Coconut end cap cutting device for food processing

A cutting device and food processing technology, applied in the field of food processing, can solve the problems of operator injury, difficult operation, easy access to the inside of coconut, etc., and achieve the effect of improving efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

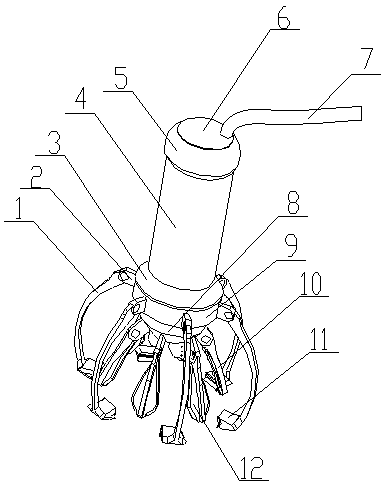

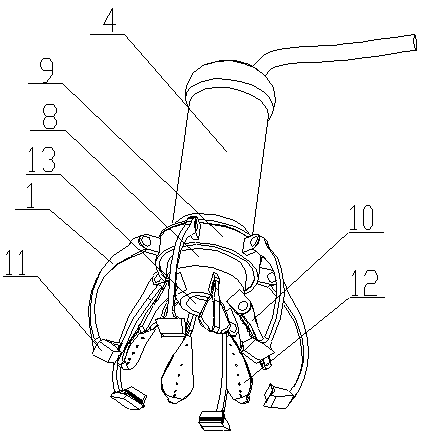

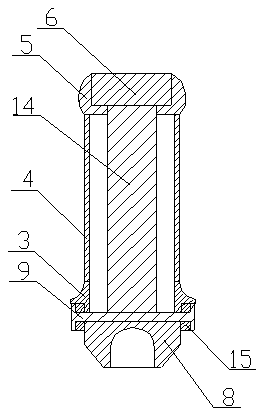

[0023] A food processing coconut end cover cutting device of the present invention is realized in this way. When in use, when cutting the coconut end cover, firstly, a plurality of splints (12) are respectively stuck on the coconut end cover, and the coconut is fixed. The stem at the top can be put into the buffer cavity (13), and a plurality of ring cutters (11) are respectively supported against the cutting parts of the outer ring of the coconut, and then one hand holds the holding cylinder (4), and the other hand Turn the rotating rod (7), the rotating rod (7) drives the transmission rod (14) to rotate through the rotating block (6), the transmission rod (14) drives the rotating plate (9) to rotate, and the rotating plate (9) drives multiple cutters to connect The rod (1) rotates around the outer ring of the coconut, and then the ring cutter (11) on the other end of the cutter connecting rod (1) cuts the outer ring of the coconut end cover, and the cutting edge (19) on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com