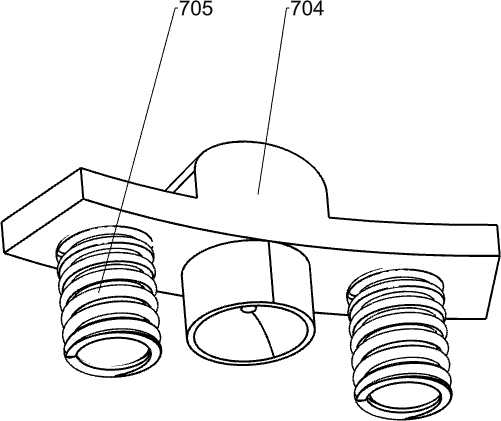

[0077] On the basis of Example 1, such as figure 2 , Figure 5 , Figure 6 , Figure 7 As shown, the cutting device includes a third rotating shaft 4, a gear one 401, a sixth pulley 402, a third flat belt 403, a fourth rotating shaft 404, a second gear 405, a seventh pulley 406, a fifth rotating shaft 407, and an eighth rotating shaft. Pulley 408, the fourth flat belt 409, cam 410, linear guide rail 5, slide block 501, chainsaw 502, follower 503 and spring one 504, support one 1 upper side rear part is rotatably connected with the third rotating shaft 4, The third rotating shaft 4 is positioned at the left side of the second rotating shaft 304, the third rotating shaft 4 bottom is connected with a gear 1 401, the middle part of the third rotating shaft 4 is connected with a sixth pulley 402, and the sixth pulley 402 and the first pulley 201 are wound around There is a third flat belt 403, a fourth shaft 404 is rotatably connected to the rear of the lower side of the bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com