Protective rubber strip cutting machine with high efficiency

A strip cutting machine and cutting machine technology, applied in metal processing and other directions, can solve the problems of lack of worker protection effect and complicated cutting operation, and achieve the effect of remarkable protection effect, good cutting effect, simple and effective structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

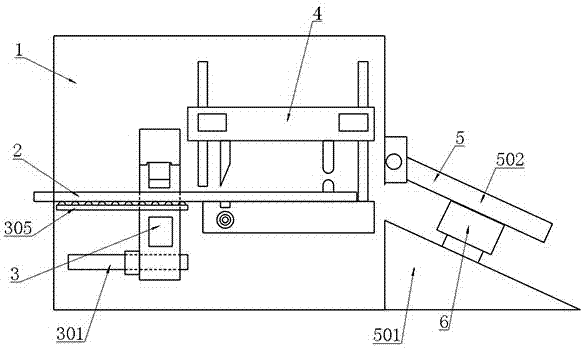

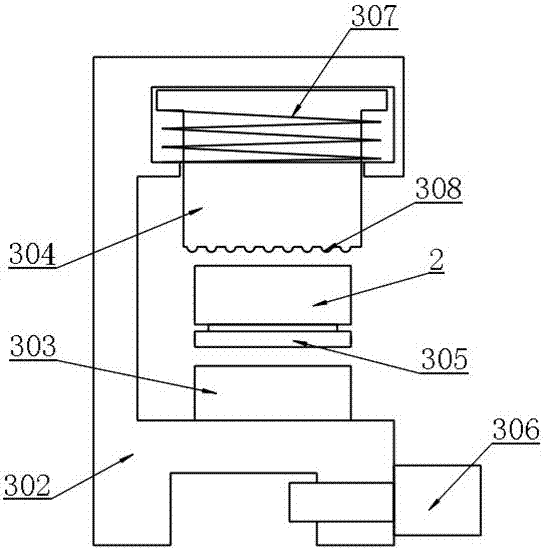

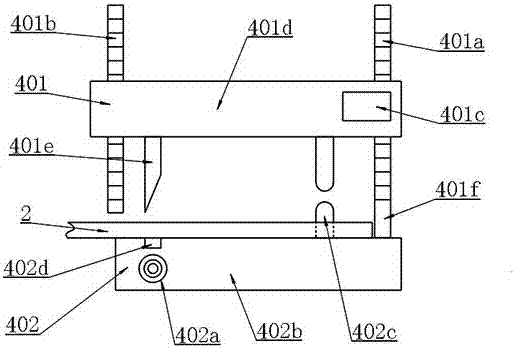

[0022] Example: as attached figure 1 , 2 , 3 and attached Figure 4 As shown, a protective high-efficiency rubber strip cutting machine includes a cutting machine main body 1, and also includes a conveying unit 3 arranged on the cutting machine main body 1 and used to convey rubber strips 2, and is arranged on one side of the conveying unit 3 And the cutting unit 4 used for rubber strip cutting and inclined discharge after cutting by downward cutting and downward dial rotation, the discharge protection unit 5 arranged on one side of the cutting unit 4, and the discharge protection unit 5 arranged on the On the discharge protection unit 5 and conductively connected with the cutting unit 4 is a cutting protection unit 6 for connecting and cutting off the circuit of the cutting unit 4 .

[0023] In this embodiment, the conveying unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com