Method for preparing soft hard combined board

A technology of a rigid-flex board and a manufacturing method, which is applied in the fields of printed circuit manufacturing, multi-layer circuit manufacturing, and processing of insulating substrates/layers, and can solve problems affecting the appearance and performance of a rigid-flex board and the formation of burrs on the edge of a flexible area , The forming accuracy of the flexible zone is not high, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The manufacturing method of the rigid-flex board provided by the technical solution will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] The manufacturing method of the rigid-flex board provided by the embodiment of the technical solution includes the following steps:

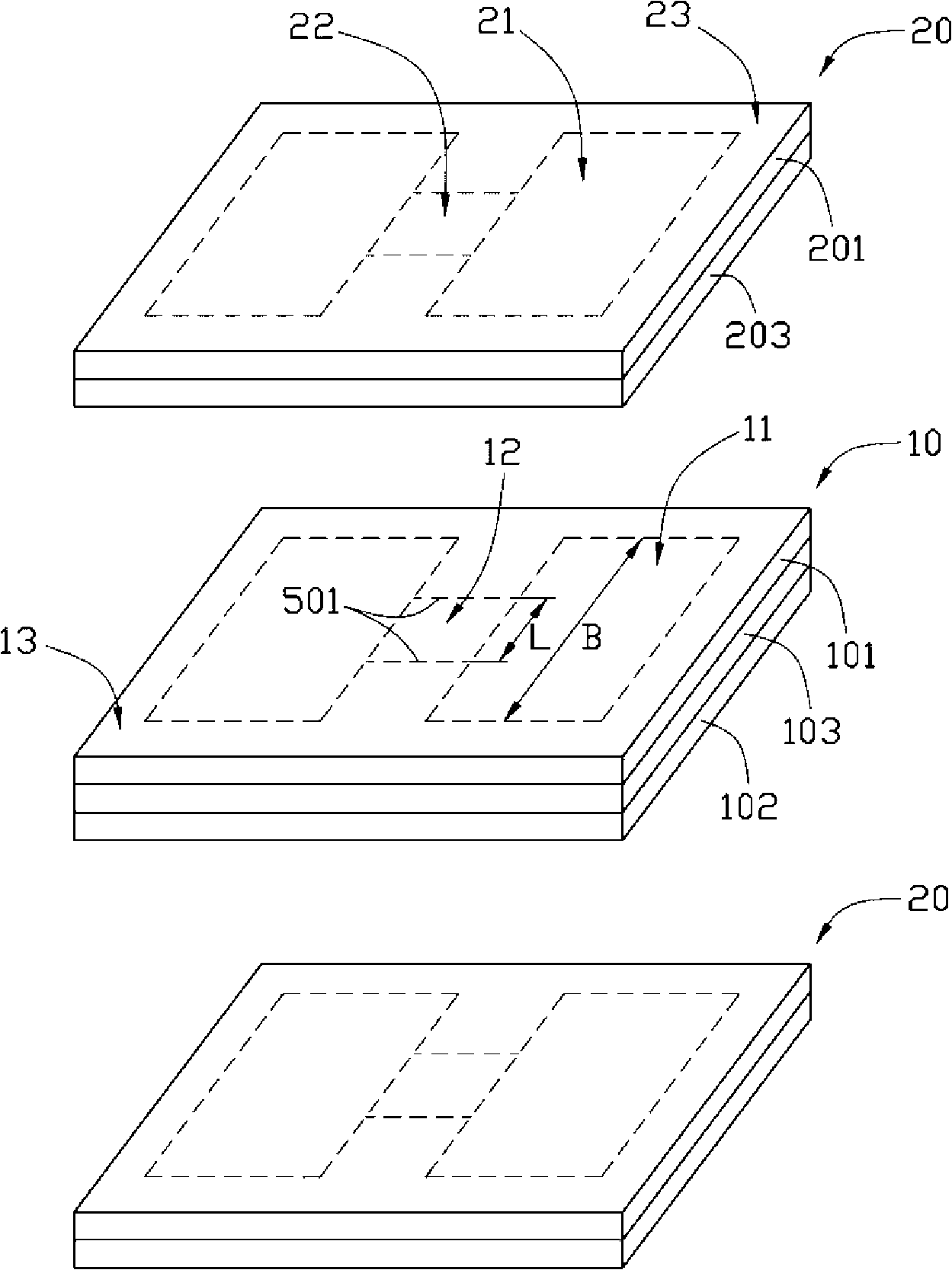

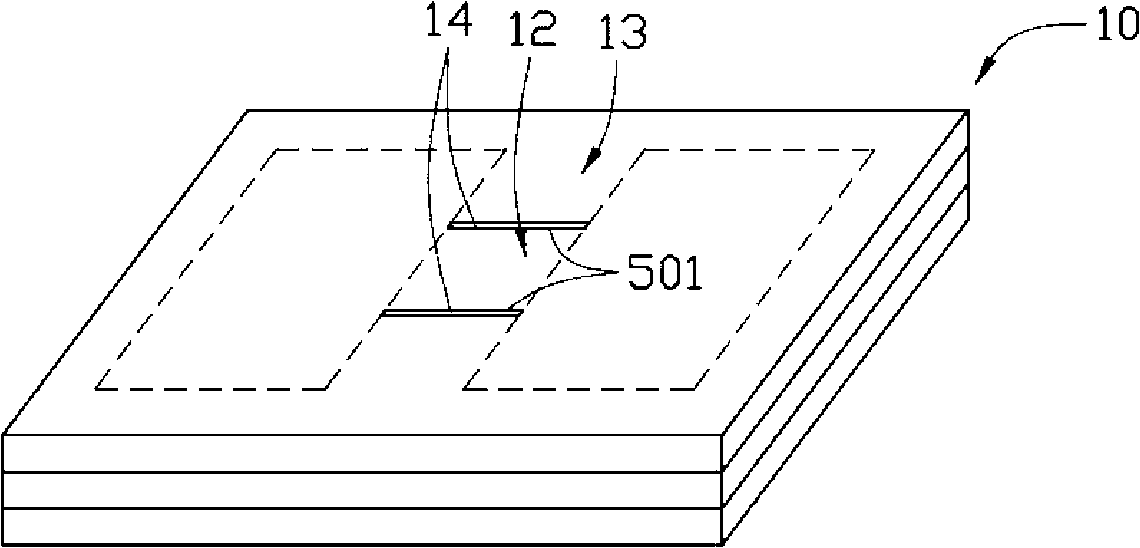

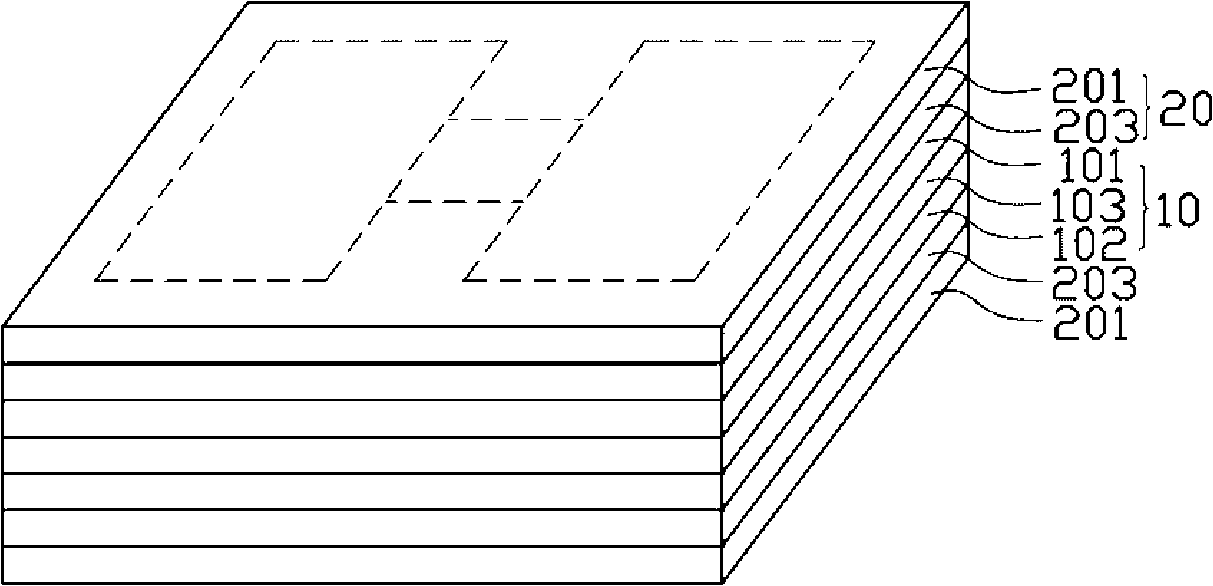

[0020] Step one, see figure 1 , at least one flexible substrate 10 and at least one rigid substrate 20 are provided.

[0021] In this embodiment, only one flexible substrate 10 and two rigid substrates 20 are provided as an example to illustrate the method of making a rigid-flex board

[0022] The flexible substrate 10 is double-sided, which includes a first conductive layer 101 , a second conductive layer 102 and a first insulating layer 103 connected between the first conductive layer 101 and the second conductive layer 102 . In this embodiment, both the first conductive layer 101 and the second conductive layer 102 have been formed with co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com