Automatic pipe cutter

A pipe cutting machine, automatic technology, applied in the direction of pipe cutting device, feeding device, positioning device, etc., to achieve the effect of improving work efficiency, remarkable effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

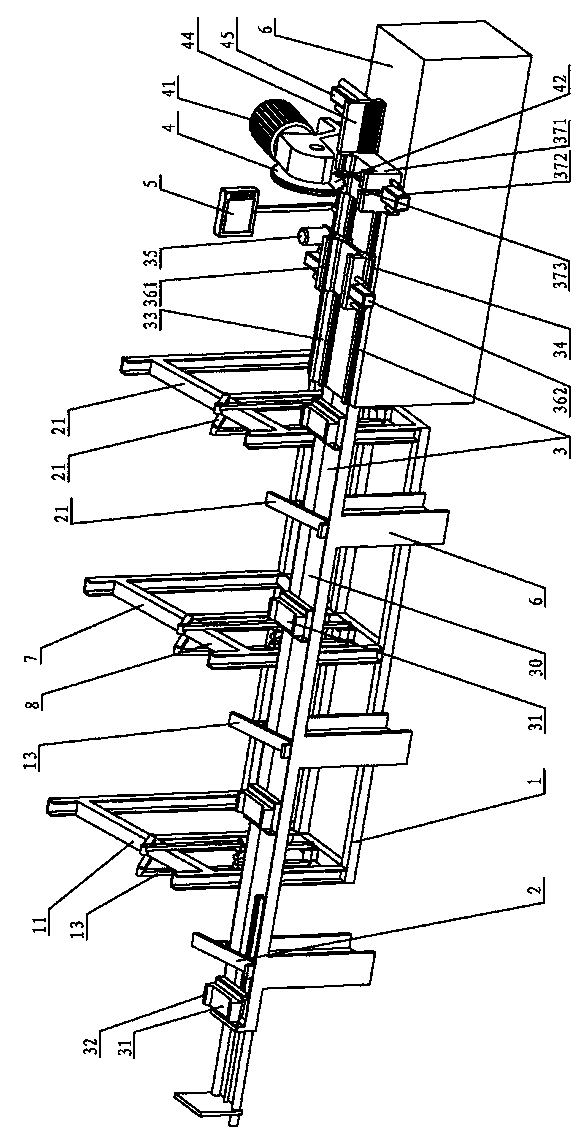

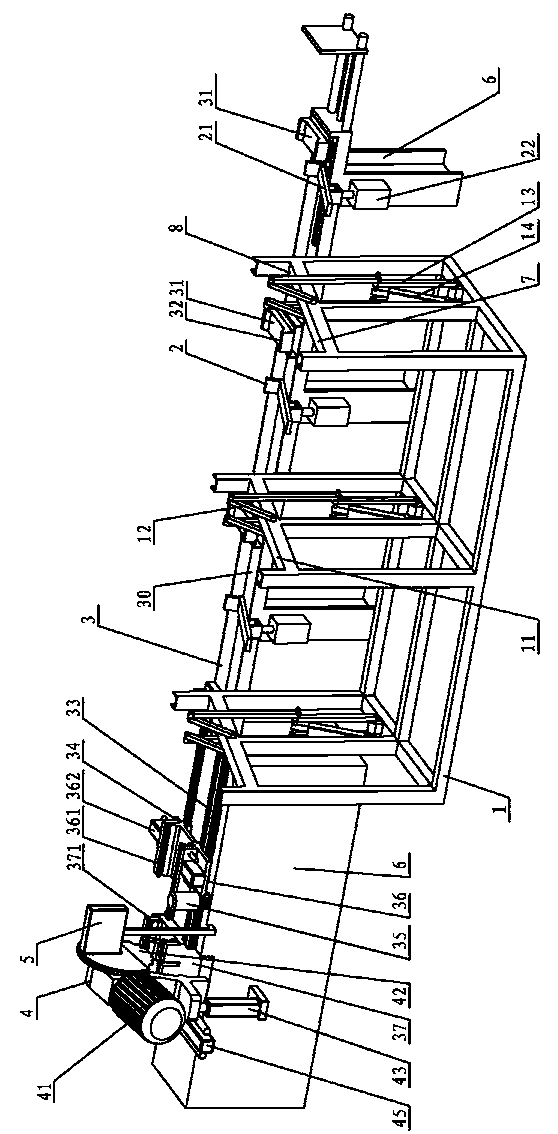

[0030] Such as figure 1 , 2 Shown, a kind of automatic pipe cutting machine comprises frame 6, and frame 6 is provided with material storage device 1, material retrieving device 2, material pushing device 3, cutting device 4, control device 5; Described cutting device 4 is positioned at The end of the frame 6; the control device 5 is fixed on one side of the frame, close to the cutting device 4.

[0031] The storage device 1 includes a storage rack 11, the storage rack 11 is formed by connecting at least two vertical frames side by side, the upper end of the frame is open, and the pipes are placed horizontally on the frame; Swing rod 12, the lower end of the swing rod 12 is hinged with the cross bar, the upper end of the swing rod is connected with the driving mechanism A, and the driving mechanism A is located below the swing rod 12, which is formed by connecting two sets of linkage mechanisms 13 through the upper and lower hinges of the short shaft , And, there is an upwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com