Laser machining method for matching with light-emitting diode (LED) inner cutting process

A laser processing method and internal cutting technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of reduced laser absorption and reduced processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

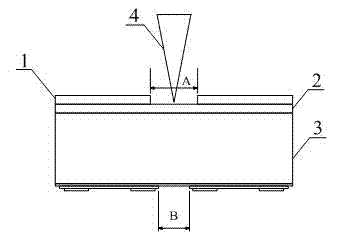

[0023] Step 1: If Figure 1a As shown, the laser light 4 is focused on the metal reflective film 1 to vaporize the metal reflective film 1 to form a trench A with a certain removal width. Before processing, use a high-precision image positioning system to strictly align the centerline of the groove A with a certain removal width with the centerline of the dicing line B reserved by the lithography on the front of the wafer. The laser processing parameters are controlled so that the distributed Bragg reflection film 2 at the bottom of the groove is not damaged, and no metal reflection film or dust remains in the groove A.

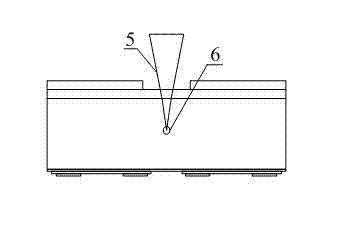

[0024] Step 2: If Figure 1b As shown, the internal cutting laser 5 is used to directly penetrate the distributed Bragg reflection film 2 in the trench and focus on the inside of the wafer to form an internal burst region 6, and form a linear array along the cutting direction.

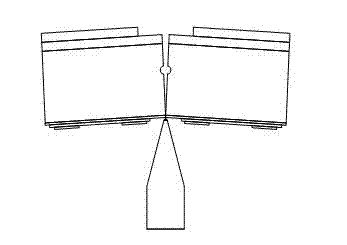

[0025] Step 3: If Figure 1c As shown, pressure is applied on the dicing line B...

Embodiment 2

[0028] Step 1: If Figure 2a As shown in , the laser light 4 is focused on the metal reflective film 1 and the distributed Bragg reflective film 2, and the metal reflective film 1 and the distributed Bragg reflective film 2 are vaporized to form a groove A with a certain removal width. Before processing, use a high-precision image positioning system to strictly align the centerline of the groove A with a certain removal width with the centerline of the dicing line B reserved by the lithography on the front of the wafer. Control the laser processing parameters so that the substrate surface at the bottom of the trench is not damaged and the front side of the wafer is not damaged. There is no metal reflective film or dust residue in groove A. When implementing this step, lasers of different types and parameters can also be used to remove the two reflective films respectively.

[0029] Step 2: If Figure 2b As shown, the inner burst zone 6 is formed by using the inner cutting l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com