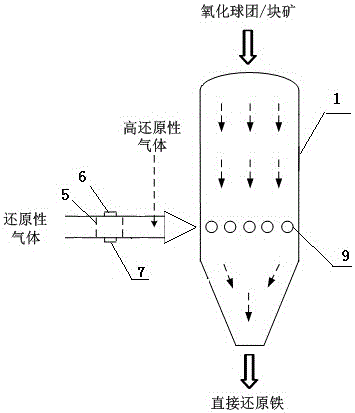

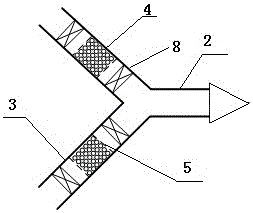

Pipeline type reduction gas charging device of gas-based vertical furnace and method utilizing pipeline type reduction gas charging device

A gas-based shaft furnace, pipeline-type technology, applied in the field of pipeline-type reducing gas into the furnace device, can solve the problems of high content, unfavorable sponge iron metallization rate, etc., to improve production efficiency, shorten gas-based reduction time, and convenient switching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The oxidized pellets with about 67% of the total iron are added from the top of the shaft furnace, and slowly move down until they are discharged from the bottom of the shaft furnace; during this period, the oxidized pellets are gradually reduced to full It is a sponge iron product with 91% iron and 94% metallization rate. About 1085°C, containing 23% CH4, 10.3% (H 2 O and CO 2 ), 64.7% (H 2 and CO) into the shaft furnace after being pre-reformed and transformed through the reduction gas inlet branch pipe filled with a large number of oxidized pellets; 67.3% oxidized pellets, the oxidized pellets are slowly reduced by a medium reducing gas, and a small amount of CH can be catalytically reformed when a small amount of metallic iron is generated 4 for H 2 And CO, after being reduced by a medium reducing gas for 9 hours, it can be reduced to a very high-quality sponge iron with a total iron of about 93% and a metallization rate of 99%. Catalytic reforming of the mediu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com